M

motomick76

Guest

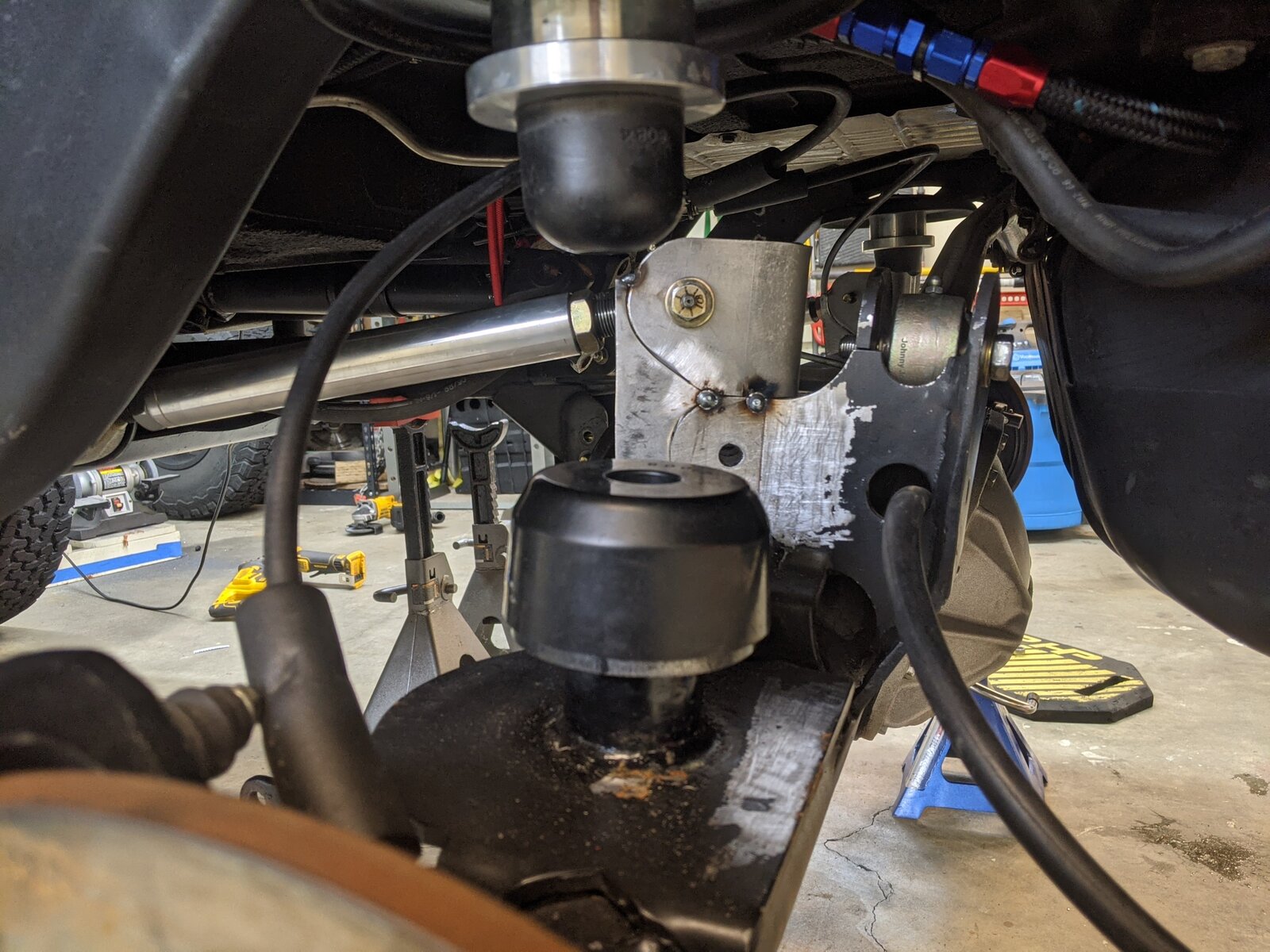

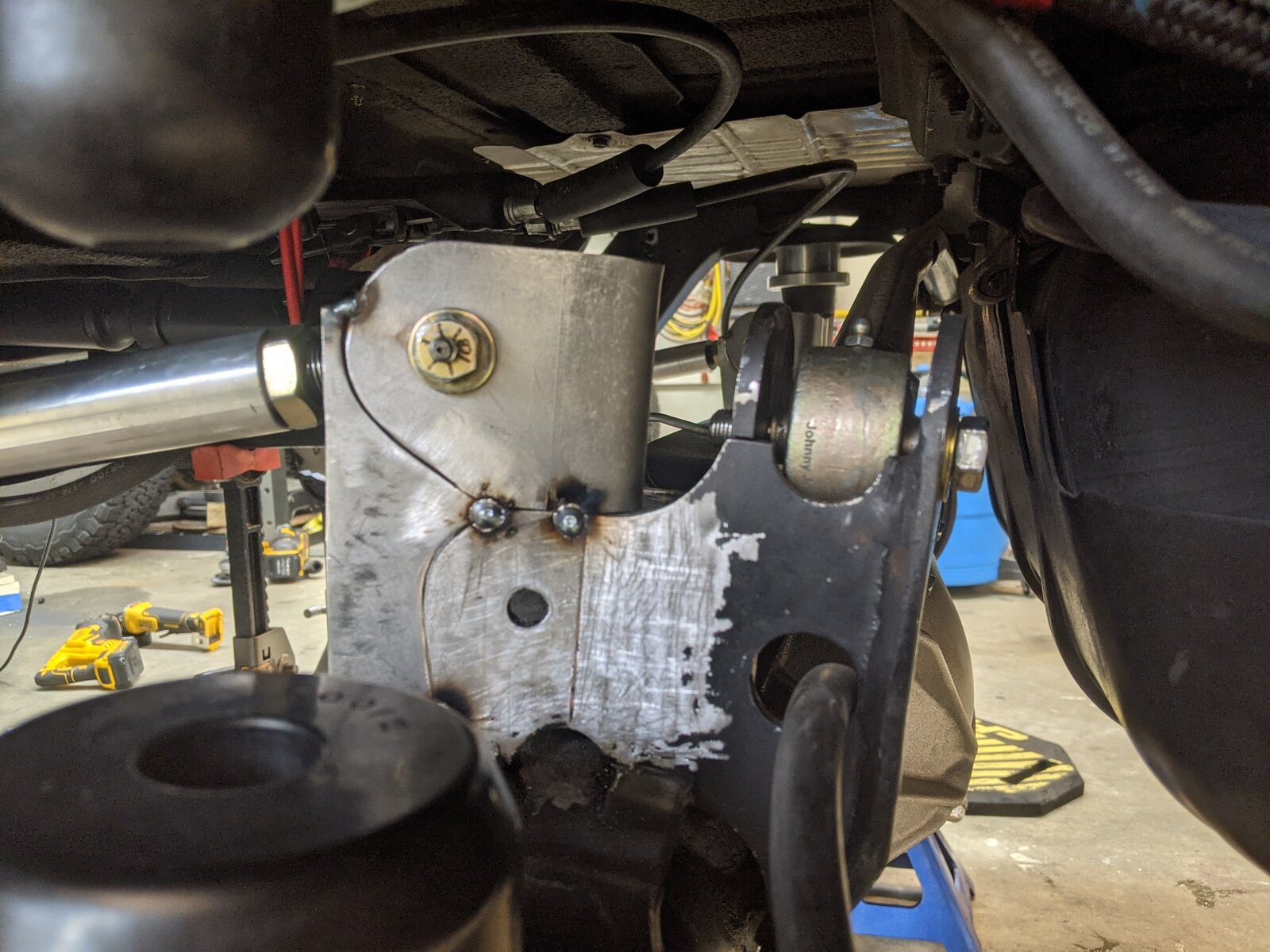

Currently I am in a futile attempt to fuck up my rig and to copy what Dave does to make Sarah handle a bit better. I have my upper mounts tacked in place, checking everything, cycling the suspension, and when I go to articulate the rear suspension, the rear track bar is binding the axle from flexing a couple of inches. either way. It moves up and down ok, when flexing it binds. I am not understanding why the track bar is binding the axle.

How does the track bar affect the articulation of the axle, and what I am I missing?

Does the track bar mount need to be same height or higher than the UCAM? Does it need to be closer to the UCAM?

Pictures are of the axle at ride height, setup is Currie short arms, Artec 8.8 truss kit, and Currie track bar.

How does the track bar affect the articulation of the axle, and what I am I missing?

Does the track bar mount need to be same height or higher than the UCAM? Does it need to be closer to the UCAM?

Pictures are of the axle at ride height, setup is Currie short arms, Artec 8.8 truss kit, and Currie track bar.