When assembled, it won't unlock.

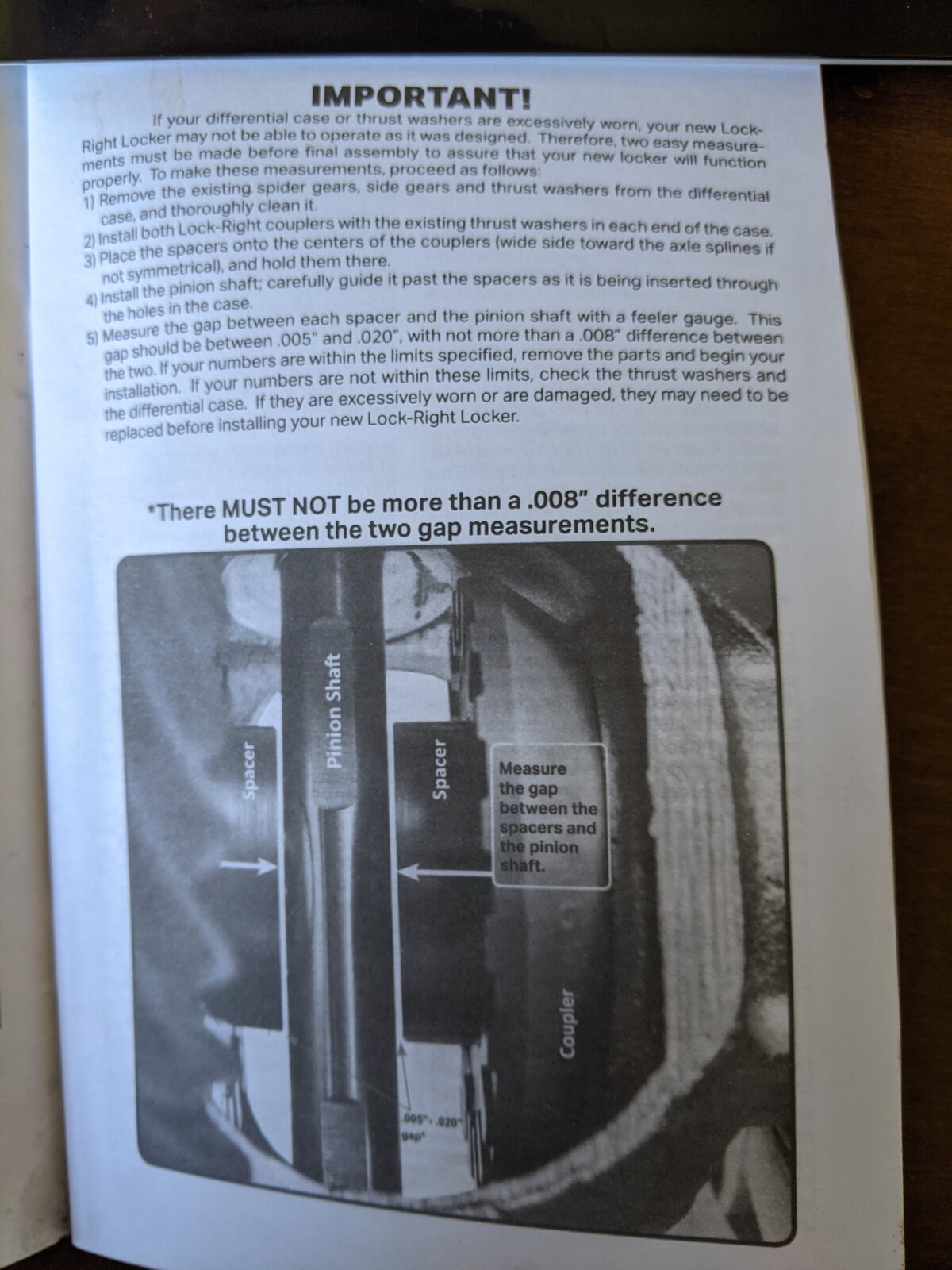

The install manual says there needs to be .005-020" clearance between the spacers and the cross pin.

I have 0.010" - so it's safely within the range and even on the lower third.

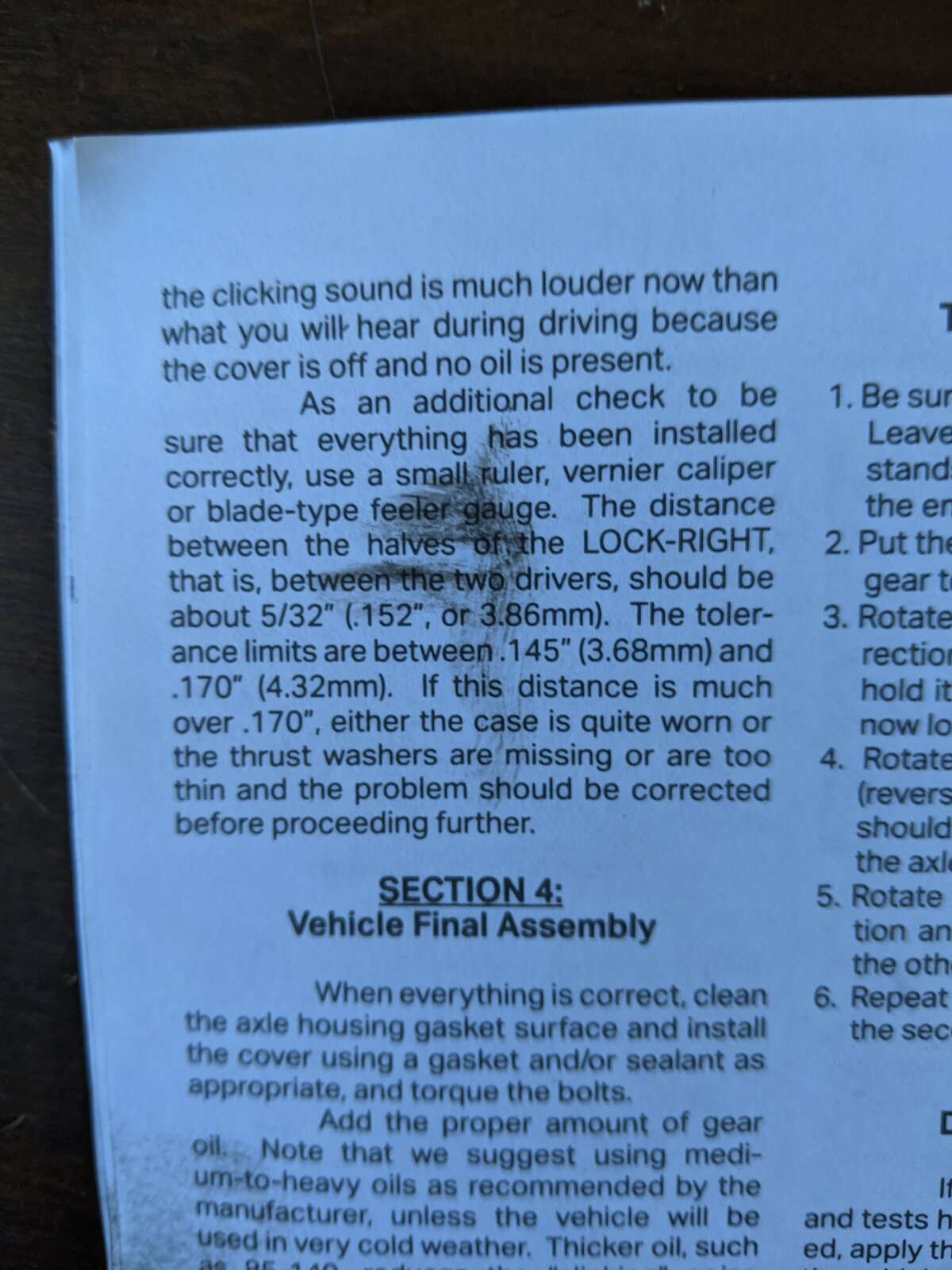

Once assembled, it says there needs to be 0.154-170" between the drivers.

Here, I have 0.178-0.186" between the drivers (significantly above the range).

The manual and their tech support guy is blaming my thrust washers and/or carrier, but the carrier has ~5k miles and the washers are brand new from Dana. Tech support guy says I can ignore the .005" minimum and go down as tight as needed without hard contact (a little concerning since I don't know what that measurement does when it heats up to 200° in operation), but I'm not seeing custom side gear thrust washer thicknesses anywhere. Even then, I'd have to get the spacer clearance between 0-0.002" to get the driver spacing right, and then I'd be at a starting point that leaves zero tolerance for wear. I don't consider 0.002" a reasonable tolerance window.

So now I'm returning this LockRight and I guess I'm gonna put it back together with spider gears. The question becomes, do I roll the dice on another LockRight, or go for an Aussie, Spartan, or Torq?

The install manual says there needs to be .005-020" clearance between the spacers and the cross pin.

I have 0.010" - so it's safely within the range and even on the lower third.

Once assembled, it says there needs to be 0.154-170" between the drivers.

Here, I have 0.178-0.186" between the drivers (significantly above the range).

The manual and their tech support guy is blaming my thrust washers and/or carrier, but the carrier has ~5k miles and the washers are brand new from Dana. Tech support guy says I can ignore the .005" minimum and go down as tight as needed without hard contact (a little concerning since I don't know what that measurement does when it heats up to 200° in operation), but I'm not seeing custom side gear thrust washer thicknesses anywhere. Even then, I'd have to get the spacer clearance between 0-0.002" to get the driver spacing right, and then I'd be at a starting point that leaves zero tolerance for wear. I don't consider 0.002" a reasonable tolerance window.

So now I'm returning this LockRight and I guess I'm gonna put it back together with spider gears. The question becomes, do I roll the dice on another LockRight, or go for an Aussie, Spartan, or Torq?

Last edited: