You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TJ's TJ

- Thread starter TJ's-TJ

- Start date

Tigger09

TJ Enthusiast

We got the doors re-assembled

Did you have to do anything to the panels (paint) or did they start out in good shape?

Your ability to take this on is impressive on its own but the fact that you have documented everything to a T and let us all tag along is admirable. Reminds me of restoring CJs with my pops. Good on ya.

Thanks. Documenting on this forum is a good way of keeping motivated to make progress believe it or not...

Did you have to do anything to the panels (paint) or did they start out in good shape?

See page 9 of this build thread, the drivers panel had the typical crack, we re-enforced both with epoxy and fiberglass cloth to hopefully avoid future cracks, then re-painted

https://wranglertjforum.com/threads/tjs-tj.10996/page-9

I had a separate post on this, but adding to the build thread. Steel Sub-Woofer enclosure.

I can get 1/4" steel cut to size at work, so we decided to build a Steel Sub enclosure. Research online said that it wouldn't sound good, but it sounds pretty good when paired with our Polks. Anyways, here are some details on the build:

Plasma cutters are good to have:

Here is the enclosure tacked together:

Seams were then fused with the TIG:

Added Roadkill Stinger Extreme damping material inside:

And about 1lb of polyfill:

Amp, sound processor (improves bass output signal into the sub amp from the factory radio) and sub in the box:

Drilled holes (very carefully due to Gas tank) for Riv-nuts:

A trick I learned somewhere along the way to prevent the drill bit from getting caught and dragged in when drilling thin metal:

Riv-nuts in:

I can get 1/4" steel cut to size at work, so we decided to build a Steel Sub enclosure. Research online said that it wouldn't sound good, but it sounds pretty good when paired with our Polks. Anyways, here are some details on the build:

Plasma cutters are good to have:

Here is the enclosure tacked together:

Seams were then fused with the TIG:

Added Roadkill Stinger Extreme damping material inside:

And about 1lb of polyfill:

Amp, sound processor (improves bass output signal into the sub amp from the factory radio) and sub in the box:

Drilled holes (very carefully due to Gas tank) for Riv-nuts:

A trick I learned somewhere along the way to prevent the drill bit from getting caught and dragged in when drilling thin metal:

Riv-nuts in:

Our jeep didn't come with a prop rod holder. there are 2 piece plastic ones on ebay that say they will fit a 99, but our hood does not have the rectangular hole for this style of clip so buyer beware.

I decided to design my own and during my search online of how the original clip mounts, I came across this one in Thingiverse that uses the original hole for the spring clip:

https://www.thingiverse.com/thing:2852748

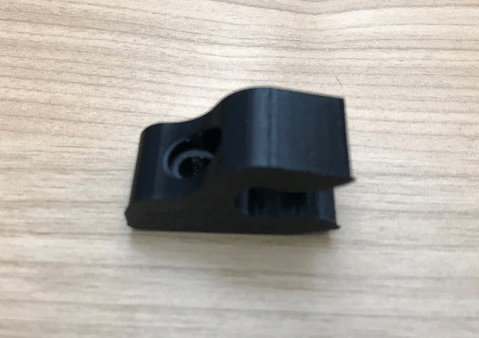

Printed one up:

Added a 4mm rivnut:

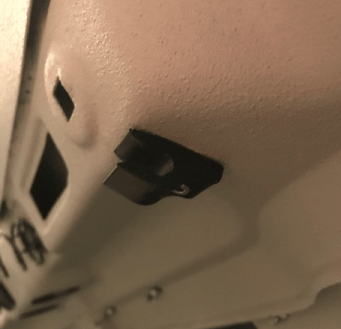

Job done, it works perfectly:

I decided to design my own and during my search online of how the original clip mounts, I came across this one in Thingiverse that uses the original hole for the spring clip:

https://www.thingiverse.com/thing:2852748

Printed one up:

Added a 4mm rivnut:

Job done, it works perfectly:

Last edited:

Thanks, it is almost done. We are just finishing up a bunch of small things. Here is how it is right now:What a phenomenal build/restoration thread! I look forward to the finished product. It looks like you are almost there!

Yes, he still has 4 months to his permit, we will be registering it soon though now that the snow is clearing, but he will have to be a passenger for now.Nice Job. Your son has to be going crazy, wanting to drive that thing.

That's just so cool you guys built that together. I have always wanted to build a car with my Dad. Closest we have come is a Golf Cart, which turned out pretty cool. He has kinda lost the drive to do a vehicle now...even though I tell him all the time how much we could do to his Jeep (2017 JK).Yes, he still has 4 months to his permit, we will be registering it soon though now that the snow is clearing, but he will have to be a passenger for now.

I'm a little late to the party, but I jumped in at page one, got sucked in and read to the end. Wow! Now this was a true build. Fantastic restoration work. I'm impressed. Thank you for sharing.

He's fortunate to have you there, willing and able to take on this project with him. I'm sure he's proud of the build.

He will be the one in his group of friends that doesn't fumble around to locate the dipstick. An upbringing like this is priceless.

The funny thing is that none of his friends get it, they just can't understand why anyone would want an old jeep that needs a ton of work...

He's fortunate to have you there, willing and able to take on this project with him. I'm sure he's proud of the build.

He will be the one in his group of friends that doesn't fumble around to locate the dipstick. An upbringing like this is priceless.

I'm a little late to the party, but I jumped in at page one, got sucked in and read to the end. Wow! Now this was a true build. Fantastic restoration work. I'm impressed. Thank you for sharing.

He's fortunate to have you there, willing and able to take on this project with him. I'm sure he's proud of the build.

He will be the one in his group of friends that doesn't fumble around to locate the dipstick. An upbringing like this is priceless.

Thanks, Yes, its been a good experience. It is good to see him genuinely interested in mechanical things the way that I always was. I think you either have that or you don't. He seems to. He got himself onto the robotics team at school as well and he really likes that, so looks like it may continue on.

Thanks, may seem like a waste of time to some, but remember 1/2 the point of this project is to teach a 14 year old...

Picked up a gallon of Fluid Film and the Fluid Film Pro Gun to spray inside the frame.

Started by putting tape over all of the holes:

Here is the pro gun with one of the extension nozzles:

This stuff is thick! I had it in the house at 70 degrees... Took a lot of stirring and I even started blowing my heat gun into it as I stirred to get it to soften up. Eventually got it pourable. Sprayed it at about 100 psi at the gun.

Put about 1/4 of the can into the frame. Garage now smells like a barnyard.

We also got the Hardtop out and replaced the bottom seals:

And got the doors on:

As it sits, it is about 1" higher in the rear, but it only has a few gallons in it, we may add some spacers up front.

My hours of calculating backspacing and tire widths for tire stickout, worked out well. Tire stickout past the wider OEM flares (Rubi and Sarah) is perfect at about 1":

Started by putting tape over all of the holes:

Here is the pro gun with one of the extension nozzles:

This stuff is thick! I had it in the house at 70 degrees... Took a lot of stirring and I even started blowing my heat gun into it as I stirred to get it to soften up. Eventually got it pourable. Sprayed it at about 100 psi at the gun.

Put about 1/4 of the can into the frame. Garage now smells like a barnyard.

We also got the Hardtop out and replaced the bottom seals:

And got the doors on:

As it sits, it is about 1" higher in the rear, but it only has a few gallons in it, we may add some spacers up front.

My hours of calculating backspacing and tire widths for tire stickout, worked out well. Tire stickout past the wider OEM flares (Rubi and Sarah) is perfect at about 1":

Last edited:

Could be the angle. But it appears that the rear axle could be pushed back towards the rear. Seems as if the axle is line centered in the rear wheel well.Picked up a gallon of Fluid Film and the Fluid Film Pro Gun to spray inside the frame.

Started by putting tape over all of the holes:

View attachment 145023

Here is the pro gun with one of the extension nozzles:

View attachment 145024

This stuff is thick! I had it in the house at 70 degrees... Took a lot of stirring and I even started blowing my heat gun into it as I stirred to get it to soften up. Eventually got it pourable. Sprayed it at about 100 psi at the gun.

View attachment 145025

Put about 1/4 of the can into the frame. Garage now smells like a barnyard.

We also got the Hardtop out and replaced the bottom seals:

View attachment 145026

And got the doors on:

View attachment 145027

View attachment 145028

View attachment 145029

As it sits, it is about 1" higher in the rear, but it only has a few gallons in it, we may add some spacers up front.

View attachment 145030

My hours of calculating backspacing and tire widths for tire stickout, worked out well. Tire stickout past the wider OEM flares (Rubi and Sarah) is perfect at about 1":

View attachment 145033