This is a Dana 30 diff cover bolt! I figure at least 50 +ft lbs before it broke loose. I did about everything under the sun to get this thing off. Finally had to drill a 1/4” hole in the bolt and use a e-z out before it broke loose. I got lucky

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Please use the proper torque spec folks

- Thread starter Eddie Greenlee

- Start date

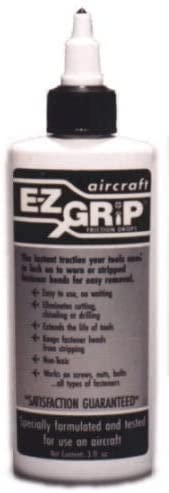

Buy some of this & keep it in your toolbox. At this point people probably think I'm paid by the manufacturer, but it really works. Stripped bolts, sockets, stuff that's too tight to get off... Put a few dabs in your socket/on the bolt/on the bit and you'll get like twice the friction. We use it in the aircraft industry, I could remove an F-16 panel with 300+ recessed heads and not strip a single fastener.

https://www.amazon.com/dp/B00BFEJY5W/?tag=wranglerorg-20

https://www.amazon.com/dp/B00BFEJY5W/?tag=wranglerorg-20

That stuff is a staple working on helicopters.Buy some of this & keep it in your toolbox. At this point people probably think I'm paid by the manufacturer, but it really works. Stripped bolts, sockets, stuff that's too tight to get off... Put a few dabs in your socket/on the bolt/on the bit and you'll get like twice the friction. We use it in the aircraft industry, I could remove an F-16 panel with 300+ recessed heads and not strip a single fastener.

https://www.amazon.com/dp/B00BFEJY5W/?tag=wranglerorg-20

View attachment 175664

Every mechanic has a bottle in his toolbag.

I love when people use a torque wrench on bolts that should be just a turn past hand tight

MountaineerTom

LJ Enthusiast, Retired USAF Weapons Loader

Supporting Member

Ride of the Month Winner

We had to use torque limiters when loading Chaff and Flare modules on the F-16 because they were very easily over torqued. 15 in. lbs, if I remember correctly.

Forgot about that stuff. Needed it constantly to pull access panels off the Cobra Helicopters. Claim (unsubstantiated) was aircraft create static charge that causes threads to 'tack weld' on exterior surface. Why internal fasteners don't do it was never explained. Good stuff. As a teen I would spit in the dust and put the screwdriver (socket, wrench,) in to pick up some grit.

We used to dip the tip of our screwdrivers in Comet cleaning powder to remove stubborn aircraft panels. Worked pretty good.

These were really expensive but they have worked for me every single time I have used them on a rounded bolt. I always hammer them on. I have removed shit that other guys couldn't remove with their Irwin extractor set. I think the benefit is having all the sizes so as it furthers rounds down you can still get a good grip by using the smaller extractor. If I could weld I probably would not have bought these.

https://shop.snapon.com/product/Twi...wist-Impact-Socket-Set-(Blue-Point)/213TSFSYA

https://shop.snapon.com/product/Twi...wist-Impact-Socket-Set-(Blue-Point)/213TSFSYA

I'm not fully following what this is, but I'm interested. So it makes the head of the bolt tacky? Not sure how that helps. Or is this primarily non hex-head bolts with recessed attach point like Allen, Torx, Philips, etc to help prevent the bit from slipping out while you crank?Buy some of this & keep it in your toolbox. At this point people probably think I'm paid by the manufacturer, but it really works. Stripped bolts, sockets, stuff that's too tight to get off... Put a few dabs in your socket/on the bolt/on the bit and you'll get like twice the friction. We use it in the aircraft industry, I could remove an F-16 panel with 300+ recessed heads and not strip a single fastener.

https://www.amazon.com/dp/B00BFEJY5W/?tag=wranglerorg-20

View attachment 175664

I'm not fully following what this is, but I'm interested. So it makes the head of the bolt tacky? Not sure how that helps. Or is this primarily non hex-head bolts with recessed attach point like Allen, Torx, Philips, etc to help prevent the bit from slipping out while you crank?

That's part of it.

It also adds a thin, sticky, gritty, layer that helps prevent slipping, so it protects against rounding off the head.

That said the OP missed a few zeroes in the torque it took for that bolt. I've used an impact wrench capable of 1100 ft/lbs at full force on old, rusty bolts and if you keep the socket seated real good the bolt will snap before the head rounds off.

On a diff cover you typically don't have rust issues, but if some of the RTV gets into the threads that can suck.

It's similar to a valve lapping compound only a little more course. Basically a paste with tons of little bits of metal. When you put a little drop on the fastener head (be it a bolt or a recessed bolt) those little bits of metal basically fill in the void between the fastener and bit, just gives the tool a much better bite. I've also used it in situations where for whatever reason I can only get an open ended wrench on the fastener in an odd area, I just put a few drops on the wrench and it keeps it from rounding off the bolt head.I'm not fully following what this is, but I'm interested. So it makes the head of the bolt tacky? Not sure how that helps. Or is this primarily non hex-head bolts with recessed attach point like Allen, Torx, Philips, etc to help prevent the bit from slipping out while you crank?

Likewise, if you're truing to get a torx bolt out that's already in poor shape you can put a few drops in there and have a better chance of not stripping it any further.

I was always told it was the extreme heat cycles that the exterior fasteners experience (on fighters anyway). They'll sit on the tarmac for days baking in the sun, then fly at altitudes where the ambient temp is -50, then land & bake in the sun again. Repeat, repeat, repeat, then try to get those screws out. I don't know a thing about heli's though, all that spinny shit might do something entirely different. All I know is that stuff really works.Forgot about that stuff. Needed it constantly to pull access panels off the Cobra Helicopters. Claim (unsubstantiated) was aircraft create static charge that causes threads to 'tack weld' on exterior surface. Why internal fasteners don't do it was never explained. Good stuff. As a teen I would spit in the dust and put the screwdriver (socket, wrench,) in to pick up some grit.

I’ve not heard of thisBuy some of this & keep it in your toolbox. At this point people probably think I'm paid by the manufacturer, but it really works. Stripped bolts, sockets, stuff that's too tight to get off... Put a few dabs in your socket/on the bolt/on the bit and you'll get like twice the friction. We use it in the aircraft industry, I could remove an F-16 panel with 300+ recessed heads and not strip a single fastener.

https://www.amazon.com/dp/B00BFEJY5W/?tag=wranglerorg-20

View attachment 175664

You need to buy 39 bottles via @Chris ‘s amazon store so he can get a bigger TV and you can get your fasteners off without stripping them.I’ve not heard of this

Last edited: