Back to trying to correct the tailgate armor with the rest oleum sunrise red. Had some suggestions from @AndyG. 220, 400, 600, base coat color, 1K clear. I hope this turns out!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

05 Flame Red TJ Build

- Thread starter JMT

- Start date

Looking goodBack to trying to correct the tailgate armor with the rest oleum sunrise red. Had some suggestions from @AndyG. 220, 400, 600, base coat color, 1K clear. I hope this turns out!

View attachment 325579

View attachment 325580

View attachment 325581

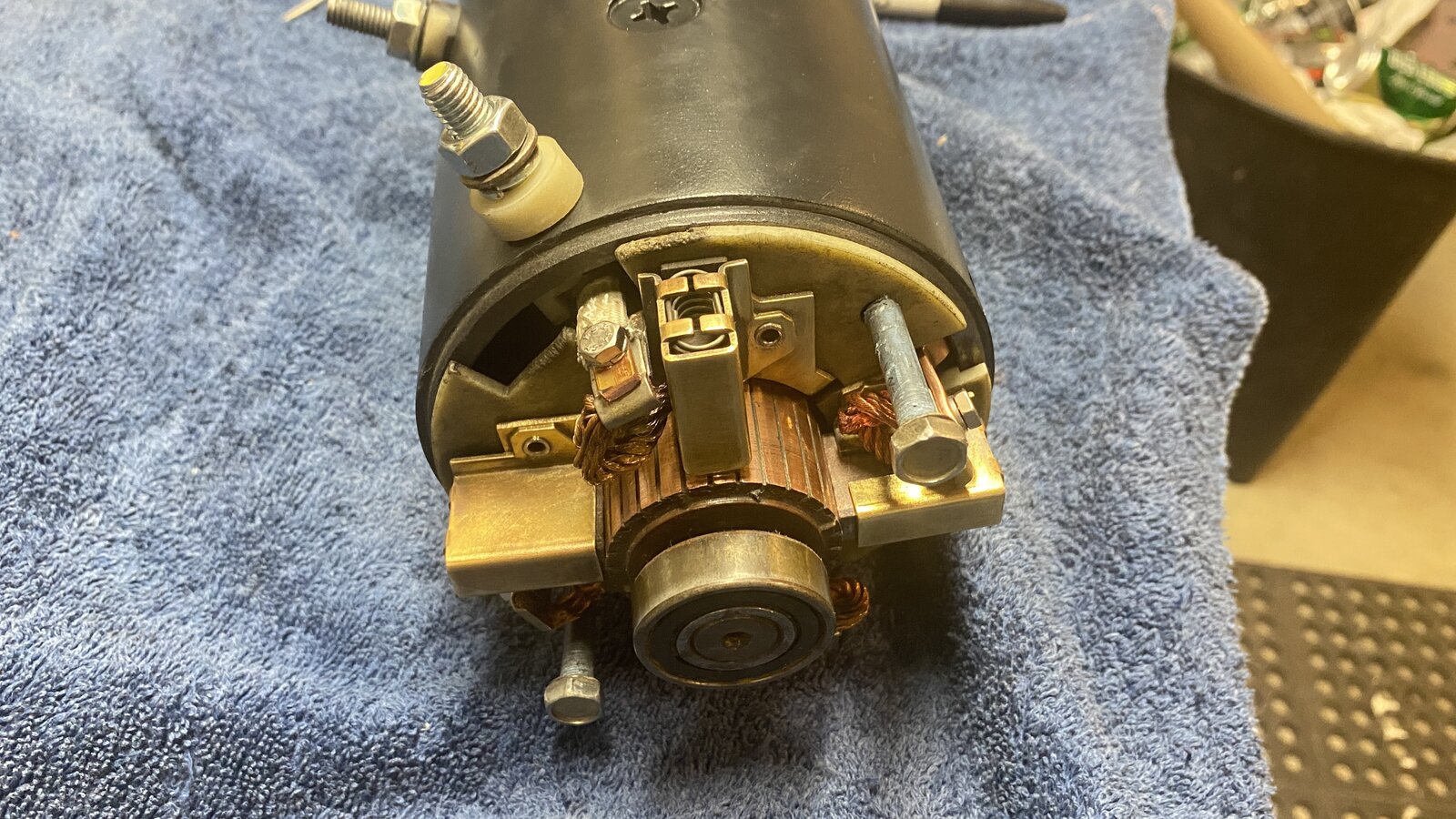

Ok after looking at a couple different motor the armature bolt and buss I sent is for a different generation of motor. But I think we can make this one work versus going with a braided wire one. I tried this on a motor here and you can rotate the bolt in the isolator so it will come basically straight out you can then strip back the insulation, trim to length and drill for the screw. If you would rather I can find a braided bolt and get it to you.

