Put some LED headlights in but I guess I put them in upside down, because I couldn't see anything unless I had my brights on, and when I pulled into my driveway I realized that I had plenty of light on low beams, it was just shooting into the sky. I guess I'l flip them and then do the alignment process.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New TJ Day - Project Goldilocks

- Thread starter hear

- Start date

Haven't done much with this one, primarily because I spend most of November/December in the Ouachita National First during deer season, and also work decided to get in the way. Here's the most recent fun & games:

Steering slop

There is a TON of slop in the wheel, on the order of 25 degrees of play before the pitman arm even thinks about budging. Done a bunch of "isolation test" I've read about here & on the line, and also Redhead's testing process. And I'm pretty well convinced the steering gear is shot. Noticed the PS hoses have fluid on them, but they don't appear to be leaking from the pump so I'll replace those hoses. Almost certainly will be getting the Redhead, although I *may* put it on MY 97 and give her the box off mine. Trying to decide if that's actually smart or if it makes me a bad dad. (as if the two were mutually exclusive).

I expected to have to replace all the tie rods etc but honestly all that stuff looks a-ok, so I guess technically this is all still just steering stuff I had budgeted for.

Transmission leak

If you're following along, you'll know that we knew about this one going in and is probably the reason we got it so cheap. What's interesting is that it seems like if you drive it, it doesn't leak (much). If it sits for an extended period of time, it will leak like a sieve. Maybe driving it keeps the fluid "in" the transmission but if it sits long enough it all drains down and ends up settling above the bad seal? Just a guess.

In anticipation of this work I got a new pan with a drain plug because anybody who has removed their TJ's transmission knows you'll probably have to do it again at some point. Plus a lube locker and 2 different flavors of dipstick "grommets" that allegedly will help the dipstick tube reseal after I remove it. This has been an ongoing problem in my other 97 auto, and I'm really hoping to overcome it this time around.

And since I'm getting a new pan, may as well get a bung & set it up for a trans temp gauge, so I bought all that too. After the new year we'll finally tackle replacing that seal. Here’s how much it caught in ~5 weeks.

Soft brakes

Even after bleeding them & replacing the cylinders they're still soft. I hear a WHOOOSH the first time I press the pedal that I don't really understand yet. I don't appear to have any vacuum problems, so I think I may go back to ground zero and bench bleed the MC, then re-bleed everything again and see where we land.

Distributor bearing

While looking at the steering, I noticed a telltale tick that seems to be coming from the distributor. My 97 had the same problem, ended up being the bearing was going. So I guess I'm replacing a distributor also. That wasn't in the budget.

Oil Pressure

We get an intermittent CHECK GAUGES along with zero oil pressure, which I'm pretty sure is just the sender, although I changed the sender with the exact same Standard Motor Products sensor I used on MY 97, but it hasn't really changed anything. Somebody will probably say I need to use a Mopar but I've had enough success with SMP that I'm not going to spend $80 on a sensor just yet. Need to use my mechanical gauge to verify the actual oil pressure (at 230k miles it's possible we have some other issues), and then determine if a new pump is needed.

It's worth noting that the last time I did this the new sensor didn't really change what the gauge was doing, but changing the oil pump resolved the oil pressure gauge issue once and for all. Which makes me wonder how long that thing was driven with bad oil pressure. So I'm starting to think ahead to those questions on this jeep.

Parts will get here first week of January, so I'm looking forward to some good under jeep time, and then enjoying what should be a rock solid jeep after that.

Steering slop

There is a TON of slop in the wheel, on the order of 25 degrees of play before the pitman arm even thinks about budging. Done a bunch of "isolation test" I've read about here & on the line, and also Redhead's testing process. And I'm pretty well convinced the steering gear is shot. Noticed the PS hoses have fluid on them, but they don't appear to be leaking from the pump so I'll replace those hoses. Almost certainly will be getting the Redhead, although I *may* put it on MY 97 and give her the box off mine. Trying to decide if that's actually smart or if it makes me a bad dad. (as if the two were mutually exclusive).

I expected to have to replace all the tie rods etc but honestly all that stuff looks a-ok, so I guess technically this is all still just steering stuff I had budgeted for.

Transmission leak

If you're following along, you'll know that we knew about this one going in and is probably the reason we got it so cheap. What's interesting is that it seems like if you drive it, it doesn't leak (much). If it sits for an extended period of time, it will leak like a sieve. Maybe driving it keeps the fluid "in" the transmission but if it sits long enough it all drains down and ends up settling above the bad seal? Just a guess.

In anticipation of this work I got a new pan with a drain plug because anybody who has removed their TJ's transmission knows you'll probably have to do it again at some point. Plus a lube locker and 2 different flavors of dipstick "grommets" that allegedly will help the dipstick tube reseal after I remove it. This has been an ongoing problem in my other 97 auto, and I'm really hoping to overcome it this time around.

And since I'm getting a new pan, may as well get a bung & set it up for a trans temp gauge, so I bought all that too. After the new year we'll finally tackle replacing that seal. Here’s how much it caught in ~5 weeks.

Soft brakes

Even after bleeding them & replacing the cylinders they're still soft. I hear a WHOOOSH the first time I press the pedal that I don't really understand yet. I don't appear to have any vacuum problems, so I think I may go back to ground zero and bench bleed the MC, then re-bleed everything again and see where we land.

Distributor bearing

While looking at the steering, I noticed a telltale tick that seems to be coming from the distributor. My 97 had the same problem, ended up being the bearing was going. So I guess I'm replacing a distributor also. That wasn't in the budget.

Oil Pressure

We get an intermittent CHECK GAUGES along with zero oil pressure, which I'm pretty sure is just the sender, although I changed the sender with the exact same Standard Motor Products sensor I used on MY 97, but it hasn't really changed anything. Somebody will probably say I need to use a Mopar but I've had enough success with SMP that I'm not going to spend $80 on a sensor just yet. Need to use my mechanical gauge to verify the actual oil pressure (at 230k miles it's possible we have some other issues), and then determine if a new pump is needed.

It's worth noting that the last time I did this the new sensor didn't really change what the gauge was doing, but changing the oil pump resolved the oil pressure gauge issue once and for all. Which makes me wonder how long that thing was driven with bad oil pressure. So I'm starting to think ahead to those questions on this jeep.

Parts will get here first week of January, so I'm looking forward to some good under jeep time, and then enjoying what should be a rock solid jeep after that.

Dropped the trans today to replace the pump seal. I can't really say why, but it felt like it took 3x as long, which is odd because we found about half of the bellhousing bolts to be missing, including the hard ones to reach. It would appear as if somebody has already been in & around this transmission.

But what I found was that the pump stator shaft looks to be really chewed up, so I'm at a minimum looking at a new pump & torque converter. I hadn't really budgeted for that. And the truth is with 220k on the clock and a transmission that was known to have "trouble" when I bought it, I probably (a) should have known and (b) shouldn't even be debating the merits of a rebuild. Plus it's actually my kid's car, so I kinda need to make it as solid as possible.

Le sigh.

But what I found was that the pump stator shaft looks to be really chewed up, so I'm at a minimum looking at a new pump & torque converter. I hadn't really budgeted for that. And the truth is with 220k on the clock and a transmission that was known to have "trouble" when I bought it, I probably (a) should have known and (b) shouldn't even be debating the merits of a rebuild. Plus it's actually my kid's car, so I kinda need to make it as solid as possible.

Le sigh.

Turns out there are tons of variations on the 904 pump, since this transmission was used on cars dating back to the 60's. Lockup/non lockup are the main variations, but even in looking at casting #'s on other TJ's I'm seeing differences. You can't find a new pump or even just the stator half, which is all I really need. Some transmssion shops online look to have pumps available but there are way too many nuanced questions that I don't immediately know the answers to. There's a rebuild 32RH pump on ebay for $180 + $20 shipping, and then there's a used/non-rebuilt 30RH pump for $100 + $30 shipping. The 30RH & 32RH use the same pump based on a bunch of research I've done on this prior. Plus all the part numbers are the same in the parts list in our resources section.

As far as used vs rebuilt, there's not much to "rebuild" in these pumps. The only moving pieces are the two pump gears, and I doubt those can be fixed if there is any issue. THen you have 2 sealing rings, a bushing, a seal, and an o-ring that goes around the whole thing. I have all those parts on hand already, so this feels like I'm saving $50, which I can put toward replacing the torque converter.

As far as used vs rebuilt, there's not much to "rebuild" in these pumps. The only moving pieces are the two pump gears, and I doubt those can be fixed if there is any issue. THen you have 2 sealing rings, a bushing, a seal, and an o-ring that goes around the whole thing. I have all those parts on hand already, so this feels like I'm saving $50, which I can put toward replacing the torque converter.

On the topic of dipstick tubes, it seems that the 97 is the outlier in that it is the only year that uses the o-ring seal which has given me fits in the past. Newer years use a grommet sort of thing over a tapered dipstock tube. You can use the later style in the 97, but used dipstick tubes are like $130 on ebay which seems insane to me. I found a note somewhere (TODO: link to the thread where I did this research) that said the same part number used on the 97 was also used on the Chevy TH350 & TH400, which was a little surprising. But a little more digging has pointed me toward nearly every auto trans using the same size bore for the dipstick tube. i have not confirmed this yet, but reports are that the hole is consistently 3/4".

I bought a dipstick "specifically" for a 904 trans that had the grommet style end for $65, but it's several inches shorter than the 32RH. I'm not sure if it matters yet, but my next move is to measure the actual length of my tube and see if anything anywhere is roughly that length. I'm optimistic I'm going to be able to make this upgrade.

https://www.amazon.com/dp/B009Q7A3J6?tag=wranglerorg-20

I bought a dipstick "specifically" for a 904 trans that had the grommet style end for $65, but it's several inches shorter than the 32RH. I'm not sure if it matters yet, but my next move is to measure the actual length of my tube and see if anything anywhere is roughly that length. I'm optimistic I'm going to be able to make this upgrade.

https://www.amazon.com/dp/B009Q7A3J6?tag=wranglerorg-20

I also ordered a deep pan with a drain from Summit for $60. I don't care about the deep pan so much on this jeep, but the drain is sort of a thing with me. If I have to drop the pan once, my rule is that when it goes back on it's going on with a drain plug. But it if you search for 32RH or even A904, you get really expensive options.

Then I found a discussion on pan gaskets for the 42RE, and listed as compatible was the 32RH. If the gasket it compatible then that means the pan perimeter shape is the same. I found a pan on Amazon for $32 with a drain. It says it doesn't fit a TJ but I'm willing to bet it does. And if it doesn't I just send it back, no hassle. The pan is a a little shallow on that one corner, so I'm hoping that corner isn't going to interfere with the valve body or anything. The overall pan looks deeper but I guess we'll see. Understanding part interchange across the dodge transmissions is turning out to be a valuable exercise.

https://www.amazon.com/dp/B00Z7NRSPU?tag=wranglerorg-20

Then I found a discussion on pan gaskets for the 42RE, and listed as compatible was the 32RH. If the gasket it compatible then that means the pan perimeter shape is the same. I found a pan on Amazon for $32 with a drain. It says it doesn't fit a TJ but I'm willing to bet it does. And if it doesn't I just send it back, no hassle. The pan is a a little shallow on that one corner, so I'm hoping that corner isn't going to interfere with the valve body or anything. The overall pan looks deeper but I guess we'll see. Understanding part interchange across the dodge transmissions is turning out to be a valuable exercise.

https://www.amazon.com/dp/B00Z7NRSPU?tag=wranglerorg-20

Last edited:

On the topic of dipstick tubes, it seems that the 97 is the outlier in that it is the only year that uses the o-ring seal which has given me fits in the past. Newer years use a grommet sort of thing over a tapered dipstock tube. You can use the later style in the 97, but used dipstick tubes are like $130 on ebay which seems insane to me. I found a note somewhere (TODO: link to the thread where I did this research) that said the same part number used on the 97 was also used on the Chevy TH350 & TH400, which was a little surprising. But a little more digging has pointed me toward nearly every auto trans using the same size bore for the dipstick tube. i have not confirmed this yet, but reports are that the hole is consistently 3/4".

I bought a dipstick "specifically" for a 904 trans that had the grommet style end for $65, but it's several inches shorter than the 32RH. I'm not sure if it matters yet, but my next move is to measure the actual length of my tube and see if anything anywhere is roughly that length. I'm optimistic I'm going to be able to make this upgrade.

https://www.amazon.com/dp/B009Q7A3J6?tag=wranglerorg-20

View attachment 491255

FWIW, on my motorhome, the oil dipstick tube is unavailable at any price. when they go, we use Flexible copper tubing and compression fittings to make new ones. I don't know why you couldn't do the same with the Trans Dipstick. Even if you have to braze a mounting boss on...

