So one of my axle joints is wore plumb out. Now I'm reaching our to you guys for some help. I know how to replace them kinda but looking for a helping hand in how to make it easier and some guidence. All help is apreciated. Thanks in advance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Axle u joint replacement

- Thread starter David Overbay

- Start date

Very helpful thank you

Very helpful thank you

No problem! It's a pretty easy job, just take your time and it will all make sense.

I'm glad I read the link before I replied. You got the basics covered but missed a few key things. First, NEVER use a press on axle u-joints. It works until it doesn't and when it doesn't, you'll either send the yoke to me to straighten back out like many have done or you'll buy a new one because I can't. The issue is the cap being pushed in hangs up from time to time and when that happens, the press squeezes the yoke ears too close together and you can't get the snap rings into the grooves because they are not fully exposed.

The hammer and socket method always prevents that. No need to protect the cap being driven it, it is much harder than any hammer so don't be afraid to beat on it.

Using your write-up you got the steps correct and in the correct order but some fine tuning is needed.

When you drive the first cap in, take it below flush so the other pin is sticking out a bit further. That way you can pull the cross halfway out of the installed cap and it sticks up high enough on the other side to get the second cap started and engage the needle bearings in both caps. That prevents a needle from falling over and getting trapped which is always a mess.

That is also when you install the clip in the first cap's groove so when you hammer in the second cap, it pushes the first one back against the snap ring.

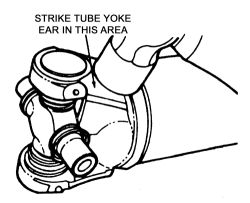

When that is done, the second groove will be showing and when you install the snap ring, it will be loose. You need to set the caps back against the snap rings so the pressure of the cap pushes them against the inside of the yoke. That is done by holding the assembled axle pointing straight away from you in one hand and then taking a nice size hammer and smacking the yoke on the fat part right below the holes for the caps. Inertia will act upon the cross and move the cap outward to lock the snap ring in place. You can check all of this very simply. Once you get the joint installed, move it back and forth and you can feel the tightness from one side being shoved against the thrust bearing inside the cap. After you set both side back against the snap rings, it will free up the joint in a most noticeable manner.

You should also try to rotate the snap ring in the groove with the end of a screwdriver by pushing on it. If it doesn't spin easily, that's good enough.

Also why you see folks struggling to remove the snap rings. They don't understand that the previous installer did it correctly and they need to release the pressure by first smacking the cap inwards before trying to pry out the snap ring and then doing the same to the other side to get that snap ring out.

I'm glad I read the link before I replied. You got the basics covered but missed a few key things. First, NEVER use a press on axle u-joints. It works until it doesn't and when it doesn't, you'll either send the yoke to me to straighten back out like many have done or you'll buy a new one because I can't. The issue is the cap being pushed in hangs up from time to time and when that happens, the press squeezes the yoke ears too close together and you can't get the snap rings into the grooves because they are not fully exposed.

The hammer and socket method always prevents that. No need to protect the cap being driven it, it is much harder than any hammer so don't be afraid to beat on it.

Using your write-up you got the steps correct and in the correct order but some fine tuning is needed.

When you drive the first cap in, take it below flush so the other pin is sticking out a bit further. That way you can pull the cross halfway out of the installed cap and it sticks up high enough on the other side to get the second cap started and engage the needle bearings in both caps. That prevents a needle from falling over and getting trapped which is always a mess.

That is also when you install the clip in the first cap's groove so when you hammer in the second cap, it pushes the first one back against the snap ring.

When that is done, the second groove will be showing and when you install the snap ring, it will be loose. You need to set the caps back against the snap rings so the pressure of the cap pushes them against the inside of the yoke. That is done by holding the assembled axle pointing straight away from you in one hand and then taking a nice size hammer and smacking the yoke on the fat part right below the holes for the caps. Inertia will act upon the cross and move the cap outward to lock the snap ring in place. You can check all of this very simply. Once you get the joint installed, move it back and forth and you can feel the tightness from one side being shoved against the thrust bearing inside the cap. After you set both side back against the snap rings, it will free up the joint in a most noticeable manner.

You should also try to rotate the snap ring in the groove with the end of a screwdriver by pushing on it. If it doesn't spin easily, that's good enough.

Also why you see folks struggling to remove the snap rings. They don't understand that the previous installer did it correctly and they need to release the pressure by first smacking the cap inwards before trying to pry out the snap ring and then doing the same to the other side to get that snap ring out.

A ball-joint press can easily overstress the yoke ears if too much pressure is needed to break the bond. You can still use a press of this type with a little care. Instead of using 2 feet of leverage and leaning into it until it pops, put moderate pressure on the shaft and give the ear that you're trying to push a little pop with your 3-lb hammer. If I use a standard 1/2 drive ratchet, the shorter length of the handle limits how much persuasion I can stress the ears with.

Or you can use a socket and good rap with the 3lb on the caps to break the bond and then do the rest of the job with the ball-joint press. You don't even need a socket with the 5-760X style as the caps stick out enough to give them a good pop with the hammer.

Good info above. The point in Blaine's 6th paragraph on smacking the yoke is especially useful. It's common to freak out after installing a new u-joint and discover it is binding/hard to move and that is the cure. That operation moves the bearing caps outward against the snap-rings which stops the binding.