This is not cheap. It is not easy. It is not going to clean your junk 100% and guarantee 100% adhesion of the Eastwood Internal Frame Coating...

However, it *does* do a very thorough job of cleaning out the rails, prepping them for painting with the Eastwood Internal Frame Coating, and ensuring that you have adequate drainage AND access in the future.

• Drill drain holes in the rails and access holes in the rear crossmember.

• Make an air gun that can get deep into the frame rails to blow them out.

• Use a sewer jet to bombard the remaining compacted crap the air gun misses.

• Use a pressure washer to spray in a good automotive degreaser.

• Use the sewer jet to carefully wash out the degreaser.

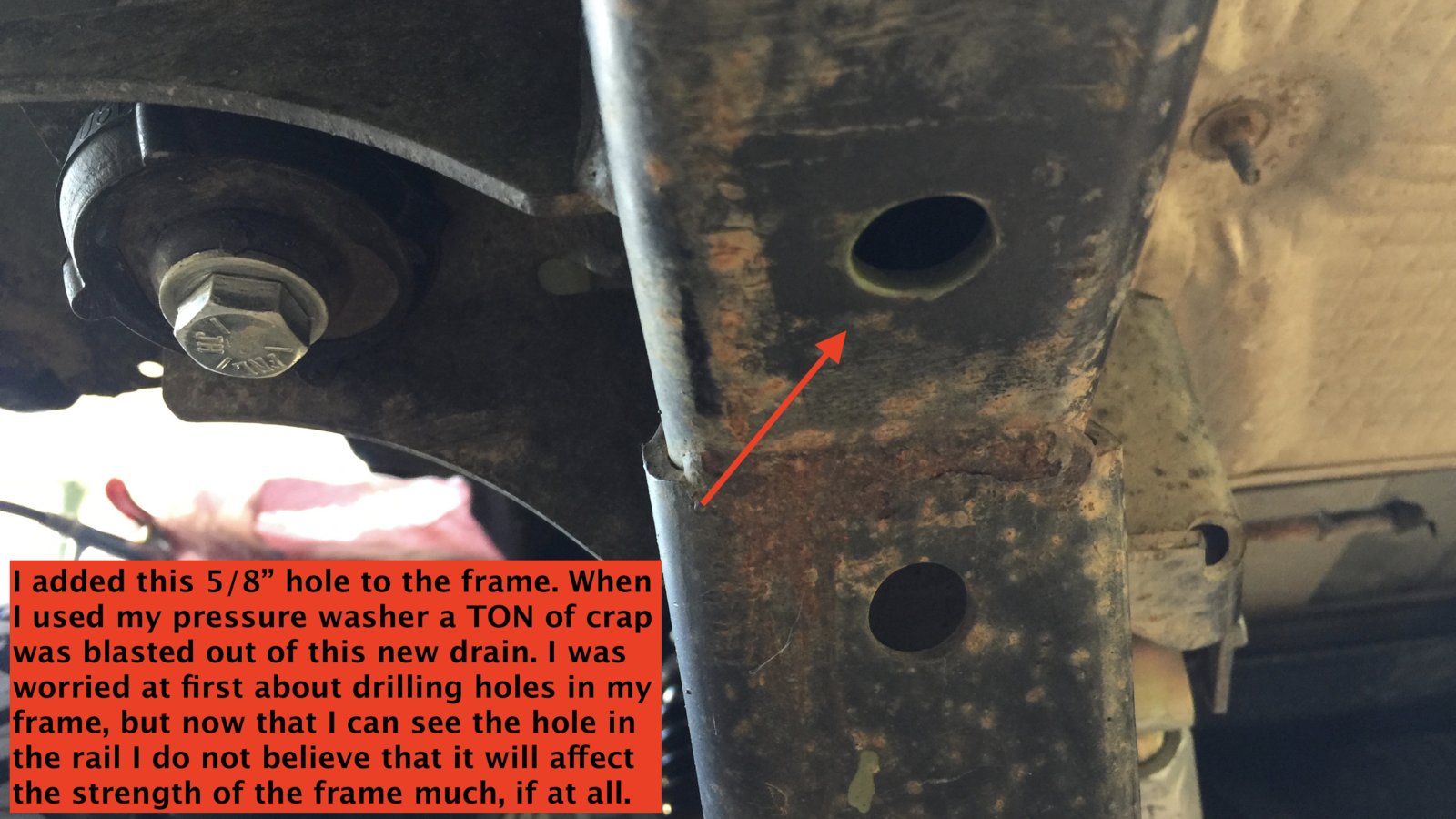

I drilled six holes in my frame for this project. I was worried about the structural integrity of the frame every time I started a new hole. After examining them carefully it does not appear that any of them are a danger. Jeep says to not add holes to the bottom or top of the rails, only to the sidewalls. However, Jeep drills holes in different locations on the frame over the various years without making any real alterations to the rails to compensate, so it is obvious to me that their words on this topic are typical corporate ass covering. If you only add small ones in places that are similar to where Jeep did they will be fine, I am pretty sure. I am not making a legal statement here. You risk your own junk if you do this to you Jeep. I will not pay you a single cent if your frame folds in half. YOU are choosing to do this to your vehicle, not me. This is only a guide for what I did to my vehicle. (Wow, speaking of covering your ass...)

My frame came with two of the needed drain holes drilled by the factory. These are behind the front wheel arches, about five inches behind the LCA brackets. I used them as guides for where I put the other two, which went in front of the rear LCA brackets. The factory holes are 5/8" (more or less) and my largest bit is a 5/8" one, so guess what size the two holes I added are?

My worst internal rust is in the last six inches of the tail end of both rails. The crossmember sort of caps the rail ends so that they do not drain at all. There are two holes about six inches from the end of the rail, but if you have wet mud in there it will not really ever drain out, so that moisture stays in the mud for long periods of time. I wanted a hole in each rail that was as close to the end as I could get. The lower bumper bolts go into the holes in the ends of the rails via captured nuts, but these are not along the centerline of the rails. The offset is enough to add a 3/8" hole next to the captured nut fixture. I looked this over about a hundred times before drilling. For several days I scratched my head over this. I imagined collisions from all angles, and when a bumper is installed (especially with proper frame tie-ins) I cannot see how these two holes could affect anything in a meaningful way. So I drilled them out.

After that I spent a few days at work farting around with ways to get access to the rails from one end to the other in a single shot. I stumbled across a thread on another forum where a guy had cut these huge holes in the crossmember to allow him to pressure wash and blow out the rails, but his method still seemed to be fairly incomplete, and those holes were HUGE! He assured me that with a bumper installed there would be no loss of structural integrity. I digested this idea for a few more days.

Then I stumbled across a sewer jet called the Clog Hog. It was too big to use in our frames unless you cut a 1" hole in the crossmember cap. It also required a pressure washer that was a lot more powerful than what I own. But for about a hundred bucks you could buy a brand new version that had a smaller head OD, was much shorter, and would work with my AR Blue Clean electric washer. (The AR390SS is the smallest one the Clog Hog "Needle Nose" attachment will work with, and that is what I own, so SCORE!)

I also wanted a really good way to get compressed air all the way into the frame. The air is most effective right at the tip of the nozzle, so I wanted a way to get the nozzle tip all the way through the frame. I ended up with a cheapo Husky air gun that I enhanced a bit. I added a three foot grease gun hose, a male/male coupler and a rubber air gun tip. It is amazing, too!

I used Simple Green Pro HD (which is not green at all but pale purple) as my degreaser. I mixed it 1:3 or a half a cup of degreaser to a cup and a half of water. I ran that through every stinking hole in the frame with the soap tip of my pressure washer. It foamed up pretty well. I let the stuff "cook" for 15 minutes. DO NOT ALLOW THIS STUFF TO DRY ON THE PAINT OR STEEL. You need to wash it off while it is wet. Do not ignore this step.

