Im going to need you to turn mine into this

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Measure Once, Cut Twice: A Story of Excitement and Impatience

- Thread starter taylormade73

- Start date

Thank you. I agree. I think it'll handle 35's quite well.

Again I'm showing my lack of knowledge for TJ size BJ's but you said the ones that had been installed last year one was already sloppy. Are there BETTER BJ's for a TJ? Like the Alloy USA ones or G2 Axle or are these just overpriced joints and it's just better to stick with Spicer or Moog?

The acceptable tolerance for lower ball joint play is 1/16" vertical play which most develop in a very short number of miles. How easy the pin moves is not an indicator of wear or imminent failure. The upper pin floats up and down about 1/4" or so and the lateral play that is acceptable is less than .003" or basically no perceptible lateral play.Got unit bearings and knuckles on the new axle assembly. Had a helluva time getting axle nuts loose. Another 4wp issue of many since I let them regear last Fall; they must've used red Loctite and torqued the shit out of it with an impact. I used a MAP torch on the nut and still snapped 2 breaker bars on the passenger side. Finally with enough heat and my air impact I got it loose. The driver side came off easy peasy with just the impact. As Blaine says: "Stop paying other people to fuck your shit up."

Anyway, got them off then on the new axle. Had to take a break after that. It's sitting on jack stands under the front right now. Man this axle is beef compared to the stock. Btw, they also replaced all the ball joints last Fall with the regear. Well, the driver's side lower is showing signs of early failure-easy to move with little resistance. That's with only 35's for 10k miles. I can see 37's chewing up some TJ BJs.

View attachment 176035

View attachment 176036

View attachment 176037

View attachment 176038

View attachment 176039

View attachment 176040

View attachment 176041

View attachment 176042

View attachment 176043

View attachment 176044

View attachment 176045

View attachment 176046

View attachment 176047

View attachment 176048

View attachment 176049

View attachment 176050

View attachment 176051

View attachment 176052

Not of high importance but the lack of dust shields move the unit bearing about .040 inward and that can cause issues with tolerance stacking and put the caliper saddles too far off center on the the rotor. Not often but sometimes you will have to clearance the pad clips by bending the little ends over tighter to keep the rotor from dragging on them.

Stick with Spicer for TJs is my understanding.Again I'm showing my lack of knowledge for TJ size BJ's but you said the ones that had been installed last year one was already sloppy. Are there BETTER BJ's for a TJ? Like the Alloy USA ones or G2 Axle or are these just overpriced joints and it's just better to stick with Spicer or Moog?

Good to know when I start working on my daughters TJ since she had a Dana 30.

Look inside the tube and see if that plastic centering ring is in there.Also, there is some odd wear on the old driver's side axle shaft that is not present on the passenger side. I did hear a pop on the highway before I parked it a few months ago. When I opened the diff it looked and sounded like it was coming from my spider gears. Got any ideas what would wear grooves into a stock axle shaft like this?

View attachment 176054

View attachment 176055

View attachment 176056

View attachment 176057

Give me a few. I already put the old Dana 44 in the crate the RJ44 camr in and it has tools and parts on top. I'm running to the store to get some hardened washers for the LCAs. I had the BMB washers on the old axles.Look inside the tube and see if that plastic centering ring is in there.

Too impatient to wait for my helper tomorrow. Took the old Dana 44 out by myself tonight.

Just couldn’t wait for me to get there! Lol Fortunately I was only there long enough to snap 2 breaker bars and not more.

I bought a RJ44 from Carbon about a year and a half ago. Has been handling 35s fine. I like the gray paint they use, If you need/wanted some its called Seymour Paint Cast Blast.

https://www.amazon.com/dp/B07RD8FP4K/?tag=wranglerorg-20

https://www.amazon.com/dp/B07RD8FP4K/?tag=wranglerorg-20

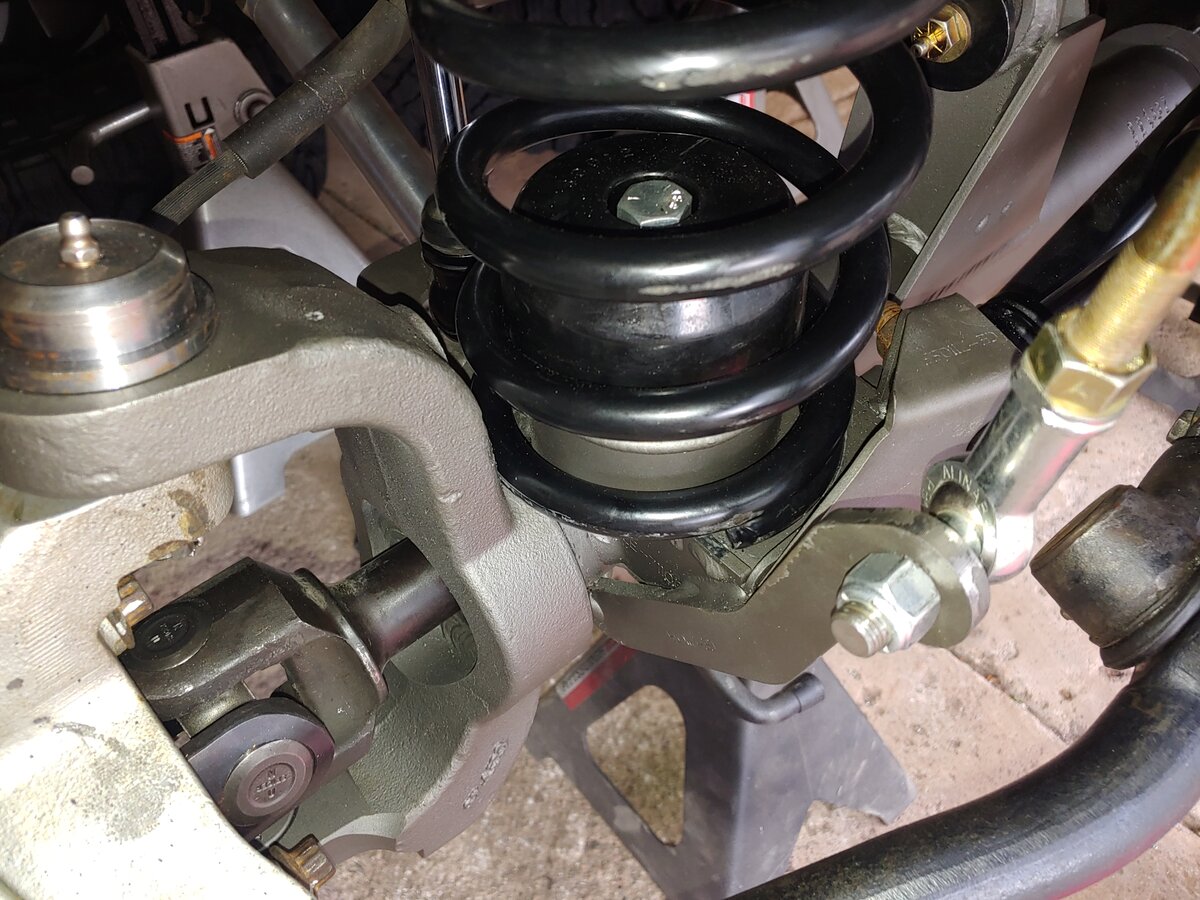

Everything hooked back up (except stabilizer-doesn't fit in the bracket) and cycling suspension to check for clearance issues. Respect to @jjvw and others who properly check how things work together rather than just installing and going. Doing things right takes time and effort. It's so much easier to just slap it together.

Def need more bump and to pull the axle back a tad. Thought I was going to have issues with the track bar and the diff since it's quite a bit larger than the stock 44, but I don't. The shock bottoms out first.

Def need more bump and to pull the axle back a tad. Thought I was going to have issues with the track bar and the diff since it's quite a bit larger than the stock 44, but I don't. The shock bottoms out first.

Also had to drill out the axle side track bar hole to 1/2" for the Currie big bolt to fit.

They actually sent a full can with it.I bought a RJ44 from Carbon about a year and a half ago. Has been handling 35s fine. I like the gray paint they use, If you need/wanted some its called Seymour Paint Cast Blast.

https://www.amazon.com/dp/B07RD8FP4K/?tag=wranglerorg-20

Everything hooked back up (except stabilizer-doesn't fit in the bracket) and cycling suspension to check for clearance issues. Respect to @jjvw and others who properly check how things work together rather than just installing and going. Doing things right takes time and effort. It's so much easier to just slap it together.

Def need more bump and to pull the axle back a tad. Thought I was going to have issues with the track bar and the diff since it's quite a bit larger than the stock 44, but I don't. The shock bottoms out first.

Yes it does take a lot more time to sit there and cycle the suspension and check clearances and how things fit. But it looks like you are getting there and once you're done you'll know it was done correctly and won't have to worry about things not fitting or things hitting.

It is really looking good.

Those front shocks are slightly longer than the typical 4" lift shocks which is why you need some extra bump. I used a hockey puck.

The currie bump kit should have come with a metal 1" hockey puck you can put under the lower poly bump.

The currie bump kit should have come with a metal 1" hockey puck you can put under the lower poly bump.

It did, but I had to use it for the rear.Those front shocks are slightly longer than the typical 4" lift shocks which is why you need some extra bump. I used a hockey puck.

The currie bump kit should have come with a metal 1" hockey puck you can put under the lower poly bump.

Rather than widen the bracket I used a flap disk to remove some sleeve and bushing material so my stabilizer will fit. Springs in as well. Not sure I like how close the passenger side spring is to the tower and the inner C.