You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trail_Krawler & Trail_Willys

- Thread starter kmas0n

- Start date

Damn! Where is that?

about a minute away from my house. Luckily things have calmed down.Damn! Where is that?

Wow... That is quite the picture.

It's tragically beautiful. Luckily this fire hasn't destroyed anyone's houses yet. Just mother nature doing her thing

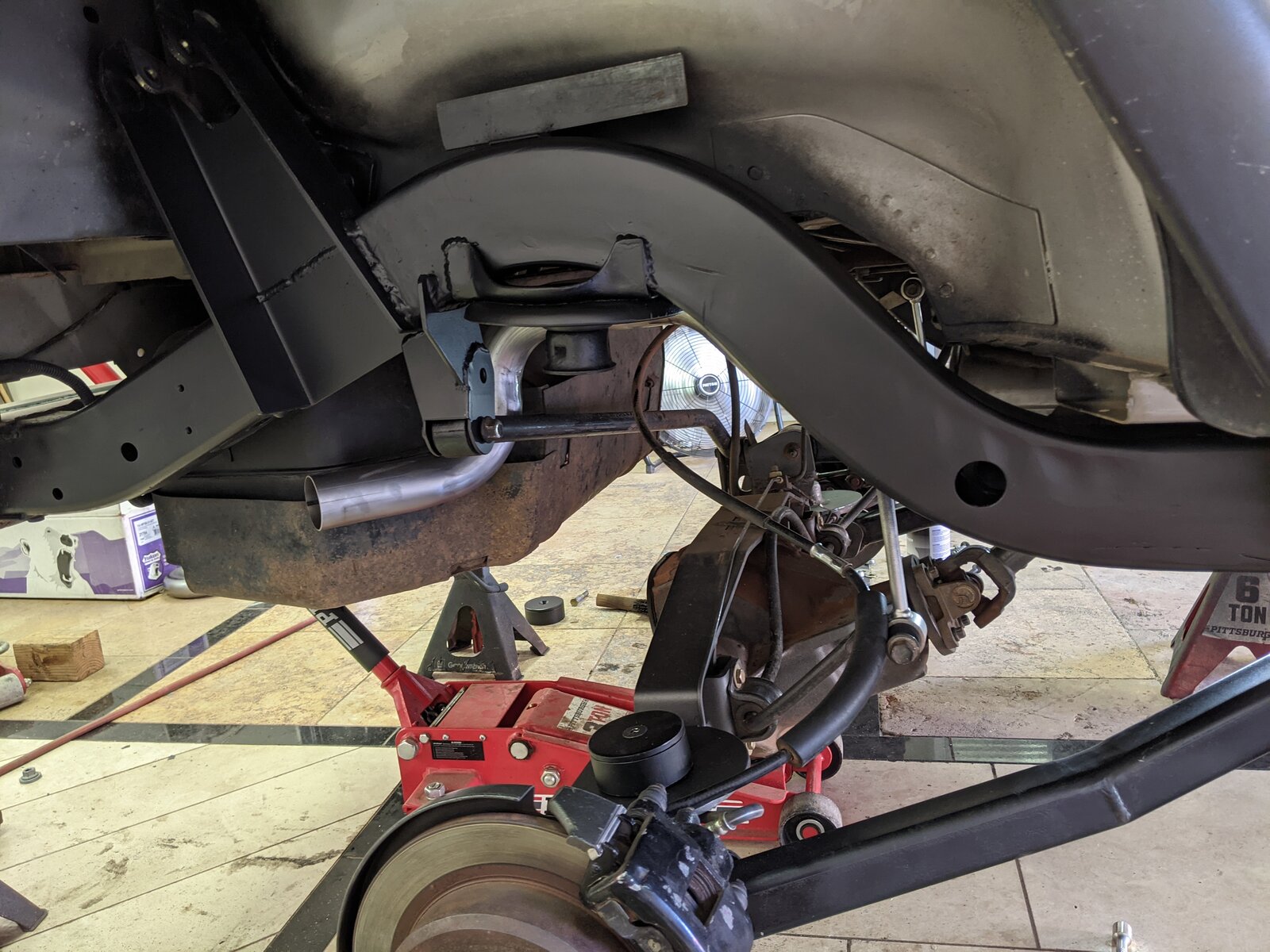

For a little tech... I reworked the exhaust to go above the track bar... It is now up out of harm's way and does not contact the axle or trackbar. This required lowering the frame side track bar mount 2 inches. Theoretically, this will lower the roll center of the rear suspension... about an inch. probably. This should induce slightly more body roll while cornering by giving the axle a little less leverage on the frame... which inversely should slightly reduce the side to side head bob when hitting a rock. I'm not expecting much, but this is in the name of science...

There should also be less bump... shimmy? The side-to-side motion the rear track bar causes.

Stubbornly I hold on to the factory track bar. I adjusted the mount instead so that at halfway through the shocks travel the axle is perfectly centered.

There should also be less bump... shimmy? The side-to-side motion the rear track bar causes.

Stubbornly I hold on to the factory track bar. I adjusted the mount instead so that at halfway through the shocks travel the axle is perfectly centered.

