There's a lot of discussion about which arms are best, etc.

While I do understand a lot of it, I'm concerned with FRONT UPPER arms only.

With most Control Arms underneath the TJ/LJ platform, there's typically two 'ends' to consider, which can drive the price up substantially.

However, the front uppers have a solid mount, with a bushing/joint on one end only, so the options become fairly comparable to each other.

(limited by only the single joint, and single vs double adjustable)

I'm having a tough time finding a reasonably priced pair of arms that AREN'T part of a full kit.

Which company seems to have the best reputation, and is there anything specifically to watch out for with front upper arms?

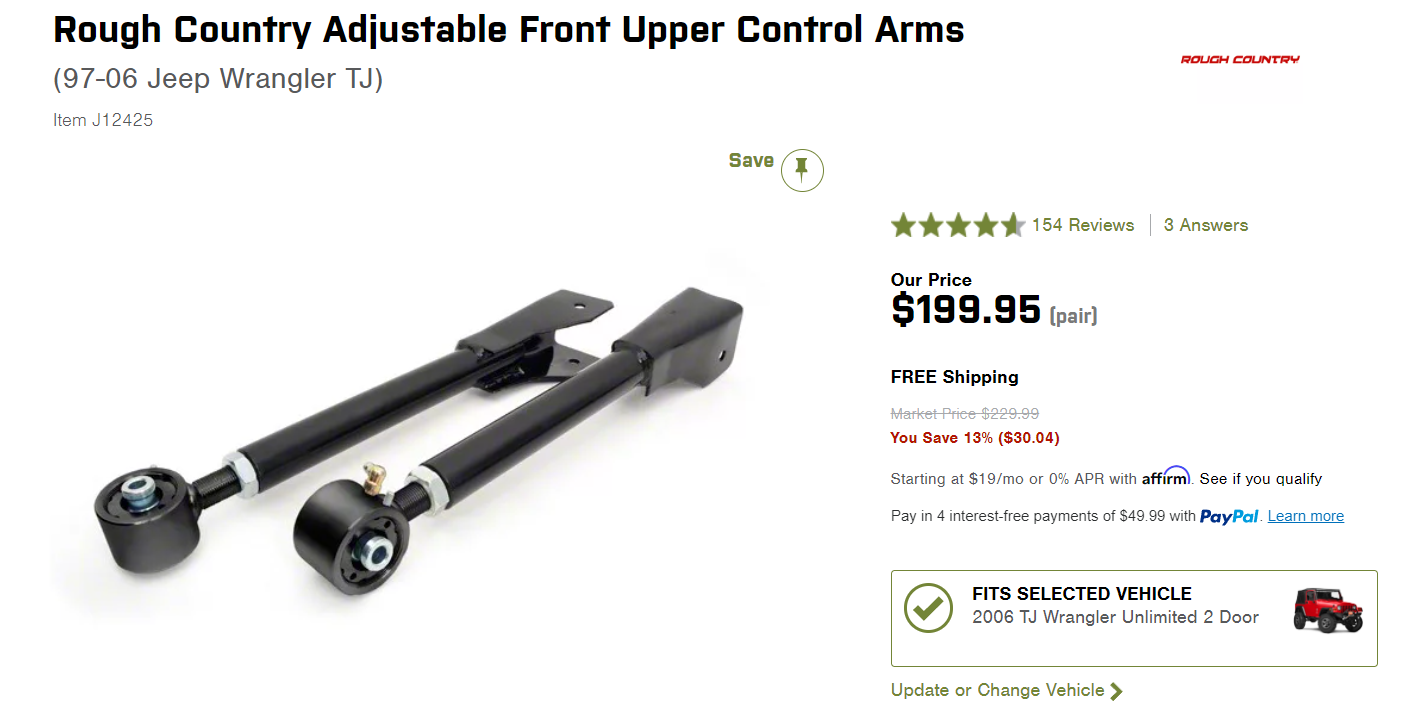

I hate to even ask, because I'm pretty sure I know the answer already, but is something like this Rough Country pair an absolute no-go?

(keep in mind, if the joint blows, there are compatible Johnny Joints that can be swapped in place)

Would love to hear some honest answers on what exactly separates the good from the bad, when dealing with front upper arms.

While I do understand a lot of it, I'm concerned with FRONT UPPER arms only.

With most Control Arms underneath the TJ/LJ platform, there's typically two 'ends' to consider, which can drive the price up substantially.

However, the front uppers have a solid mount, with a bushing/joint on one end only, so the options become fairly comparable to each other.

(limited by only the single joint, and single vs double adjustable)

I'm having a tough time finding a reasonably priced pair of arms that AREN'T part of a full kit.

Which company seems to have the best reputation, and is there anything specifically to watch out for with front upper arms?

I hate to even ask, because I'm pretty sure I know the answer already, but is something like this Rough Country pair an absolute no-go?

(keep in mind, if the joint blows, there are compatible Johnny Joints that can be swapped in place)

Would love to hear some honest answers on what exactly separates the good from the bad, when dealing with front upper arms.