I think I can do that. I’ll get to work. You’ve been very helpful by the way. Can’t thank you enough for the time, thought, effort, and parts.Ok after looking at a couple different motor the armature bolt and buss I sent is for a different generation of motor. But I think we can make this one work versus going with a braided wire one. I tried this on a motor here and you can rotate the bolt in the isolator so it will come basically straight out you can then strip back the insulation, trim to length and drill for the screw. If you would rather I can find a braided bolt and get it to you.

View attachment 325605

Last edited:

No problem at all. Let me know how it turns out.I think I can do that. I’ll get to work. You’ve been very helpful by the way. Can’t thank you enough for the time, thought, and effort.

Got it done. Thanks!Ok after looking at a couple different motor the armature bolt and buss I sent is for a different generation of motor. But I think we can make this one work versus going with a braided wire one. I tried this on a motor here and you can rotate the bolt in the isolator so it will come basically straight out you can then strip back the insulation, trim to length and drill for the screw. If you would rather I can find a braided bolt and get it to you.

View attachment 325605

Make sure to keep insulation on that buss but that looks good.

I trimmed the insulation and lightly burned the ends to keep it from fraying. It’s just laying outside of view.Make sure to keep insulation on that buss but that looks good.

Here it is assembled. We put painters tape on the brushes to hold them in against the springs while we moved the motor into position. It made it much easier. Then just remove the tape.

Looks good. I wish I knew you were missing those two ground screws I would have sent you some. Also make sure the lock washer is between the flat washer and nut or reuse the serrated nut from the old bolt.Here it is assembled. We put painters tape on the brushes to hold them in against the springs while we moved the motor into position. It made it much easier. Then just remove the tape.

View attachment 325690

View attachment 325691

View attachment 325692

@Blackjack

Coolest part of my day! I hadn’t opened this yet. I’ve been looking for a good replacement. These are the right size and have the silver edge just like I wanted!

Coolest part of my day! I hadn’t opened this yet. I’ve been looking for a good replacement. These are the right size and have the silver edge just like I wanted!

@Blackjack The motor splines are slipped onto the clutch thingy all the way. Is it normal for the brushes to not entirely be sitting on the Commutator? I do have to push the motor on another 1/8” inch or so, but the brushes still won’t be entirely on the commutator.

To help with this I usually put a washer on the shaft before I slip it into the bearing on the drum support. What you will want to is slip the motor back just far enough you can slip slip something lever like (paint stick is a safe bet) and pry the armature back into the brushes. Once you do that you will want to install the motor cap holding pressure on the armature so you lock the bearing into the cap.

Ok, good. Helpful. I’ll see what I can do tomorrow or Thursday. I still need 3 bolts anyway. Thanks!To help with this I usually put a washer on the shaft before I slip it into the bearing on the drum support. What you will want to is slip the motor back just far enough you can slip slip something lever like (paint stick is a safe bet) and pry the armature back into the brushes. Once you do that you will want to install the motor cap holding pressure on the armature so you lock the bearing into the cap.

In other news I bolted up the tailgate armor. I only waited 24 hours because I was afraid someone would damage it again. A lot goes on at my house. It’s soo much better than the Duplicolor PR4. Honestly, it’s almost as good as factory.

What paint did you use again?In other news I bolted up the tailgate armor. I only waited 24 hours because I was afraid someone would damage it again. A lot goes on at my house. It’s soo much better than the Duplicolor PR4. Honestly, it’s almost as good as factory.

View attachment 325961

Rustoleum Enamel in Glossy Sunrise Red base coat with a Duplicolor 1K Glossy Clear coatWhat paint did you use again?

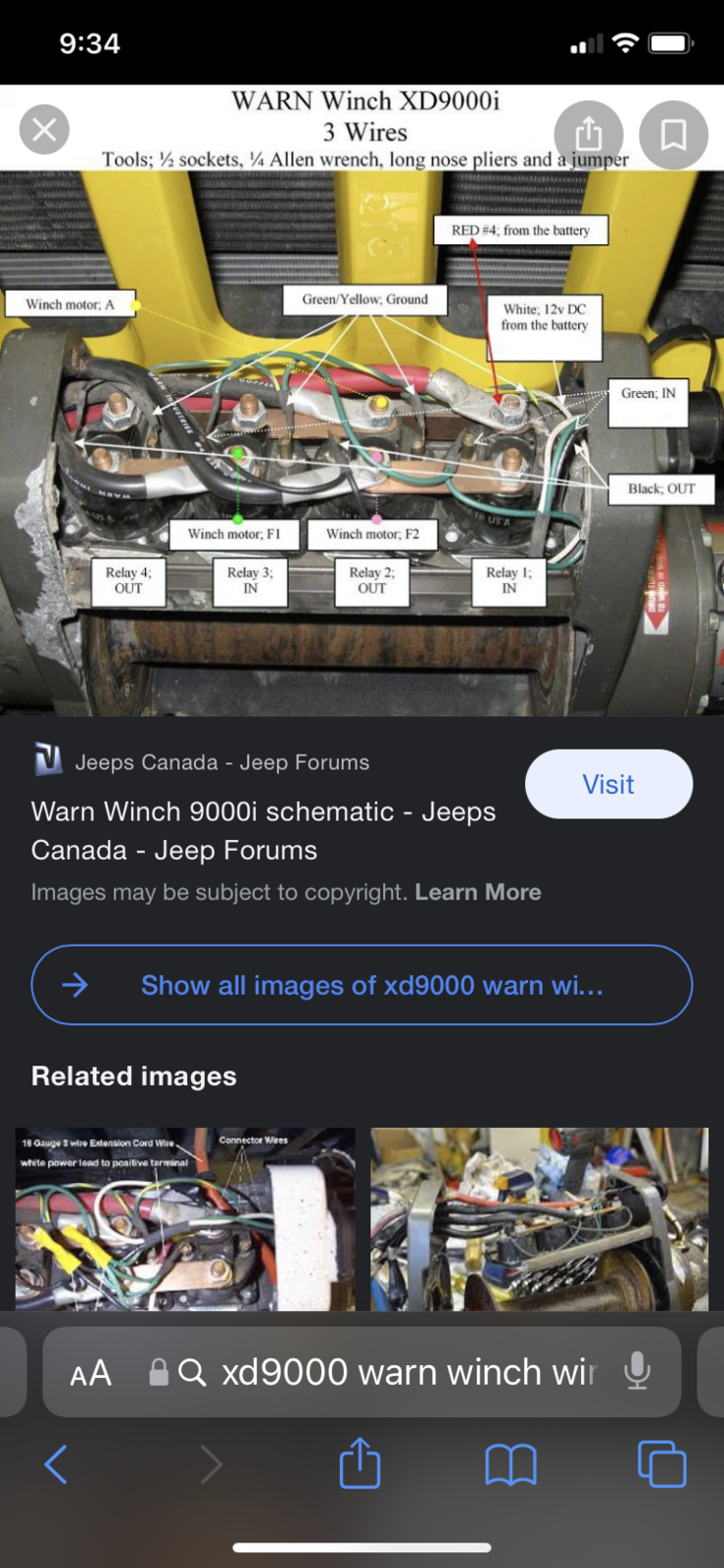

@Blackjack . Just want to make sure this is correct for the A, F1, and F2 connections on the Warn XD9000i.

If so, I had the F1 and F2 reversed and it killed my battery after a couple attempts to turn the drum with the remote. I just had the hot and ground touching my battery rather than bolted on, which may have also been a problem. I have some terminal studs I’m going to add to the side of my battery for final install. Battery is an AGM and is 3yr 10months old. I hoped to get 5 years + out of this one. I did jump it off and it started quickly. Left it running for 30 minutes. About to go out and see if it held the charge from the alternator.

If so, I had the F1 and F2 reversed and it killed my battery after a couple attempts to turn the drum with the remote. I just had the hot and ground touching my battery rather than bolted on, which may have also been a problem. I have some terminal studs I’m going to add to the side of my battery for final install. Battery is an AGM and is 3yr 10months old. I hoped to get 5 years + out of this one. I did jump it off and it started quickly. Left it running for 30 minutes. About to go out and see if it held the charge from the alternator.

Last edited: