If you want to go with a #1 Moly I can get you this https://phillips66lubricants.com/product/moly-low-temp/ Interestingly, this is what Warn currently uses in their planetary winches. What also may be interesting is that it is aluminum thickened which has some unique properties when exposed to water.the joints I put the Energy Suspension F5 prelube in were the first to creak and looked and felt like they had never been greased, so I won't be using that again.

I came across Currie's recommendation of a non-synthetic, moly grease, and I'm on the hunt to see what else I can try since CV2 is synthetic. Wondering if anybody has tried an NLGI #1? It's supposed to be softer which might be counterintuitive for its longevity, but maybe the lower viscosity will allow it to flow in through the grease zerks? I could tolerate more frequent greasing if I didn't have to pull it and disassemble.

Chevron has a product but I can't find it to buy online, so I may have to bundle it in with a trip to the city.

View attachment 477618

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Johnny Joint grease—an experiment

- Thread starter Mike_H

- Start date

https://www.evolubesupply.com/moly-low-temperature-grease-nlgi-1-14-oz-396-89-g-tube-1082439/

I believe the chevron starplex M5 you are looking for can be found at

https://www.evolubesupply.com/

By Searching for “632385000535”

I believe the chevron starplex M5 you are looking for can be found at

https://www.evolubesupply.com/

By Searching for “632385000535”

Last edited:

Brianj5600

TJ Expert

I can see using moly in metal to metal, but not metal to polyurethane? Moly and the thickeners seem to get embedded on the on the ball and the polyurethane. The Hotchkis silicone grease is a #2 grease and I had no trouble getting the grease through the drilled urethane. I did not disassemble the joints to clean them up, which I should have, but it seems to still have silicone grease in the joint.

Question regarding the zerk fittings. Are you guys leaving them in place? Or somehow capping them off?

I am in the process of installing the midarm, and just a quick observation it looks if I put the zerks where I can access easily it also places them in harms way and the first rock will smash them.

Maybe with a different fitting on my grease gun I could get to them if I tuck them up, but just curious what you guys are doing

I am in the process of installing the midarm, and just a quick observation it looks if I put the zerks where I can access easily it also places them in harms way and the first rock will smash them.

Maybe with a different fitting on my grease gun I could get to them if I tuck them up, but just curious what you guys are doing

Brianj5600

TJ Expert

I can see using moly in metal to metal, but not metal to polyurethane? Moly and the thickeners seem to get embedded on the on the ball and the polyurethane. The Hotchkis silicone grease is a #2 grease and I had no trouble getting the grease through the drilled urethane. I did not disassemble the joints to clean them up, which I should have, but it seems to still have silicone grease in the joint.

that was my thought process initially as well. I tended to take Currie's word for it but maybe they just recommend that because it works well enough in their testing environment. There are definitely some inferences to be made of the fact that most other established suspension companies using polyurethane bushings use silicone. I don't really care what it is if it works, and If I can get something to pump through then it's problem solved.

The Energy Suspension stuff seems a lot thicker than #2. More like vaseline. Maybe I'll continue this experiment with Hotchkis. Wish they weren't so proud of that stuff...I can buy 6 tubes of the Chevron moly for the price of 1 Hotchkis silicone.

I'm in the process of swapping DDB's into a few of my JJ locations but I'm keeping the JJ's in case I end up going back, and some locations (like the ones in a welded barrel) aren't likely to ever get changed so I'm still interested in solving this issue (I'm aware that Metalcloak makes a DF kit to fit in a JJ barrel but I'm unwilling to make the barrel the bearing surface when I can't easily replace it).

that was my thought process initially as well. I tended to take Currie's word for it but maybe they just recommend that because it works well enough in their testing environment. There are definitely some inferences to be made of the fact that most other established suspension companies using polyurethane bushings use silicone. I don't really care what it is if it works, and If I can get something to pump through then it's problem solved.

The Energy Suspension stuff seems a lot thicker than #2. More like vaseline. Maybe I'll continue this experiment with Hotchkis. Wish they weren't so proud of that stuff...I can buy 6 tubes of the Chevron moly for the price of 1 Hotchkis silicone.

I'm in the process of swapping DDB's into a few of my JJ locations but I'm keeping the JJ's in case I end up going back, and some locations (like the ones in a welded barrel) aren't likely to ever get changed so I'm still interested in solving this issue (I'm aware that Metalcloak makes a DF kit to fit in a JJ barrel but I'm unwilling to make the barrel the bearing surface when I can't easily replace it).

Have you considered taking a look at the Ag Talk forum? A quick search for "best grease for mud and clay applications" showed that there's a bit of discussion on it from many people who pull their equipment through some of the dustiest and dirtiest environments all day long.

Example: https://talk.newagtalk.com/forums/thread-view.asp?tid=650743&DisplayType=flat&setCookie=1

Brianj5600

TJ Expert

MountaineerTom

LJ Enthusiast, Retired USAF Weapons Loader

Supporting Member

Ride of the Month Winner

Question regarding the zerk fittings. Are you guys leaving them in place? Or somehow capping them off?

I am in the process of installing the midarm, and just a quick observation it looks if I put the zerks where I can access easily it also places them in harms way and the first rock will smash them.

Maybe with a different fitting on my grease gun I could get to them if I tuck them up, but just curious what you guys are doing

I put 90* zerks on mine and put them on top when I installed them. They probably ain’t going to take any grease. I guess I’ll find out when they need their first service.

Have you considered taking a look at the Ag Talk forum? A quick search for "best grease for mud and clay applications" showed that there's a bit of discussion on it from many people who pull their equipment through some of the dustiest and dirtiest environments all day long.

Example: https://talk.newagtalk.com/forums/thread-view.asp?tid=650743&DisplayType=flat&setCookie=1

haven't even thought about it, but that makes some sense.

That thread you linked had an interesting post.

Any of the synthetic greases don't turn to dirt. I was a cheapy grease man until someone finally convinced me to try synthetic. Now I spend less time trying to unclog grease fittings and bushings. I just need to figure out how to convince my help not to waste so much. It is expensive.

That doesn't sound promising for the non synthetic stuff, and I think some of us can attest that yes, even the synthetic stuff will eventually turn to dirt. Maybe it takes longer.

haven't even thought about it, but that makes some sense.

That thread you linked had an interesting post.

That doesn't sound promising for the non synthetic stuff, and I think some of us can attest that yes, even the synthetic stuff will eventually turn to dirt. Maybe it takes longer.

I liked this one

Why for years did we put clay (dirt)in bearings and think it was a good idea?

Last edited:

I will probably skip to a silicone PTFE like Super Lube next time.

interesting. Cheaper than the Hotchkis stuff, and seems like PTFE would be a welcome addition.

https://www.amazon.com/dp/B0081JE2PQ/?tag=wranglerorg-20

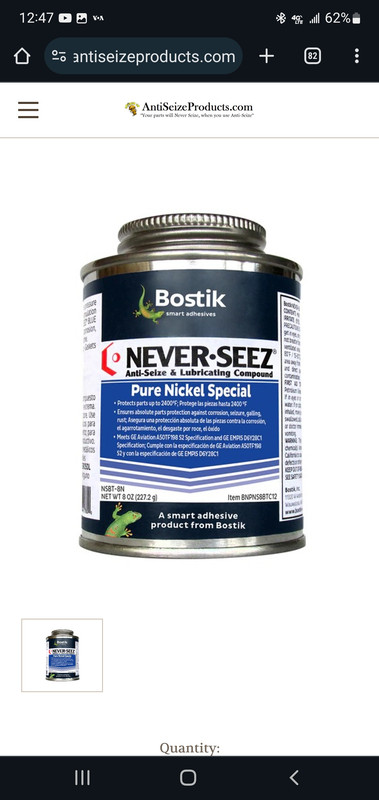

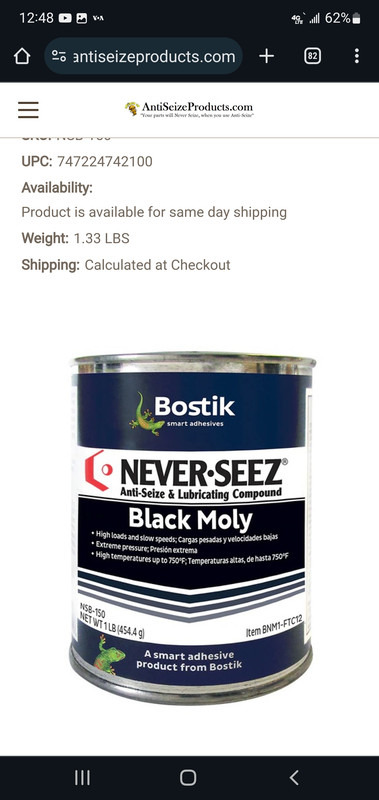

Ok ppl way smarter than me, which do y'all think??

https://postimg.cc/0btNj4S8]

[/url]

[/url]

https://postimg.cc/hXftd08V]

[/url]

[/url]

https://postimg.cc/TLXdBMzc]

[/url]

[/url]

https://postimg.cc/xXhTybgh]

[/url]

[/url]

https://postimg.cc/4Kc48NSd]

[/url]

[/url]

https://postimg.cc/JDcrLYmC]

[/url]

[/url]

https://postimg.cc/bSyzN0ND]

[/url]

[/url]

https://postimg.cc/0btNj4S8]

https://postimg.cc/hXftd08V]

https://postimg.cc/TLXdBMzc]

https://postimg.cc/xXhTybgh]

https://postimg.cc/4Kc48NSd]

https://postimg.cc/JDcrLYmC]

https://postimg.cc/bSyzN0ND]

Ok ppl way smarter than me, which do y'all think??

https://postimg.cc/0btNj4S8]

View attachment 478408[/url]

https://postimg.cc/hXftd08V]View attachment 478409[/url]

https://postimg.cc/TLXdBMzc]View attachment 478410[/url]

https://postimg.cc/xXhTybgh]View attachment 478411[/url]

https://postimg.cc/4Kc48NSd]View attachment 478412[/url]

https://postimg.cc/JDcrLYmC]View attachment 478413[/url]

https://postimg.cc/bSyzN0ND]View attachment 478414[/url]

We use the blue moly on our AR's and tool holders at work. Its good stuff. Not sure how it will work in a Johnny Joint, but given every thing else's track record, no sense in NOT trying it.

Ok ppl way smarter than me, which do y'all think??

https://postimg.cc/0btNj4S8]

View attachment 478408[/url]

https://postimg.cc/hXftd08V]View attachment 478409[/url]

https://postimg.cc/TLXdBMzc]View attachment 478410[/url]

https://postimg.cc/xXhTybgh]View attachment 478411[/url]

https://postimg.cc/4Kc48NSd]View attachment 478412[/url]

https://postimg.cc/JDcrLYmC]View attachment 478413[/url]

https://postimg.cc/bSyzN0ND]View attachment 478414[/url]

I’d go with the food grade. I always like to eat off of my control arms.

I will probably skip to a silicone PTFE like Super Lube next time.

I got a tube of this delivered from Amazon today.

Super Lube 92150 Silicone Lubricating Grease with PTFE, 14.1 oz Cartridge, Translucent White https://www.amazon.com/dp/B0081JE2PQ/?tag=wranglerorg-20

I'll use it on my LCAs and see what happens.

Brianj5600

TJ Expert

I’d go with the food grade. I always like to eat off of my control arms.

What grease are you using and when disassembled are there deposits on the ball and bushings?

You didn't ask me, but

Yes....Lucas red n tacky

Yes....CV2

I cleaned the balls up with emery cloth, smooth to the touch but you can still see theyre rough, replace em or run em?

Yes....Lucas red n tacky

Yes....CV2

I cleaned the balls up with emery cloth, smooth to the touch but you can still see theyre rough, replace em or run em?