That's why I haven't shared pics of mine over here.That's when you know it's done correctly!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to raise the rear frame and eliminate your butt crack

- Thread starter hosejockey61

- Start date

But it works! (No pun intended)That's why I haven't shared pics of mine over here.

Hasn't fallen off yet...But it works! (No pun intended)

Just checked this out, awesome vid. Your how-to's are great!

LONGJP2

TJ Expert

Is your receiver welded to the first crossmember instead of the bumper? I didn’t connect the two permanently since mine is to the bumper and I ultimately made a sleeve on the second crossmember.I welded tabs to the receiver so it could be bolted to the second crossmember.

View attachment 269085

LONGJP2

TJ Expert

Got it, thanks!It's only welded to the flat plate bumper. I notched the bottom of the crossmember to make it removeable. Lots of ways to do it, really didn't put much thought into it.

View attachment 269088

Did you use crush sleeves or something similar in the secondary crossmember?

Last edited:

LONGJP2

TJ Expert

It's an open C channel. Just nuts and bolts.Got it, thanks!

Did you use crush sleeves or something similar in the secondary crossmember?

There are those that do, and those that talk about doing. I'm still in the category of talking about doing!That's why I haven't shared pics of mine over here.

Funny I was just under there and already forgot thatIt's an open C channel. Just nuts and bolts.

I’m not entirely sure how I stumbled upon this thread, it definitely wasn’t something I was looking for and it isn’t something I even knew was a thing people were already doing, but it is something I have given a lot of thought to over the years because I hate that rear gap. Anyway it is a long way down on my to-do list. I know these examples have been done on LJs with a lot more space to play with but I thought I had a way to make it work on a TJ. Also I see @jjvw has eluded to doing it and since I am about 40 pages into his build thread I know he has a TJ.

Let me also say that even though I have thought about it a lot, I am a computer nerd, I have zero fabrication experience so my ideas may all be complete shit. Welding is probably the number one thing I wish I was able to do, right behind time travel. But right now I simply do not have the time or space to learn. I can turn a wrench and follow directions well enough to do repairs and install upgrades but I don’t know what would or wouldn’t affect the structural integrity of the frame. With all the people on here that are waaaaaay smarter than I am I am sure there is a good reason my idea wouldn’t work and hopefully someone can set me straight.

Instead of cutting the entire rear frame off why not cut through the bottom and sides and leave the top uncut so you can bend the frame upwards? The further away from the end of the frame the smaller the radius of the bend in the top would need to be. This would leave a pie shaped gap with the widest part being the bottom of the frame. There would be no need to try to have to weld along the top of the frame where the tub is in the way.

So maybe cut here:

Bend up to create this gap to fill:

One thing I am not sure about is how the savvy gts would work with the rear cross member raised. I assume you could use the lower adjustment on the skid on the rear but keep the higher adjustment on the front side, Also the rear cross member would be a few degrees out of perpendicular, but I figure with all the different lifts and heavy bumpers and all that we add on that very few are still at the original angle anyway.

And it if works on the back, would it also work on the front?

Cut Here:

Create this gap to fill:

No actual math or testing went into determining the size of the gaps that would be created and need to be filled in my pictures, just guestimates that might be way off.

As I said, I am sure there is a good reason not to do it this way, but it seems easier.

Let me also say that even though I have thought about it a lot, I am a computer nerd, I have zero fabrication experience so my ideas may all be complete shit. Welding is probably the number one thing I wish I was able to do, right behind time travel. But right now I simply do not have the time or space to learn. I can turn a wrench and follow directions well enough to do repairs and install upgrades but I don’t know what would or wouldn’t affect the structural integrity of the frame. With all the people on here that are waaaaaay smarter than I am I am sure there is a good reason my idea wouldn’t work and hopefully someone can set me straight.

Instead of cutting the entire rear frame off why not cut through the bottom and sides and leave the top uncut so you can bend the frame upwards? The further away from the end of the frame the smaller the radius of the bend in the top would need to be. This would leave a pie shaped gap with the widest part being the bottom of the frame. There would be no need to try to have to weld along the top of the frame where the tub is in the way.

So maybe cut here:

Bend up to create this gap to fill:

One thing I am not sure about is how the savvy gts would work with the rear cross member raised. I assume you could use the lower adjustment on the skid on the rear but keep the higher adjustment on the front side, Also the rear cross member would be a few degrees out of perpendicular, but I figure with all the different lifts and heavy bumpers and all that we add on that very few are still at the original angle anyway.

And it if works on the back, would it also work on the front?

Cut Here:

Create this gap to fill:

No actual math or testing went into determining the size of the gaps that would be created and need to be filled in my pictures, just guestimates that might be way off.

As I said, I am sure there is a good reason not to do it this way, but it seems easier.

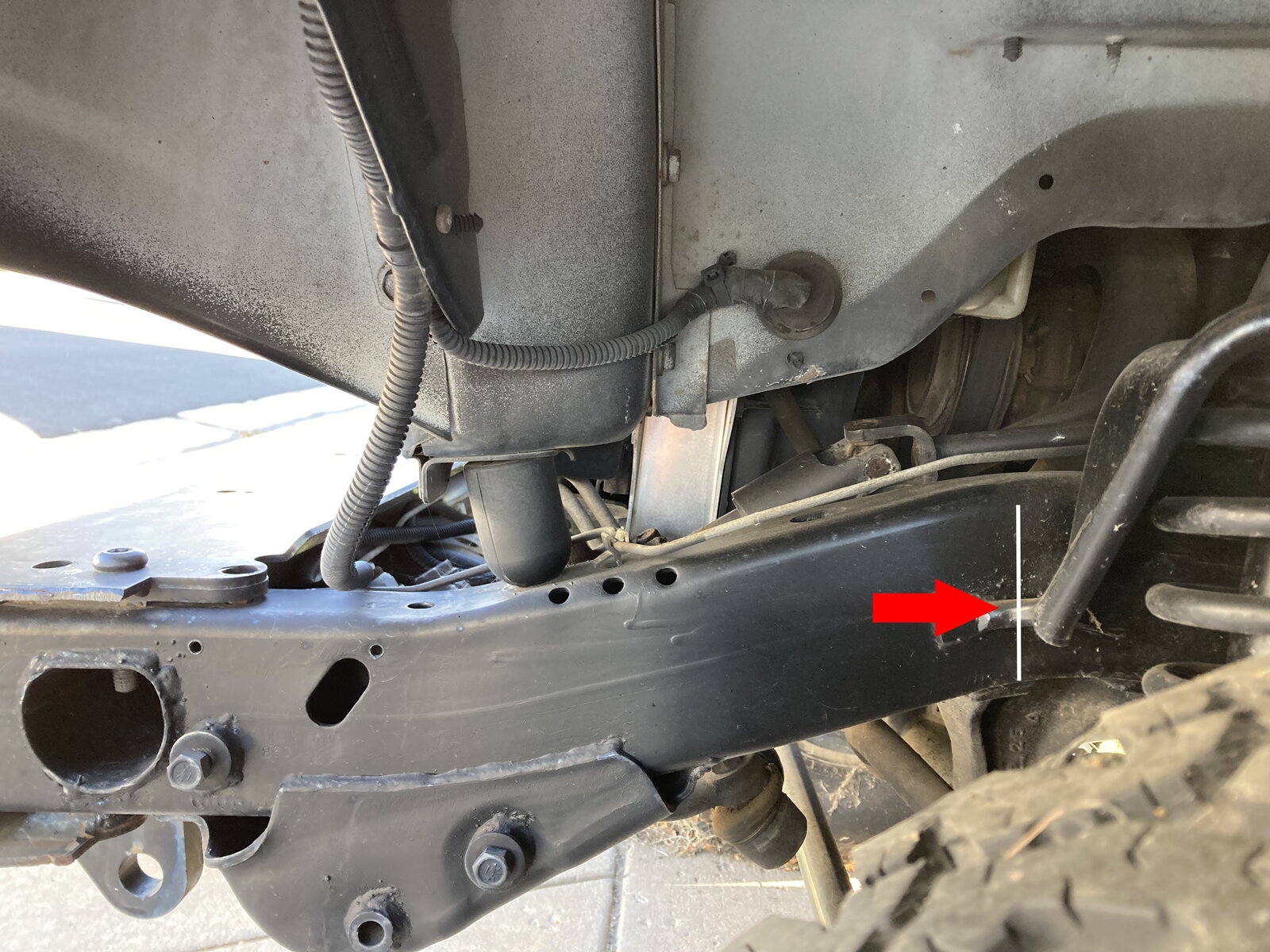

If that is a pic of your rig, hopefully you have put that missing steering gear bolt back in by now.I’m not entirely sure how I stumbled upon this thread, it definitely wasn’t something I was looking for and it isn’t something I even knew was a thing people were already doing, but it is something I have given a lot of thought to over the years because I hate that rear gap. Anyway it is a long way down on my to-do list. I know these examples have been done on LJs with a lot more space to play with but I thought I had a way to make it work on a TJ. Also I see @jjvw has eluded to doing it and since I am about 40 pages into his build thread I know he has a TJ.

Let me also say that even though I have thought about it a lot, I am a computer nerd, I have zero fabrication experience so my ideas may all be complete shit. Welding is probably the number one thing I wish I was able to do, right behind time travel. But right now I simply do not have the time or space to learn. I can turn a wrench and follow directions well enough to do repairs and install upgrades but I don’t know what would or wouldn’t affect the structural integrity of the frame. With all the people on here that are waaaaaay smarter than I am I am sure there is a good reason my idea wouldn’t work and hopefully someone can set me straight.

Instead of cutting the entire rear frame off why not cut through the bottom and sides and leave the top uncut so you can bend the frame upwards? The further away from the end of the frame the smaller the radius of the bend in the top would need to be. This would leave a pie shaped gap with the widest part being the bottom of the frame. There would be no need to try to have to weld along the top of the frame where the tub is in the way.

So maybe cut here:

View attachment 273469

Bend up to create this gap to fill:

View attachment 273466

One thing I am not sure about is how the savvy gts would work with the rear cross member raised. I assume you could use the lower adjustment on the skid on the rear but keep the higher adjustment on the front side, Also the rear cross member would be a few degrees out of perpendicular, but I figure with all the different lifts and heavy bumpers and all that we add on that very few are still at the original angle anyway.

And it if works on the back, would it also work on the front?

Cut Here:

View attachment 273470

Create this gap to fill:

View attachment 273471

No actual math or testing went into determining the size of the gaps that would be created and need to be filled in my pictures, just guestimates that might be way off.

As I said, I am sure there is a good reason not to do it this way, but it seems easier.

This would cant the rear crossmember and, consequently, the rear body mount tabs forward.I’m not entirely sure how I stumbled upon this thread, it definitely wasn’t something I was looking for and it isn’t something I even knew was a thing people were already doing, but it is something I have given a lot of thought to over the years because I hate that rear gap. Anyway it is a long way down on my to-do list. I know these examples have been done on LJs with a lot more space to play with but I thought I had a way to make it work on a TJ. Also I see @jjvw has eluded to doing it and since I am about 40 pages into his build thread I know he has a TJ.

Let me also say that even though I have thought about it a lot, I am a computer nerd, I have zero fabrication experience so my ideas may all be complete shit. Welding is probably the number one thing I wish I was able to do, right behind time travel. But right now I simply do not have the time or space to learn. I can turn a wrench and follow directions well enough to do repairs and install upgrades but I don’t know what would or wouldn’t affect the structural integrity of the frame. With all the people on here that are waaaaaay smarter than I am I am sure there is a good reason my idea wouldn’t work and hopefully someone can set me straight.

Instead of cutting the entire rear frame off why not cut through the bottom and sides and leave the top uncut so you can bend the frame upwards? The further away from the end of the frame the smaller the radius of the bend in the top would need to be. This would leave a pie shaped gap with the widest part being the bottom of the frame. There would be no need to try to have to weld along the top of the frame where the tub is in the way.

So maybe cut here:

View attachment 273469

Bend up to create this gap to fill:

View attachment 273466

One thing I am not sure about is how the savvy gts would work with the rear cross member raised. I assume you could use the lower adjustment on the skid on the rear but keep the higher adjustment on the front side, Also the rear cross member would be a few degrees out of perpendicular, but I figure with all the different lifts and heavy bumpers and all that we add on that very few are still at the original angle anyway.

And it if works on the back, would it also work on the front?

Cut Here:

View attachment 273470

Create this gap to fill:

View attachment 273471

No actual math or testing went into determining the size of the gaps that would be created and need to be filled in my pictures, just guestimates that might be way off.

As I said, I am sure there is a good reason not to do it this way, but it seems easier.

Doing this way you're going to change the orientation of the crossmember as you pivot around that point. It won't sit quite right vs effectively sliding everything up.I’m not entirely sure how I stumbled upon this thread, it definitely wasn’t something I was looking for and it isn’t something I even knew was a thing people were already doing, but it is something I have given a lot of thought to over the years because I hate that rear gap. Anyway it is a long way down on my to-do list. I know these examples have been done on LJs with a lot more space to play with but I thought I had a way to make it work on a TJ. Also I see @jjvw has eluded to doing it and since I am about 40 pages into his build thread I know he has a TJ.

Let me also say that even though I have thought about it a lot, I am a computer nerd, I have zero fabrication experience so my ideas may all be complete shit. Welding is probably the number one thing I wish I was able to do, right behind time travel. But right now I simply do not have the time or space to learn. I can turn a wrench and follow directions well enough to do repairs and install upgrades but I don’t know what would or wouldn’t affect the structural integrity of the frame. With all the people on here that are waaaaaay smarter than I am I am sure there is a good reason my idea wouldn’t work and hopefully someone can set me straight.

Instead of cutting the entire rear frame off why not cut through the bottom and sides and leave the top uncut so you can bend the frame upwards? The further away from the end of the frame the smaller the radius of the bend in the top would need to be. This would leave a pie shaped gap with the widest part being the bottom of the frame. There would be no need to try to have to weld along the top of the frame where the tub is in the way.

So maybe cut here:

View attachment 273469

Bend up to create this gap to fill:

View attachment 273466

One thing I am not sure about is how the savvy gts would work with the rear cross member raised. I assume you could use the lower adjustment on the skid on the rear but keep the higher adjustment on the front side, Also the rear cross member would be a few degrees out of perpendicular, but I figure with all the different lifts and heavy bumpers and all that we add on that very few are still at the original angle anyway.

And it if works on the back, would it also work on the front?

Cut Here:

View attachment 273470

Create this gap to fill:

View attachment 273471

No actual math or testing went into determining the size of the gaps that would be created and need to be filled in my pictures, just guestimates that might be way off.

As I said, I am sure there is a good reason not to do it this way, but it seems easier.

And the sway bar, and the gas tank? This jeep isn't going anywhere anytime soon.If that is a pic of your rig, hopefully you have put that missing steering gear bolt back in by now.

You can drive without a swaybar, you can put the fuel tank in the back, the missing steering gear bolt will cost you dearly.And the sway bar, and the gas tank? This jeep isn't going anywhere anytime soon.

I did realize the angle of the rear cross member would be affected, I wasn't sure if it would be great enough to cause the bolts be out of allignment. Like I said, it sounded like a good idea in my head, but if it really was a good idea, I am sure someone else would have already done it. Thank you for letting me know why!This would cant the rear crossmember and, consequently, the rear body mount tabs forward.

Hopefully I didn't come across as too much of a smart-ass. Yes, I am aware that the bolt is missing, but thank you for pointing it out in case I wasn't.You can drive without a swaybar, you can put the fuel tank in the back, the missing steering gear bolt will cost you dearly.

Thank you Rasband. I wasn't sure if it would be enough to matter, but probably so.Doing this way you're going to change the orientation of the crossmember as you pivot around that point. It won't sit quite right vs effectively sliding everything up.