So, from beginning to end:

I pulled my rear bumper, drilled my four drain holes, drilled my two access holes, made sure everything was well de-burred so the Clog Hog (and my finger tips) were not cut or gouged, assembled my 36" flexible air gun and blew out as much dirt and trash as I could. I reversed direction at each hole many times. When it seemed that no more would come out, I would switch direction. When that was tapped out I would reverse the direction I was blowing again and HEY more crap would explode out the open, downstream holes. It took me hours to get most of it out. I ended up with a 5 gallon bucket about half full of sand and river silt. Remember that a huge part of what came out blew away on the wind; this bucket contained what was left over!

Once the frame was more or less free of the loose stuff I ran magnets (and fingers) into all the big holes to fish out whatever I could that was too heavy for the air gun. (I also did the body mount torque box channels on the tub. Net catch from these channels: a mechanical pencil, a Bic pen, three water bottle caps, one beer bottle cap, a handful of gravel and handful of pocket change. The frame mostly got me rust chips and stones.)

Next step was to fire up the Clog Hog. It is self-propelled: there is a single jet forward, but three that point back at a 45º angle. These clean, too, but mainly they push the head forward. Super cool. It was cold out when I did this part and I got soaked. But I was smiling because the Clog Hog is my new friend. HAHAHA!!! That thing was fun to use, man!

Once the frame and body mount channels had been washed out I let them dry for a few days. It was very cold out when I did this, so drying time was pretty long. The next more-or-less warm day was about a week later, and it was actually in the 70s (in January!) so I decided to to do the degreasing part and see how it went. I started early and had no way to run the degreaser through the Clog Hog, so I had to use the gun and wand with the Soap tip installed. No matter. The pressure washer managed to blow tons of degreaser into the frame and body mount channels - no problem. I did not need direct high pressure water in this case. I just needed the degreaser to get all over the internal surfaces of the rails and channels. Then I let it soak as per my above comments.

The Clog Hog then blew the snot out of everything again (still laughing) until there was absolutely no remaining suds in anything except my hair and clothes.

I decided to let stuff dry for two hours after having run my homemade air gun through everything to remove as much standing water as possible. The less that has to evaporate the faster it will be dried out. After two hours of watching Netflix my alarm went off. I went out to check, expecting to find wetness everywhere. It was bone dry. The degreaser seemed to clean it well enough that it was able to cook off the last water very fast. I decided to paint right then as I had enough sunlight left.

Three cans later and the coverage looked really good. It was about to get down below freezing highs and single digit lows for about a week. The body mount channels did not dry out well, so I decided to do them later. I would allow stuff to sit until it warmed up again.

A week later I check inside the frame with an endoscope (borescope) and the coverage was NOT all that wonderful. It looked great near all the holes, but there were patches inside that got very little of the Eastwood Internal Frame Coating on them. I am glad I checked. I ordered another can for touchups and I got one can of the black. I had bought the green because it was much easier to see the coverage. My inside of the body mount channels is that green/gray Jeep factory primer and very little paint at all. I decided to use black for these for the same reason: it was easier to see where it did not cover well.

Please note that the body mount channels are not fully welded and have zero seam sealer. When I sprayed the Eastwood Internal Frame Coating in your hair, on your face, up your nose, etc. FULLY tape off the seams from one end to the other, on both sides of both boxes or you will have a hell of a time cleaning your face with mineral spirits. This stuff will stay on your skin for over two weeks. Go-Jo and Fast Orange will not remove *any* of it from you, and forget regular soap... TAPE THOSE SEAMS!

Here are some photos of the holes I drilled, the tool I made, the tool I bought, and the results of the work.

Cheers!

Rear Crossmember Hole - 5/8" - A 3/4" hole would have been much more useful.

Air gun from my inexpensive Husky kit from HD with 1/4" NPT fitting...

Rubber blow out tip and a male/male 1/8" NPT coupler to 36" of 40,000 PSI grease gun hose...

Passenger rear added 5/8" hole...

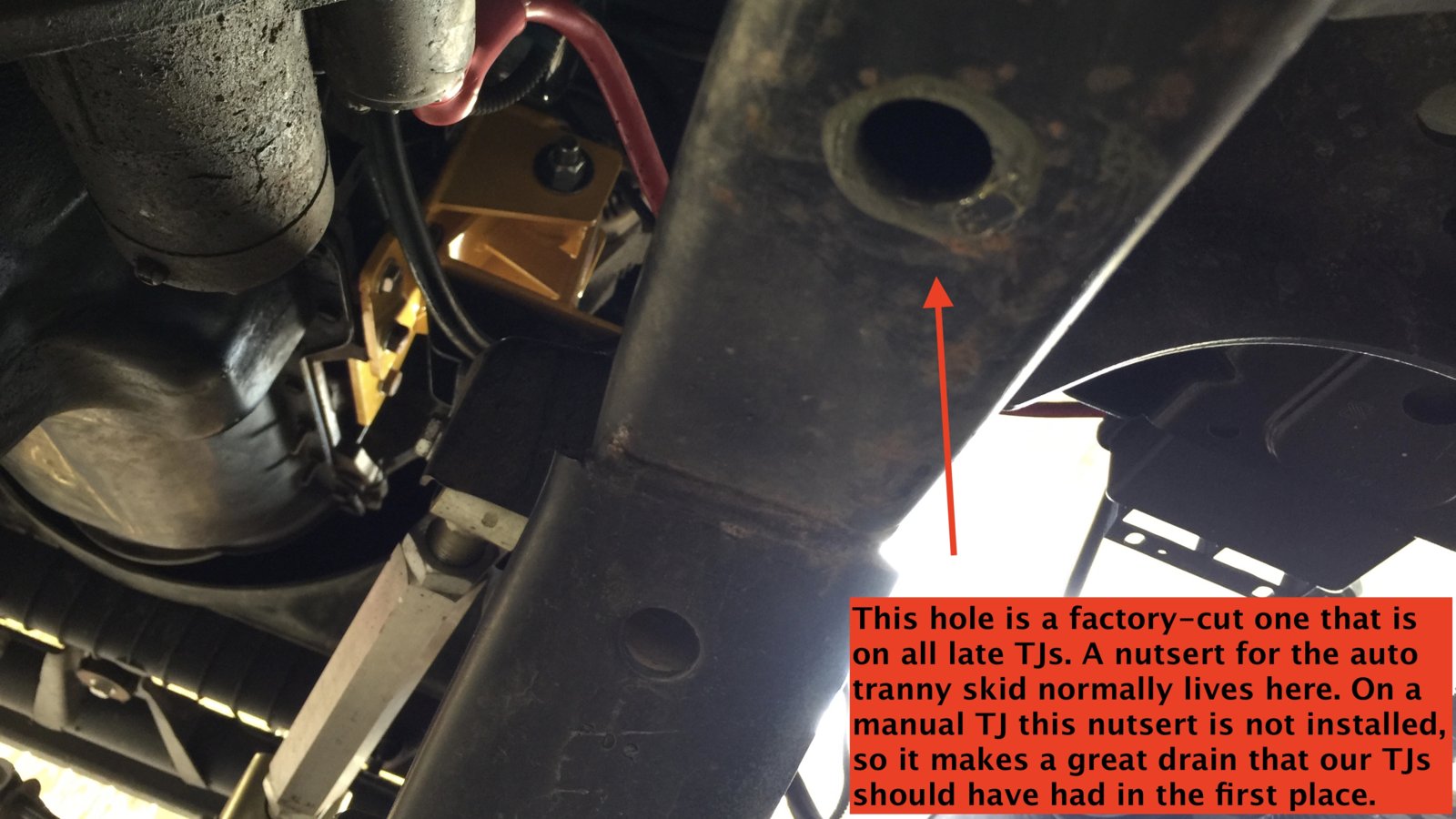

Passenger front stock drain hole...

Driver rear added 5/8" drain hole...

Driver front stock drain hole...

Driver side added 3/8" drain hole...

Passenger side added 3/8" drain hole...

My air gun does not fit into my 5/8" access holes. Rats...

My air gun fits very well through a 3/4" hole...

Green inside the black frame. Black inside the green tub. Nice...

This is the Clog Hog "Needle Nose" and it simply rocks for this job...

The Clog Hog fits in the 5/8" hole very neatly...

However, it *does* do a very thorough job of cleaning out the rails, prepping them for painting with the Eastwood Internal Frame Coating, and ensuring that you have adequate drainage AND access in the future.

• Drill drain holes in the rails and access holes in the rear crossmember.

• Make an air gun that can get deep into the frame rails to blow them out.

• Use a sewer jet to bombard the remaining compacted crap the air gun misses.

• Use a pressure washer to spray in a good automotive degreaser.

• Use the sewer jet to carefully wash out the degreaser.

I drilled six holes in my frame for this project. I was worried about the structural integrity of the frame every time I started a new hole. After examining them carefully it does not appear that any of them are a danger. Jeep says to not add holes to the bottom or top of the rails, only to the sidewalls. However, Jeep drills holes in different locations on the frame over the various years without making any real alterations to the rails to compensate, so it is obvious to me that their words on this topic are typical corporate ass covering. If you only add small ones in places that are similar to where Jeep did they will be fine, I am pretty sure. I am not making a legal statement here. You risk your own junk if you do this to you Jeep. I will not pay you a single cent if your frame folds in half. YOU are choosing to do this to your vehicle, not me. This is only a guide for what I did to my vehicle. (Wow, speaking of covering your ass...)

My frame came with two of the needed drain holes drilled by the factory. These are behind the front wheel arches, about five inches behind the LCA brackets. I used them as guides for where I put the other two, which went in front of the rear LCA brackets. The factory holes are 5/8" (more or less) and my largest bit is a 5/8" one, so guess what size the two holes I added are?

My worst internal rust is in the last six inches of the tail end of both rails. The crossmember sort of caps the rail ends so that they do not drain at all. There are two holes about six inches from the end of the rail, but if you have wet mud in there it will not really ever drain out, so that moisture stays in the mud for long periods of time. I wanted a hole in each rail that was as close to the end as I could get. The lower bumper bolts go into the holes in the ends of the rails via captured nuts, but these are not along the centerline of the rails. The offset is enough to add a 3/8" hole next to the captured nut fixture. I looked this over about a hundred times before drilling. For several days I scratched my head over this. I imagined collisions from all angles, and when a bumper is installed (especially with proper frame tie-ins) I cannot see how these two holes could affect anything in a meaningful way. So I drilled them out.

After that I spent a few days at work farting around with ways to get access to the rails from one end to the other in a single shot. I stumbled across a thread on another forum where a guy had cut these huge holes in the crossmember to allow him to pressure wash and blow out the rails, but his method still seemed to be fairly incomplete, and those holes were HUGE! He assured me that with a bumper installed there would be no loss of structural integrity. I digested this idea for a few more days.

Then I stumbled across a sewer jet called the Clog Hog. It was too big to use in our frames unless you cut a 1" hole in the crossmember cap. It also required a pressure washer that was a lot more powerful than what I own. But for about a hundred bucks you could buy a brand new version that had a smaller head OD, was much shorter, and would work with my AR Blue Clean electric washer. (The AR390SS is the smallest one the Clog Hog "Needle Nose" attachment will work with, and that is what I own, so SCORE!)

I also wanted a really good way to get compressed air all the way into the frame. The air is most effective right at the tip of the nozzle, so I wanted a way to get the nozzle tip all the way through the frame. I ended up with a cheapo Husky air gun that I enhanced a bit. I added a three foot grease gun hose, a male/male coupler and a rubber air gun tip. It is amazing, too!

I used Simple Green Pro HD (which is not green at all but pale purple) as my degreaser. I mixed it 1:3 or a half a cup of degreaser to a cup and a half of water. I ran that through every stinking hole in the frame with the soap tip of my pressure washer. It foamed up pretty well. I let the stuff "cook" for 15 minutes. DO NOT ALLOW THIS STUFF TO DRY ON THE PAINT OR STEEL. You need to wash it off while it is wet. Do not ignore this step.

So, from beginning to end:

I pulled my rear bumper, drilled my four drain holes, drilled my two access holes, made sure everything was well de-burred so the Clog Hog (and my finger tips) were not cut or gouged, assembled my 36" flexible air gun and blew out as much dirt and trash as I could. I reversed direction at each hole many times. When it seemed that no more would come out, I would switch direction. When that was tapped out I would reverse the direction I was blowing again and HEY more crap would explode out the open, downstream holes. It took me hours to get most of it out. I ended up with a 5 gallon bucket about half full of sand and river silt. Remember that a huge part of what came out blew away on the wind; this bucket contained what was left over!

Once the frame was more or less free of the loose stuff I ran magnets (and fingers) into all the big holes to fish out whatever I could that was too heavy for the air gun. (I also did the body mount torque box channels on the tub. Net catch from these channels: a mechanical pencil, a Bic pen, three water bottle caps, one beer bottle cap, a handful of gravel and handful of pocket change. The frame mostly got me rust chips and stones.)

Next step was to fire up the Clog Hog. It is self-propelled: there is a single jet forward, but three that point back at a 45º angle. These clean, too, but mainly they push the head forward. Super cool. It was cold out when I did this part and I got soaked. But I was smiling because the Clog Hog is my new friend. HAHAHA!!! That thing was fun to use, man!

Once the frame and body mount channels had been washed out I let them dry for a few days. It was very cold out when I did this, so drying time was pretty long. The next more-or-less warm day was about a week later, and it was actually in the 70s (in January!) so I decided to to do the degreasing part and see how it went. I started early and had no way to run the degreaser through the Clog Hog, so I had to use the gun and wand with the Soap tip installed. No matter. The pressure washer managed to blow tons of degreaser into the frame and body mount channels - no problem. I did not need direct high pressure water in this case. I just needed the degreaser to get all over the internal surfaces of the rails and channels. Then I let it soak as per my above comments.

The Clog Hog then blew the snot out of everything again (still laughing) until there was absolutely no remaining suds in anything except my hair and clothes.

I decided to let stuff dry for two hours after having run my homemade air gun through everything to remove as much standing water as possible. The less that has to evaporate the faster it will be dried out. After two hours of watching Netflix my alarm went off. I went out to check, expecting to find wetness everywhere. It was bone dry. The degreaser seemed to clean it well enough that it was able to cook off the last water very fast. I decided to paint right then as I had enough sunlight left.

Three cans later and the coverage looked really good. It was about to get down below freezing highs and single digit lows for about a week. The body mount channels did not dry out well, so I decided to do them later. I would allow stuff to sit until it warmed up again.

A week later I check inside the frame with an endoscope (borescope) and the coverage was NOT all that wonderful. It looked great near all the holes, but there were patches inside that got very little of the Eastwood Internal Frame Coating on them. I am glad I checked. I ordered another can for touchups and I got one can of the black. I had bought the green because it was much easier to see the coverage. My inside of the body mount channels is that green/gray Jeep factory primer and very little paint at all. I decided to use black for these for the same reason: it was easier to see where it did not cover well.

Please note that the body mount channels are not fully welded and have zero seam sealer. When I sprayed the Eastwood Internal Frame Coating in your hair, on your face, up your nose, etc. FULLY tape off the seams from one end to the other, on both sides of both boxes or you will have a hell of a time cleaning your face with mineral spirits. This stuff will stay on your skin for over two weeks. Go-Jo and Fast Orange will not remove *any* of it from you, and forget regular soap... TAPE THOSE SEAMS!

Here are some photos of the holes I drilled, the tool I made, the tool I bought, and the results of the work.

Cheers!

Rear Crossmember Hole - 5/8" - A 3/4" hole would have been much more useful.

Air gun from my inexpensive Husky kit from HD with 1/4" NPT fitting...

Rubber blow out tip and a male/male 1/8" NPT coupler to 36" of 40,000 PSI grease gun hose...

Passenger rear added 5/8" hole...

Passenger front stock drain hole...

Driver rear added 5/8" drain hole...

Driver front stock drain hole...

Driver side added 3/8" drain hole...

Passenger side added 3/8" drain hole...

My air gun does not fit into my 5/8" access holes. Rats...

My air gun fits very well through a 3/4" hole...

Green inside the black frame. Black inside the green tub. Nice...

This is the Clog Hog "Needle Nose" and it simply rocks for this job...

The Clog Hog fits in the 5/8" hole very neatly...