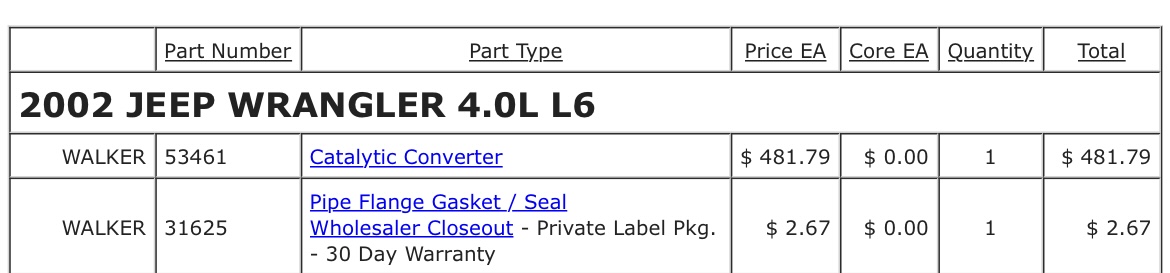

Forgive me for any ignorance here, but I’m going to be replacing my front cats with the Walker 53461 cats. 2002 Jeep TJ, 4.0, automatic. On rockauto, it told me I need the pipe flange gasket/seal as well, so I went ahead and added the Walker brand one to my cart (in photo). I assume this will go between the end of the Walker pipe to the rear cat converter?

Are there any other gaskets, bolts, nuts, or pieces I need to complete this install?

Also, any tips for installing this with ease? (It won’t be me, but a great mechanically inclined friend). Thanks!

Are there any other gaskets, bolts, nuts, or pieces I need to complete this install?

Also, any tips for installing this with ease? (It won’t be me, but a great mechanically inclined friend). Thanks!