M

motomick76

Guest

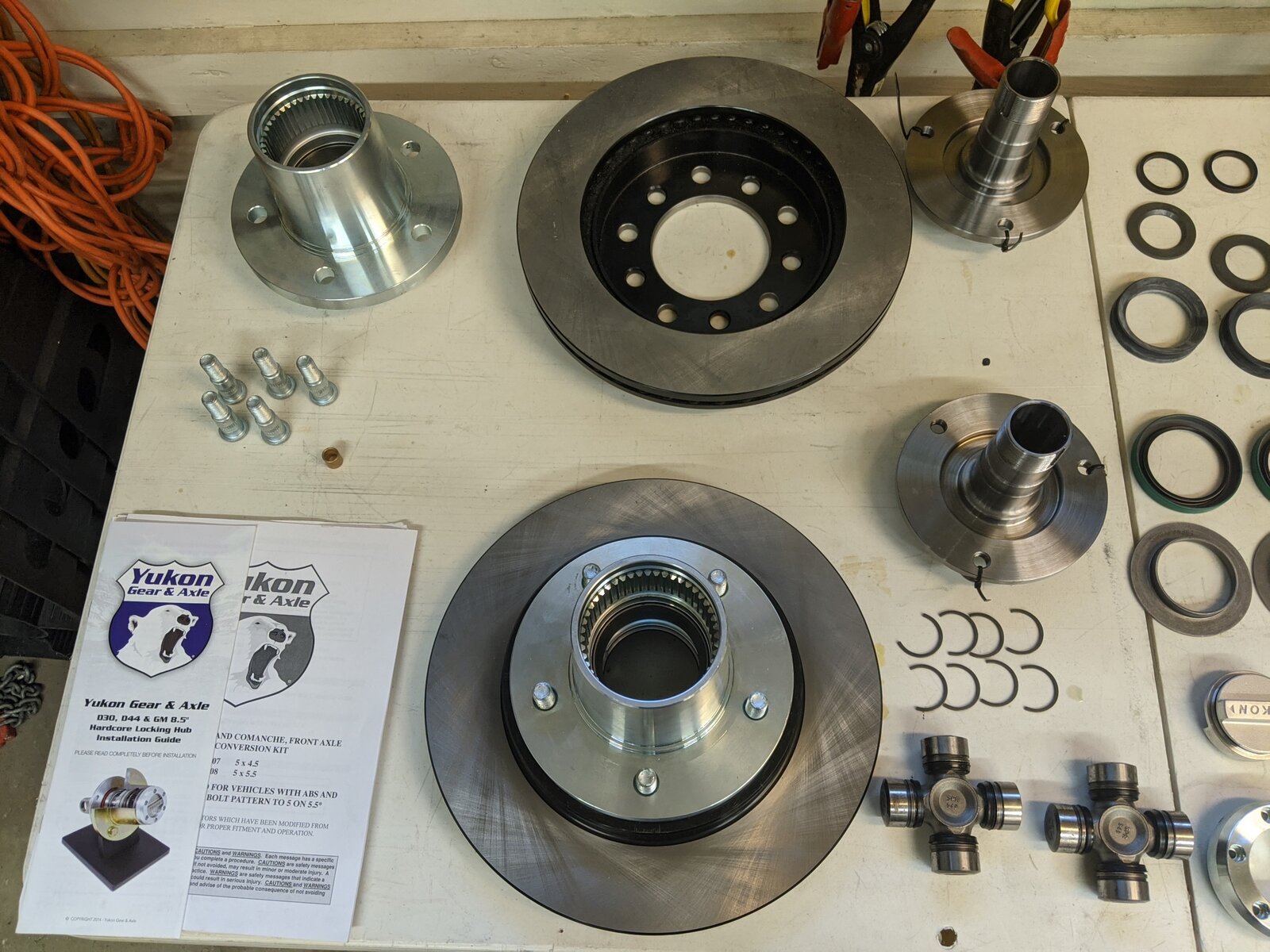

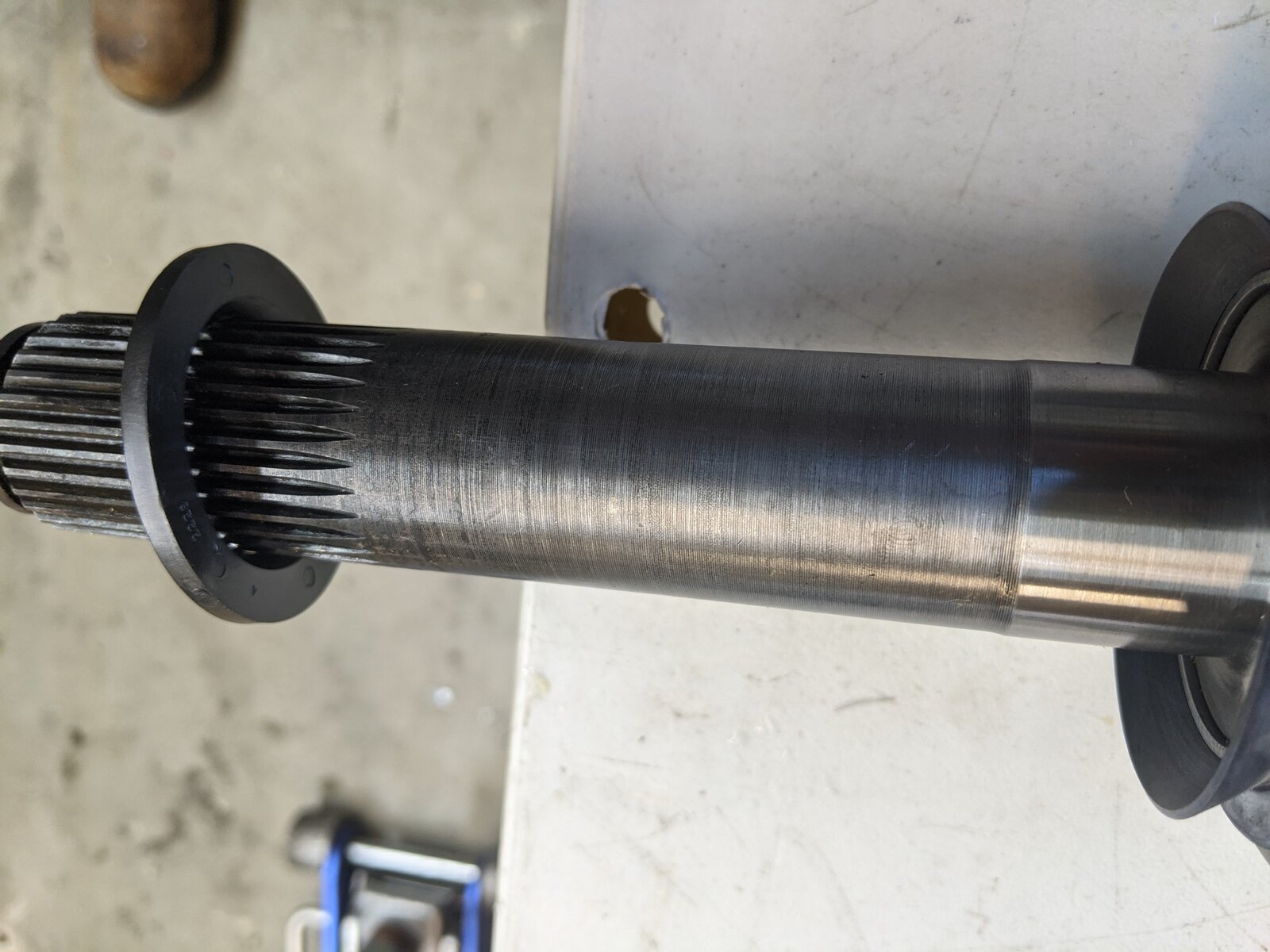

There are two hub kits available for the Dana 30 from Yukon, the WU-07 and WU-08. Both are pretty spendy, 07 being just less than $1000, and the 08 right at $1450. I chose the 08 feeling it was a bit more robust hub unit, with the 07 being very similar to old Bronco II hub units. I have no real world experience to verify the strength of either one, just personal preference. The second biggest difference it hub pattern, the 07 kit keeps the standard 5 x 4.5 pattern, and the 08 changes it to a 5 x 5.5 pattern. This bigger pattern was not a large issue for me, as I was also installing a Yukon Super 88 kit also, which lets you choose between a 4.5 or 5.5 pattern. This kit includes the stub shafts, 720 u-joints, but not the axle shafts. The stub shafts are a 4340 hardened, so I got some 4340, 27 spline axle shafts also.

There is a downfall in this, if you have a Black Magic Brake kit installed, you are going to end up with some rotors that are unusable, (The ones that come in the kit). I currently had the 15" kit installed, and one advantage to that kit is it accepts 15" or 16" rotors. I was going to 17" rims, makes perfect sense to upgrade to 16" rotors since I had to get new ones anyway. Blaine is able to take his rotors, wave his wand, and wolla!, a set of rotors that will work with either hub kit with his brake kit.

First you must get the kit, then send him the spindle, bearing hub, inner and outer races, inner and outer bearings. wheel studs. and inner spindle nut. He machines his rotors and makes a few other adjustments, makes some measurements, and sends back everything with his rotors. Once all of that is back, it is ready to assemble.

There are a few tools that you will need, and one I did not foresee needing and that was a shop press. You will need a press to get the races in if Blane did not do that for you and to install the wheel studs into the rotor/hub assembly. So I went to everyone's favorite high quality tool store, HF. I selected one of their top of the line shop presses, a 20 ton unit. Any smart person knows there are always coupons available, and I found one that gave me 30 or 40 bucks off, so I had less that $180 bucks in a shop press.

Second you will need a 4 lug socket for a Dana 44. I got mine at NAPA, worked great for this project. Also needed is a 36mm socket to get the unit bearing nut off, snap ring pliers, can of extreme pressure premium red grease, various tools and you should be ready to go.

I get OCD when assembling anything, and lay everything out on a table, organize it, and do a parts count before I dig into any project to ensure I have all the parts, and am familiar with assembly with everything. I do a 'dry run' to ensure fit, as soon everything is going to be smothered in grease.

First step is to assemble the stub shafts, u-joints, and axles for both sides. We have all done this, pretty simple to do. I then got the front end on stands, took wheels off, and began to take calipers off. I removed the 19mm bolts from the knuckle, and be careful, as the brake line is probably short and will want to secure the caliper and assemble to the control arm with zip ties to prevent damage to brake line.

Now it is time to disassemble the hub unit. Take out cotter pin, lock nut, and then 36mm nut. On the back side remove the three 19mm bolts holding the unit bearing. Remove the unit bearing from the knuckle. It might need some taps from a hammer to get it loose. Unit bearing is out, remove the axle shaft. With just the bare knuckle, we are ready for installation of new axles.

Before installing the axles, a few parts need to be installed. First the metal dust shield needs to be installed on outer axle shaft.

Then install v-seal (thick side towards yoke) on outer shaft. It should fit snug over the dust shield.

Then there is the plastic thrust washer, in the lower left of the above picture. The chamfered edge you see faces towards the inside of outer axle, so it fits flush.

Now it is time to install the axles. With the old ones removed, the new ones should slide right in.

The spindle bearing is now ready to install. First, there is a small seal that goes on back of spindle. Make sure seal is placed cup side is facing away from needle bearing.

Install the disk brake dust shield, the spindle spacer, and finally the spindle. Install 3 bolts and torque to 75 ft-lbs.

When Blaine had my hub and bearings, he was king enough to install the races into the hub. Normally this would be the next step, but that was already done. Once that is completed, the rotors, hub, and wheel studs need to be assembled. The wheel studs press through the back of rotor into the hub, and this press fit holds the rotor and hub assembly together. This is where the shop press is needed, for installing the races and studs. I had an ides the wheel studs would be tight fit, and they definitely were. There is no way these could be installed without a press, this is a very tight fit, and I could see the press flexing as I was driving everything together.

Now the rotor/hub assembly is ready for bearings. If you have gloves, I highly recommend them. There are different ways to pack bearings, some like a bearing packer, some people use their palm of their hand. I have always done it with my palm. I put a bunch on my palm, and push it in the bottom of the bearing until grease comes out the other side. I slathered the races, installed the bearing, and then drove in the rear hub seal in. There is a front and rear bearing, pay attention to which bearing goes where. Once you drive in the rear seal, the rear bearing is in.