And just to further hedge, this DIY drainplug is only $10 and is probably a better option on the assumption that the cheap summit pan ever comes in. Plus I have a spare 32RH pan from when I put a deep pan on my other 97. I knew there was a reason I saved that thing!

Dorman 65128 Transmission Oil Drain Plug Piggyback 1/2-20

https://www.amazon.com/dp/B000CO96EK?tag=wranglerorg-20

View attachment 491668

Dorman 65128 Transmission Oil Drain Plug Piggyback 1/2-20

https://www.amazon.com/dp/B000CO96EK?tag=wranglerorg-20

View attachment 491668

FWIW, on my motorhome, the oil dipstick tube is unavailable at any price. when they go, we use Flexible copper tubing and compression fittings to make new ones. I don't know why you couldn't do the same with the Trans Dipstick. Even if you have to braze a mounting boss on...

Oh interesting. Tapping a hole in the trans and building my own dipstick seems like a heavy handed approach, but it doesn't sound that hard and sounds like a much more secure way. And a potential aftermarket opportunity.

Oh interesting. Tapping a hole in the trans and building my own dipstick seems like a heavy handed approach, but it doesn't sound that hard and sounds like a much more secure way. And a potential aftermarket opportunity.

I should explain further. We use the factory end, and adapt the copper. In my particular case, the engine oil dipstick goes behind the exhaust manifold and they get REALLY hot. That causes the tube to break down and disintegrate over time. So, you rebuild the tube from time to time, but keep the original end that pokes into the block casting.

Maybe I still don't understand. Any chance you have a picure or a sketch of what you're describing?

This came in today. It's a perfect fit. That little notch in the corner isn't nearly as big or as deep as it appears to be in the stock photo. I laid my LubeLocker-in-waiting over the pan and it lines up 100%. My other 97 with the deep pan is currently not on-site so I can't compare, but this pan might actually be DEEPER than the deep pan I got from summit. I just measured, it's about 2-3/4" deep. On Goldilocks here, it definitely won't be a problem because it uses a skid plate drop, but it could be a tight fit otherwise. The Skyjacker deep pan claims to be 2-1/4" deep For $32 this is looks to be an absolute WIN.

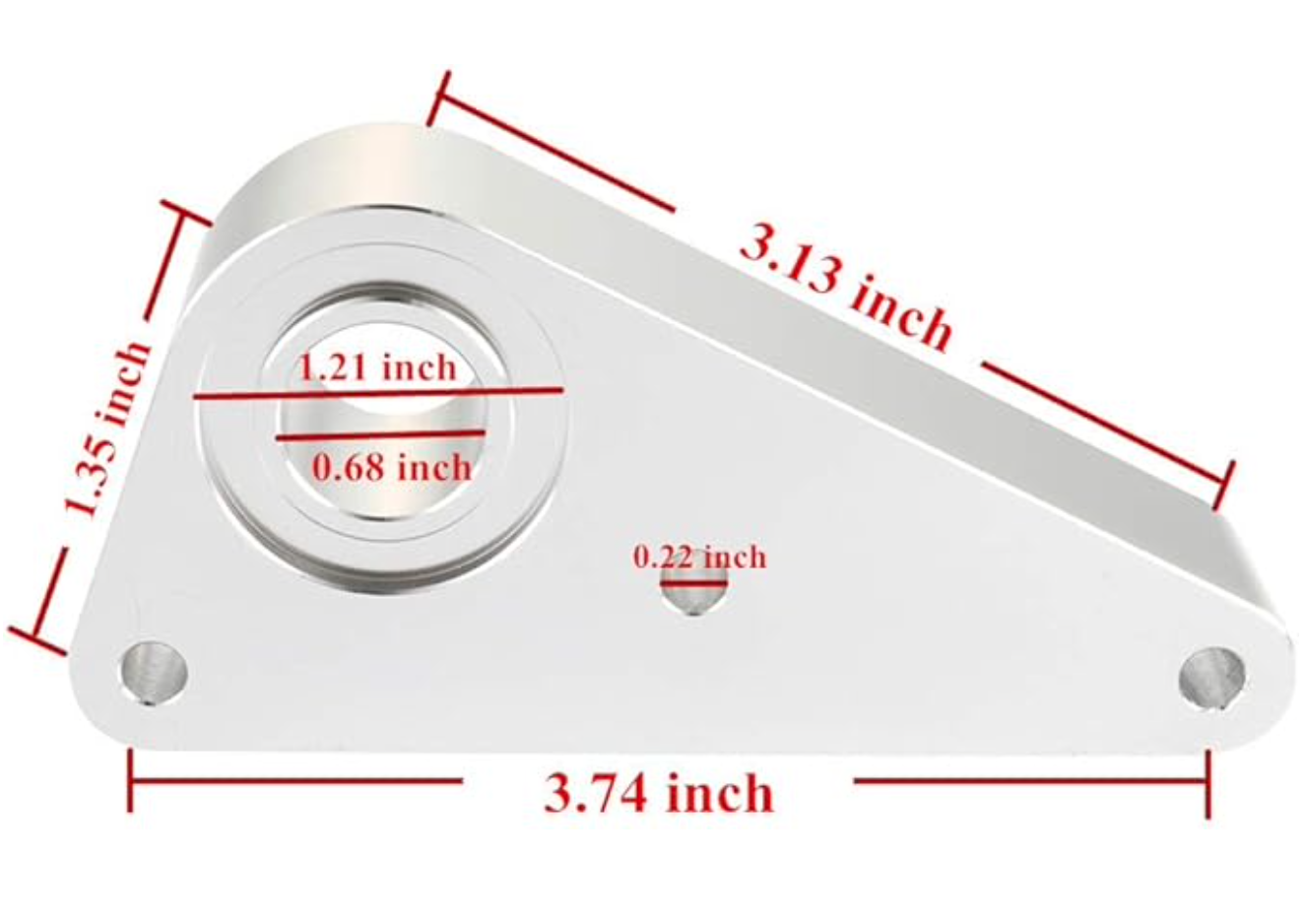

Now the trick is to find the aluminum filter extension bracket that comes with the summit pan. It would be very easy to machine, but I need the dimensions.

I also ordered a deep pan with a drain from Summit for $60. I don't care about the deep pan so much on this jeep, but the drain is sort of a thing with me. If I have to drop the pan once, my rule is that when it goes back on it's going on with a drain plug. But it if you search for 32RH or even A904, you get really expensive options.

Then I found a discussion on pan gaskets for the 42RE, and listed as compatible was the 32RH. If the gasket it compatible then that means the pan perimeter shape is the same. I found a pan on Amazon for $32 with a drain. It says it doesn't fit a TJ but I'm willing to bet it does. And if it doesn't I just send it back, no hassle. The pan is a a little shallow on that one corner, so I'm hoping that corner isn't going to interfere with the valve body or anything. The overall pan looks deeper but I guess we'll see. Understanding part interchange across the dodge transmissions is turning out to be a valuable exercise.

https://www.amazon.com/dp/B00Z7NRSPU?tag=wranglerorg-20

View attachment 491484

This came in today. It's a perfect fit. That little notch in the corner isn't nearly as big or as deep as it appears to be in the stock photo. I laid my LubeLocker-in-waiting over the pan and it lines up 100%. My other 97 with the deep pan is currently not on-site so I can't compare, but this pan might actually be DEEPER than the deep pan I got from summit. I just measured, it's about 2-3/4" deep. On Goldilocks here, it definitely won't be a problem because it uses a skid plate drop, but it could be a tight fit otherwise. The Skyjacker deep pan claims to be 2-1/4" deep For $32 this is looks to be an absolute WIN.

Now the trick is to find the aluminum filter extension bracket that comes with the summit pan. It would be very easy to machine, but I need the dimensions.

Last edited:

Hmm. Looks like that pan goes on a Dodge Dakota.... But now my $32 pan has become a $50 pan. Le sigh.

https://www.amazon.com/dp/B07SRS2QS6?tag=wranglerorg-20

https://www.amazon.com/dp/B07SRS2QS6?tag=wranglerorg-20

Dropped the 42RE pan off at a buddies to get a bung welded in for a temperature sensor, he'll have it ready tomorrow, in time for the new pump, torque converter, and filter extension to arrive.

