I run of set of these exact headers (but with the EGR tube) on my RamCharger with the 408. I can't speak for the TJ, but I know they clear the YJ firewall just fine...I'd like to try some headers like this instead of the block huggers that I have but no one that I can find has ever tried to use any of these. My thought is that if it works on a Ram truck or Jeep Grand Cherokee they "SHOULD" work in the TJ but as you know it doesn't work that way.

https://www.amazon.com/dp/B001CI62MY/?tag=wranglerorg-20

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

You ever share a photo of yours? Now that I got to thinking about it, I don't think I've seen one... I need to go dig through your build threadI run a cowl intake on mine as well. That stroked Hemi puts out a crazy amount of heat, and it was roasting my IAT’s.

EDIT: I just took a look, OMG I love the attention to detail!!

Last edited:

I run of set of these exact headers (but with the EGR tube) on my RamCharger with the 408. I can't speak for the TJ, but I know they clear the YJ firewall just fine...

That is good to know. I'm thinking I might order a set thru Amazon so if they don't work I can at least return them.

You ever share a photo of yours? Now that I got to thinking about it, I don't think I've seen one... I need to go dig through your build thread

EDIT: I just took a look, OMG I love the attention to detail!!That's a wicked build if I've ever seen one and love how you do it all "in house". I couldn't imagine paying someone to build my rigs (not that there's anything wrong with it, I just get a lot of satisfaction from building stuff, messing up a lot, and learning along the way).

Yes he has done an awesome job on his Jeep and makes me look at my work and know I need to up the game if I want it to be anywhere near as good.

I really like how that Hemi looks in your TJ.

Thanks for the kind words.You ever share a photo of yours? Now that I got to thinking about it, I don't think I've seen one... I need to go dig through your build thread

EDIT: I just took a look, OMG I love the attention to detail!!That's a wicked build if I've ever seen one and love how you do it all "in house". I couldn't imagine paying someone to build my rigs (not that there's anything wrong with it, I just get a lot of satisfaction from building stuff, messing up a lot, and learning along the way).

Hey @NashvilleTJ - by chance can you take a pic of your firewall clearance??I run a cowl intake on mine as well. That stroked Hemi puts out a crazy amount of heat, and it was roasting my IAT’s.

You really aren't messing around!

When people say they are going to have a V8 swap done in a short amount of time, I usually roll my eyes, because I know that as men we tend to procrastinate. However, it looks like you really will have it done in a decent amount of time. Very cool!

When people say they are going to have a V8 swap done in a short amount of time, I usually roll my eyes, because I know that as men we tend to procrastinate. However, it looks like you really will have it done in a decent amount of time. Very cool!

Tough to see with everything surrounding the mill, but I have about a finger‘s worth of clearance at the heads. I positioned the engine as far back as I could for fan clearance. I thought I’d have all kinds of clearance given the length of the I6 vs the V8, but as you also found out the firewall is not flat and recessed in the center so the 6 can sit much farther back than the 8.Hey @NashvilleTJ - by chance can you take a pic of your firewall clearance??

What are you looking for in a picture? I might be able to dig up one from when I did the swap, but give me a better idea what you need to narrow it down.

You touched on it - the space between the heads and firewall mainly, as well as the general orientation. I was hoping to see how these Holley mounts placed the engine compared to others. Based on Holley’s statement that it retains factory driveshaft length with a 545/65RFE (which is 3” longer), I was expecting more room back there. I’m at the point where I may file off one of the harness slots on my valve cover...Tough to see with everything surrounding the mill, but I have about a finger‘s worth of clearance at the heads. I positioned the engine as far back as I could for fan clearance. I thought I’d have all kinds of clearance given the length of the I6 vs the V8, but as you also found out the firewall is not flat and recessed in the center so the 6 can sit much farther back than the 8.

What are you looking for in a picture? I might be able to dig up one from when I did the swap, but give me a better idea what you need to narrow it down.

I’m not one to sit and ponder - when I have made up my mind, I go into execute mode and don’t often let off the throttle (pun intended) until I’m finishedYou really aren't messing around!

When people say they are going to have a V8 swap done in a short amount of time, I usually roll my eyes, because I know that as men we tend to procrastinate. However, it looks like you really will have it done in a decent amount of time. Very cool!

That said, I am susceptible to scope creep. Once I get the motor set and pull the tub to start painting, I’m toying with the idea of doing the rear stretch and outboard while it’s all apart. Wouldn’t be a bad time to raise the body mounts up either...

Watching this build progress, as well as those by @NashvilleTJ and @Wildman is really making me want to do a conversion. The last one I did was a TPI L98 in my 1985 Toyota pickup. I miss the sound of a V8 in a small 4wd platform. Super nice work here!

Well I got the transmission bolted in, but the skid was barely touching the transmission pan..

The fix was fairly straight forward, just mark out where I wanted to cut and make it happen.

I used a drill bit to drill a hole on the horizontal line, then used a jigsaw with a HSS blade to trim the sides up, then from the center hole outward. I cleaned up the cuts and edges with an angle grinder and grinding wheel.

I ended up buying a transmission jack. I was originally hesitant about getting one, knowing I would not use it much, but that assumption has already proven to be wrong. Not only did I use the jack to get the transmission in place, it was super handy for moving that beefy UCF Ultra-High 3/16" steel skid plate in place. I'll probably use this for the fuel-tank as well. It's not hydraulic, so it can be used to stabilize without high-risk of collapse, and there are no seals to leak so it should last a long time if I keep it greased.

With the skid notched, it feel into place like it was meant to be there! I have confirmed that the transmission pan on this is the same for 2WD and 4WD, so there is no advantage in one pan over the other. As you can see, the pan is very much exposed - something I'll have to address once the swap is over!

The motor in its new home - I left the cherry picker attached as a safety precaution (the chains are taught but no tension is on them) but the motor is sitting directly and fully on the new mounts. Per the Holley instructions, I will adjust as necessary and throw in a few tack welds on each welded edge before removing.

Overall the clearance of the engine and trans is great - it's tight (as expected) but fits well. The one exception is the valve-cover on the passenger side. The valve covers have these little cast-in pockets that are used for tall plastic posts. Those posts are used for various functions - wire support, heater hose support, etc. I will likely take a small handsaw to this one to prevent any firewall boo-boos.

Next up - tacking the mounts in place then removing everything for the "full burn"!

The fix was fairly straight forward, just mark out where I wanted to cut and make it happen.

I used a drill bit to drill a hole on the horizontal line, then used a jigsaw with a HSS blade to trim the sides up, then from the center hole outward. I cleaned up the cuts and edges with an angle grinder and grinding wheel.

I ended up buying a transmission jack. I was originally hesitant about getting one, knowing I would not use it much, but that assumption has already proven to be wrong. Not only did I use the jack to get the transmission in place, it was super handy for moving that beefy UCF Ultra-High 3/16" steel skid plate in place. I'll probably use this for the fuel-tank as well. It's not hydraulic, so it can be used to stabilize without high-risk of collapse, and there are no seals to leak so it should last a long time if I keep it greased.

With the skid notched, it feel into place like it was meant to be there! I have confirmed that the transmission pan on this is the same for 2WD and 4WD, so there is no advantage in one pan over the other. As you can see, the pan is very much exposed - something I'll have to address once the swap is over!

The motor in its new home - I left the cherry picker attached as a safety precaution (the chains are taught but no tension is on them) but the motor is sitting directly and fully on the new mounts. Per the Holley instructions, I will adjust as necessary and throw in a few tack welds on each welded edge before removing.

Overall the clearance of the engine and trans is great - it's tight (as expected) but fits well. The one exception is the valve-cover on the passenger side. The valve covers have these little cast-in pockets that are used for tall plastic posts. Those posts are used for various functions - wire support, heater hose support, etc. I will likely take a small handsaw to this one to prevent any firewall boo-boos.

Next up - tacking the mounts in place then removing everything for the "full burn"!

With the motor set in place, the Holley instructions call you to loosen the mounts and use a jack and prybar as needed to get the mounts to sit square and flush on the frame. This process is also used to center the drivetrain. With the transmission bolted in, I was able to use the spacing from the cylinder heads to the firewall as well as how square the transmission mount say in the crossmember to make sure the engine was centered.

The driver-side mount was near perfect and was nice and flush. The passenger mount caused me some grief. Nothing I tried would allow the 4 frame contact points to touch the frame. I moved, checked for interferences, adjusted and pried for quite some time. You can see in the image below just how much it was shifting with the engine in place by the bolt-head markings in the primer coat. Ultimately, I found where the mount was most happy, kept the engine/drivetrain centered and had 3 solid contact points (I would simply buildup and close the gap on the one that was slightly off, ~1/16"). I put few tack welds in place - which was quite the challenge while trying to hold a prybar and a 500-lb engine in temporary position!

With the mounts tacked in place, I double checked fit and alignment, then began removing the trans and engine from the chassis; luckily I had my YJ buddy on hand to help out. Once the engine was out, I burned all the mounts in and then put on a coat of self-etching primer, followed by some VHT Epoxy spray paint. The mounts have lots of weldable surface area and are quite strong.

Since I'm going to be removing the tub for paint, I decided to scrap the idea of painting the firewall ahead of time. This allowed us to bolt the engine and trans back in place, which not only helps keep my garage clean but also will let me do some other prep work while it's in (like layout the harness and check for fitment/routing).

Before putting the motor back in, I made sure to take care of the little post hole on the valve cover that was too close to the firewall. A small coping saw with thin kerf blade made for quick and easy work.

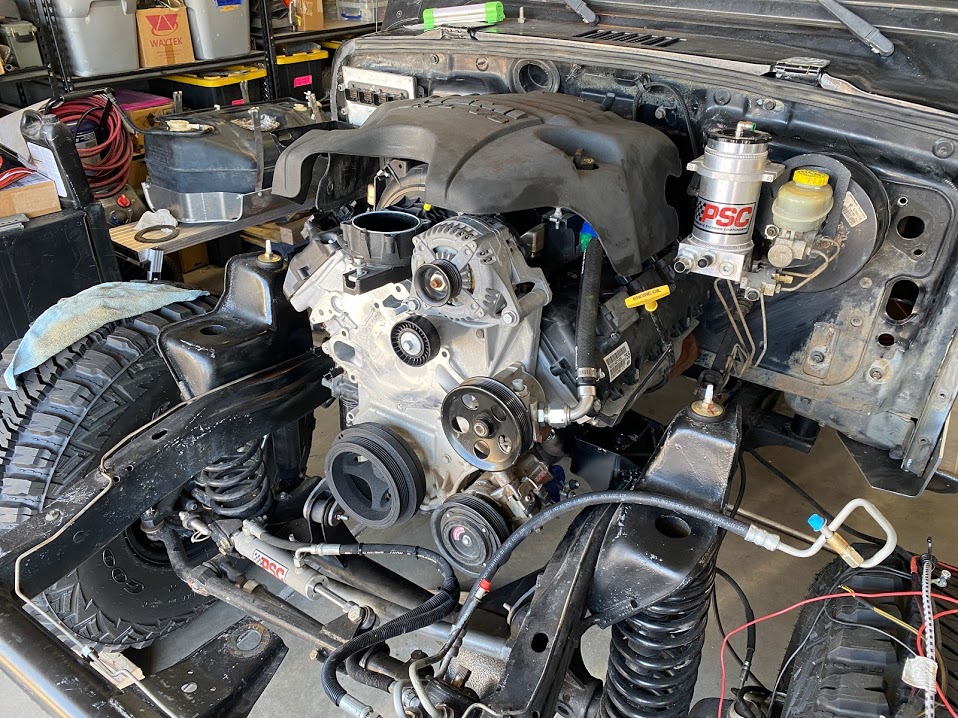

With the motor in place, I placed the intake and cover on top, then put the PSC reservoir back in place as well to check clearance - I swear it's like this swap was meant to be! The cover is a tad bulky and the truck intake points the TB directly at the hood. I will need to play around some and see if I have the room here but I may not be able to run the cowl intake after all. I won't be able to check until I get the body work done and everything bolted back together but I will have to keep this in mind as the swap progresses...

The driver-side mount was near perfect and was nice and flush. The passenger mount caused me some grief. Nothing I tried would allow the 4 frame contact points to touch the frame. I moved, checked for interferences, adjusted and pried for quite some time. You can see in the image below just how much it was shifting with the engine in place by the bolt-head markings in the primer coat. Ultimately, I found where the mount was most happy, kept the engine/drivetrain centered and had 3 solid contact points (I would simply buildup and close the gap on the one that was slightly off, ~1/16"). I put few tack welds in place - which was quite the challenge while trying to hold a prybar and a 500-lb engine in temporary position!

With the mounts tacked in place, I double checked fit and alignment, then began removing the trans and engine from the chassis; luckily I had my YJ buddy on hand to help out. Once the engine was out, I burned all the mounts in and then put on a coat of self-etching primer, followed by some VHT Epoxy spray paint. The mounts have lots of weldable surface area and are quite strong.

Since I'm going to be removing the tub for paint, I decided to scrap the idea of painting the firewall ahead of time. This allowed us to bolt the engine and trans back in place, which not only helps keep my garage clean but also will let me do some other prep work while it's in (like layout the harness and check for fitment/routing).

Before putting the motor back in, I made sure to take care of the little post hole on the valve cover that was too close to the firewall. A small coping saw with thin kerf blade made for quick and easy work.

With the motor in place, I placed the intake and cover on top, then put the PSC reservoir back in place as well to check clearance - I swear it's like this swap was meant to be! The cover is a tad bulky and the truck intake points the TB directly at the hood. I will need to play around some and see if I have the room here but I may not be able to run the cowl intake after all. I won't be able to check until I get the body work done and everything bolted back together but I will have to keep this in mind as the swap progresses...

Last edited:

I think I'm gonna have to drive my TJ to Arizona for a week and we'll have a thrash fest to install a hemi... Sounds good? LolWith the motor set in place, the Holley instructions call you to loosen the mounts and use a jack and prybar as needed to get the mounts to sit square and flush on the frame. This process is also used to center the drivetrain. With the transmission bolted in, I was able to use the spacing from the cylinder heads to the firewall as well as how square the transmission mount say in the crossmember to make sure the engine was centered.

The driver-side mount was near perfect and was nice and flush. The passenger mount caused me some grief. Nothing I tried would allow the 4 frame contact points to touch the frame. I moved, checked for interferences, adjusted and pried for quite some time. You can see in the image below just how much it was shifting with the engine in place by the bolt-head markings in the primer coat. Ultimately, I found where the mount was most happy, kept the engine/drivetrain centered and had 3 solid contact points (I would simply buildup and close the gap on the one that was slightly off, ~1/16"). I put few tack welds in place - which was quite the challenge while trying to hold a prybar and a 500-lb engine in temporary position!

View attachment 230024

With the mounts tacked in place, I double checked fit and alignment, then began removing the trans and engine from the chassis; luckily I had my YJ buddy on hand to help out. Once the engine was out, I burned all the mounts in and then put on a coat of self-etching primer, followed by some VHT Epoxy spray paint. The mounts have lots of weldable surface area and are quite strong.

View attachment 230014

Since I'm going to be removing the tub for paint, I decided to scrap the idea of painting the firewall ahead of time. This allowed us to bolt the engine and trans back in place, which not only helps keep my garage clean but also will let me do some other prep work while it's in (like layout the harness and check for fitment/routing).

View attachment 230015

Before putting the motor back in, I made sure to take care of the little post hole on the valve cover that was too close to the firewall. A small coping saw with thin kerf blade made for quick and easy work.

View attachment 230016

With the motor in place, I placed the intake and cover on top, then put the PSC reservoir back in place as well to check clearance - I swear it's like this swap was meant to be! The cover is a tad bulky and the truck intake points the TB directly at the hood. I will need to play around some and see if I have the room here but I may not be able to run the cowl intake after all. I won't be able to check until I get the body work done and everything bolted back together but I will have to keep this in mind as the swap progresses...

View attachment 230017View attachment 230018

Have you thought about running it without the engine cover? Would that give you room for the cowl intake?With the motor set in place, the Holley instructions call you to loosen the mounts and use a jack and prybar as needed to get the mounts to sit square and flush on the frame. This process is also used to center the drivetrain. With the transmission bolted in, I was able to use the spacing from the cylinder heads to the firewall as well as how square the transmission mount say in the crossmember to make sure the engine was centered.

The driver-side mount was near perfect and was nice and flush. The passenger mount caused me some grief. Nothing I tried would allow the 4 frame contact points to touch the frame. I moved, checked for interferences, adjusted and pried for quite some time. You can see in the image below just how much it was shifting with the engine in place by the bolt-head markings in the primer coat. Ultimately, I found where the mount was most happy, kept the engine/drivetrain centered and had 3 solid contact points (I would simply buildup and close the gap on the one that was slightly off, ~1/16"). I put few tack welds in place - which was quite the challenge while trying to hold a prybar and a 500-lb engine in temporary position!

View attachment 230024

With the mounts tacked in place, I double checked fit and alignment, then began removing the trans and engine from the chassis; luckily I had my YJ buddy on hand to help out. Once the engine was out, I burned all the mounts in and then put on a coat of self-etching primer, followed by some VHT Epoxy spray paint. The mounts have lots of weldable surface area and are quite strong.

View attachment 230014

Since I'm going to be removing the tub for paint, I decided to scrap the idea of painting the firewall ahead of time. This allowed us to bolt the engine and trans back in place, which not only helps keep my garage clean but also will let me do some other prep work while it's in (like layout the harness and check for fitment/routing).

View attachment 230015

Before putting the motor back in, I made sure to take care of the little post hole on the valve cover that was too close to the firewall. A small coping saw with thin kerf blade made for quick and easy work.

View attachment 230016

With the motor in place, I placed the intake and cover on top, then put the PSC reservoir back in place as well to check clearance - I swear it's like this swap was meant to be! The cover is a tad bulky and the truck intake points the TB directly at the hood. I will need to play around some and see if I have the room here but I may not be able to run the cowl intake after all. I won't be able to check until I get the body work done and everything bolted back together but I will have to keep this in mind as the swap progresses...

View attachment 230017View attachment 230018

The intake manifold on your mill is nice looking. With a little cleanup and removal of a few of the extraneous mounting tabs, I think it would look pretty sharp.

That’s exactly what my neighbor said to do...Have you thought about running it without the engine cover? Would that give you room for the cowl intake?

The intake manifold on your mill is nice looking. With a little cleanup and removal of a few of the extraneous mounting tabs, I think it would look pretty sharp.

I’m not dead set on the cover but would like to to have it if possible. If not, so be it - function over form is the winning philosophy for me!

Water Pump Bolt Length Guide

The 2009+ Eagle Hemis with truck front covers utilize four different sized bolts on the water-pump. A quick look on the interwebs shows that there is much confusion about what bolts go where. This is because there is no indication as to what is the appropriate bolt length by the front cover (on many older engines, it was just a matter of looking at the water pump and matching up the longer bolts with the thicker/est parts of the casting).

Since I had to install my new Mopar water-pump, I made a quick guide for bolt lengths to help anyone who may need it. Looking at the lengths in this guide shows the logic behind the bolt lengths. The short length bolts (34mm) go into the timing cover only, the longer (84mm) bolts go through the cover to the block behind it; the short, then long, then short pattern can be see around the perimeter.

Bolt length for each spot is listed below. All lengths are measured from under the bolt head (not the washer) and rounded to the closest whole number. The "*115 mm" bolt under the temp sender is a stud and uses a 15mm socket (all others use a 13mm socket).

Torque on all bolts is 18 ft-lbs per the FSM. The water pump uses an o-ring seal and needs no supplemental sealing means.

The 2009+ Eagle Hemis with truck front covers utilize four different sized bolts on the water-pump. A quick look on the interwebs shows that there is much confusion about what bolts go where. This is because there is no indication as to what is the appropriate bolt length by the front cover (on many older engines, it was just a matter of looking at the water pump and matching up the longer bolts with the thicker/est parts of the casting).

Since I had to install my new Mopar water-pump, I made a quick guide for bolt lengths to help anyone who may need it. Looking at the lengths in this guide shows the logic behind the bolt lengths. The short length bolts (34mm) go into the timing cover only, the longer (84mm) bolts go through the cover to the block behind it; the short, then long, then short pattern can be see around the perimeter.

Bolt length for each spot is listed below. All lengths are measured from under the bolt head (not the washer) and rounded to the closest whole number. The "*115 mm" bolt under the temp sender is a stud and uses a 15mm socket (all others use a 13mm socket).

Torque on all bolts is 18 ft-lbs per the FSM. The water pump uses an o-ring seal and needs no supplemental sealing means.

Last edited:

I'm trying to button up the motor and at least make it "complete". I hooked up the factory p/s hose to the PSC box and it fit just fine. I can tweak placement once everything is back together but I don't expect any issues. The PSC reservoir return line needed to be redone. I had ordered an extra 180º JIC fitting but ended up using the spare 45º fitting on the pump and straight fitting on the reservoir (the PSC kit I ordered originally included the 45º but I needed a 90º since I tweaked the placement of the reservoir to clear my GR Hi-Fenders).

With the water pump, p/s pump and related parts back on the motor, I put the intake manifold on, as well as the TB and cover. You can see that the factory air-hose simply will not work...

There are a few companies that sell 90º throttle body adapters specifically to help with the 5.7 VVT truck motors. JSS, aka "Jeep Speed Shop", makes a really nice all-metal adapter that physically relocates the TB to the side of the motor. It's a nice unit, but it's also $500, so I'm hoping to find a better alternative before dumping the $$.

With the water pump, p/s pump and related parts back on the motor, I put the intake manifold on, as well as the TB and cover. You can see that the factory air-hose simply will not work...

There are a few companies that sell 90º throttle body adapters specifically to help with the 5.7 VVT truck motors. JSS, aka "Jeep Speed Shop", makes a really nice all-metal adapter that physically relocates the TB to the side of the motor. It's a nice unit, but it's also $500, so I'm hoping to find a better alternative before dumping the $$.

Last edited:

Damn! 500 bucks? You could probably have something like that 3d printed...I'm trying to button up the motor and at least make it "complete". I hooked up the factory p/s hose to the PSC box and it fit just fine. I can tweak placement once everything is back together but I don't expect any issues. The PSC reservoir return line needed to be redone. I had ordered an extra 180º JIC fitting but ended up using the spare 45º fitting on the pump and straight fitting on the reservoir (the PSC kit I ordered originally included the 45º but I needed a 90º since I tweaked the placement of the reservoir to clear my GR Hi-Fenders).

View attachment 230625

With the water pump, p/s pump and related parts back on the motor, I put intake manifold on, as well as the TB and cover. You can see that the factory air-hose simply will not work...

View attachment 230626

There are a few companies that sell 90º throttle body adapters specifically to help with the 5.7 VVT truck motors. JSS, aka "Jeep Speed Shop", makes a really nice all-metal adapter that physically relocates the TB to the side of the motor. It's a nice unit, but it's also $500, so I'm hoping to find a better alternative before dumping the $$.

View attachment 230624