@Equilibrium31 that turned out good, man! Nice job. Those vents get so brittle over time. I've been needing to do something with mine too. I used perforated aluminum sheeting in mine, but I don't like it. I've eyeballed that same material you used for yours, but I have yet to buy a roll and try it. Never seen it used before. Gotta say, it looks pretty nice!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's your favorite DIY mod?

- Thread starter Tjtravis

- Start date

Thanks. I found the stuff at Goodwill for 2 bucks, so it was a pretty good deal.@Equilibrium31 that turned out good, man! Nice job. Those vents get so brittle over time. I've been needing to do something with mine too. I used perforated aluminum sheeting in mine, but I don't like it. I've eyeballed that same material you used for yours, but I have yet to buy a roll and try it. Never seen it used before. Gotta say, it looks pretty nice!

I still have a crack in my driver-side door panel near the window that's also from heat/sun/age and I know that someone around here posted an awesome write-up with a way to fix it and make it look like new again. One of these days I'll have to look up that guide and fix mine up.

I still have a crack in my driver-side door panel near the window that's also from heat/sun/age and I know that someone around here posted an awesome write-up with a way to fix it and make it look like new again. One of these days I'll have to look up that guide and fix mine up.

Funny you say that. One of those popped up on mine a few months ago. I'll try locating it too when I get a little more time. When/If you locate it, will you tag me in it? I'm pretty well rounded when it comes to repairs, but this one has me a little hesitant.

@bedhed (probably didn't need to tag ya since I quoted ya, but on well, lol)Funny you say that. One of those popped up on mine a few months ago. I'll try locating it too when I get a little more time. When/If you locate it, will you tag me in it? I'm pretty well rounded when it comes to repairs, but this one has me a little hesitant.

I believe this was the one I came across from @AndyG :

https://wranglertjforum.com/threads/door-panel-crack-repair.13615/

Thanks, man! I'm in the same boat as you. This khaki color becomes annoying when maintenance gets involved.

Tailgate table on the outside. Good for going to get gas for the lawn mower, hauling a bag of trash to the dumpster, anything you want to haul, but not inside.View attachment 122265

View attachment 122267

I saw this post and I though, " I have a spare tire though". Then I thought that I could probable use one of those tires step things that are made for trucks. Just hang it on the spare and it gives me a flat surface. LOL

One of these.

My favorite DIY is my trunk drawer. Sure comes in handy. I use it all the time.

I would have one of those if I could talk the wife out of the back seat. She wants it in just in case the grown kids want to ride.My favorite DIY is my trunk drawer. Sure comes in handy. I use it all the time.View attachment 122340

Awesome fab work!My favorite thus far. Although, it hasn't been completed. Throughout the time spent gathering parts to finish it up, I've found ways to make it an easier build and better overall. So, I'm now planning to jump into another build. Simpler and lighter weight next time. The latching mechanism wasn't put onto this one, but it's a non lock-out indexing plunger.

I used 608 ZZ bearings that have a claimed 308 pound static load capacity per bearing. The bearings are bolted onto 3/8" acrylic, which is bolted onto 2" angled steel, and mounted to the tub using the rear seat's mounting points. The slide-out is welded up using ~1/16" walled 1" square steel tubing. The slide-out frame is topped with 1/2" plywood and covered using an "industrial" type, rubber floor runner from Lowe's.

View attachment 122296

View attachment 122298

I need to fix that vent screen too.Does the dash pop off easy there?

Yea, you can use a flathead screwdriver to pop it off in a few places. Just be gentle with the middle part though since it's a bit weaker there.

Here's a tailgate table that I fabricated for my LJ.

Nice job on the table.

I like the repurposed exhaust hanger holding the chain.

This is my tailgate table. I’m better with wood then metal.

The kinks in the cable are from “training” them to tuck behind the folded table.

It’s a tie for my favorite mod between my storage drawer and the cargo basket.

Both have been well worth the effort.

I seriously modified the fridge slide but didn’t make it from scratch.

The kinks in the cable are from “training” them to tuck behind the folded table.

It’s a tie for my favorite mod between my storage drawer and the cargo basket.

Both have been well worth the effort.

I seriously modified the fridge slide but didn’t make it from scratch.

Brianj5600

TJ Expert

Mine is still in progress. I am still working on getting the rear short arm geometry with 4" lift more to my liking. I always have one obstacle that causes wheel hop. When I installed a DC driveshaft I decided to replace the axle UCA mounts with thicker aftermarket ones. While I was at it I extended the mounts, added an adjustable trackbar mount and rotated the UCA mounts forward from stock. There is no bolt on trackbar mount on the axle and stock like clearance for the TB to fuel tank. Just driving around town I can tell there is still too much anti squat. I need to make some changes to the LCAs and maybe go to the top hole on the UCA.

Kiwi TJ

I don't suffer from insanity I enjoy every minute

Supporting Member

Ride of the Month Winner

My Ammo can center console....Started with 2 and welded them together...bit of grinding and painting to match the outside body colour.

Still needs a bit of tweaking but happy overall.....Next time I'd go with a fat 50cal box instead

Still needs a bit of tweaking but happy overall.....Next time I'd go with a fat 50cal box instead

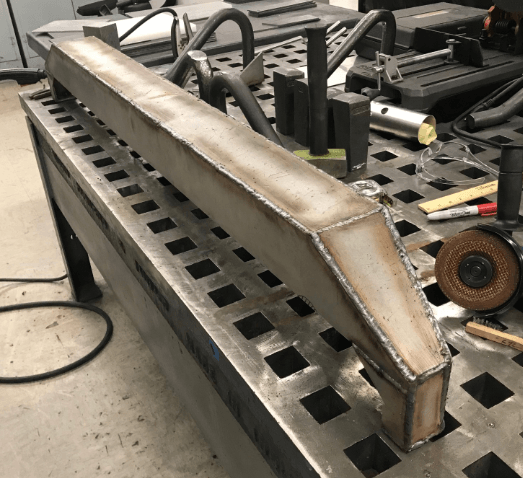

Our home made rear bumper:

That was a lot of weld, and a lot of grinding...

That was a lot of weld, and a lot of grinding...

DustyRhodes03

TJ Enthusiast

My favorite thus far. Although, it hasn't been completed. Throughout the time spent gathering parts to finish it up, I've found ways to make it an easier build and better overall. So, I'm now planning to jump into another build. Simpler and lighter weight next time. The latching mechanism wasn't put onto this one, but it's a non lock-out indexing plunger.

I used 608 ZZ bearings that have a claimed 308 pound static load capacity per bearing. The bearings are bolted onto 3/8" acrylic, which is bolted onto 2" angled steel, and mounted to the tub using the rear seat's mounting points. The slide-out is welded up using ~1/16" walled 1" square steel tubing. The slide-out frame is topped with 1/2" plywood and covered using an "industrial" type, rubber floor runner from Lowe's.

View attachment 122296

View attachment 122298

Awesome job!

Funny I saw a truck the other day with a tailgate extender and thought damn something similar for the back of a Jeep would be sweet haha

If I get a free minute, I'll take a pic of the back side of the early defrost dash trim to show you why the later ones break the grill out so easily. The early ones are heavily reinforced around the hole with a diverter for the air.Kind of a small, cheap fix, but the plastic grating of the defroster vent had been falling apart (I think the heat and sun from living in Texas so long had got to it), so I just cut out the entire middle section and used some spare plastic gutter screen material along with some epoxy to replace it. Personally, I think it looks better than the way it did when it was in stock form.

View attachment 122315

View attachment 122316

And the finished product:

View attachment 122317

I also added a cabin winch switch, which is nothing particularly special, but I found a switch with a cover that lights up when opened that I think looks pretty good.

View attachment 122321

View attachment 122319

I've fixed several with wire mesh and JB Weld epoxy. Works well.

McMaster Carr sells a very wide variety of stainless steel mesh in 1 foot squares.@Equilibrium31 that turned out good, man! Nice job. Those vents get so brittle over time. I've been needing to do something with mine too. I used perforated aluminum sheeting in mine, but I don't like it. I've eyeballed that same material you used for yours, but I have yet to buy a roll and try it. Never seen it used before. Gotta say, it looks pretty nice!