You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

High travel, high clearance & high octane, a streetable adventure LJ story

- Thread starter toximus

- Start date

Boxes look great! Making a gasket for the boxes would be easy too. Looking good!

How would you make a gasket? Do you think that it'd seal variations in thickness just as well as silicone?

My first thought would be a foam tape similar to what is used on the hard top where it contacts the tub.How would you make a gasket? Do you think that it'd seal variations in thickness just as well as silicone?

Stox5225

TJ Enthusiast

Subscribed!!! This is awesome. Got a set of axles out of an ‘06 Cummins I plan on throwin’ under my Jeep. This will be a solid guide!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Subscribed!!! This is awesome. Got a set of axles out of an ‘06 Cummins I plan on throwin’ under my Jeep. This will be a solid guide!

Sent from my iPhone using Tapatalk

Be sure to start a build thread one you begin!

I tested full articulation some more and found the with the 37" monsters (yes, they're starting to look bigger than they did before) and 14" travel suspension I am sending the tire through the spot welds on the fender.

Cutting out the spot welds will cause the inner-fender to separate from the outer fender. To prevent that I flipped the inner-fender flange from down to up.

So I ordered angled 16ga sheet steel (I ordered extra if anybody else wants to repeat this I can send you a few pieces), cut them down to 10", drilled a bunch of holes in them, put seam sealer on the back being careful to avoid the spot weld holes. I probably went overkill on the spot welds but I wanted to make sure this area didn't fail after all of the other cutting I've done.

Paint sanded away:

New flange cut to length and drilled:

Spot welded in:

(carpet will be covering this later on)

It hurts to be ruining the paint I did last year but it's the only way to progress.

I then mounted a tire and would lift, mark what needed to be cut out, lower, cut, and repeat until I had clearance all the way around the tire. This picture is part way through that process:

Once I was happy with my wheel arch I traced it to a sheet of cardboard and copied it to the other side:

At this point I am very happy that I didn't go with 16" coilovers. I never would have fit them...

Cutting out the spot welds will cause the inner-fender to separate from the outer fender. To prevent that I flipped the inner-fender flange from down to up.

So I ordered angled 16ga sheet steel (I ordered extra if anybody else wants to repeat this I can send you a few pieces), cut them down to 10", drilled a bunch of holes in them, put seam sealer on the back being careful to avoid the spot weld holes. I probably went overkill on the spot welds but I wanted to make sure this area didn't fail after all of the other cutting I've done.

Paint sanded away:

New flange cut to length and drilled:

Spot welded in:

(carpet will be covering this later on)

It hurts to be ruining the paint I did last year but it's the only way to progress.

I then mounted a tire and would lift, mark what needed to be cut out, lower, cut, and repeat until I had clearance all the way around the tire. This picture is part way through that process:

Once I was happy with my wheel arch I traced it to a sheet of cardboard and copied it to the other side:

At this point I am very happy that I didn't go with 16" coilovers. I never would have fit them...

The corner guard blanks from Savvy went on. It's nice following a kit for a change and being able to sip a cold drink not worrying about if you forgot something. All of the body damage that I've gotten over the years (including my most recent tree debacle) didn't cause too much fuss during the install. Just a few clamps to draw those areas into the corner guard straightened them out. Based on how little material is above the tire I am thankful to have the rubrails to add strength to that area.

Once the blanks were on, I traced the wheel arch and my round taillight holes onto the blank. A jigsaw with an aluminum blade is the best way I've found to cut the aluminum. A hole saw was used for the lights.

I personally like the wrapped license plate look. Over wrapping the radius slightly allows for the plate to sit tight against the tub and not catch wind.

Over the last few years I've been improving my plate mounting solution. I previously used bolts with LED lights on the ends. They weren't super reliable for me and were difficult to replace since I had to solder in new ones each time.

This time I went with Off Road Only's license plate light. It features stainless steel construction and I am able to use the standard license plate mounting holes.

I drilled and tapped the holes for 1/4-20" stainless steel button head bolts. The plug fits through the main taillight hole and the wire slides down into a notch.

Once the blanks were on, I traced the wheel arch and my round taillight holes onto the blank. A jigsaw with an aluminum blade is the best way I've found to cut the aluminum. A hole saw was used for the lights.

I personally like the wrapped license plate look. Over wrapping the radius slightly allows for the plate to sit tight against the tub and not catch wind.

Over the last few years I've been improving my plate mounting solution. I previously used bolts with LED lights on the ends. They weren't super reliable for me and were difficult to replace since I had to solder in new ones each time.

This time I went with Off Road Only's license plate light. It features stainless steel construction and I am able to use the standard license plate mounting holes.

I drilled and tapped the holes for 1/4-20" stainless steel button head bolts. The plug fits through the main taillight hole and the wire slides down into a notch.

Someday I may go to a flat belly skid and I may go to an Atlas and maybe a aluminum block V8. All of that is down the road though and in the meantime I didn't want to hack up the transmission tunnel to only do it again in the future (and I just LOVE body work... not...). Once I finalize my drivetrain combo I can see redoing the belly skid. For now Savvy Under Armor is the best option for me and honestly with 37s and a 4" lift I may end up perfectly happy with the belly clearance.

The C brackets with the Savvy kit don't work with the Genright raised body mount brackets I installed previously so I changed up the way it mounts to the frame.

First I flipped the ends of the crossmember at the welding table so the bolt flange faces up. (I ruined the ends cutting them off so I actually cut down the length of a 1/8" wall tube and redrilled)

Next I bolted the crossmember to the skid and bolted it to the 6 frame skid mounts. I don't have nutserts on my frame so I omitted the 1/8" skid spacers (look back at my earlier post when I rebuilt the frame). I bolted 1/4" tabs I made to the crossmember and welded the tabs to the frame:

(I don't envision driving with the skid off much, but I added a beefy gusset to reduce any fatigue on the tabs. I can live without the unlikely chance of a transmission falling on my head while I'm working under it.)

This resulted in a perfect placement and it's easier to take down when needed than using the inner and outer Cs that the Savvy kit uses!

While I had the crossmember on the welding table I drilled 4 drain holes in it so it doesn't fill up with water and rust out:

The C brackets with the Savvy kit don't work with the Genright raised body mount brackets I installed previously so I changed up the way it mounts to the frame.

First I flipped the ends of the crossmember at the welding table so the bolt flange faces up. (I ruined the ends cutting them off so I actually cut down the length of a 1/8" wall tube and redrilled)

Next I bolted the crossmember to the skid and bolted it to the 6 frame skid mounts. I don't have nutserts on my frame so I omitted the 1/8" skid spacers (look back at my earlier post when I rebuilt the frame). I bolted 1/4" tabs I made to the crossmember and welded the tabs to the frame:

(I don't envision driving with the skid off much, but I added a beefy gusset to reduce any fatigue on the tabs. I can live without the unlikely chance of a transmission falling on my head while I'm working under it.)

This resulted in a perfect placement and it's easier to take down when needed than using the inner and outer Cs that the Savvy kit uses!

While I had the crossmember on the welding table I drilled 4 drain holes in it so it doesn't fill up with water and rust out:

In order to finalize the brackets on the rear axle I need to get the pinion angle set which is now possible with the output height on the transfercase set. As of right now I suspect I'm within 3 degrees of where it needs to be. I measured for a driveshaft and ordered up one from Tom Woods specifying sealed 1310 Spicer joints since Jerry Bransford is always preaching how the seals are better than TW's gold joints — something that is important in my climate. I also requested extended spline for the additional travel and strength and no grease boot since I find they tend to rip off as soon as they get nicked by rocks.

My my SS-SYE and stock wheelbase my rear driveshaft is cut for 27-3/8". I was not expecting that I'd be able to get such a long shaft in there.

My my SS-SYE and stock wheelbase my rear driveshaft is cut for 27-3/8". I was not expecting that I'd be able to get such a long shaft in there.

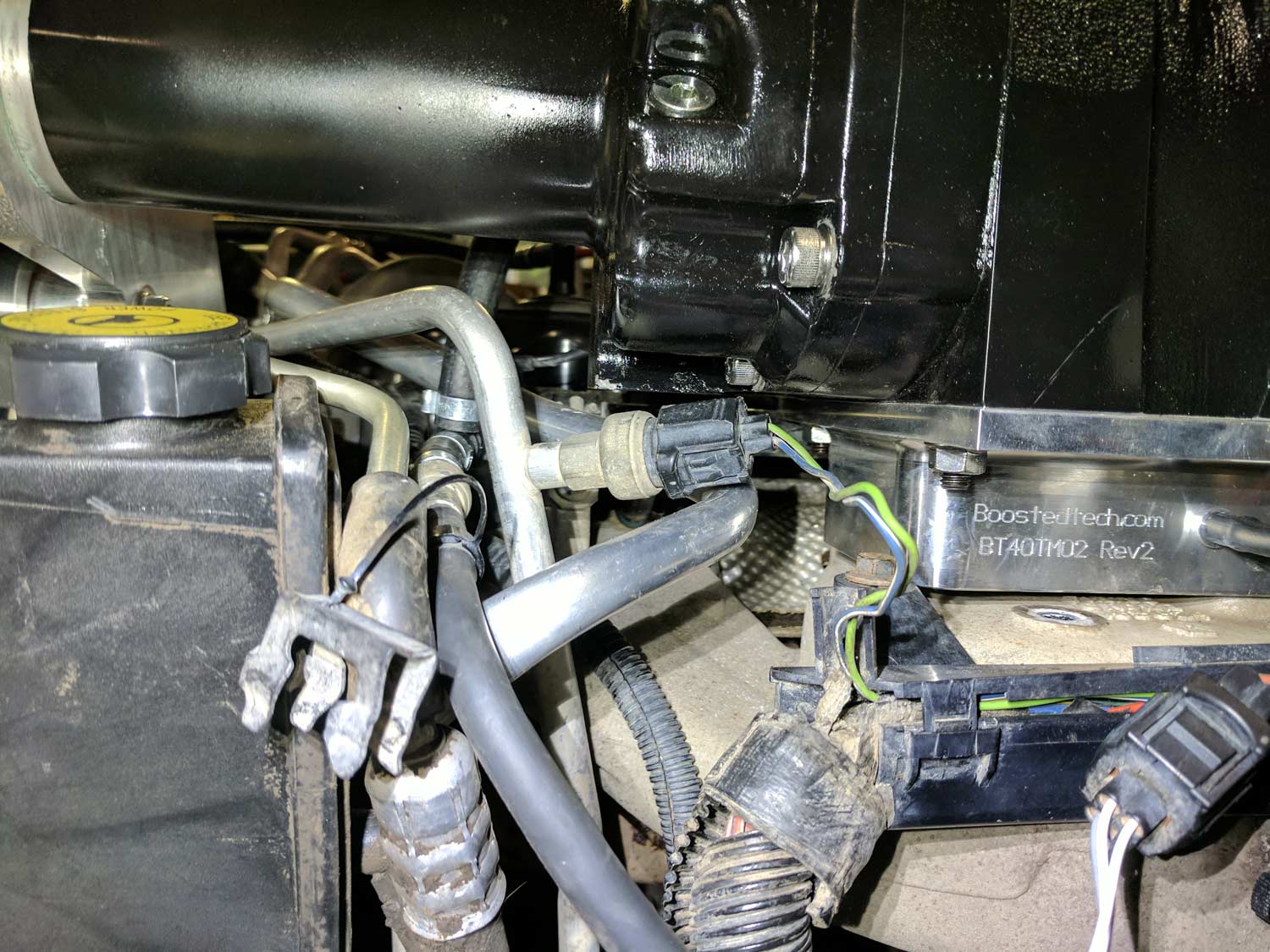

While waiting for the rear driveshaft to come in I decided to clean the garage and tackle some various smaller projects before starting on the front (Tom Wood said I'd receive the DS a week after I ordered). I have been super excited to install my supercharger kit from BoostedTech and have the luxurious break of follow instructions again. These kits are awesome because they use the ultra reliable Eaton M90 and provide all of the install brackets to allow the hood to fully close without cutting a hole in the hood.

First I washed the engine bay to make things nicer for me to work on and prevent any dust from getting into the engine. I removed the hoodliner which I plan to wash separately and reinstall towards the end of my build.

For use with the supercharger I needed to change my spark plugs out to some that are 1 heat range colder. BoostedTech suggests Autolite XP5224 Iridium. They came out of the box gapped from 0.000-0.050" so I spent the extra effort to make sure I had them all gapped at 0.029-0.031".

I setup my laptop on a table next to my Jeep with the PDF instructions from BoostedTech pulled up and got to work taking the engine intake apart:

As I progressed through the install there were some steps that seemed downright missing vital details and calling BoostedTech didn't provide many answers about installing their kit. Between my general knowledge, some online searching and the FSM I was able to get things figured out. At one point the instructions simply mention to connect up the vacuum hoses and don't mention what connects up to what. Thankfully BoostedTech wonderfully labeled each bag of bolts individually and each of the hoses to where they go. The overall physical quality and packaging of the kit is top notch.

The AC lines had to be bent quite a bit to clear the steering pump and supercharger. I found that unbolting the clamp holding them in the middle of the engine and using a soft-face hammer helped get them where I wanted.

The included belt wouldn't install for the life of me unless I placed idler pulleys too close and over tensioned the belt. BoostedTech told me this would all be fine but I felt uncomfortable with that so I purchased a larger belt to fit. Around this point I realized that our build philosophies are very different which surprised me due to the well thought out nature of their kit. The luxurious break of follow instructions I dreamed of remained a dream.

(The air filter pictured was only used for testing the engine after installing, I'll be going with a better solution towards the end of my build.)

My 2004 year requires a the ECU to be programmed to go into open loop when the MAP sensor sees boost. If the ECU stays in closed loop it can run the engine too lean. When I purchased the kit there was an option for a replacement ECU that is already programmed for my Jeep which I opted for. This is where my major issues with BoostedTech started, my Jeep has SKIM enabled and the ECU they provided has a SKIM delete enabled of some sort. This allows the engine to run but for the SKIM key functionality to not work and for a "No Key" light to stay lit on the dash. I called BoostedTech on this issue and they told me it was my issue and suggested putting tape over the dash light and they wanted $140 to fix it. Now if it was my issue I get it, but I ordered a kit and provided all of the details about my Jeep they asked for. Additionally, as we talked further about how they'd resolve this issue it became clear that they had no clue how SKIM works. After I explained how I didn't understand how it was my responsibility to pay for their oversight (which they agreed with me that they should have asked me more questions during the checkout process — and will be adding those questions to better help future customers) they became defensive and unwilling to waver from the ECU problem being my issue.

Thankfully I have a few contacts that I called up including 1 of the only 2 known people in America (or maybe the world) who can fully program the Jeep ECUs. I sent my ECU to him to have SKIM re-enabled so it could be programmed to my SKIM module again. While he has my ECU he'll also be doing a few other small changes that I'll cover later in my build. The other person I contacted is the only person I know of who is able to pair my SKIM module with my ECU without the dealer. Once we're all done playing hot potato with my ECU I will hopefully have a properly functioning SKIM security system again. In the meantime if I need to move my Jeep I still have the factory ECU in my possession. Thankfully I didn't install it as a weekend project!

Overall I would buy another supercharger from BoostedTech, but with the understanding that there's not much support after purchasing and that I'd need to spend an extra chunk of cash to actually get it working properly.

First I washed the engine bay to make things nicer for me to work on and prevent any dust from getting into the engine. I removed the hoodliner which I plan to wash separately and reinstall towards the end of my build.

For use with the supercharger I needed to change my spark plugs out to some that are 1 heat range colder. BoostedTech suggests Autolite XP5224 Iridium. They came out of the box gapped from 0.000-0.050" so I spent the extra effort to make sure I had them all gapped at 0.029-0.031".

I setup my laptop on a table next to my Jeep with the PDF instructions from BoostedTech pulled up and got to work taking the engine intake apart:

As I progressed through the install there were some steps that seemed downright missing vital details and calling BoostedTech didn't provide many answers about installing their kit. Between my general knowledge, some online searching and the FSM I was able to get things figured out. At one point the instructions simply mention to connect up the vacuum hoses and don't mention what connects up to what. Thankfully BoostedTech wonderfully labeled each bag of bolts individually and each of the hoses to where they go. The overall physical quality and packaging of the kit is top notch.

The AC lines had to be bent quite a bit to clear the steering pump and supercharger. I found that unbolting the clamp holding them in the middle of the engine and using a soft-face hammer helped get them where I wanted.

The included belt wouldn't install for the life of me unless I placed idler pulleys too close and over tensioned the belt. BoostedTech told me this would all be fine but I felt uncomfortable with that so I purchased a larger belt to fit. Around this point I realized that our build philosophies are very different which surprised me due to the well thought out nature of their kit. The luxurious break of follow instructions I dreamed of remained a dream.

(The air filter pictured was only used for testing the engine after installing, I'll be going with a better solution towards the end of my build.)

My 2004 year requires a the ECU to be programmed to go into open loop when the MAP sensor sees boost. If the ECU stays in closed loop it can run the engine too lean. When I purchased the kit there was an option for a replacement ECU that is already programmed for my Jeep which I opted for. This is where my major issues with BoostedTech started, my Jeep has SKIM enabled and the ECU they provided has a SKIM delete enabled of some sort. This allows the engine to run but for the SKIM key functionality to not work and for a "No Key" light to stay lit on the dash. I called BoostedTech on this issue and they told me it was my issue and suggested putting tape over the dash light and they wanted $140 to fix it. Now if it was my issue I get it, but I ordered a kit and provided all of the details about my Jeep they asked for. Additionally, as we talked further about how they'd resolve this issue it became clear that they had no clue how SKIM works. After I explained how I didn't understand how it was my responsibility to pay for their oversight (which they agreed with me that they should have asked me more questions during the checkout process — and will be adding those questions to better help future customers) they became defensive and unwilling to waver from the ECU problem being my issue.

Thankfully I have a few contacts that I called up including 1 of the only 2 known people in America (or maybe the world) who can fully program the Jeep ECUs. I sent my ECU to him to have SKIM re-enabled so it could be programmed to my SKIM module again. While he has my ECU he'll also be doing a few other small changes that I'll cover later in my build. The other person I contacted is the only person I know of who is able to pair my SKIM module with my ECU without the dealer. Once we're all done playing hot potato with my ECU I will hopefully have a properly functioning SKIM security system again. In the meantime if I need to move my Jeep I still have the factory ECU in my possession. Thankfully I didn't install it as a weekend project!

Overall I would buy another supercharger from BoostedTech, but with the understanding that there's not much support after purchasing and that I'd need to spend an extra chunk of cash to actually get it working properly.

Last edited:

We share the same sentiments on BoostedTech. Great product, but don't be expecting a simple kit that includes everything you need to install it.

Let me know how you like it once you get it installed. This time around I'm putting a Sprintex supercharger on mine. I figured since I gave the BoostedTech one a try on my last TJ, I'm going to see how the Sprintex works this time around.

Let me know how you like it once you get it installed. This time around I'm putting a Sprintex supercharger on mine. I figured since I gave the BoostedTech one a try on my last TJ, I'm going to see how the Sprintex works this time around.

While cleaning up the wiring and hoses from the supercharger install I decided that the Split-Second box has no business being in my engine bay with all of the water crossings I do.

I placed the box behind my dash and ran the wires and hose through the firewall where the factory harness goes through. Cutting grommets with a knife tends to cause the grommet to continue to tear. Instead I sharpened the end of tubing and punched a hole in the grommet using a C-clamp. I then cut from the edge into that hole so i could fit the large plugs on the SS box through.

Electrical tape was used over all other exposed wires to help protect them from abrasion:

I placed the box behind my dash and ran the wires and hose through the firewall where the factory harness goes through. Cutting grommets with a knife tends to cause the grommet to continue to tear. Instead I sharpened the end of tubing and punched a hole in the grommet using a C-clamp. I then cut from the edge into that hole so i could fit the large plugs on the SS box through.

Electrical tape was used over all other exposed wires to help protect them from abrasion:

We share the same sentiments on BoostedTech. Great product, but don't be expecting a simple kit that includes everything you need to install it.

Let me know how you like it once you get it installed. This time around I'm putting a Sprintex supercharger on mine. I figured since I gave the BoostedTech one a try on my last TJ, I'm going to see how the Sprintex works this time around.

I still think the M90 and BoostedTech's brackets and mounting boost tub are the best design as far as packaging into the engine bay.

I will be sure to update once I get to driving and tuning. Right now I obviously can't speak as to how well the kit performs aside from "it starts".

I have the larger water pump housing (various Jeeps ended up with these) which causes the serpentine belt to rub against it after the SC install. I removed the belt and clearanced the housing with a bur on a grinder. After that the belt was able to clear just enough to slip a sheet of paper by.

Around the same time I had talked to Chris Jumonville who runs Wrangler TJ Forum and previously ran a BT supercharger. He mentioned that the low boost pulley that comes on the SC only put out a couple pounds of boost for him at sea level and suggested skipping it all together and going with the medium boost pulley which I did. I'm at 2000ft so I don't expect any issue with that either. That helped the belt clear the water pump even better.

I still think the M90 and BoostedTech's brackets and mounting boost tub are the best design as far as packaging into the engine bay.

I will be sure to update once I get to driving and tuning. Right now I obviously can't speak as to how well the kit performs aside from "it starts".

I haven't looked that in depth at the Sprintex unit, but I'll have to look more just to see what I'm dealing with. Supposedly it makes the same power as the M90 from what I'm told.

I have the larger water pump housing (various Jeeps ended up with these) which causes the serpentine belt to rub against it after the SC install.

I didn't have the larger water pump housing on my 2005. I didn't even realize there was a larger version.

While I was looking for a good spot to send the split-second plugs through the firewall I found the transfercase breather had gotten too close to the exhaust and cracked, while repairing that I noticed that water was in that line, so I lowered the transfercase to disconnect the full line. While removing that line I noticed a bunch of "forest dirt" (not hard packed mud but spongy junk) packed up behind the engine, digging that out I found the cowl drain to be completely clogged up.

I sprayed water down and used my finger to dig out dirt from the bottom end. What finally got it moving was a zip-it. And oh boy did that hole erupt unleashing sand and pine needles from it's depths. The pine needles I understand but I'm a bit shocked by how much sand was clogged up in that tunnel.

I sprayed water down and used my finger to dig out dirt from the bottom end. What finally got it moving was a zip-it. And oh boy did that hole erupt unleashing sand and pine needles from it's depths. The pine needles I understand but I'm a bit shocked by how much sand was clogged up in that tunnel.

I didn't have the larger water pump housing on my 2005. I didn't even realize there was a larger version.

I don't know if it was a difference in some of their molds or what, but I don't think it effects the functionality of the pump any just the housing size.

Last edited:

For the front axle, I had a slight change of plans and will be using a mounting plate on top tied into the diff cover instead of the bridge/truss.

Currie has 2 versions of their fabricated diff cover floating around. One is a Dana 70 cover and sticks out too far. The other one is the Dana 60 cover which is the one I need (Currie support doesn't understand that they have 2 covers, the correct part number is: 60-1005F).

This 60-1005F fabricated cover touches the ring gear on the RJ60VXR (it clears the regular RJ60). I suspect it's due to the larger Super 60 ring gear.

I ground down the 2 spots to clear the ring gear:

This cover does not include a breather like the forged cover did so I added that to my list of things to do later.

Currie has 2 versions of their fabricated diff cover floating around. One is a Dana 70 cover and sticks out too far. The other one is the Dana 60 cover which is the one I need (Currie support doesn't understand that they have 2 covers, the correct part number is: 60-1005F).

This 60-1005F fabricated cover touches the ring gear on the RJ60VXR (it clears the regular RJ60). I suspect it's due to the larger Super 60 ring gear.

I ground down the 2 spots to clear the ring gear:

This cover does not include a breather like the forged cover did so I added that to my list of things to do later.

I ground a little off the top of the cover so the plate will fit over top:

Currie's own JohnnyJoints don't fit with the TJ LCA bracket on the driver's side of the 60VXR housing (I'm unclear if this is an oversight on their end or of they are in the process of changing the physical size of their joint.).

So I did a little more grinding to the diff housing to make it fit:

So I did a little more grinding to the diff housing to make it fit: