You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A lesson learned—keep it light and nimble!

- Thread starter Irun

- Start date

That's exactly what I ended up doing.I just use a regular nut of the right size to make sure I have the right tap.

I helped a guy remove and mount some tires on a set of Walker Evans bead locks. The holes have Timeserts and the owner did not anti-seize the bolts. They came out with the bolts so you have to turn each bolt a couple of turns, go to the next and repeat all the way around many times. I did not think they were magic that day.Timeserts are magic when you want to put a steel fastener into soft metals like Aluminum and Magnesium.

Last edited:

never monday

TJ Addict

Let’s be accurate here.....that wasn't the timeserts faultI helped a guy remove and mount some tires on a set of Walker Evans bead locks. The holes have Timeserts and the owner did not anti-seize the bolts. They came out with the bolts so you have to turn each bolt a couple of turns, go to the next and repeat all the way around many times. I did not think they were magic that day.

I don't believe I blamed the inserts at all. You unscrew 5 bead lock rings 2 turns per bolt x 24 bolts per rim and tell me how fucking magic you think that experience is.Let’s be accurate here.....that wasn't the timeserts fault

never monday

TJ Addict

Admittedly thats a sucky job. But the timeserts worked. Their still magic to me for repairing pulled head studs in AL and Mag cases.I don't believe I blamed the inserts at all. You unscrew 5 bead lock rings 2 turns per bolt x 24 bolts per rim and tell me how fucking magic you think that experience is.

You still make it sound like I have a problem with them. Why would I have recommended them if that were the case?Admittedly thats a sucky job. But the timeserts worked. Their still magic to me for repairing pulled head studs in AL and Mag cases.

never monday

TJ Addict

Because it’s the internetYou still make it sound like I have a problem with them. Why would I have recommended them if that were the case?

You’re welcome to call me and chew my ass, let’s not much up his thread further

MountaineerTom

LJ Enthusiast, Retired USAF Weapons Loader

Supporting Member

Ride of the Month Winner

Helicoils are wound wire inserts that work very well to put threads in blind holes, not as well in through holes because a burr or nick on the fastener can snag them and thread them out. They are hard to lock into through holes because thread locker just wicks through the threads.

There are alternates to that which use different methods to lock them in the threads so they are difficult or impossible to screw out in a through hole. Some like the EZ-Lok use thread locker to lock them in.

Time-serts have an expanded top thread which makes a shoulder that can't be screwed through the hole. The top edge of the hole is chamfered so they can sit flush where that matters.

There is also the key locking inserts. They have grooves through the threads on 4 sides that a little key sits in. After the insert is installed, the keys get tapped down to lock the insert in place. Spiraloc, Recoil, Keensert, and Loksert are some of that style.

After those there are the big selection of rivnut and nutserts for threads in thin materials.

I hadn't heard of them before, but they're a very good solution for situations where you can't put a nut, due to depth limitations. Or, you can't use a nutsert, because the splined barrel part is to long.

View attachment 235878

Very interesting and good info to know. Thanks.

I agree with @MountaineerTom. Lots of good info in this whole thread. Thanks for continuing to share  .

.

83.5mm - The hubs are roughly 69mm

Earlier I was asking about the centerbore. For my wheels (Mamba MR1X), I checked the specs online and they said centerbore is 71.5mm. I just went out and measured and turns out they are actually 54mm. Whoops. I guess I’ll need new wheels if I do the locking hub conversion.

You still going with those Enduros? I see they have the 15x9 and 15x7. The 15x9 has 4.5” backspacing which is the same as I have now. The 15x7 has less backspacing - with the additional 3/4” from the Yukon hub conversion, that would start to push things out a little too far for me.

I ended up ordering new ProComp wheels. Decided I didn't want to use the black ones I had. These are a 15x8, with a 3.75" BS. A 4.5" BS would have been better for me, but these will work. Especially, since I have a set of wider Rubicon flares.Earlier I was asking about the centerbore. For my wheels (Mamba MR1X), I checked the specs online and they said centerbore is 71.5mm. I just went out and measured and turns out they are actually 54mm. Whoops. I guess I’ll need new wheels if I do the locking hub conversion.

You still going with those Enduros? I see they have the 15x9 and 15x7. The 15x9 has 4.5” backspacing which is the same as I have now. The 15x7 has less backspacing - with the additional 3/4” from the Yukon hub conversion, that would start to push things out a little too far for me.

I have the sport flares but I’m working on a deal for some Sahara flares from Craigslist.I ended up ordering new ProComp wheels. Decided I didn't want to use the black ones I had. These are a 15x8, with a 3.75" BS. A 4.5" BS would have been better for me, but these will work. Especially, since I have a set of wider Rubicon flares.

View attachment 236408

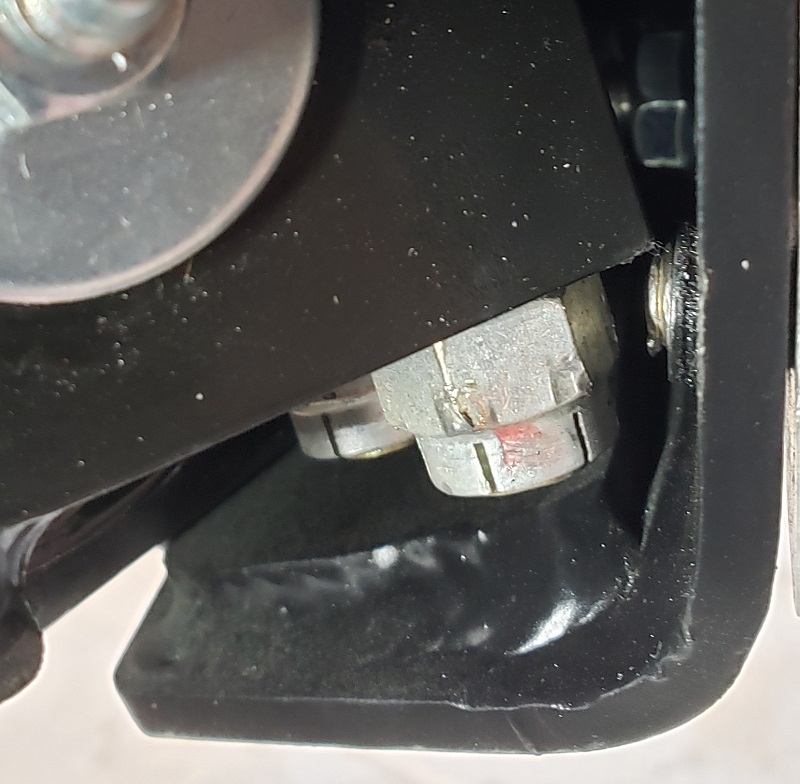

Made a bunch of progress over the weekend. For anyone wondering just how tight the clearance is on a Savvy bumper, when combining a SwayLoc and the Savvy Hardcore bumper ends, here you go:

Driver side clears with a little over 1/16"

The passenger side only clears by literally two sheets of paper. However, I can pull the bolt out and shave off a little more, making it flush like the driver side.

Driver side clears with a little over 1/16"

The passenger side only clears by literally two sheets of paper. However, I can pull the bolt out and shave off a little more, making it flush like the driver side.

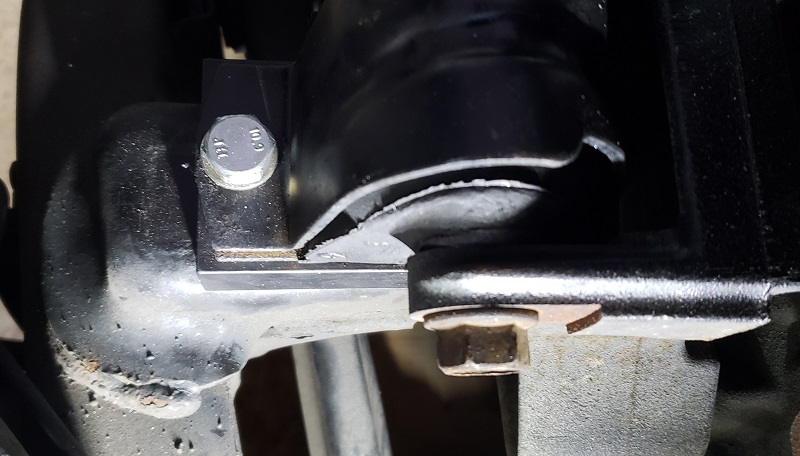

Savvy motor mount lift is in. Installing the driver side was easy, because I removed the entire bracket from the block. The passenger side was a different story. I didn't remove the bracket, but did end up having to remove the bottom bolt that attaches the bracket to the block. Without doing so, I couldn't get a nut the MM bolt closest to the block.

Also, a new OMIX 17105.12 Fan Clutch (Made in USA) is installed and I set the fan shroud clearance. FWIW, the new fan clutch seems as quiet as the original, so I'm happy there.

Also, a new OMIX 17105.12 Fan Clutch (Made in USA) is installed and I set the fan shroud clearance. FWIW, the new fan clutch seems as quiet as the original, so I'm happy there.

The TRE rope and thimble came in, so I pulled the Warn XP out of the box and weighed it with the cable, roller fairlead, hook, Contactor pack, and H/W. It came in at 82 lbs.

Un-spooled the cable, then weighed it again with the Contactor pack, rope, thimble, Hawse fairled, and H/W. This time the XP weighed in at 54.6 lbs.

Un-spooled the cable, then weighed it again with the Contactor pack, rope, thimble, Hawse fairled, and H/W. This time the XP weighed in at 54.6 lbs.

While I have a high appreciation for both of those products, I wonder with the overall diet you're building to if one of the narrow drum competition winches may not have been a better choice.The TRE rope and thimble came in, so I pulled the Warn XP out of the box and weighed it with the cable, roller fairlead, hook, Contactor pack, and H/W. It came in at 82 lbs.

View attachment 236425

Un-spooled the cable, then weighed it again with the Contactor pack, rope, thimble, Hawse fairled, and H/W. This time the XP weighed in at 54.6 lbs.

View attachment 236426

Make sure you look at the lower end of the frame mount and its clearance to the cast mount on the block. I have to trim them more often than not but some of them have a mile of room. Just bizarre.Savvy motor mount lift is in. Installing the driver side was easy, because I removed the entire bracket from the block. The passenger side was a different story. I didn't remove the bracket, but did end up having to remove the bottom bolt that attaches the bracket to the block. Without doing so, I couldn't get a nut the MM bolt closest to the block.

Also, a new OMIX 17105.12 Fan Clutch (Made in USA) is installed and I set the fan shroud clearance. FWIW, the new fan clutch seems as quiet as the original, so I'm happy there.

View attachment 236419

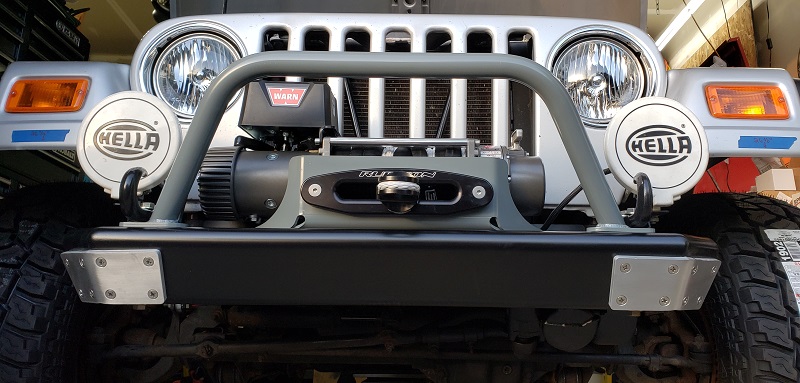

Now that I had the winch and rope, I installed the winch plate on the Savvy bumper. Then, with the bumper off the vehicle, I set the winch on the plate and tightened everything down. Once the plate and winch were on the bumper, I set the entire assembly on the frame rails and moved the bumper around until everything was properly clearanced. The hoop was set in place, light brackets went on top of the hoop, then the tow hooks. Everything got tightened up and Hella lights were installed.

All in all, I'm extremely happy with the setup. Total, I spent 8 hours on the bumper alone. This included multiple mock ups of the Hardcore ends, each time resulting in flap disk grinding on both the bumper and ends, and the Time Sert installs. The final results were definitely worth it. In terms of the bumper H/W, everything needed was included. The only substitution I had to do was add two longer bolts, because of the hoop. This wasn't a big deal, since they're a standard bolt and I have plenty Grade 8 bolts on hand.

Here's the final result:

All in all, I'm extremely happy with the setup. Total, I spent 8 hours on the bumper alone. This included multiple mock ups of the Hardcore ends, each time resulting in flap disk grinding on both the bumper and ends, and the Time Sert installs. The final results were definitely worth it. In terms of the bumper H/W, everything needed was included. The only substitution I had to do was add two longer bolts, because of the hoop. This wasn't a big deal, since they're a standard bolt and I have plenty Grade 8 bolts on hand.

Here's the final result: