You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nashville TJ's Build - Continued

- Thread starter NashvilleTJ

- Start date

I thought I was the only one…

My new catch phrase:

Tonz and Fiddy-Faux's...

These were close to fiddy-faux’s. I think this was Moab in 2018. Note my son in the top pic.

Last edited:

Designed and 3D printed a cage to make it a little more LJ like. Plus the spyder lock wheels lol

Mask Police! Cover yo face.

View attachment 469178

Designed and 3D printed a cage to make it a little more LJ like. Plus the spyder lock wheels lol

That is really cool.

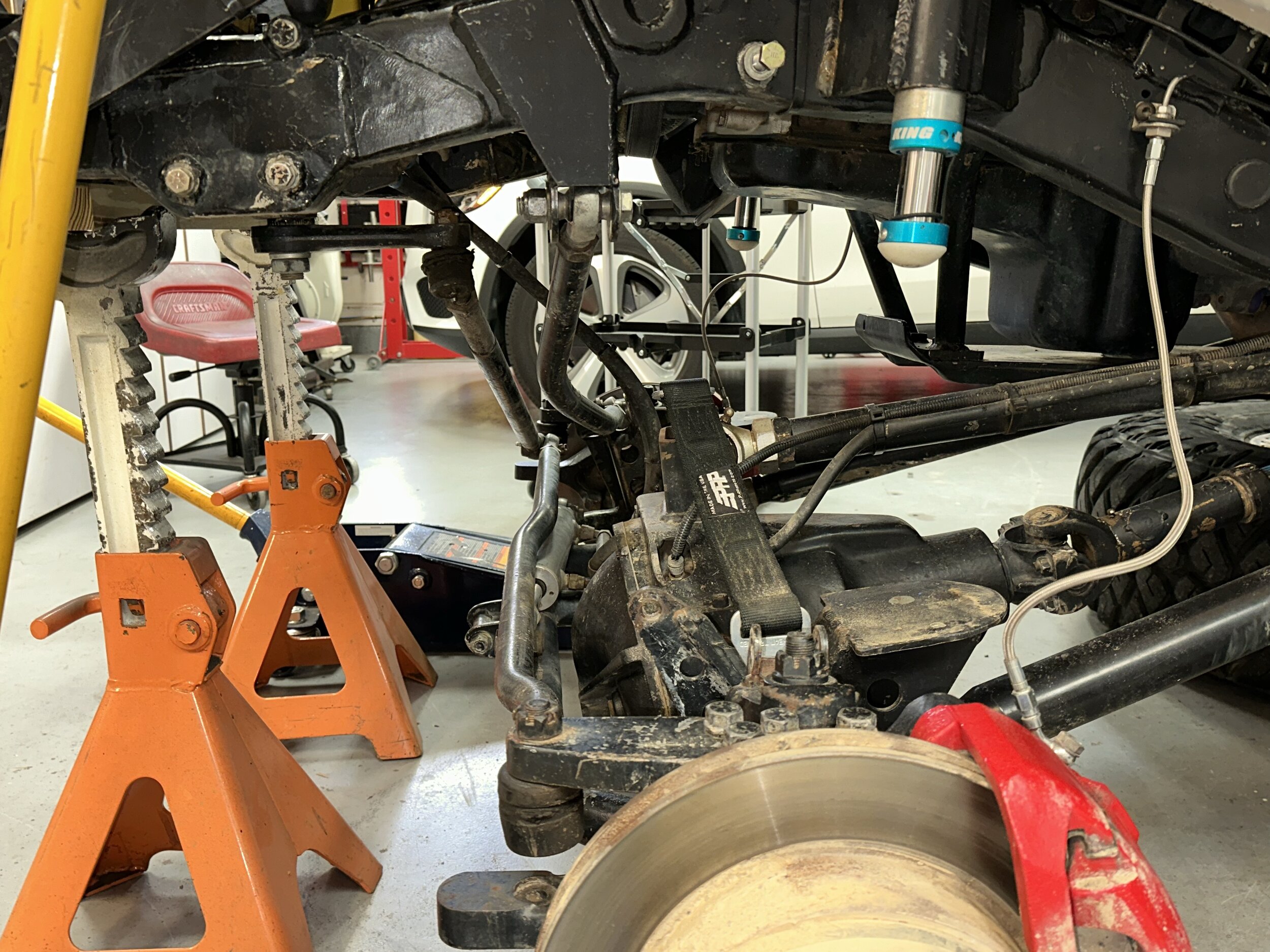

This afternoon I dug into the track bar replacement. I'm still waiting for the heavier tubing I ordered, but I figured I'd get a head start. Since I'll need to flex test the front end to check the clearance on the new design, I pulled the coilovers. It's easy to see the bend with everything out of the way.

