The last thing I need to do to the axle before Sliding it under the Jeep and mocking it up for spring pads and shock mounts is address the fill plug mistake I made.

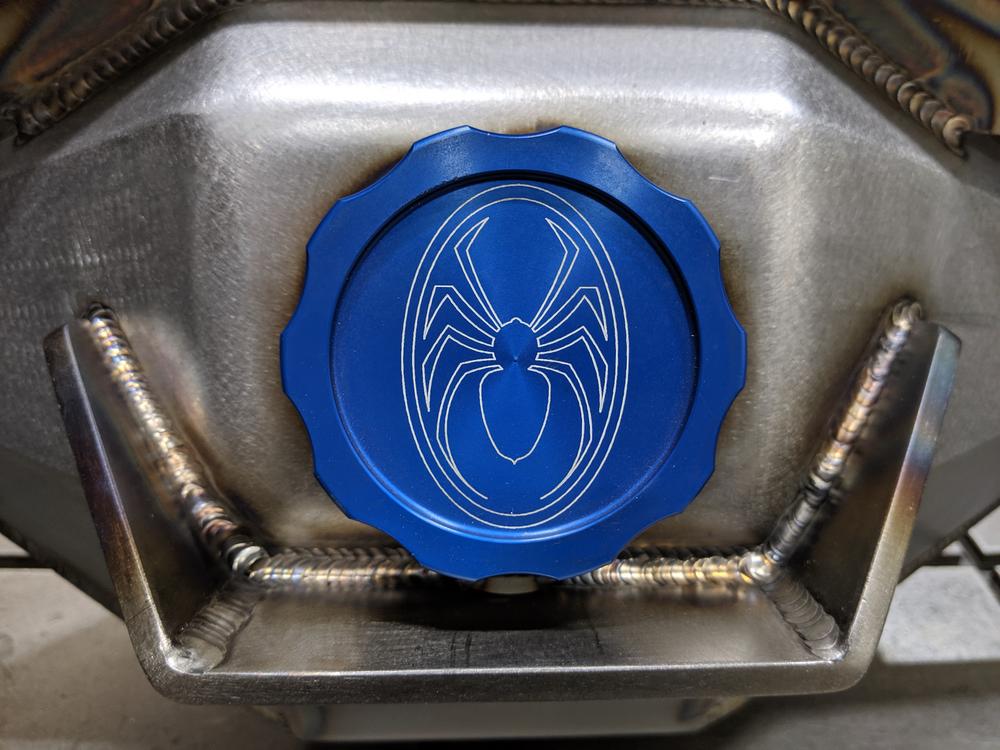

Purchased some Spidertrax fill caps and bungs to move the fill cap.

Trying to eyeball a new location for the fill which will help keep it out of the rocks.

Eye balling it:

Looking back, I shouldn't have ordered the housing with the fill bung and cap welded in. It can be ordered with or without the weld in bung. But they will only weld it in the location in which mine is located.

My issue is with the placement. While it may be a non-issue, I would like to do what I can in an effort to be proactive in protecting it from damage while in the rocks.

My options as I see it; examples provided.

Weld up a skid for it...

OR

Cut it out, weld in a rosette “plug” or plug weld. (Doubtful it will work)

Purchased some Spidertrax fill caps and bungs to move the fill cap.

Trying to eyeball a new location for the fill which will help keep it out of the rocks.

Eye balling it:

Looking back, I shouldn't have ordered the housing with the fill bung and cap welded in. It can be ordered with or without the weld in bung. But they will only weld it in the location in which mine is located.

My issue is with the placement. While it may be a non-issue, I would like to do what I can in an effort to be proactive in protecting it from damage while in the rocks.

My options as I see it; examples provided.

Weld up a skid for it...

OR

Cut it out, weld in a rosette “plug” or plug weld. (Doubtful it will work)