You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your TJ today?

- Thread starter LJRubiconGuy

- Start date

Oldguy

TJ Enthusiast

New adjustable control arms all the way around and new kenwood speakers

Kiwi TJ

I don't suffer from insanity I enjoy every minute

Supporting Member

Ride of the Month Winner

You only have to do it once and now your hooked...I look for any excuse to strip offI needed to put the soft top down to get the front knob screws out of the upper door frames to test fit my copy/version of the Arizona Rocky Road CB mount. Using the Rugged Ridge mount for mic cable control. Still in early mock up.

View attachment 104048

First time since I bought it, I put the top down and took the doors off.

View attachment 104049

Driving around late last night felt awesome!

Kiwi TJ

I don't suffer from insanity I enjoy every minute

Supporting Member

Ride of the Month Winner

Thanks...I mocked them up and didn't like the big black steel and wanted to bring a bit of the out side colour in the cab...indoor/outdoor flow I think they call it haha. I'm happy with the result and they are sturdy lil things.Nice touch color matching the steel blue color...looks great!

Replaced my rear upper and lower control arms. This project started while trying to find a clunking noise in the suspension. I'd picked up the parts and then my son found that a sway bar link was loose. We torqued it down and that fixed the issue. Still replaced the control arms with new ones from Crown. Will take care of the front ones in the future as I update the original suspension. @Squatch mentioned in a thread that on control arms he'd worked on the bushings on the lower arms were worn out while the upper arm bushings still looked good. This is exactly what I found on my '97.

What did I do to my TJ today? Well, not exactly what I set out to do, but progress none the less. My goal was to extend the spare wheel snubbers to make contact with the tire correctly. She had JK wheels and spare when I bought her, and I knew the spacer was a tad funky, the top bolt holding the tire was welded, the bottom two were wheel studs. It looked as is the welds had broken where bolts had been, and the studs had been used in their place, but they didn’t really fit right. It worked, and it hasn’t been high on my priority list to reconcile. When I got it apart I found what a dog’s breakfast it really was. The studs were used because someone had hacked off the original bolts, left the heads in place and drilled right up against them and through part of the original bolt heads instead of grinding them off, to make it fit a larger wheel. One of the studs I couldn’t get a grip on enough to turn it, so it got torched off (things you’d rather find out in the drive than on the trail). Torched and ground the heads/welds of the original two bolts and welded on new bolts. Cleaned and painted the spacer, reattached everything. The snubbers get pushed back a couple days now. So it goes.

Last edited:

Found out today a TJ serpentine belt fits perfectly as a power steering bypass belt on my f150...

Finished changing out my worn out RE control arms with MetalCloak aluminum double adjustable uppers and lowers.

BoldlyGoing

TJ Addict

Ugh. That's the same situation I had when I got my LJ.What did I do to my TJ today? Well, not exactly what I set out to do, but progress none the less. My goal was to extend the spare wheel snubbers to make contact with the tire correctly. She had JK wheels and spare when I bought her, and I knew the spacer was a tad funky, the top bolt holding the tire was welded, the bottom two were wheel studs. It looked as is the welds had broken where bolts had been, and the studs had been used in their place, but they didn’t really fit right. It worked, and it hasn’t been high on my priority list to reconcile. When I got it apart I found what a dog’s breakfast it really was. The studs were used because someone had hacked off the original bolts, left the heads in place and drilled right up against them and through part of the original bolt heads instead of grinding them off, to make it fit a larger wheel. One of the studs I couldn’t get a grip on enough to turn it, so it got torched off (things you’d rather find out in the drive than on the trail). Torched and ground the heads/welds of the original two bolts and welded on new bolts. Cleaned and painted the spacer, reattached everything. The snubbers get pushed back a couple days now. So it goes.

View attachment 104472

View attachment 104473

View attachment 104474

View attachment 104475

View attachment 104476

View attachment 104477

No idea what the PO was thinking.

Ended up just using the tire carrier I had from my old TJ and tossing the one that came with mine.

Curious what you've got in mind to extend the snubbers. My tire is just kind of hanging back there which is no doubt slowly destroying my tailgate.

Finished up the CB mount. I knew I should have tested latching the top before I finished it. But I didn't. Have a small issue getting the top latched/unlatched, but it is possible. Wouldn't be too hard to mod the bar mount for full regular function. Not sure how often I'll have the need to put the top down, so we'll worry about that down the road.

