Twice!? LolYup .. HP30 (reverse cut gears) are 30% stronger going forward. 30% weaker going backwards .. lol

Broke ring gears twice doing the same thing. Pulling someone in reverse, in sand, in 4 low with a V8 behind it. Won't be doing that again. Other than that it's ok for what I use the Jeep for.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alex01 Silver Sport Build Thread

- Thread starter Alex01

- Start date

Had no idea the gears broke until I got home the first time.Twice!? Lol

Second time I felt it when it happened and that's when I knew how I broke them the first time

Good tip. I'm really hoping that clocking the T-case a bit will allow a bit more caster without binding at full droop. @mrblaine told me a while back that if I sandblast the axle, heavily concentrating on the plugs, and lay a large puddle in the plugs I have a 50% chance of stopping the leak.That seeping oil leak would bug the crap out of me, so I can see the value in swapping to a HP30. Just don't try to pull anyone out in reverse. Ask @Indy about that.

If I can stop the weeping and regain 1 degree of caster I could live with it. Otherwise, I'll likely be on CR trying to source a HP30 and start building it on the side.

It is very hard to get all the gear oil out. If you don't, it won't weld very well. The worse part is the tube is sealed with RTV when they press them in. If it leaks, it is leaking past the RTV and short of welding every plug weld and around the tubes to the diff casting, it will be hard to make it quit leaking.Good tip. I'm really hoping that clocking the T-case a bit will allow a bit more caster without binding at full droop. @mrblaine told me a while back that if I sandblast the axle, heavily concentrating on the plugs, and lay a large puddle in the plugs I have a 50% chance of stopping the leak.

If I can stop the weeping and regain 1 degree of caster I could live with it. Otherwise, I'll likely be on CR trying to source a HP30 and start building it on the side.

I've messed with a few of them. I'm to the point where I'm almost not willing to try.

Good to know. I would bet it went past the RTV since I have 2 on the short end that are leaking.It is very hard to get all the gear oil out. If you don't, it won't weld very well. The worse part is the tube is sealed with RTV when they press them in. If it leaks, it is leaking past the RTV and short of welding every plug weld and around the tubes to the diff casting, it will be hard to make it quit leaking.

I've messed with a few of them. I'm to the point where I'm almost not willing to try.

I just finished reclocking the atlas. The driveshaft went from 15.3 to 13.3.

Not bad for 3hrs work. I'm not in the mood to test for finding the caster limit before binding at full droop so that will need to wait.

Not bad for 3hrs work. I'm not in the mood to test for finding the caster limit before binding at full droop so that will need to wait.

I just finished reclocking the atlas. The driveshaft went from 15.3 to 13.3.

Not bad for 3hrs work. I'm not in the mood to test for finding the caster limit before binding at full droop so that will need to wait.

Awesome. Hope this helps and then you can tackle that seeping axle.

The vibs are in the rear end so it shouldn't make any difference. My goal is to get a bit more caster out of the jeep without binding since I currently was feeling a bit of resistance when turning the shaft by hand at full droop.That netted a significant change! Hope it quells the vibes.

Thanks. I'll pull the axle once the midarm comes in, assuming I have enough time to get it together before the next run, and tackle the seeping plugs.Awesome. Hope this helps and then you can tackle that seeping axle.

The rear shaft is back in Tom Woods hands and should be returned late next week, rebalanced, and upgraded to an X spline. I still need to droop the front axle to test for binding. I did notice the corner of the atlas is hitting the center skid in its new orientation. I think I'll just add a washer or two in between the trans mount and UCF mount to raise it up a hair.any updates?

Did you reclock It one set or two sets of holes? should clear the skid better than mine because you mounted your trans mount higher on the frame.

yours

yours

Last edited:

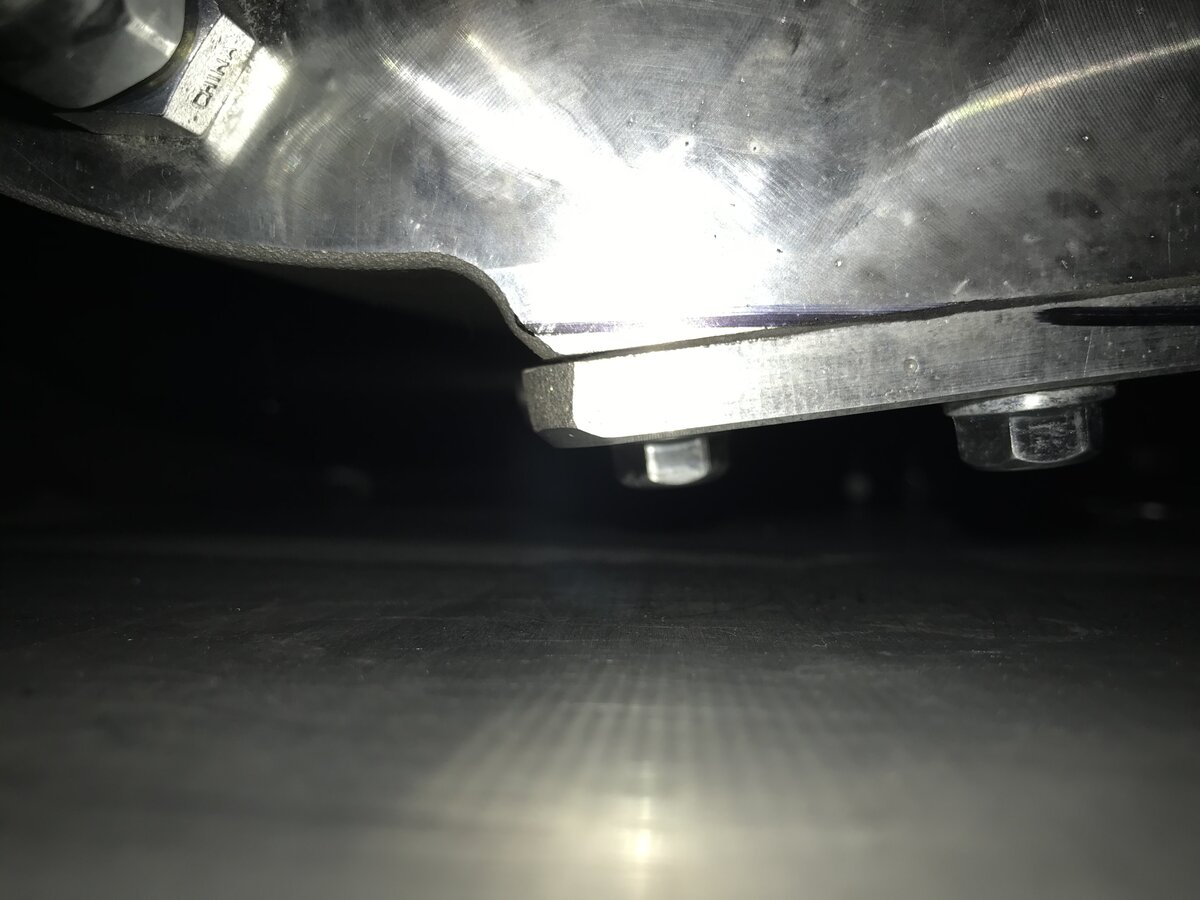

I moved the threads 1 hole away from flat. Mine does not clear the furthest bolt on the rear of the atlas, drivers side. So far I have raised it with 1 thick washer and still hits. I'm going to add one more washer and see where I get. Hopefully clearing that bolt doesn't lose me the ds angle I saved. If so it's going back flat and a HP30 is in my future. Truth be told I'll likely buy a hp30 if one pops up on CR, ideally semi built already.Did you reclock It one set or two sets of holes? should clear the skid better than mine because you mounted your trans mount higher on the frame.View attachment 168539View attachment 168540 yours

I'm guessing my mml is the reason mine is lower towards the rear than yours.

All I have is a mig. I'm thinking I'd sandblast the holes then drill them out a bit just to give the puddle a bit more room to fill.Stick weld will burn through any gear oil in those plug welds once you clean them out.

so much alike and yet so different, man these things are fickle. I’ll keep my eyes open for one too.I moved the threads 1 hole away from flat. Mine does not clear the furthest bolt on the rear of the atlas, drivers side. So far I have raised it with 1 thick washer and still hits. I'm going to add one more washer and see where I get. Hopefully clearing that bolt doesn't lose me the ds angle I saved. If so it's going back flat and a HP30 is in my future. Truth be told I'll likely buy a hp30 if one pops up on CR, ideally semi built already.

I'm guessing my mml is the reason mine is lower towards the rear than yours.

I have a buzz box if you want to stick weld it.All I have is a mig. I'm thinking I'd sandblast the holes then drill them out a bit just to give the puddle a bit more room to fill.

Thanks for the offer. I'll keep that in the back of my head.I have a buzz box if you want to stick weld it.

You should be able to recoop a lot selling the 44. JB Weld might actually stop that seeping if you can get it clean enough.