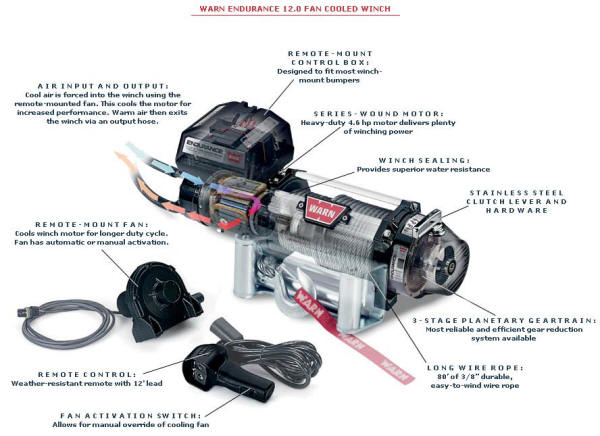

Finally there is the Endurance 12.0. This winch was in a way Warn throwing the kitchen sink at the mid frame platform. The Endurance used the high speed layout like the 9.5ti with lower gears and added fan forced cooling to the mix. Cooling was provided by a remote mounted blower with hoses that attached to the brush cap on the motor. I was lucky enough Warn sent me one to test (most likely to get my modded 8274 off the TJ) and while it was no 8274 it was an excellent winch with decent speed and very good amp draw at lower loads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Warn mid frame winch resource thread

- Thread starter Blackjack

- Start date

Hmmmm - I'm thinking that a solenoid that shorts out the motor when not running would help with the run-on.

Hmmmm - I'm thinking that a solenoid that shorts out the motor when not running would help with the run-on.

Aren't these series wound though? I understood that feature to be specific to a permanent magnet motor.

Warn has a contactor that is used on their series wound motors on the DC hoist line but it is expensive and with the faster line speeds of the recreational winches leads to drivetrain shock.Hmmmm - I'm thinking that a solenoid that shorts out the motor when not running would help with the run-on.

Permanent magnet motors are naturally self braking but I have seen some that will have a small amount of run on.Aren't these series wound though? I understood that feature to be specific to a permanent magnet motor.

Warn has a contactor that is used on their series wound motors on the DC hoist line but it is expensive and with the faster line speeds of the recreational winches leads to drivetrain shock.

Permanent magnet motors are naturally self braking but I have seen some that will have a small amount of run on.

The run on is just a function of the rotor and gears flywheeling until their inertia burns up in friction though, right?...IIRC, PM motors brake because the magnets induce a current in the stator (when it's shorted together) that creates a field which opposes the motion of the spinning rotor. As a result, the braking is strongest when the rotor is still moving pretty quickly, and diminishes as it slows, so the run on should be reduced as the speed falls off quickly initially but loses the braking effect as it slows.

The run on is just a function of the rotor and gears flywheeling until their inertia burns up in friction though, right?...IIRC, PM motors brake because the magnets induce a current in the stator (when it's shorted together) that creates a field which opposes the motion of the spinning rotor. As a result, the braking is strongest when the rotor is still moving pretty quickly, and diminishes as it slows, so the run on should be reduced as the speed falls off quickly initially but loses the braking effect as it slows.

I’m no electrical engineer, but that’s how I understand it too.

I’m no electrical engineer, but that’s how I understand it too.

I'm just mechanical, but an electrical engineer helped me solve a mechanical problem with that feature. It's been too long to remember exactly what the problem was but I can think of a few bad things that can happen from letting a fan or a compressor spin itself down or spin backwards due to flow reversal so I'm sure it was something like that.

The run on is just a function of the rotor and gears flywheeling until their inertia burns up in friction though, right?...IIRC, PM motors brake because the magnets induce a current in the stator (when it's shorted together) that creates a field which opposes the motion of the spinning rotor. As a result, the braking is strongest when the rotor is still moving pretty quickly, and diminishes as it slows, so the run on should be reduced as the speed falls off quickly initially but loses the braking effect as it slows.

Yes especially with larger series wound motors and lower friction winches like the 8274 run on can be significant. Warn does not short the armature on their permanent magnet motors (Dynamic Braking IIRC) on things like ATV winches so it is just the magnetic fields pulling on the iron in the armature to slow it down.

Last edited:

TRULY outstanding information @Blackjack thank you!

I have a general question on Warn's earlier solenoids as compared to their current contactors. I'm an electrical guy but have only seen comments that a contactor is better, but I don't know why that is. When Warn replaced my 9.5Xp's motor, they also upgraded it from its original solenoid pack to the latest contactor pack. How would you explain the differences?

By the way, my 9.5Xp's motor didn't burn up on its own. I bought a synthetic winch line from TRE and the screw they included to secure it to the drum was a little too long. It created steel shavings which worked their way into the motor shorting it out. Warn lived up to its superb support reputation by replacing it at no charge. The upgrade to the contactor pack was even more icing on the cake.

I have a general question on Warn's earlier solenoids as compared to their current contactors. I'm an electrical guy but have only seen comments that a contactor is better, but I don't know why that is. When Warn replaced my 9.5Xp's motor, they also upgraded it from its original solenoid pack to the latest contactor pack. How would you explain the differences?

By the way, my 9.5Xp's motor didn't burn up on its own. I bought a synthetic winch line from TRE and the screw they included to secure it to the drum was a little too long. It created steel shavings which worked their way into the motor shorting it out. Warn lived up to its superb support reputation by replacing it at no charge. The upgrade to the contactor pack was even more icing on the cake.

@Blackjack Is there anything specific I should know about an old HS9500 such as specific maintenance tips, dos and donts, weaknesses, etc? Watch my fingers goes without saying

TRULY outstanding information @Blackjack thank you!

I have a general question on Warn's earlier solenoids as compared to their current contactors. I'm an electrical guy but have only seen comments that a contactor is better, but I don't know why that is. When Warn replaced my 9.5Xp's motor, they also upgraded it from its original solenoid pack to the latest contactor pack. How would you explain the differences?

By the way, my 9.5Xp's motor didn't burn up on its own. I bought a synthetic winch line from TRE and the screw they included to secure it to the drum was a little too long. It created steel shavings which worked their way into the motor shorting it out. Warn lived up to its superb support reputation by replacing it at no charge. The upgrade to the contactor pack was even more icing on the cake.

Warn did you a solid and most likely replaced your solenoid pack since the XP solenoids are discontinued and they thought one of yours might be compromised.

So a contactor has a few advantages over solenoids. Biggest is weather resistance and efficiency. They are IP68 rated and since they cut out all the buss bars and other extra connections there is less to corrode and increase resistance to the circuit. Next would be that they are more compact allowing more mounting options. Finally is reliability, Albright has been in the contactor business for a long time and they produce an excellent product that has been beaten mercilessly all over the planet.

Last edited:

@Blackjack Is there anything specific I should know about an old HS9500 such as specific maintenance tips, dos and donts, weaknesses, etc? Watch my fingers goes without saying

Biggest thing is to manage your line to avoid panic plugging the winch. Other that they are the same as other winches, keep them clean and it does not hurt to tear them down and give them a clean and grease.

Great response, thank you!Warn did you a solid and most likely replaced your solenoid pack since the XP solenoids are discontinued and they thought one of yours might be compromised.

So a contactor has a few advantages over solenoids. Biggest is weather resistance and efficiency. They are IP68 rated and since they cut out all the buss bars and other extra connections there is less to corrode and increase resistance to the circuit. Next would be that they are more compact allowing more mounting options. Finally is reliability, Albright has been in the contactor business for a long time and they produce and excellent product that has been beaten mercilessly all over the planet.

Ok this last bit took a bit of digging but one last bit of history/breakdown and we can start getting into some techy stuff.

Over the course of the midframes run there have been three different brakes used. Each has its strengths and weaknesses and I will try to show those.

First up is the spring brake. Unfortunately this one is frozen up so I cannot get it apart to show all its parts. This brake was interesting in that it uses a sprag (one way roller bearing) which ensures no frictional loss of the motor while powering in. This gave maximum pulling power and no load line speed from the lower HP motors of the day. The disadvantage was long term durability. The three pieces I placed next to the main assembly is the spring brake from a current ATV winch just to show what is inside doing the load holding and as you can see those parts are pretty small.

Next is the first gen cone brake. These were are huge step up in load holding and durability. The tradeoff was a small loss in efficiency, are much more complicated in design as well as requiring being greased making them more expensive to produce. Versions of these continued to be used in Warns industrial winches and hoists because of how effective they are.

Over the course of the midframes run there have been three different brakes used. Each has its strengths and weaknesses and I will try to show those.

First up is the spring brake. Unfortunately this one is frozen up so I cannot get it apart to show all its parts. This brake was interesting in that it uses a sprag (one way roller bearing) which ensures no frictional loss of the motor while powering in. This gave maximum pulling power and no load line speed from the lower HP motors of the day. The disadvantage was long term durability. The three pieces I placed next to the main assembly is the spring brake from a current ATV winch just to show what is inside doing the load holding and as you can see those parts are pretty small.

Next is the first gen cone brake. These were are huge step up in load holding and durability. The tradeoff was a small loss in efficiency, are much more complicated in design as well as requiring being greased making them more expensive to produce. Versions of these continued to be used in Warns industrial winches and hoists because of how effective they are.

Finally there is the current cone brake. The one I am showing here is from a Large Frame winch but they are identical other than scale. This version of the cone brake uses loose brake frictions that are made up of material similar to that used on disc brake pads requiring no lubrication. Even the cam only requires the smallest amount of lubrication when being assembled. You will also notice that I have the one brake and frictions zip tied together. Here is my first bit of tech: Unless you are replacing the brake I do not recommend removing it from the drum. If you need to remove it you do not want to let the cam unwind which means not letting the frictions loose from the brake hence the zip ties or some other means of keeping the brake together. That also means you do not want to remove the snap ring from the brake either. Anything that allows the brake cam to unwind risks the chance of damage to the clock spring leading to brake failure while in operation.

The brake:

The cam and cones. You can also see the clock spring between the cones:

The motor coupler. This combined with the dry frictions give this brake its distinctive bolt in the blender sound (more prevalent on the M8000 and other winches using the lower gear ratios) especially under low load conditions.

The snap ring that should never be removed.

This brake for the most part is relatively simple, reliable in most all conditions other than if not being serviced after deep water excusrions on the older non sealed winches. The one big thing to note is the use of this brake with synthetic winch line and why it took Warn so long to adopt any kind of synthetic line at all. Like the brakes on your Jeep the cone brake works by converting rotational energy to heat and that heat is absorbed into the drum pin and thus into your winch line potentially causing the line to degrade and fail. This is why there are many Warnings in the Warn winch manuals about not powering out the winch for extended periods of time and why Warn over the years came up with different synthetic lines to combat the brake heat problem. The truth is that it is actually pretty rare that you would need to do so anyway thus being cognizant of what can happen and adjusting your winching stategy will prevent excessive brake heat in the first place.

The brake:

The cam and cones. You can also see the clock spring between the cones:

The motor coupler. This combined with the dry frictions give this brake its distinctive bolt in the blender sound (more prevalent on the M8000 and other winches using the lower gear ratios) especially under low load conditions.

The snap ring that should never be removed.

This brake for the most part is relatively simple, reliable in most all conditions other than if not being serviced after deep water excusrions on the older non sealed winches. The one big thing to note is the use of this brake with synthetic winch line and why it took Warn so long to adopt any kind of synthetic line at all. Like the brakes on your Jeep the cone brake works by converting rotational energy to heat and that heat is absorbed into the drum pin and thus into your winch line potentially causing the line to degrade and fail. This is why there are many Warnings in the Warn winch manuals about not powering out the winch for extended periods of time and why Warn over the years came up with different synthetic lines to combat the brake heat problem. The truth is that it is actually pretty rare that you would need to do so anyway thus being cognizant of what can happen and adjusting your winching stategy will prevent excessive brake heat in the first place.

Last edited:

Years ago I bought an m8000 dirt cheap, with a couple broken tie rod mounting ears broken off the case, and the rope wound backwards. Turns out the remote switch was bad and would only power out the motor. His fix was to wind the rope to power in. I have no idea how much use this got. How bad do you think the brake could be, and is it fixable? I've written off new casing and strut bars due to the high cost of those items.

Years ago I bought an m8000 dirt cheap, with a couple broken tie rod mounting ears broken off the case, and the rope wound backwards. Turns out the remote switch was bad and would only power out the motor. His fix was to wind the rope to power in. I have no idea how much use this got. How bad do you think the brake could be, and is it fixable? I've written off new casing and strut bars due to the high cost of those items.

I would be as much or more worried about the motor. Running the winch like that is equivalent to driving with your foot on the brake the whole time. Only way to know is to break the winch down and look inside the drum. If you see bluing on any of the parts the brake is compromised and would need to be replaced.

I've used it a few times, more strenuously than I would have liked, on my Samurai. The motor pulled fine after I replaced the switch with a radio shack special that kinda fit. One of the solenoids gave up on powering in until you bumped it with a hammer. At that point a black friday specail smittybilt was installed in its place. Oddly enough I still have more confidence in the beat up warn than the SB. Lol. You wouldn't have a lead on new struts/case halves, would you?

I've used it a few times, more strenuously than I would have liked, on my Samurai. The motor pulled fine after I replaced the switch with a radio shack special that kinda fit. One of the solenoids gave up on powering in until you bumped it with a hammer. At that point a black friday specail smittybilt was installed in its place. Oddly enough I still have more confidence in the beat up warn than the SB. Lol. You wouldn't have a lead on new struts/case halves, would you?

Send me a pick of your winch and I will see if I can scrounge up some good used ones.