If you do mess up, seals are readily available. The rear seal is a CR 22353, which can be found at NAPA stores. The rear bearing is a Timken LM 102949 and outer bearing is a Timken LM501349.

With the rear bearing and seal installed, it is time to slide the rotor/hub assembly onto the spindle. It is a tight fit, and be cautious of the rear seal. Once it is slid on, install the smaller outer bearing on inboard side of hub. Ensure the bearing is packed, and the inner race is coated before installing the bearing. The bearing should slide in easily and the rotor assembly should set level. I recommend to not be skimpy with the grease in this area. Now install larger spindle nut, and you will need the special 4 lug socket. Take note of the position of the pin on the spindle nut, it must face outward. Torque the spindle nut to 50 ft-lbs, and rotate the rotor/hub assembly while tightening. This is to seat the bearings. Then turn the nut counterclockwise 1/4 turn, and retorque to 15-20 ft-lbs. Install lock washer onto spindle nut. Ensure the pin from the spindle nut engages the hole in locking nut. Some adjustment may be needed. Install the smaller spindle nut, and torque to 125 to 150 ft-lbs.

Now it is time to assemble the locking hub. All of the components going in need a coating to grease on them. Starting with the hub, coat the inside with grease. Next, install the spring retainer, and flat end must face out.

Next install the coil spring. Verify it compresses easily and not interfere with anything.

Coat spacer with grease on all sides and install over outer axle.

Verify inner axle has coating of grease. Coat the coupler and driver with grease. Mesh the two together, and install in the hub. You will be pushing against the spring, and the hub may need rotation to get the assembly to slide in. With the assembly compressed, install the snap ring onto the outer axle.

Coat the cam spacer and retainer plate in grease. Install the cam spacer into retainer plate by aligning the ears with the notches in the plate. Install into the hub. Install the hub snap ring, Verify it is fully seated into the groove of the hub.

Test the operation of cam spacer by pushing it in and out. It should freely move. Now it is time to install the selector and bezel. Slide them together and align them to 'Lock'. Apply a light coat of grease on the back side of selector assembly. Slide assembly on hub, it should easily go on. Install the nylon washers on the 10-24 bolts. Install bolts and tighten to 22 in-lbs. Turn selector to 'Free' and back to 'Lock', verifying smooth operation and engagement of axle. Install brake caliper assembly and wheel. Ready to go!

There is a downfall in this, if you have a Black Magic Brake kit installed, you are going to end up with some rotors that are unusable, (The ones that come in the kit). I currently had the 15" kit installed, and one advantage to that kit is it accepts 15" or 16" rotors. I was going to 17" rims, makes perfect sense to upgrade to 16" rotors since I had to get new ones anyway. Blaine is able to take his rotors, wave his wand, and wolla!, a set of rotors that will work with either hub kit with his brake kit.

First you must get the kit, then send him the spindle, bearing hub, inner and outer races, inner and outer bearings. wheel studs. and inner spindle nut. He machines his rotors and makes a few other adjustments, makes some measurements, and sends back everything with his rotors. Once all of that is back, it is ready to assemble.

There are a few tools that you will need, and one I did not foresee needing and that was a shop press. You will need a press to get the races in if Blane did not do that for you and to install the wheel studs into the rotor/hub assembly. So I went to everyone's favorite high quality tool store, HF. I selected one of their top of the line shop presses, a 20 ton unit. Any smart person knows there are always coupons available, and I found one that gave me 30 or 40 bucks off, so I had less that $180 bucks in a shop press.

Second you will need a 4 lug socket for a Dana 44. I got mine at NAPA, worked great for this project. Also needed is a 36mm socket to get the unit bearing nut off, snap ring pliers, can of extreme pressure premium red grease, various tools and you should be ready to go.

I get OCD when assembling anything, and lay everything out on a table, organize it, and do a parts count before I dig into any project to ensure I have all the parts, and am familiar with assembly with everything. I do a 'dry run' to ensure fit, as soon everything is going to be smothered in grease.

First step is to assemble the stub shafts, u-joints, and axles for both sides. We have all done this, pretty simple to do. I then got the front end on stands, took wheels off, and began to take calipers off. I removed the 19mm bolts from the knuckle, and be careful, as the brake line is probably short and will want to secure the caliper and assemble to the control arm with zip ties to prevent damage to brake line.

Now it is time to disassemble the hub unit. Take out cotter pin, lock nut, and then 36mm nut. On the back side remove the three 19mm bolts holding the unit bearing. Remove the unit bearing from the knuckle. It might need some taps from a hammer to get it loose. Unit bearing is out, remove the axle shaft. With just the bare knuckle, we are ready for installation of new axles.

Before installing the axles, a few parts need to be installed. First the metal dust shield needs to be installed on outer axle shaft.

Then install v-seal (thick side towards yoke) on outer shaft. It should fit snug over the dust shield.

Then there is the plastic thrust washer, in the lower left of the above picture. The chamfered edge you see faces towards the inside of outer axle, so it fits flush.

Now it is time to install the axles. With the old ones removed, the new ones should slide right in.

The spindle bearing is now ready to install. First, there is a small seal that goes on back of spindle. Make sure seal is placed cup side is facing away from needle bearing.

Install the disk brake dust shield, the spindle spacer, and finally the spindle. Install 3 bolts and torque to 75 ft-lbs.

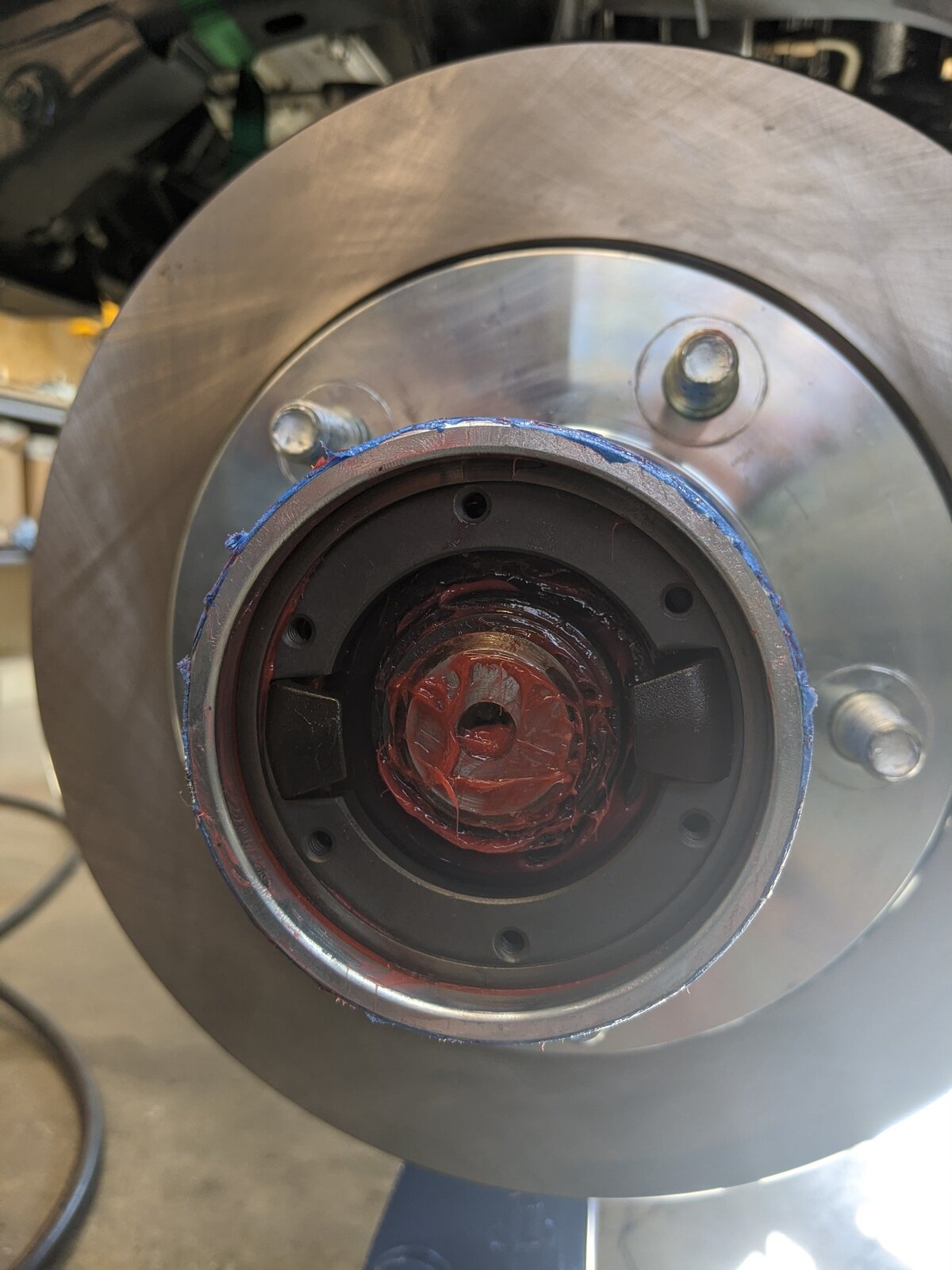

When Blaine had my hub and bearings, he was king enough to install the races into the hub. Normally this would be the next step, but that was already done. Once that is completed, the rotors, hub, and wheel studs need to be assembled. The wheel studs press through the back of rotor into the hub, and this press fit holds the rotor and hub assembly together. This is where the shop press is needed, for installing the races and studs. I had an ides the wheel studs would be tight fit, and they definitely were. There is no way these could be installed without a press, this is a very tight fit, and I could see the press flexing as I was driving everything together.

Now the rotor/hub assembly is ready for bearings. If you have gloves, I highly recommend them. There are different ways to pack bearings, some like a bearing packer, some people use their palm of their hand. I have always done it with my palm. I put a bunch on my palm, and push it in the bottom of the bearing until grease comes out the other side. I slathered the races, installed the bearing, and then drove in the rear hub seal in. There is a front and rear bearing, pay attention to which bearing goes where. Once you drive in the rear seal, the rear bearing is in.

If you do mess up, seals are readily available. The rear seal is a CR 22353, which can be found at NAPA stores. The rear bearing is a Timken LM 102949 and outer bearing is a Timken LM501349.

With the rear bearing and seal installed, it is time to slide the rotor/hub assembly onto the spindle. It is a tight fit, and be cautious of the rear seal. Once it is slid on, install the smaller outer bearing on inboard side of hub. Ensure the bearing is packed, and the inner race is coated before installing the bearing. The bearing should slide in easily and the rotor assembly should set level. I recommend to not be skimpy with the grease in this area. Now install larger spindle nut, and you will need the special 4 lug socket. Take note of the position of the pin on the spindle nut, it must face outward. Torque the spindle nut to 50 ft-lbs, and rotate the rotor/hub assembly while tightening. This is to seat the bearings. Then turn the nut counterclockwise 1/4 turn, and retorque to 15-20 ft-lbs. Install lock washer onto spindle nut. Ensure the pin from the spindle nut engages the hole in locking nut. Some adjustment may be needed. Install the smaller spindle nut, and torque to 125 to 150 ft-lbs.

Now it is time to assemble the locking hub. All of the components going in need a coating to grease on them. Starting with the hub, coat the inside with grease. Next, install the spring retainer, and flat end must face out.

Next install the coil spring. Verify it compresses easily and not interfere with anything.

Coat spacer with grease on all sides and install over outer axle.

Verify inner axle has coating of grease. Coat the coupler and driver with grease. Mesh the two together, and install in the hub. You will be pushing against the spring, and the hub may need rotation to get the assembly to slide in. With the assembly compressed, install the snap ring onto the outer axle.

Coat the cam spacer and retainer plate in grease. Install the cam spacer into retainer plate by aligning the ears with the notches in the plate. Install into the hub. Install the hub snap ring, Verify it is fully seated into the groove of the hub.

Test the operation of cam spacer by pushing it in and out. It should freely move. Now it is time to install the selector and bezel. Slide them together and align them to 'Lock'. Apply a light coat of grease on the back side of selector assembly. Slide assembly on hub, it should easily go on. Install the nylon washers on the 10-24 bolts. Install bolts and tighten to 22 in-lbs. Turn selector to 'Free' and back to 'Lock', verifying smooth operation and engagement of axle. Install brake caliper assembly and wheel. Ready to go!