IT'S ALL SO EXCITING

IT'S ALL SO EXCITING

I opted to hold off on putting the transmission back in for a couple of days. I forgot I wanted to inspect all the wiring under there that I know have wide open access to. In my experience there is ALWAYS trouble in this section of the harness. It's not THAT much trouble to pull it up into the engine bay, but with the transmission out it will be just about as easy to do from underneath with all that space.

In the meanwhile I wanted to re-bench bleed the master cylinder. There's a little bit of sponginess in the brakes even after I replaced the wheel cylinders and bled everything. And I'm not convinced a "helper" didn't let it go dry while I was bleeding. That project ended quickly. My line wrench won't budge them, and are actually even rounding the nuts off at the master cylinder. A new m/c on a 27 yr old vehicle probably isn't the worst idea, so shopping those now too. Finding replacement brake lines to go from the m/c to the combo block is proving a little challenging. I may end up having a "custom set" made which isn't quite as dramatic as it sounds.

Fitting sizes at the combo block according to my research:

https://www.wranglerforum.com/threads/jeep-tj-brake-fitting-sizes.1869513/

Combo Block fittings:

Port 1- 11mm x 1.0- input from front port on master for rear brake circuit

Port 2- 1/2-20- input from rear port on master for front brake circuit

A 9/16 line wrench fit those perfectly, so I'm having casual doubts about them being different sizes.

M/C fittings:

Possibly 1/2-20 & 11mm x 1.0 but I'm still trying to confirm. I'll hopefully remember to update this for future readers (such as myself).

In the meanwhile I wanted to re-bench bleed the master cylinder. There's a little bit of sponginess in the brakes even after I replaced the wheel cylinders and bled everything. And I'm not convinced a "helper" didn't let it go dry while I was bleeding. That project ended quickly. My line wrench won't budge them, and are actually even rounding the nuts off at the master cylinder. A new m/c on a 27 yr old vehicle probably isn't the worst idea, so shopping those now too. Finding replacement brake lines to go from the m/c to the combo block is proving a little challenging. I may end up having a "custom set" made which isn't quite as dramatic as it sounds.

Fitting sizes at the combo block according to my research:

https://www.wranglerforum.com/threads/jeep-tj-brake-fitting-sizes.1869513/

Combo Block fittings:

Port 1- 11mm x 1.0- input from front port on master for rear brake circuit

Port 2- 1/2-20- input from rear port on master for front brake circuit

A 9/16 line wrench fit those perfectly, so I'm having casual doubts about them being different sizes.

M/C fittings:

Possibly 1/2-20 & 11mm x 1.0 but I'm still trying to confirm. I'll hopefully remember to update this for future readers (such as myself).

What is the chance that the 42RE filter will fit the 32RH and make up the depth difference in the pans?

zero. They use a different style filter. I have the transmission out from under the jeep to do the pump replacement. I'll flip it over and do some real investigation on pan & filter depth.

The filter extension is trivial. All it does is provide a pathway for the hole in the filter to mate with the bottom of the valve body. I'm confident I could make one any size if I had access to a milling machine.

Well I broke down and bought the Redhead steering box. $566 shipped, including the $150 core and the $35 return label. So it will be ~$400 all told, which includes the $25 coupon I found online. This thing better steer itself.....although that's kinda the problem right now, lol.

I didn't really budget that big ticket item, nor did I expect to need a $150 pump and $175 torque converter. Proof that even the really good deals can have gotchas that drive up the TCO.

I didn't really budget that big ticket item, nor did I expect to need a $150 pump and $175 torque converter. Proof that even the really good deals can have gotchas that drive up the TCO.

A popular myth you'll find on just about every 32RH (and by extension 30RH) discussion is that the pump doesn't run in park, and that's why you need to have it in neutral to check the fluid level. It's true you have to be in neutral, but it isn't true that the pump isn't running.

In reality, the pump gears are turned by the flat spots on the shaft of the torque converter. The torque converter is bolted to the flex plate. The flex plate it bolted to the crankshaft. So if the engine is running, the pump is running. The manual valve (that's the valve that moves when you move the shifter) is designed such that some fluid flows don't happen while in park, thereby making it impossible to get a good reading unless you're in neutral. Other side effects are that the torque converter may not be charged & the cooler lines may not be flowing in parts.

Sonnax has a simple solution to part of this problem, by replacing the manual valve, and optionally the pressure regulator valve. These valves are not hard to change, but they do involve removing the valve body from the transmission. Sonnax says that the manual valve can be replaced alone, but the optimal path is to replace both. Note that their instructions have a callout that you still need to be in neutral to get a good reading.

Specifically for the manual valve:

and then regarding the pressure regulator valve:

https://www.sonnax.com/parts/1835-manual-valve

https://www.sonnax.com/parts/1840-lube-regulated-pressure-regulator-valve

Manual valve on Amazon is $18

https://www.amazon.com/dp/B00DP5YUL2?tag=wranglerorg-20

Pressure regulator valve on Amazon is $45

https://www.amazon.com/dp/B010MNVJ4A?tag=wranglerorg-20

Note that Amazon doesn't directly state that these work on the 30/32RH transmissions, but (a) Sonnax does explicitly state it and (b) Amazon says that it will work with RH family transmissions.

Since I have the transmission out right now awaiting a pump replacement, I think I'll replace these valves as well & do a how to.

In reality, the pump gears are turned by the flat spots on the shaft of the torque converter. The torque converter is bolted to the flex plate. The flex plate it bolted to the crankshaft. So if the engine is running, the pump is running. The manual valve (that's the valve that moves when you move the shifter) is designed such that some fluid flows don't happen while in park, thereby making it impossible to get a good reading unless you're in neutral. Other side effects are that the torque converter may not be charged & the cooler lines may not be flowing in parts.

Sonnax has a simple solution to part of this problem, by replacing the manual valve, and optionally the pressure regulator valve. These valves are not hard to change, but they do involve removing the valve body from the transmission. Sonnax says that the manual valve can be replaced alone, but the optimal path is to replace both. Note that their instructions have a callout that you still need to be in neutral to get a good reading.

Specifically for the manual valve:

Chrysler transmissions often suffer delayed engagement, converter bushing failure, overheated converters and dragging Forward clutches. These symptoms can be a direct result of the design of the OE manual valve, which does not allow converter or cooler charge in Park. Sonnax manual valve 22771-09 is engineered to overcome the OE shortcoming by allowing fluid into these critical circuits when in Park.

and then regarding the pressure regulator valve:

Under extreme pressure or temperature conditions, the converter/lube circuit in listed Chrysler RWD units can be restricted by the pressure regulator valve. The practice of drilling a hole between passages is problematic. This outdated technique contributes to slow engagements or, if the hole is improperly drilled, excessive converter pressure and low line pressure.

https://www.sonnax.com/parts/1835-manual-valve

https://www.sonnax.com/parts/1840-lube-regulated-pressure-regulator-valve

Manual valve on Amazon is $18

https://www.amazon.com/dp/B00DP5YUL2?tag=wranglerorg-20

Pressure regulator valve on Amazon is $45

https://www.amazon.com/dp/B010MNVJ4A?tag=wranglerorg-20

Note that Amazon doesn't directly state that these work on the 30/32RH transmissions, but (a) Sonnax does explicitly state it and (b) Amazon says that it will work with RH family transmissions.

Since I have the transmission out right now awaiting a pump replacement, I think I'll replace these valves as well & do a how to.

May have thrown out my back standing this sucker up into the Mopar Transmission Fluid Catch Pan (TM).

My videos on a 32RH rebuild missed a few steps, including pump removal/installation and also clutch & piston seal replacement. It occurred to me this morning that if you’re going to have the pump out, the amount of effort to get the two drums with the clutches out is very nearly zero, so I may as well see what those look like & add those steps to the YouTube channel.

My videos on a 32RH rebuild missed a few steps, including pump removal/installation and also clutch & piston seal replacement. It occurred to me this morning that if you’re going to have the pump out, the amount of effort to get the two drums with the clutches out is very nearly zero, so I may as well see what those look like & add those steps to the YouTube channel.

I'm dumb. I forgot that while you CAN get the drums out easily from this point, it is very hard to get them back IN w/o removing the band, which requires removal of the valve body to reset the band apply strut. So I'm either going to just replace the pump and leave everything well enough alone, or I'm going to put this thing on it's back and take off the valve body too.

It's probably going to be the latter.

It's probably going to be the latter.