This past weekend I made an emergency trip from upstate NY to my sister's in Cape Coral (ground zero for Hurricane Ian) to help her recover from the hurricane. I towed my Safari Cab trailer down full of emergency supplies - water, gasoline, huge tarps, drinking water, washing water etc.

Along the way from upstate NY to South Florida and back at probably half the gas or food stops I made someone came up to me to ask about the trailer and I probably got a half dozen thumbs up from people passing my on the highway so I thought if that many people liked the trailer on that trip maybe people here would be interested in it.

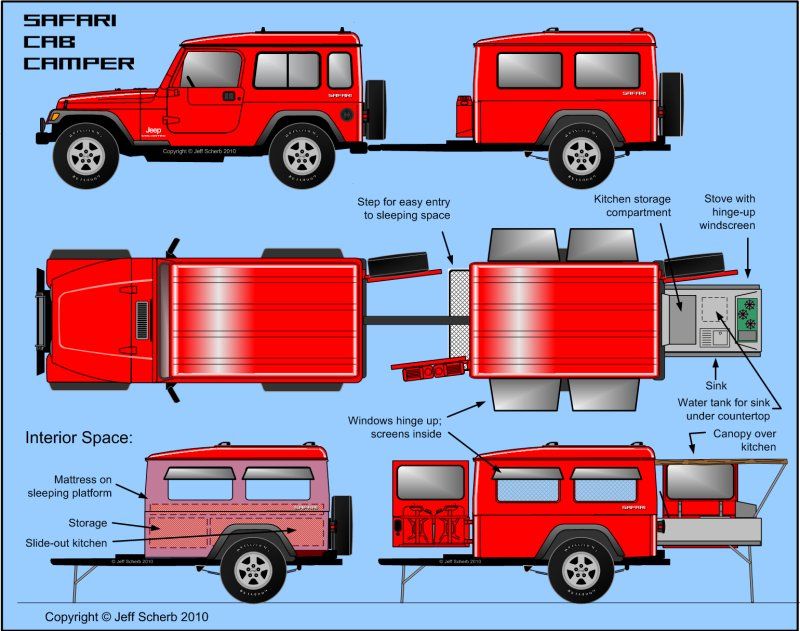

The camper top was part of the original design for my LJ Safari Cab hardtop - I did this sketch in 2010 when I was working on the Safari Cab design and I designed the molds for the fiberglass parts such that variations of the parts could be made for either the Jeep hardtop or the camper top version.

After finishing the hardtop for the LJ, in order to make the camper I needed a Jeep-tub trailer to put the camper top on, so I used the back half of the LJ tub I cut off when making my pickup and the back half of a YJ tub I got from a friend, and put them together to make a tub the correct length to work with the LJ Safari Cab parts. These photos show the tub before painting; the red parts used to be part of the Jeep that's now the pickup and the black parts are from a YJ.

Because each of the tubs had wheel arches and it would be a ton of finicky sheet metal welding to close them up, I made new sides from 16-gauge sheet metal. The top edges of the tubs were saved and welded to the top of the new sides.

Once the trailer was done, the LJ Safari Cab molds were used to make a set of parts for the camper top. Gr8Tops made some of the parts when they were molding their first preproduction LJ Safari Cab in their production molds and I made some of the parts in my garage using my original molds. This was in 2011, and Gr8Tops showed the prototype camper at the All Breeds Jeep Show in York, PA as a possible future product.

In the back the camper has a barn door just like the Safari Cab on the Jeep, and in the front the same molds were used to make a lift-up hatch. And just like the Safari Cab on the LJ, am XJ Cherokee rack on top.

Gr8Tops decided not to turn the camper into a product so I disassembled the camper top and stored it in the back yard - I had other plans for the Jeep-tub trailer. The parts sat in the yard for about 10 years and this year I decided to put them back in service.

I hadn't installed windows/side hatches in the parts back then, so I did that and applied a textured acrylic finish to everything.

On the tailgate I installed a MORryde Tailgate Reinforcement so I could carry whatever I wanted back there and in these photos there's a jerry can tray and a propane tank tray installed:

I thought it would be fun to paint the inside of the roof sky blue:

In the photo above a MORryde Trail Kitchen is bolted to the floor; it slides out the front:

The interior design is to have a sleeping platform above the kitchen; storage would be under the platform as well.

The platform would be sectional so when not being used for sleeping part of it can be moved to provide sitting/dressing space.

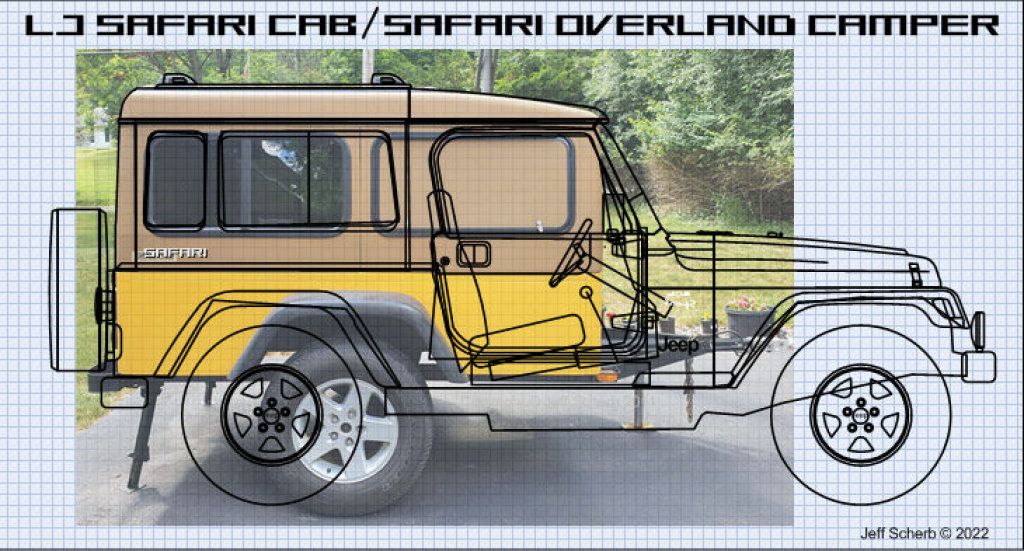

A wireframe of the LJ Safari Cab superimposed on a photo of the camper:

Another part of the design I haven't implemented yet is a pop-top roof. It could be hinged either in the front or on the side; I prefer the side:

I'm not sure if I'll ever finish off the camper interior. I end up using the trailer so often for hauling cargo around (it's done almost 10,000 miles so far this year hauling cargo) and the camper interior would have to be removed regularly for that use so maybe it'll just be a cargo trailer forever.

If anyone is interested in building a Jeep-tub trailer of their own or even a camper I'll be happy to share more about this project and other ways to turn a Jeep-tub trailer into a camper.

Along the way from upstate NY to South Florida and back at probably half the gas or food stops I made someone came up to me to ask about the trailer and I probably got a half dozen thumbs up from people passing my on the highway so I thought if that many people liked the trailer on that trip maybe people here would be interested in it.

The camper top was part of the original design for my LJ Safari Cab hardtop - I did this sketch in 2010 when I was working on the Safari Cab design and I designed the molds for the fiberglass parts such that variations of the parts could be made for either the Jeep hardtop or the camper top version.

After finishing the hardtop for the LJ, in order to make the camper I needed a Jeep-tub trailer to put the camper top on, so I used the back half of the LJ tub I cut off when making my pickup and the back half of a YJ tub I got from a friend, and put them together to make a tub the correct length to work with the LJ Safari Cab parts. These photos show the tub before painting; the red parts used to be part of the Jeep that's now the pickup and the black parts are from a YJ.

Because each of the tubs had wheel arches and it would be a ton of finicky sheet metal welding to close them up, I made new sides from 16-gauge sheet metal. The top edges of the tubs were saved and welded to the top of the new sides.

Once the trailer was done, the LJ Safari Cab molds were used to make a set of parts for the camper top. Gr8Tops made some of the parts when they were molding their first preproduction LJ Safari Cab in their production molds and I made some of the parts in my garage using my original molds. This was in 2011, and Gr8Tops showed the prototype camper at the All Breeds Jeep Show in York, PA as a possible future product.

In the back the camper has a barn door just like the Safari Cab on the Jeep, and in the front the same molds were used to make a lift-up hatch. And just like the Safari Cab on the LJ, am XJ Cherokee rack on top.

Gr8Tops decided not to turn the camper into a product so I disassembled the camper top and stored it in the back yard - I had other plans for the Jeep-tub trailer. The parts sat in the yard for about 10 years and this year I decided to put them back in service.

I hadn't installed windows/side hatches in the parts back then, so I did that and applied a textured acrylic finish to everything.

On the tailgate I installed a MORryde Tailgate Reinforcement so I could carry whatever I wanted back there and in these photos there's a jerry can tray and a propane tank tray installed:

I thought it would be fun to paint the inside of the roof sky blue:

In the photo above a MORryde Trail Kitchen is bolted to the floor; it slides out the front:

The interior design is to have a sleeping platform above the kitchen; storage would be under the platform as well.

The platform would be sectional so when not being used for sleeping part of it can be moved to provide sitting/dressing space.

A wireframe of the LJ Safari Cab superimposed on a photo of the camper:

Another part of the design I haven't implemented yet is a pop-top roof. It could be hinged either in the front or on the side; I prefer the side:

I'm not sure if I'll ever finish off the camper interior. I end up using the trailer so often for hauling cargo around (it's done almost 10,000 miles so far this year hauling cargo) and the camper interior would have to be removed regularly for that use so maybe it'll just be a cargo trailer forever.

If anyone is interested in building a Jeep-tub trailer of their own or even a camper I'll be happy to share more about this project and other ways to turn a Jeep-tub trailer into a camper.