Oh, but it is! Pretty sure this one was your mid-arm video. I was watching that, along with the front shock tower replacement.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to / in your garage / shop today?

- Thread starter Zorba

- Start date

More work in the indoor mancave this weekend, though I have little but destruction (or maybe deconstruction) to show for it.

Decided I wanted to have an indoor spray booth for shooting small parts. The need/desire was born from wanting a small setup to do fine cerakote work on handgun parts, but I figure it may well have other uses in the future. I picked up a suitable airbrush and, as it turns out, the 2 gallon air compressor I replaced when I shot my hardtop recently will work perfectly for indoor use with an airbrush, and it's quiet, too.

I considered buying a plastic portable booth from a place like Amz, but I wasn't feeling it for the money. While buying something would be faster, my hope is to make something potentially a bit better, for less money and using some materials I've already got on hand.

Design criteria:

The bits I'm starting with, the aforementioned destruction/deconstruction....

- must be somewhat portable/packable

- incorporate inexpensive, switchable LED lighting for good all around visibility and finish verification

- incorporate particulate and activated carbon filtration

- must feature exhaust to exterior via window opening

- utilize controls, fan motor and impeller from an air purifier as the basis for the extraction fan

- utilize numerous pieces of 12" x 72" 5mm luan ply coupled with 3D printed parts for booth, blower housing, etc.

View attachment 665959

Suffice it to say this will never function as an air purifier again, no matter what happens from this point forward. Currently working the booth design in CAD, more to follow...unless I get electrocuted or something catches fire in the interim...

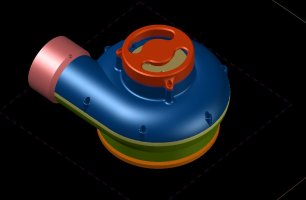

Progress. Magic'd up a suitable housing design in CAD, sliced it and printed in ABS-GF.

Chucked up a sanding drum in the drill press and cleaned off the fin remnants and unified the size. Controls mounted in new faceplate, the white part of the print was supposed to glow with backlighting on the control board, but it seems the BL white ABS has a bit higher solids content so it barely illuminates. Oh well, it was just a last minute trick thing I threw in the design.

Proceeded to bond the housing parts using ABS glue and acetone, fishing the power wires before doing so. Once dry, set the fan motor, bonded in the captive nuts for the mounting collar, installed the power jack and fitted the collar to check clearances.

Not too bad for a few hours work. Appears to be fully functional and moves air.

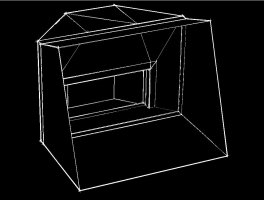

Next, finalized the basic booth design and dimensions. Currently working on developing this into 3D parts for laser cutting.

Last edited:

Progress. Magic'd up a suitable housing design in CAD, sliced it and printed in ABS-GF.

View attachment 668524

View attachment 668525

Chucked up a sanding drum in the drill press and cleaned off the fin remnants and unified the size. Controls mounted in new faceplate, the white part of the print was supposed to glow with backlighting on the control board, but it seem the BL white ABS has a bit higher solids content so it barely illuminates. Oh well, it as just a last minute trick thing I threw in the design.

View attachment 668526

Proceeded to bond the housing parts using ABS glue and acetone, fishing the power wires before doing so. Once dry, set the fan motor, bonded in the captive nuts for the mounting collar, installed the power jack and fitted the collar to check clearances.

View attachment 668527

Not too bad for a few hours work. Appears to be fully functional and moves air.

View attachment 668528

Next, finalized the basic booth design and dimensions. Currently working on developing this into 3D parts for laser cutting.

View attachment 668529

You only made 1/2 of a turbo????? Just think how much air it could make with the other half....

You only made 1/2 of a turbo????? Just think how much air it could make with the other half....

Funny you say that, I was going to write it up as something like "This thing blows! Dumbass makes plastic turbo for Jeep"...

My volute design does involve a fair bit of guesstimation, if I'm honest.

That’s really cool, Chili. That’s some crazy design skill.Progress. Magic'd up a suitable housing design in CAD, sliced it and printed in ABS-GF.

View attachment 668524

View attachment 668525

Chucked up a sanding drum in the drill press and cleaned off the fin remnants and unified the size. Controls mounted in new faceplate, the white part of the print was supposed to glow with backlighting on the control board, but it seems the BL white ABS has a bit higher solids content so it barely illuminates. Oh well, it was just a last minute trick thing I threw in the design.

View attachment 668526

Proceeded to bond the housing parts using ABS glue and acetone, fishing the power wires before doing so. Once dry, set the fan motor, bonded in the captive nuts for the mounting collar, installed the power jack and fitted the collar to check clearances.

View attachment 668527

Not too bad for a few hours work. Appears to be fully functional and moves air.

View attachment 668528

Next, finalized the basic booth design and dimensions. Currently working on developing this into 3D parts for laser cutting.

View attachment 668529

Meanwhile, in my shop I’m thrilled that I was able to design a jar to store axle seals…

That’s really cool, Chili. That’s some crazy design skill.

Meanwhile, in my shop I’m thrilled that I was able to design a jar to store axle seals…

View attachment 668541

Everyone in this thread is light years ahead of me.........

Anything I did would probably look like a dog turd.........

That’s really cool, Chili. That’s some crazy design skill.

Meanwhile, in my shop I’m thrilled that I was able to design a jar to store axle seals…

View attachment 668541

Don't sell yourself short, good geometric construction of things like screw threads are very important skills....and you've got to start somewhere. The fact that you're trying and doing is the important thing.

Hmm I see a vacation in Alabama in you're future.......... free room and board???????

Hmm I see a vacation in Alabama in you're future.......... free room and board???????

Actually I fly to Huntsville this week...

Might have to check out your rig...

-Mac

Heck yeah holler at me, @AndyG has to cool rig!!!!!!Actually I fly to Huntsville this week...

Might have to check out your rig...

-Mac

Everyone in this thread is light years ahead of me.........

Not everyone, maybe not anyone, really. To be fair, I've been a designer and CAD jockey for a number of decades now, I should be somewhat good at it....that or I've been an ace bullshitter for the last 35 years and somehow managed to remain employed, but I digress...

Anything I did would probably look like a dog turd

Probably not true, surely you've got some mechanical aptitude (you do own a Jeep) and an eye for things that look good (you purchased a TJ). Everything starts with simple shapes, even the most complex things can be broken down. That fan housing literally started as two stacked cylinders with different radii, doesn't get much simpler than that.

I feel inadequate with finishing up my simple paper towel holder for my teardrop camper. High school wood shop project.

MountaineerTom

LJ Enthusiast, Retired USAF Weapons Loader

Supporting Member

Ride of the Month Winner

That’s really cool, Chili. That’s some crazy design skill.

Meanwhile, in my shop I’m thrilled that I was able to design a jar to store axle seals…

View attachment 668541

Y’all get fancy. I just wash out old peanut butter jars and medicine bottles.

WestCoastDan

TJ Addict

Worked on the road bike a bit last night. Tuned up the drivetrain, cleaned the cogs, & lubed the chain, etc.

Almost ready for another new set of tires…

Not too bad for being 15 years old!

Almost ready for another new set of tires…

Not too bad for being 15 years old!

Worked on the road bike a bit last night. Tuned up the drivetrain, cleaned the cogs, & lubed the chain, etc.

Almost ready for another new set of tires…

Not too bad for being 15 years old!

View attachment 669246

CAD aluminum frame with some spinergy…I raced in college and a while after. love it.

I’ve been helping a friend pull the guts out of his not-for-street C5 to replace the clutch and rebuild the torque tube. No fun.