Then I reworked the spring retainer/bump stop extension. See the post above for the turds they used to be. I welded the cap to the tube from the inside for an extra clean look. The bolt is recessed so it doesn't chew up the jounce bumper.

I installed the yukon super 88 kit for my 8.8. among other cool things like chromoly shafts, it increases the width of the axle by 2". This gives a little breathing room for the outboard and could possibly set the path for coil over shocks. Since I had everything apart I cleaned the flame up and sprayed it with steel it...

https://www.amazon.com/dp/B07L8PD2YX/?tag=wranglerorg-20

Instagram says it's the shit so I thought I would give it a try.

Before...

After...

https://www.amazon.com/dp/B07L8PD2YX/?tag=wranglerorg-20

Instagram says it's the shit so I thought I would give it a try.

Before...

After...

And finally, exhaust reworked, shocks tuned, lower spring perches adjusted, pinion angle adjusted, super 88 kit installed, fabricated track bar mount, fabricated coil spring seat, frame painted with steel it, a whole bunch of other small things I've already forgotten about.

You may notice the exhaust does actually dump at the rear bumper and it seems like it's too high. I'll finish the last bit when I do the body lift delete.

You may notice the exhaust does actually dump at the rear bumper and it seems like it's too high. I'll finish the last bit when I do the body lift delete.

The disassembly and cleaning has begun.

oh, and the research... so much research.

The engine is either a LY5 (flex fuel) or a LMG (non flex fuel) from a 2008 Silverado. It does have Active fuel management (which i'll be deactivating) but no variable valve timing. This makes it a Gen IV 5.3. In its current setup that should be 315 HP and 338 ftlb of torque. I've been reading through the incredible amount of info on @toximus build thread.

I picked up the engine from marketplace and a good buddy of mine was kind enough to drive down to Phoenix to get it for me. The engine was at a high-end build shop that specialized in hot rods. The owner was cleaning house and this one was in the way. The wiring harness and ecu, along with all of the accessories were included.

At this point, I'm collecting information, but I have decided I'll be mating the engine to a 6L80e transmission.

oh, and the research... so much research.

The engine is either a LY5 (flex fuel) or a LMG (non flex fuel) from a 2008 Silverado. It does have Active fuel management (which i'll be deactivating) but no variable valve timing. This makes it a Gen IV 5.3. In its current setup that should be 315 HP and 338 ftlb of torque. I've been reading through the incredible amount of info on @toximus build thread.

I picked up the engine from marketplace and a good buddy of mine was kind enough to drive down to Phoenix to get it for me. The engine was at a high-end build shop that specialized in hot rods. The owner was cleaning house and this one was in the way. The wiring harness and ecu, along with all of the accessories were included.

At this point, I'm collecting information, but I have decided I'll be mating the engine to a 6L80e transmission.

I'll be mating the engine to a 6L80e transmission.

Good transmission, but decide on how you're going to handle the electronics/wiring before you go and buy one.

After reading your thread I've contacted zero gravity performance. They offer stand alone harnesses. I've been told with the gen 4 ecu it's plug and play. The only thing holding my back is thier harnesses have no provisions for any emissions controls. Although currently where I live we have no inspections, I worry that may change with the EPA unleashedGood transmission, but decide on how you're going to handle the electronics/wiring before you go and buy one.

I am very interested in the rear 3-link and how it has performed. When did you actually install the rear 3-link? You said you bought jeep in 2005 and this is how it sits in 2019, however, how long have you actually been running the 3-link?

It appears from the picture that you installed the upper at the stock driver side upper location, but attached it to the truss (which is attached to the passenger side at the stock upper location). Is there a reason you did not attach it to the center of the truss? I am assuming it is due to the fact that your frame side was actually mounted to the frame and you didn't want to add a truss to center the body side upper mount, but is there any other advantages/disadvantages to having the upper link centered? Seems like there would be a higher load on this upper link and it's attachments due to the offset.

Have you ever had any issues with cracking/breakage of the control arm brackets?

It appears from the picture that you installed the upper at the stock driver side upper location, but attached it to the truss (which is attached to the passenger side at the stock upper location). Is there a reason you did not attach it to the center of the truss? I am assuming it is due to the fact that your frame side was actually mounted to the frame and you didn't want to add a truss to center the body side upper mount, but is there any other advantages/disadvantages to having the upper link centered? Seems like there would be a higher load on this upper link and it's attachments due to the offset.

Have you ever had any issues with cracking/breakage of the control arm brackets?

The 3 link rear has been installed for about 6 years now. I love the way it performs. No hop on hill climbs, very predictable handling.I am very interested in the rear 3-link and how it has performed. When did you actually install the rear 3-link? You said you bought jeep in 2005 and this is how it sits in 2019, however, how long have you actually been running the 3-link?

It appears from the picture that you installed the upper at the stock driver side upper location, but attached it to the truss (which is attached to the passenger side at the stock upper location). Is there a reason you did not attach it to the center of the truss? I am assuming it is due to the fact that your frame side was actually mounted to the frame and you didn't want to add a truss to center the body side upper mount, but is there any other advantages/disadvantages to having the upper link centered? Seems like there would be a higher load on this upper link and it's attachments due to the offset.

Have you ever had any issues with cracking/breakage of the control arm brackets?

Originally I had a cross member that went under the transfer case tail shaft. The upper-link paralleled the drive shaft in lived in the tunnel. I forgot the exact numbers, but Antisquat was adjustable from something like 60% 90%, and 120% by using the upper, middle or lower holes.

The link then attached to the top of the Artec truss. You can see it in this pic...

This setup worked great. zero bind, favorable geometry. Because the upper link was in the tunnel it could be straight. The cross member allowed me to move the lower links slightly closer together while maintaining my desired angle and at full flex they would almost touch the frame.

I was sure that the artec truss was strong enough to mount the link on top of, without the support bracket they recomended. I was wrong.

I'm not sure when it happened, but at some point, the truss rolled forward. you can see how it bent in this pic.

As a result, I rebuild the three-link to what it is now. Compromises had to be made. The upper link was moved to the driver side and is tied in with the trackbar mount. As a result, it has to have a bend to clear the body at full stuff. The cross member was removed and the lower links were moved out a few inches and have to have a bend to clear the frame. Eventually, I'll stretch the rear 5-6 inches and slide the entire suspension back (notice the c shaped mounts that can be cut free and slid back). At which point I can use straight links again. I've never had a crack or failure.

I've built everything out of 1/4" steel because I don't have @mrblaine 's understanding of how thick material needs to be. So I overbuilt it. The upper link is made from 1/4" wall and has 2.5" joints (same as lowers) since it has to do the work that normally would be done by two arms.

I'm still rocking the factory track bar

I talked with Jim at Zero Gravity Performance today, he's going to send over a Stage 1 reman 6L80e 6 speed auto and a new stand-alone Engine/trans harness.

I think I've decided on a stage 1 cam from Texas Speed. Seems like there is plenty of support for their cams and I could get away with a mail-in tune. That should get me about 365 hp at the crank

I'm considering holly/hooker blackheart engine mounts because they mount to the existing 4.0 engine mounts after trimming off an inch or two. This appeals to me because the upper link of my 3 links comes within half an inch of the bottom of the mount at full stuff, so if it doesn't mess with the bottom of the mount, I may not have to mess with my links. From what I've read it doesn't mess with the steering shaft either. Anyone used these?

I'm planning to use Novak for the 6l80 -> np 231 adapter. From what I read on @toximus thread, they (atlas) recommend a 3:1 transfer case with the 6l80. The 2.73:1 of my NP231 will have to do. I already have an sye, but I might need the super short sye if my rear driveline gets any shorter... its already at its limit so we'll see

I think I've decided on a stage 1 cam from Texas Speed. Seems like there is plenty of support for their cams and I could get away with a mail-in tune. That should get me about 365 hp at the crank

I'm considering holly/hooker blackheart engine mounts because they mount to the existing 4.0 engine mounts after trimming off an inch or two. This appeals to me because the upper link of my 3 links comes within half an inch of the bottom of the mount at full stuff, so if it doesn't mess with the bottom of the mount, I may not have to mess with my links. From what I've read it doesn't mess with the steering shaft either. Anyone used these?

I'm planning to use Novak for the 6l80 -> np 231 adapter. From what I read on @toximus thread, they (atlas) recommend a 3:1 transfer case with the 6l80. The 2.73:1 of my NP231 will have to do. I already have an sye, but I might need the super short sye if my rear driveline gets any shorter... its already at its limit so we'll see

I’d like to hear how those engine mounts workout. They look to be above the factory mount from what I’ve seen also. I intend to try them unless I hear otherwise.I talked with Jim at Zero Gravity Performance today, he's going to send over a Stage 1 reman 6L80e 6 speed auto and a new stand-alone Engine/trans harness.

I think I've decided on a stage 1 cam from Texas Speed. Seems like there is plenty of support for their cams and I could get away with a mail-in tune. That should get me about 365 hp at the crank

I'm considering holly/hooker blackheart engine mounts because they mount to the existing 4.0 engine mounts after trimming off an inch or two. This appeals to me because the upper link of my 3 links comes within half an inch of the bottom of the mount at full stuff, so if it doesn't mess with the bottom of the mount, I may not have to mess with my links. From what I've read it doesn't mess with the steering shaft either. Anyone used these?

I'm planning to use Novak for the 6l80 -> np 231 adapter. From what I read on @toximus thread, they (atlas) recommend a 3:1 transfer case with the 6l80. The 2.73:1 of my NP231 will have to do. I already have an sye, but I might need the super short sye if my rear driveline gets any shorter... its already at its limit so we'll see

What about the hooker headers? Thoughts?

1) what front 3-link? Savvy goes up into the area that those brackets occupy.

2) check the cam characteristics. Choppy isn't fun crawling.

3) 2.72 or 3:1 isn't going to be the same in mine vs yours since our engines have different outputs. I'd look into a jk 4:1 for yours.

2) check the cam characteristics. Choppy isn't fun crawling.

3) 2.72 or 3:1 isn't going to be the same in mine vs yours since our engines have different outputs. I'd look into a jk 4:1 for yours.