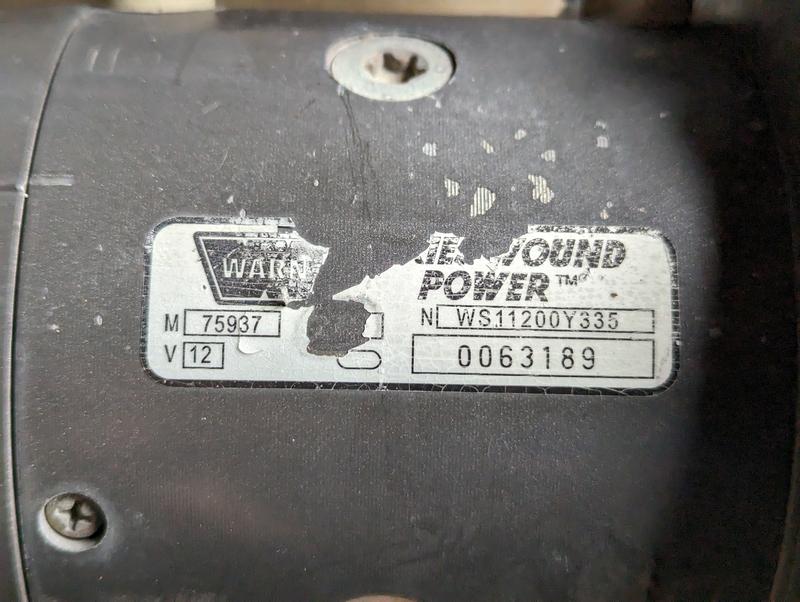

Found a used Warn M8000 locally.

Its in decent shape but needs a few things. Here’s what I know so far:

For the clutch lever stiffness, what should I be looking for when I open the gear box?

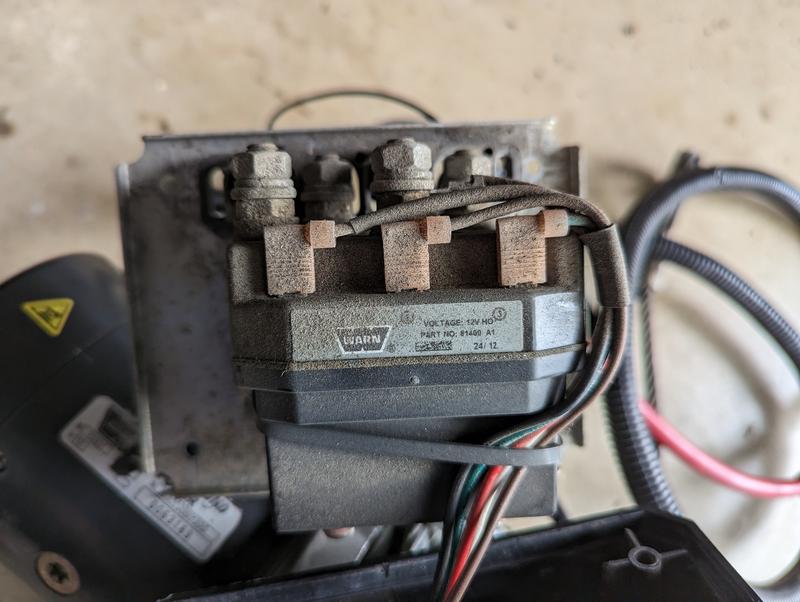

Any tips for straightening/correcting the bent contactor pin?

Its in decent shape but needs a few things. Here’s what I know so far:

- Missing ground screw (M8 x 1.25 x 12mm)

- Missing ground lead (2 guage, 72in) - Spartan Power

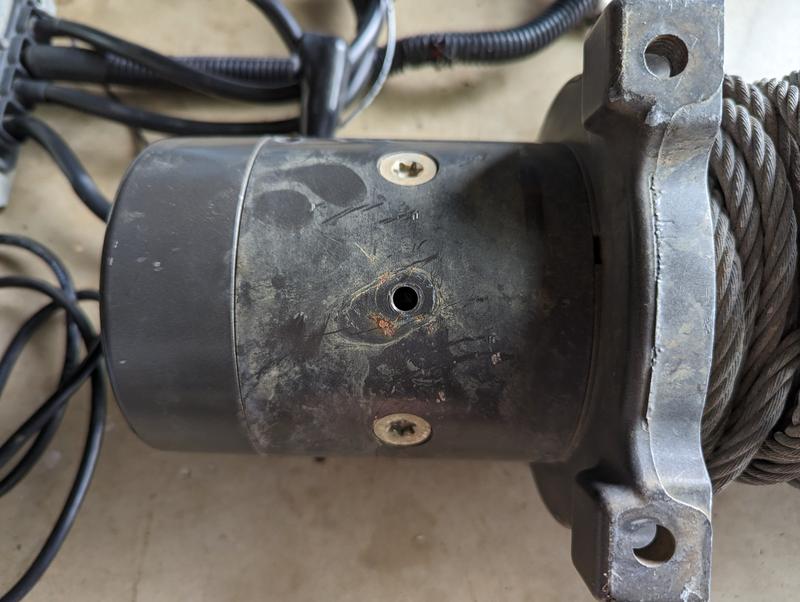

- Winch line is kinked and I want to run synthetic

- Winch free spools fine, but the lever is very difficult to turn. I’ll crack the gearbox and see where its getting hung up.

- Mounting hardware

- Square nuts (3/8-16)

- Washers (3/8)

- Bolts (3/8-16 x 1 1/4”)

- One of the contactor plug pins is bent. The plug wont insert all the way in. Winch works, but I’m going to see if I can fix the pin.

- General clean up, grease and paint

- Decal for the side of the contactor pack because vanity

For the clutch lever stiffness, what should I be looking for when I open the gear box?

Any tips for straightening/correcting the bent contactor pin?