After getting home, I put in a little time while the family caught a nap.

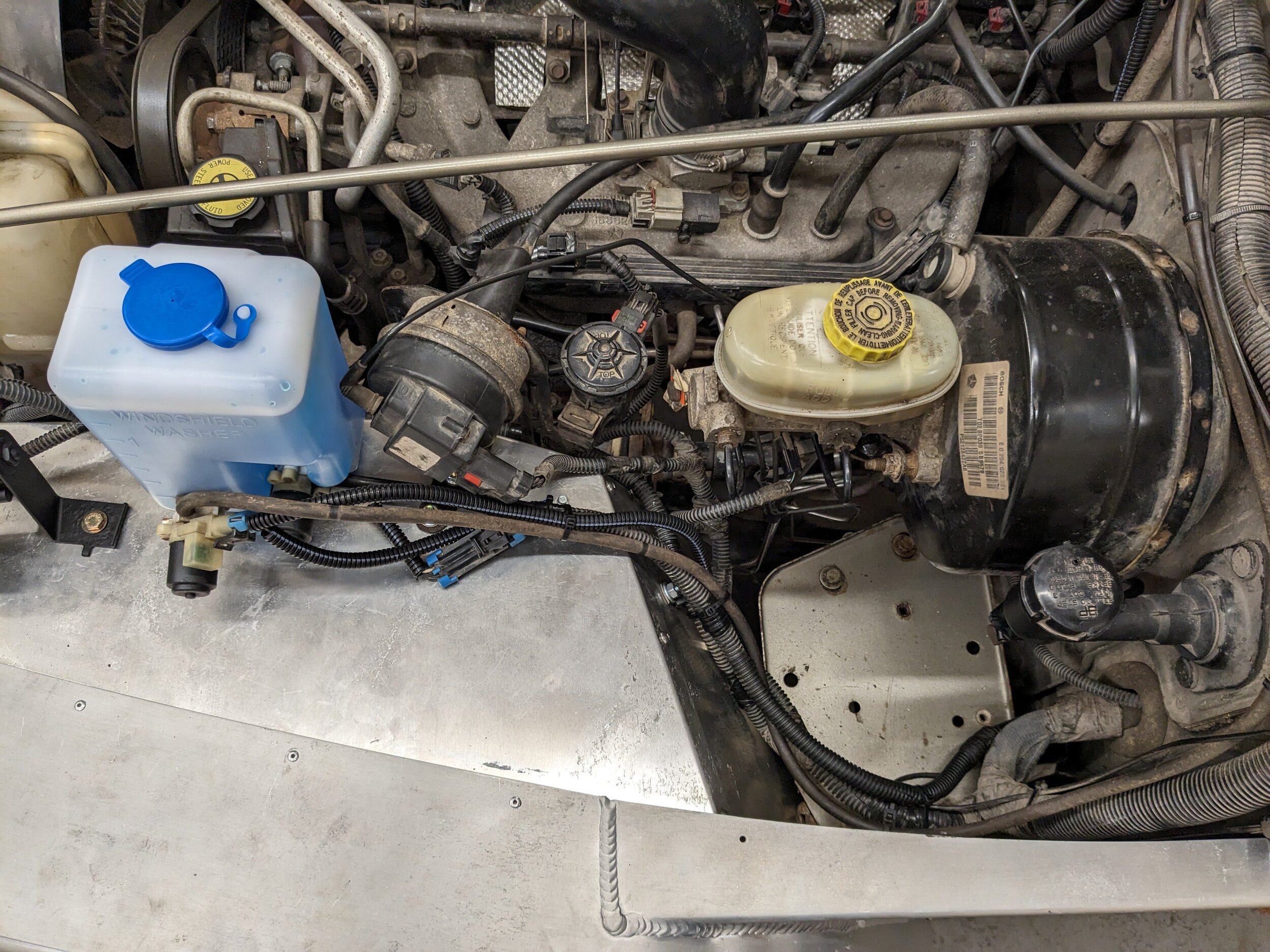

Washer fluid reservoir worked perfectly. Mount bracket to the reservoir and put some blue painters tape down to trace it's location on the fender so I could locate the mounting holes. I put a flashlight along side it and closed the hood to be sure it cleared and the hood didn't rest on it.

Love a Jeep - There was enough room between the hood and the grill to peer in (even with the hood latches) and get a view of the reservoir and hood.

Had to drill a new, slightly higher, mounting hole in the bracket to gain clearance for the mount bolt with the full weight of the fluid on the bracket.

Leaves plenty of space for future projects.

Trying to pay more attention to the little details to make this Heep look like less of a piece of crap. Repaint on the horn and washer fluid motors looks good.

Washer fluid reservoir worked perfectly. Mount bracket to the reservoir and put some blue painters tape down to trace it's location on the fender so I could locate the mounting holes. I put a flashlight along side it and closed the hood to be sure it cleared and the hood didn't rest on it.

Love a Jeep - There was enough room between the hood and the grill to peer in (even with the hood latches) and get a view of the reservoir and hood.

Had to drill a new, slightly higher, mounting hole in the bracket to gain clearance for the mount bolt with the full weight of the fluid on the bracket.

Leaves plenty of space for future projects.

Trying to pay more attention to the little details to make this Heep look like less of a piece of crap. Repaint on the horn and washer fluid motors looks good.