No doubt about it in this view...

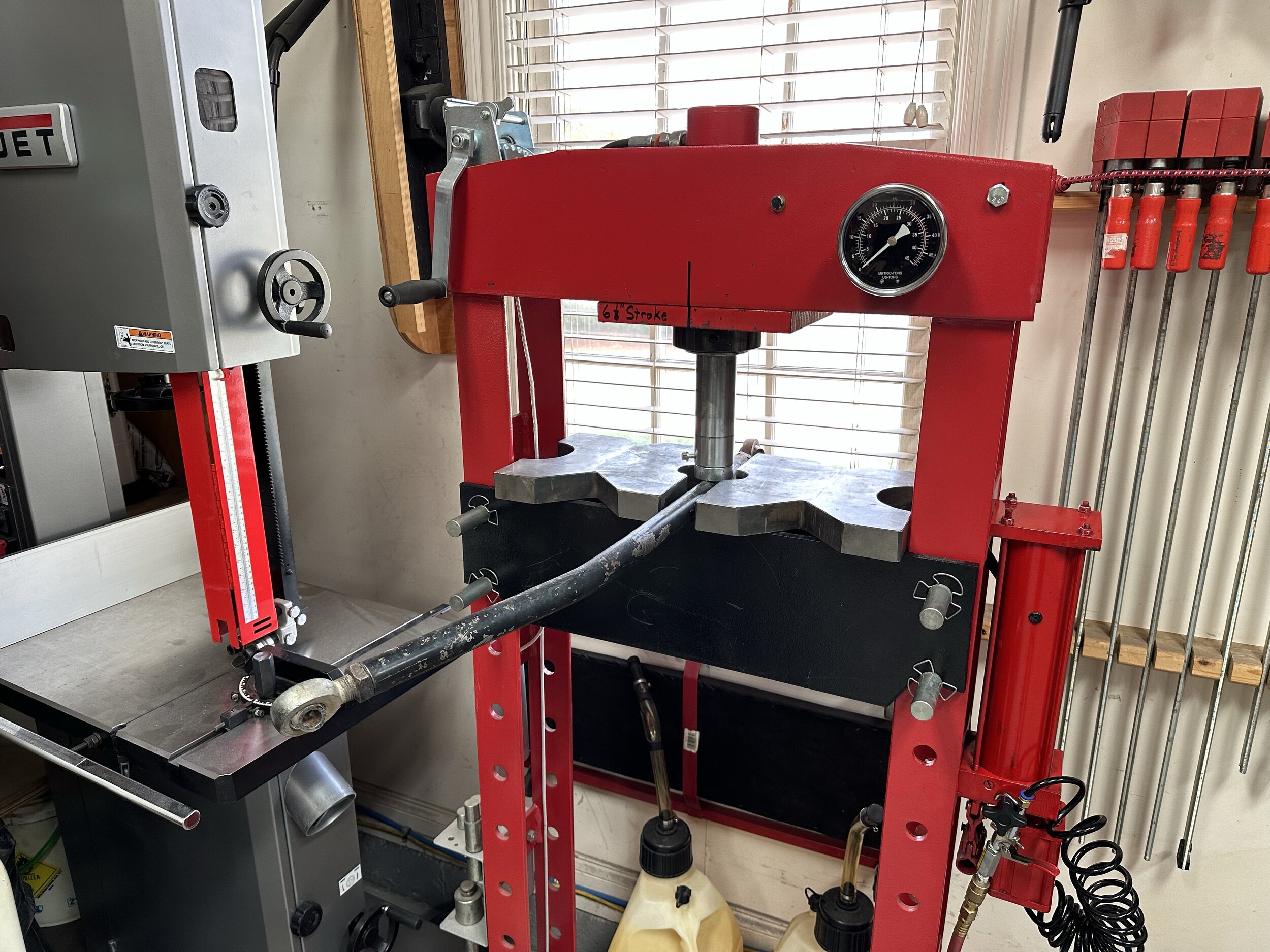

I'll use the current track bar to mockup the new one, so I straightened it out on the press to get a fresh start.