I keep my tools fairly-well organized, but even with careful (slow) drawer closing and opening, the drawers end up messy over time, causing me to move everything. I've used several methods of keeping the tools in place, but now that I have a 3D printer, making custom tool holders is possible. My first effort was to clear out my punch and chisel drawer and make trays for everything. First up, two trays - one for all my roll-pin punches, and one for all my taper/alignment punches:

These were painstakingly-designed to fit in the drawer, with room for more trays as I get them designed:

They were designed so that I can push down on either end of the punch I want, which tilts it up so that the opposite end can be grabbed. Each sits in two cradles that perfectly match the punch. In order to design it like that, I had to first model each punch and use those models to make the cuts in the cradle. Here's the Fusion 360 model for one of the trays:

Bottom Line: I don't think I'll take the time to get this detailed for other tool trays. It took many, many hours to design these two trays, and it's not worth it. I'd rather be working on other projects. I'll be trying other design strategies next, but I don't have any good ideas on how to retain all the features while simplifying the design.

These were painstakingly-designed to fit in the drawer, with room for more trays as I get them designed:

They were designed so that I can push down on either end of the punch I want, which tilts it up so that the opposite end can be grabbed. Each sits in two cradles that perfectly match the punch. In order to design it like that, I had to first model each punch and use those models to make the cuts in the cradle. Here's the Fusion 360 model for one of the trays:

Bottom Line: I don't think I'll take the time to get this detailed for other tool trays. It took many, many hours to design these two trays, and it's not worth it. I'd rather be working on other projects. I'll be trying other design strategies next, but I don't have any good ideas on how to retain all the features while simplifying the design.

I keep my tools fairly-well organized, but even with careful (slow) drawer closing and opening, the drawers end up messy over time, causing me to move everything. I've used several methods of keeping the tools in place, but now that I have a 3D printer, making custom tool holders is possible. My first effort was to clear out my punch and chisel drawer and make trays for everything. First up, two trays - one for all my roll-pin punches, and one for all my taper/alignment punches:

View attachment 669936

These were painstakingly-designed to fit in the drawer, with room for more trays as I get them designed:

View attachment 669937

They were designed so that I can push down on either end of the punch I want, which tilts it up so that the opposite end can be grabbed. Each sits in two cradles that perfectly match the punch. In order to design it like that, I had to first model each punch and use those models to make the cuts in the cradle. Here's the Fusion 360 model for one of the trays:

View attachment 669938

Bottom Line: I don't think I'll take the time to get this detailed for other tool trays. It took many, many hours to design these two trays, and it's not worth it. I'd rather be working on other projects. I'll be trying other design strategies next, but I don't have any good ideas on how to retain all the features while simplifying the design.

That is really cool, Scott. I've been doing some 3D storage projects like that as well.

I think you and I are wired in similar ways. For me, I get as much enjoyment out of building storage solutions as I do with any other project. So I actually don't look at is as taking time from other things. It's all about how you look at it.

Yes, I do thing we're wired similarly, Jeff. If it was the only project I had on my list, I'd enjoy it more, but I have a LOT of projects in play, and shop organization is way down the priority list. My LJ build has taken a back seat to a more important project - getting my rainwater collection system, which is over-engineered like all sab projects, operational. It will be the homestead's only source of water eventually because I'm miles from any public water supply mains and my 800' deep well is emptying at an alarming rate due to all the population growth in the area. I've mentioned that several times on the forum, so I apologize for the repetition. If I don't get it operational before the well water disappears, I'll be forced to buy water and have it trucked in, which is not cheap.I think you and I are wired in similar ways. For me, I get as much enjoyment out of building storage solutions as I do with any other project. So I actually don't look at is as taking time from other things. It's all about how you look at it.

Right now, I'm working on the stand for a 1,500 gallon (6.5 tons!) water tank that will get all the untreatable roof runoff for use in the garden. I've decided not to take the time to post as I build it, but once it's done, I'll post some pictures. It's been a lot of hard work because I'm using scrap structural steel I've gotten for free over the years, so everything is big and heavy - hard on my weary bones! After that's done, I may be able to get back to the LJ build.