I have a 1/4" steel skid that I need to trim down and make two straight cuts about 18" long. Is there a special blade or disc that would make quick work of this and a nice clean straight cut with minimal grinding afterwards? Skid is off the vehicle. I have a sawzall and a right angle grinder, but no band saw or torch and don't really want to buy a new tool just for this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Easiest way to cut 1/4” steel skid?

- Thread starter GASnBRASS

- Start date

EzPeezy

TJ Enthusiast

When I had to cut 3/16 plate I just let the angle grinder lay against the line and do the job slow and steady. Jig saw with a guide sounds a lot cleaner if you have a shaky hand. I've never put a metal blade in my jigsaw, I need to try it!

.045 Sait cut off disc. Near zero clean-up if you can hold a straight line.I have a 1/4" steel skid that I need to trim down and make two straight cuts about 18" long. Is there a special blade or disc that would make quick work of this and a nice clean straight cut with minimal grinding afterwards? Skid is off the vehicle. I have a sawzall and a right angle grinder, but no band saw or torch and don't really want to buy a new tool just for this.

The slightest bit of off line angularity and the blade will bend and walk off the line. Straight edges, metal, and jig saws don't play well together not to mention that is 36" of cut that will suck with a jig saw.Jigsaw with metal blade and a cramped straight edge as a guide.

Still very slow even with good cut off discs. The Sait I mentioned will make that cut in 1/4" plate in less than 2 minutes per cut.If it were me i'd most likely try a cutoff wheel on an air gun but only because I have that and use one frequently.

Awesome, thanks for the disc recommendation! I'll make a couple practice cuts before I commit to the final edge cut..045 Sait cut off disc. Near zero clean-up if you can hold a straight line.

.045 Sait cut off disc. Near zero clean-up if you can hold a straight line.

Second This.

Clamp a straightedge on and run the full length of the cut scoring the surface, then a few more passes lightly to cut deeper, followed by a final through cut and you should get a very, very straight cut. Finish off with a straight file. It's how I do it anyways. Less chance to go off course this way.

Either ferrous-metal-cutting diamond blades for a grinder

https://www.homedepot.com/b/Tools-P...fault&storeSelection=1802,1807,4414,1805,4411

or a ferrous metal carbide cutting blade for a circular saw, the circular saw blade would probably be the fastest and cleanest.

https://www.homedepot.com/b/Tools-P...vZc2jqZ1z0sjn9Z1z13133?experienceName=default

https://www.homedepot.com/b/Tools-P...fault&storeSelection=1802,1807,4414,1805,4411

or a ferrous metal carbide cutting blade for a circular saw, the circular saw blade would probably be the fastest and cleanest.

https://www.homedepot.com/b/Tools-P...vZc2jqZ1z0sjn9Z1z13133?experienceName=default

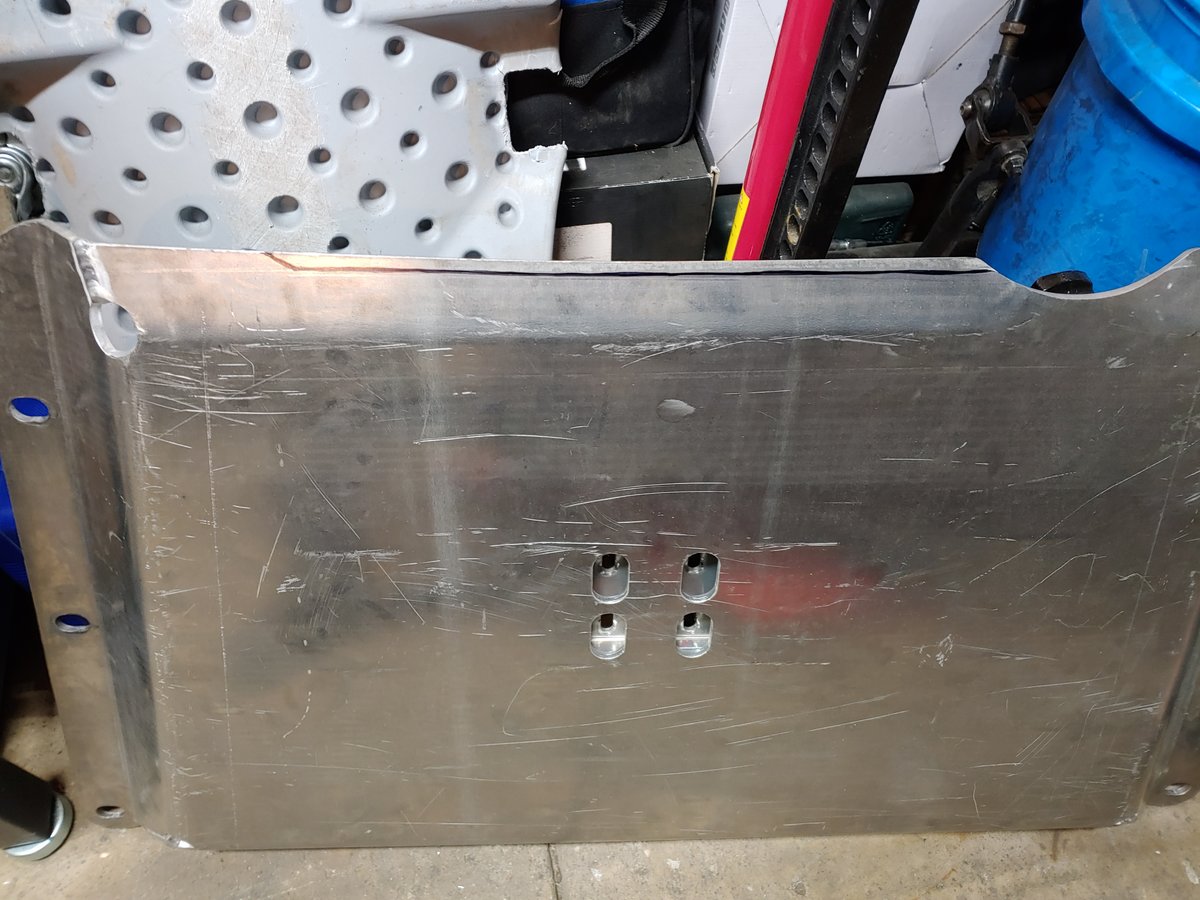

Just used my cut off disc to on my 1/4" aluminum skid. Not steel but same process of several passes, albeit with a steady hand.

Just used my cut off disc to on my 1/4" aluminum skid. Not steel but same process of several passes, albeit with a steady hand.

Cool - wasn't sure if anyone else did it like that...

The first pass or two is like drawing on your line, you can correct if needed. The final cut is really easy to feel because your cutting thinner material.

Plasma cranked up to the max with a ruler would be easiest and would give a clean cut if you can move fast. But I wouldn't buy one just for this... I'd recommend Walter Zip Discs. I find they balance well and give a clean cut. A quick flap disc over the edge will clean up any bur followed by hand sanding with 120 grit.

If you're cutting off an end, I'd use calipers to score a line. Quick and easy.

If you're cutting off an end, I'd use calipers to score a line. Quick and easy.

Last edited:

99% of the time a kick is due to improper use of the angle grinder. Very few who use them implicitly understand that you should never do a push cut. A push cut is one where the sparks are flying away from you and lots of folks do that because they don't like the sparks coming back toward them. Push cuts are dangerous and will hurt you with a quickness that is astounding. Only do pull cuts where the sparks are flying towards you. If the blade binds or has an issue, the grinder is being forced away from you, not towards. That and it is nearly impossible to get a bad kick that jams the blade in the cut and kicks toward your tender bits if you are doing a pull cut.just be careful. spinning blades and steel can a recipe for an accident. go slow do your best not bind the blade.

i've seen many times what a cutoff wheel can do if it kicks and your not ready for it.

Last edited:

Aluminum should be cut with aluminum specific discs if possible. Aluminum loads the abrasives and can make them blow up. I use Sait aluminum specific discs and the difference cutting aluminum versus steel is obvious.Just used my cut off disc to on my 1/4" aluminum skid. Not steel but same process of several passes, albeit with a steady hand.

View attachment 127131

View attachment 127132

View attachment 127133

View attachment 127134

I also don't cut aluminum very often with abrasives. I do the vast majority of it with non ferrous carbide blades on a variety of circular saws.

That cut on the skid would have taken about 20 seconds with my Milwaukee 6 1/4 M18 and a Diablo non ferrous blade.

I'm in the process of converting to Fuel tools. Still have Dewalt grinder with 1.5aH battery lol. So, while it cut fairly quickly, the battery drained even quicker. Took 2 batteries over 2 charges each. Would just let it charge while doing other things concerning the tuck.Aluminum should be cut with aluminum specific discs if possible. Aluminum loads the abrasives and can make them blow up. I use Sait aluminum specific discs and the difference cutting aluminum versus steel is obvious.

I also don't cut aluminum very often with abrasives. I do the vast majority of it with non ferrous carbide blades on a variety of circular saws.

That cut on the skid would have taken about 20 seconds with my Milwaukee 6 1/4 M18 and a Diablo non ferrous blade.

The Fuel grinder and a 9.0 will easily cut both sides of a 3/8" thick belly skid in 6061 T6 with an aluminum cutting disc and then both sides of the frame to extend the wheelbase.I'm in the process of converting to Fuel tools. Still have Dewalt grinder with 1.5aH battery lol. So, while it cut fairly quickly, the battery drained even quicker. Took 2 batteries over 2 charges each. Would just let it charge while doing other things concerning the tuck.

Maybe Santa will bring me one.The Fuel grinder and a 9.0 will easily cut both sides of a 3/8" thick belly skid in 6061 T6 with an aluminum cutting disc and then both sides of the frame to extend the wheelbase.