No doubt about it in this view...

I'll use the current track bar to mockup the new one, so I straightened it out on the press to get a fresh start.

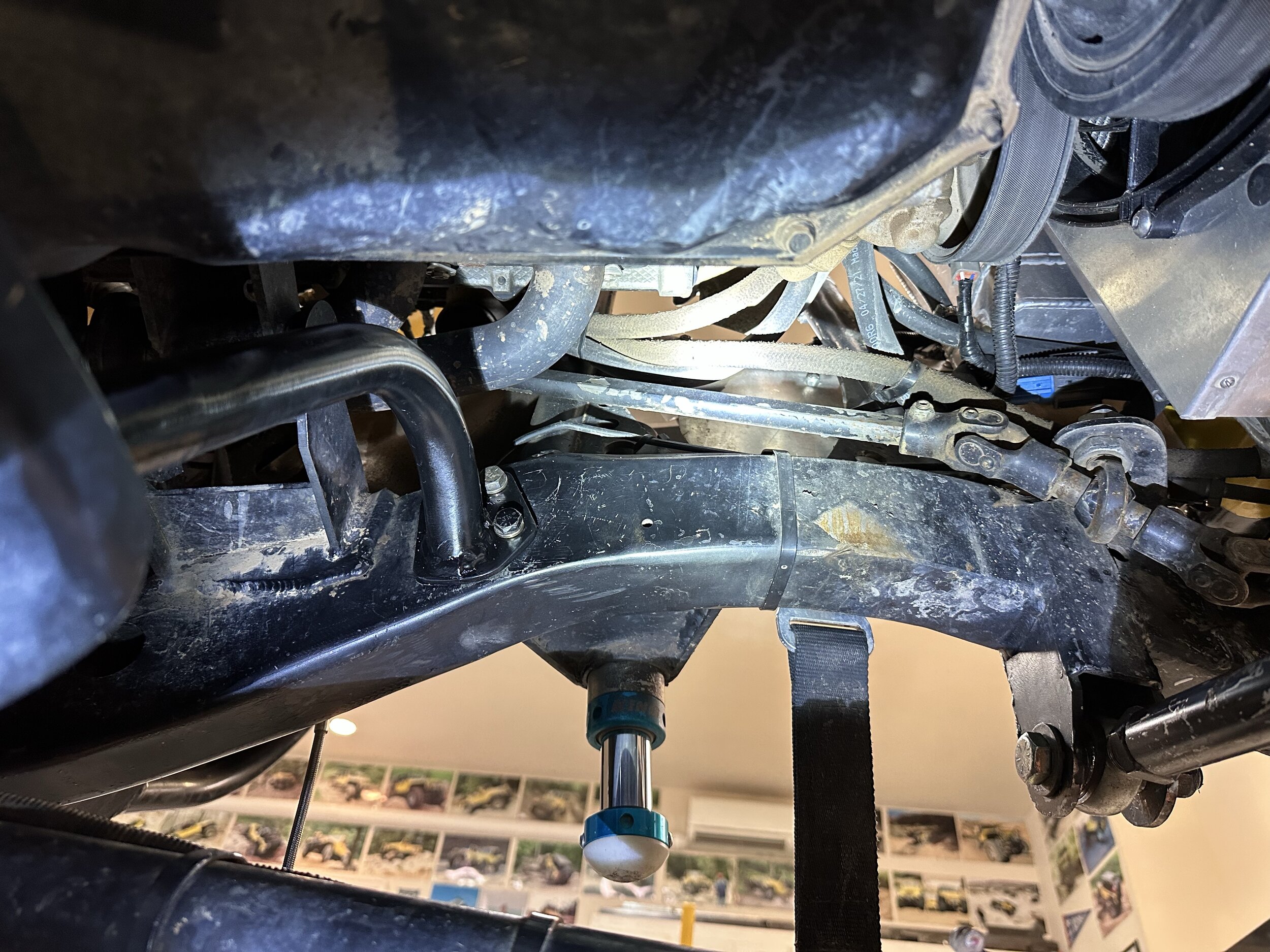

With the bent track bar out of the way, I centered the axle at ride height to begin mocking up the new track bar.

