The good news is that means that block is most likely GOOD. New heads and you should have a good engine. It ran great until it started overheating. I'd check the bearings and stuff but if they all look good I'd run it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wildman's TJ is getting a face lift

- Thread starter Wildman

- Start date

tykesplace

TJ Enthusiast

Just one more pic for clarity, without the valve. It's difficult to see but the crack goes down into the rougher casting area.

Intake side isn't as bad, but it's there.

Intake side isn't as bad, but it's there.

Yes I can see it and it explains a lot about how it ran and acted between when it was cold and then hot. That is a serious crack and I'd say that head is beyond repair. I wouldn't trust a pair of stock Dodge magnum heads after all the bad I've read. Get some aftermarket heads either cast iron or aluminum.

tykesplace

TJ Enthusiast

Yes thank you for posting the pictures. It's nice to know I wasn't just chasing my tail when I was trying to figure out why it was overheating. It sucks that I might have been able to just bolt on new heads and go but my Jeep needed a redo anyhow.

You'll have to let me know what the rest of the engine looks like.

You'll have to let me know what the rest of the engine looks like.

Had other chores to do today so I didn't get anything done to the Jeep. Hope to work on it some for the rest of the week. Then this weekend I'm headed down to Coos Bay, OR to take my daughter down to check out the college there. She starts school there in September and is taking their Culinary course since she wants to have her own place some day. They offer a Baking/Pastries program and then a Culinary course that covers not just the cooking but also the management side of things.

SWOCC? I’ve heard good things! I had no idea they had a culinary institute as well.Had other chores to do today so I didn't get anything done to the Jeep. Hope to work on it some for the rest of the week. Then this weekend I'm headed down to Coos Bay, OR to take my daughter down to check out the college there. She starts school there in September and is taking their Culinary course since she wants to have her own place some day. They offer a Baking/Pastries program and then a Culinary course that covers not just the cooking but also the management side of things.

SWOCC? I’ve heard good things! I had no idea they had a culinary institute as well.

Yes and it is suppose to be a good program also. Part of the schooling is that you actually go to work at a bakery or restaurant for approx 3 months as part of the schooling. And it's graded just like the rest of your classes. And the fact that they also teach management was a big plus in her choosing SWOCC.

That’s awesome. Any school that prioritizes getting that experience on the resume gets my vote!Yes and it is suppose to be a good program also. Part of the schooling is that you actually go to work at a bakery or restaurant for approx 3 months as part of the schooling. And it's graded just like the rest of your classes. And the fact that they also teach management was a big plus in her choosing SWOCC.

That’s awesome. Any school that prioritizes getting that experience on the resume gets my vote!

She had to take over the cooking duties in the house when she was about 13 so she has had a lot of experiance doing some stuff. I think it is what helped push her in this direction. She had looked around at a lot of other programs and at one point had thought about going to FL for a school there.

When the one in Seattle closed she had to start looking at other options. And yes any school that gives you hands on training IMHO is a lot better.

She already does a pretty good job with the decorating part on cakes and stuff.

OK back to Jeep stuff.

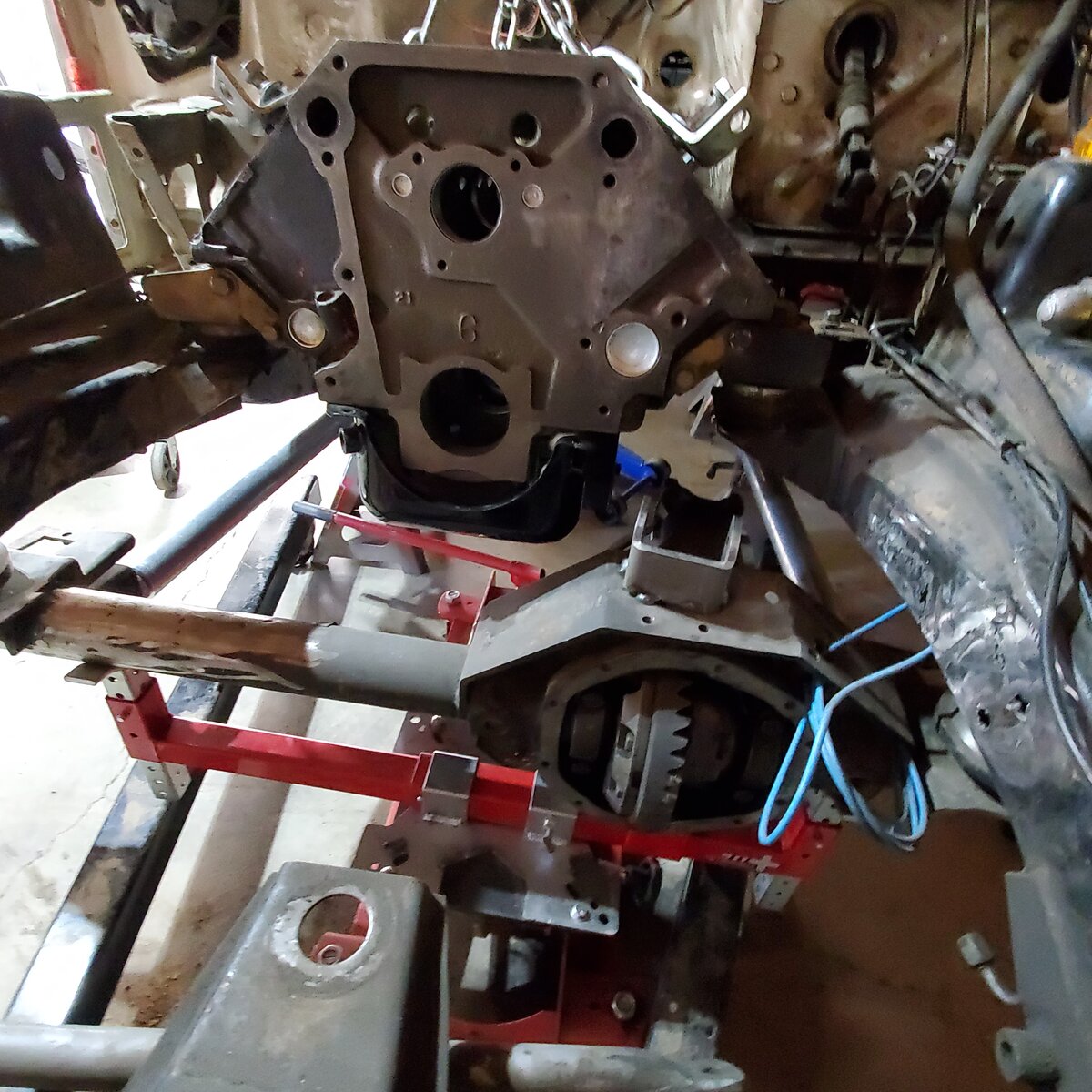

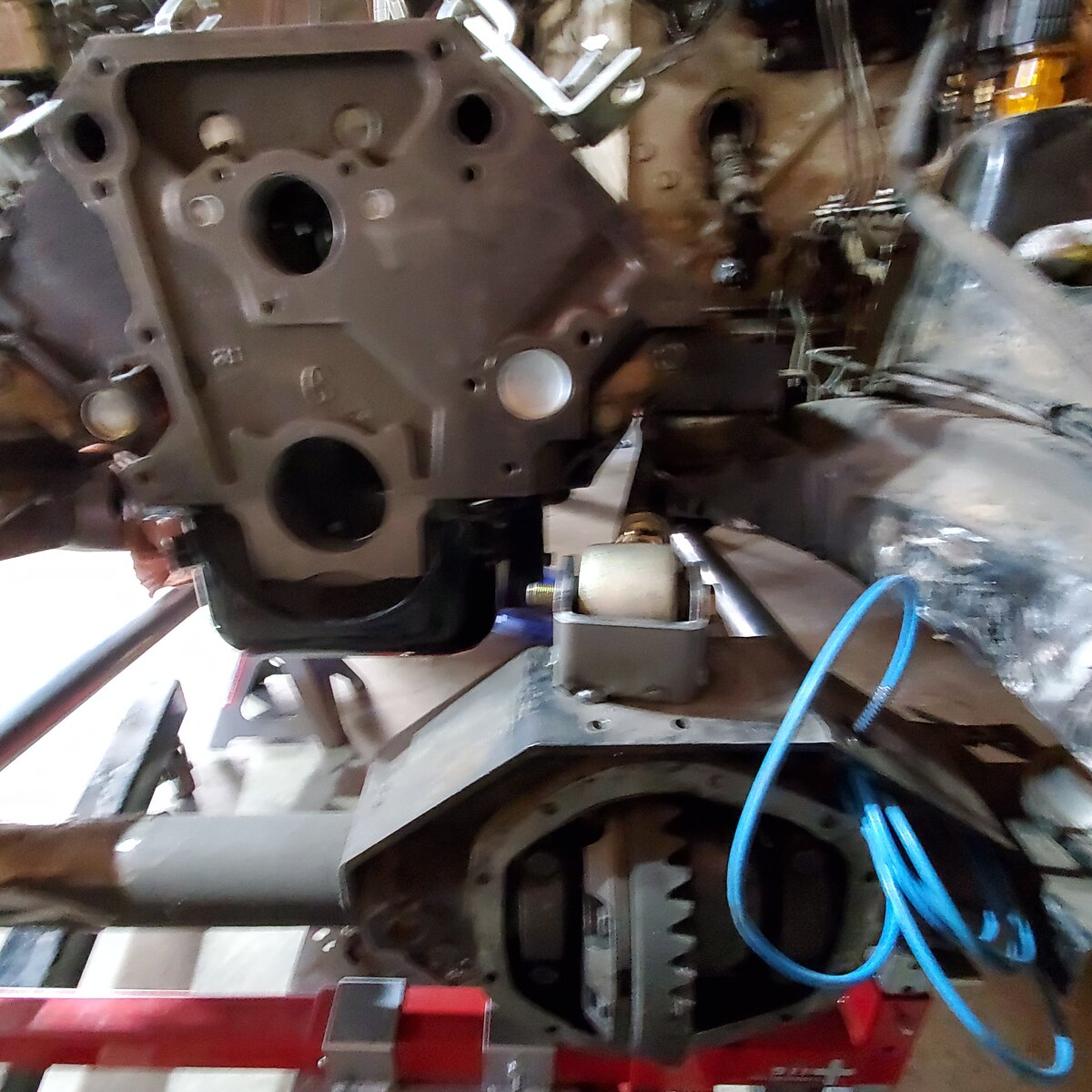

Set the engine block and transmission into the frame. Found out that I will need to move the axle forward some to clear the oil pan if I want to try and get as much up travel as possible.

Because I have LJ rear lower arms they are 2.25" longer than my front arms. So I installed them just for grins and giggles.

It puts the axle just forward of the block.

So at this point I'm going to raise the frame back up and see how everything fits.

My idea for how to do this is to move the upper mounts forward. I can try cutting the stock mounts off and reuse them or get the ones offered by Artec.

Set the engine block and transmission into the frame. Found out that I will need to move the axle forward some to clear the oil pan if I want to try and get as much up travel as possible.

Because I have LJ rear lower arms they are 2.25" longer than my front arms. So I installed them just for grins and giggles.

It puts the axle just forward of the block.

So at this point I'm going to raise the frame back up and see how everything fits.

My idea for how to do this is to move the upper mounts forward. I can try cutting the stock mounts off and reuse them or get the ones offered by Artec.

Damn I always forget just how big this thing is...

Going under the Jeep.

Going under the Jeep.

Interesting idea moving the mounts forward.......OK back to Jeep stuff.

Set the engine block and transmission into the frame. Found out that I will need to move the axle forward some to clear the oil pan if I want to try and get as much up travel as possible.

View attachment 175413View attachment 175414

Because I have LJ rear lower arms they are 2.25" longer than my front arms. So I installed them just for grins and giggles.

View attachment 175415

It puts the axle just forward of the block.

View attachment 175416

View attachment 175417

View attachment 175418

So at this point I'm going to raise the frame back up and see how everything fits.

My idea for how to do this is to move the upper mounts forward. I can try cutting the stock mounts off and reuse them or get the ones offered by Artec.

Well I forgot to put the rear output in gear and fought with the transfer case for a while before I realized the input shaft wasn't turning.

Once I engaged the rear output and was spinning the input it slipped right in.

Threw the front driveline on to see if I was going to have any clearance issues. Everything fits...

I can't clock it any flatter than this without cutting the floorboard.

I was a little worried it wasn't going to.

Once I engaged the rear output and was spinning the input it slipped right in.

Threw the front driveline on to see if I was going to have any clearance issues. Everything fits...

I can't clock it any flatter than this without cutting the floorboard.

I was a little worried it wasn't going to.

Interesting idea moving the mounts forward.......

I borrowed it from others. Wish I could say it was my idea.

And because my front axle is a little wider than stock the lower spring pads are a little farther out so moving the upper mounts forward won't hurt.

With the Nth Degree tummy tuck I'll have room for the t-case to hang down where it is no problem.

@B00mb00m how did you make your crossmember? Is your transmission hard mounted to the crossbeam and then the joints at the frame are what isolate it?

I have the GenRight universal crossmembers that I am going to use. Just trying to decide if I should put a rubber mount on the transmission.

@B00mb00m how did you make your crossmember? Is your transmission hard mounted to the crossbeam and then the joints at the frame are what isolate it?

I have the GenRight universal crossmembers that I am going to use. Just trying to decide if I should put a rubber mount on the transmission.

You weren't kidding when you said that T case was massive.

My GR cross member is hard mounted to the transmission and uses the poly bushings at the frame. There are more vibrations than stock at idle but not enough to make want to change anything.With the Nth Degree tummy tuck I'll have room for the t-case to hang down where it is no problem.

@B00mb00m how did you make your crossmember? Is your transmission hard mounted to the crossbeam and then the joints at the frame are what isolate it?

I have the GenRight universal crossmembers that I am going to use. Just trying to decide if I should put a rubber mount on the transmission.

You weren't kidding when you said that T case was massive.

My GR cross member is hard mounted to the transmission and uses the poly bushings at the frame. There are more vibrations than stock at idle but not enough to make want to change anything.

Alex thanks that is what I was wondering. I bought 2 of the GR cross members so I could do one for the transmission and one for the transfer case. I know some feel it isn't needed for the t-case but that damn thing is 150 lbs so I figured better safe than sorry.

That's one heavy case. For comparison an np241 weighs 92lbs and my atlas 2 speed is 110. When I was doing research it seemed like for my application it was unneeded, given my T-case is lighter than yours. I found more people complaining about issues due to the rear support than people having problems not having one. To me, it only seemed necessary in race or buggy applications.Alex thanks that is what I was wondering. I bought 2 of the GR cross members so I could do one for the transmission and one for the transfer case. I know some feel it isn't needed for the t-case but that damn thing is 150 lbs so I figured better safe than sorry.

But since you already have the second mount it's better to have it and not need it than to need it and not have it...

Have you tested the Nth degree with the cross members mocked up? On my jeep, it wasn't an issue since the transmission mount bolts would hit before the bar. But adding a rear I'm guessing would have required me to lift the case higher due to the MML angling the trans downwards.

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

With the Nth Degree tummy tuck I'll have room for the t-case to hang down where it is no problem.

@B00mb00m how did you make your crossmember? Is your transmission hard mounted to the crossbeam and then the joints at the frame are what isolate it?

I have the GenRight universal crossmembers that I am going to use. Just trying to decide if I should put a rubber mount on the transmission.

Here's the full write-up:

https://wranglertjforum.com/threads...on-cross-member-and-transfer-case-skid.34524/

I used JL control arm bushings at the frame that I picked up off Craigslist and hard mounted to transmission. I have an extra control arm you can cut up if you want the bushings. I'd be happy to mail it to you. I don't notice any extra vibes for me now that I finished up the new exhaust. I also have a set of autofab poly bushings