Then I installed the straight bar to flex it out and see where I would have clearance issues. And I found one right away - one that had nothing to do with the track bar:

The upper control arm was contacting the support for the engine skid, and that was stopping the uptravel about an inch before full stuff on the drivers side.

Crap.

When I did the Hemi a few years ago, I had to build a new support structure for the engine skid. How I missed this I have no idea.

So out came the death wheel to remove my problem. I'll have to build a new mount to clear the upper link. Properly this time, I guess...

Then I installed the straight bar to flex it out and see where I would have clearance issues. And I found one right away - one that had nothing to do with the track bar:

The upper control arm was contacting the support for the engine skid, and that was stopping the uptravel about an inch before full stuff on the drivers side.

Crap.

When I did the Hemi a few years ago, I had to build a new support structure for the engine skid. How I missed this I have no idea.

So out came the death wheel to remove my problem. I'll have to build a new mount to clear the upper link. Properly this time, I guess...

After just a little trial and error, I came up with a bend which clears the diff. The bend is actually very slight, the orientation of the picture makes it look much greater that it actually is.

The old track bar actually had two bends originally. It was a leftover design from when I had a stock radiator in place, and the extra bend was to clear the lower hanging bottom tank. The radiator I use for the Hemi is a cross flow design which does not have a lower tank, and tucks up much higher. This allows for a much straighter track bar in the current setup.

I am sure that the heavier tube will have no problem dealing with this bend. But I may take Blaine's suggestion and add some .750 solid stock to the bend area before I bend it. Probably overkill, but I'll decide when I see the new material.

The old track bar actually had two bends originally. It was a leftover design from when I had a stock radiator in place, and the extra bend was to clear the lower hanging bottom tank. The radiator I use for the Hemi is a cross flow design which does not have a lower tank, and tucks up much higher. This allows for a much straighter track bar in the current setup.

I am sure that the heavier tube will have no problem dealing with this bend. But I may take Blaine's suggestion and add some .750 solid stock to the bend area before I bend it. Probably overkill, but I'll decide when I see the new material.

Last edited:

TNHEADDUCK

TJ Enthusiast

Are you using DOM or Chromoly?

DOM.

DOM.

Maybe it's time you start putting round stock in all your links. I'm glad im just busting u joints. It's much cheaper / easier to fix.

I spent this morning fixing my mistake with the engine skid mount. First order of business was to cut off the bracket which bolts to the frame from the old problematic mount. Easier to do this than to make a new one.

Next, cut off the other side of the tube from the plate to which the skid bolts.

And then after some cypherin' and fittin' - off to the tube bender.

A little CAD to get to the final shape....

..some quality time under the welding helmet...

...and finally a little paint.

Next, cut off the other side of the tube from the plate to which the skid bolts.

And then after some cypherin' and fittin' - off to the tube bender.

A little CAD to get to the final shape....

..some quality time under the welding helmet...

...and finally a little paint.

Since the new shape changes the load forces on the bracket, I added a third bolt to better secure the bracket to the frame.

And with that - we have Clearance Clarence.

And with that - we have Clearance Clarence.

Last edited:

There are far too many tools in this thread. Reading this and Rick's thread only confirms I'm an Amateur, at best.

There are far too many tools in this thread. Reading this and Rick's thread only confirms I'm an Amateur, at best.

Nonsense, Dude. And when it comes to a clean rig, we all bow at your feet.

And it’s all relative. Everytime I post something like this I get a PM from Blaine saying “Really?”

Nonsense, Dude. And when it comes to a clean rig, we all bow at your feet.

And it’s all relative. Everytime I post something like this I get a PM from Blaine saying “Really?”

Shit, I was happy when in my late 40's I finally bought a proper toolbox.

Lay Em down and smack em yak em.

Where are you getting your metal? I was having to get it from a pretty big supplier here in Memphis and they always look at me like I am crazy when I tell them what I am looking for. We just got a metal supermarket and they are willing to order anything (if they don't already have it) and sell as little or as much as I need, but damn are they expensive. I understand that I am paying for the convenience and small order but still hard to swallow some days.

Where are you getting your metal? I was having to get it from a pretty big supplier here in Memphis and they always look at me like I am crazy when I tell them what I am looking for. We just got a metal supermarket and they are willing to order anything (if they don't already have it) and sell as little or as much as I need, but damn are they expensive. I understand that I am paying for the convenience and small order but still hard to swallow some days.