I have a bag of hammers. Rubber ones.Ugh. That's the same situation I had when I got my LJ.

No idea what the PO was thinking.

Ended up just using the tire carrier I had from my old TJ and tossing the one that came with mine.

Curious what you've got in mind to extend the snubbers. My tire is just kind of hanging back there which is no doubt slowly destroying my tailgate.

There’s a How To thread on this forum where one of the posters used Harbor Freight rubber mallets, cut off the handles and trimmed/drilled/countersunk to fit. That’s the direction I’m going. I liked the look, and he’d stated they’d held up for 10 years as of his posting. Works for me.

I’ll post pics as/when I mount them.

It’s a decent mount. I’ve had one in for a year with no issues.Finished up the CB mount. I knew I should have tested latching the top before I finished it. But I didn't. Have a small issue getting the top latched/unlatched, but it is possible. Wouldn't be too hard to mod the bar mount for full regular function. Not sure how often I'll have the need to put the top down, so we'll worry about that down the road.

View attachment 104509

View attachment 104510

View attachment 104511

Also look into Coppinger Cove. I do ask you as we head to Tn quite often to wheel because it has quite few offroad activity especially on weeks days.I was thinking Windrock, Adventure offroad Park, and Land Between The Lakes/ Turkey Bay. Haven’t heard of Estill Fork or Aetna Mountain but I’ll definitely look into it now. I haven’t lived in this state that long to know every place. All I know is there’s a lot less places than the west coast.

We will be on Windrock around Aug 21-22 if you like to join Us.

By now Wind rock has more trails for Jeeps and rock bouncers. ATV and SxS are still welcome but can't tell you about trails for them as I didn't enjoy them.We did Wind Rock on ATV’s a few years back over New Year’s. Took us about 5 hours to do about 10 miles that was supposed to be a loop. We within about a mile of the end of the trail and they had logged it, we couldn’t get through there was a drop off on one side and a rock wall on the other. We have to turn around and go back, it was dark by the time we made it back to the truck and trailer. When we were there it didn’t look like there was anything wide enough for a Jeep.

Received my JKS body lift and Brown Dog MML and thought I would knock out both in a day. Silly me. Had some POR-15 laying around so decided to do the frame. Ended up removing the rock sliders (PO installed) and had 5lbs of dirt and rust between them and the body, cleaned up and painted. Noticed my cam bolt on the right front control arm (loose) had spun around and was 180* off from the left, adjusted and re-torqued. Went ahead and wire brushed and painted both block mounts while they were out. And so, and so on.

Two days later and I am pleased to say I have gotten rid of that ugly transfer case drop, and I have no vibes! Plus, I'm a little more comfortable with the corrosion control.

Quick question, is there a fabric, or some other type of material that is used between the rock sliders and body to mitigate any further chaffing/dirt/corrosion? I have seen where people run a bead of silicone along the top to keep water and dirt out, but I'm wondering if there is something else worth doing. Thanks.

Two days later and I am pleased to say I have gotten rid of that ugly transfer case drop, and I have no vibes! Plus, I'm a little more comfortable with the corrosion control.

Quick question, is there a fabric, or some other type of material that is used between the rock sliders and body to mitigate any further chaffing/dirt/corrosion? I have seen where people run a bead of silicone along the top to keep water and dirt out, but I'm wondering if there is something else worth doing. Thanks.

MountaineerTom

LJ Enthusiast, Retired USAF Weapons Loader

Supporting Member

Ride of the Month Winner

Received my JKS body lift and Brown Dog MML and thought I would knock out both in a day. Silly me. Had some POR-15 laying around so decided to do the frame. Ended up removing the rock sliders (PO installed) and had 5lbs of dirt and rust between them and the body, cleaned up and painted. Noticed my cam bolt on the right front control arm (loose) had spun around and was 180* off from the left, adjusted and re-torqued. Went ahead and wire brushed and painted both block mounts while they were out. And so, and so on.

Two days later and I am pleased to say I have gotten rid of that ugly transfer case drop, and I have no vibes! Plus, I'm a little more comfortable with the corrosion control.

Quick question, is there a fabric, or some other type of material that is used between the rock sliders and body to mitigate any further chaffing/dirt/corrosion? I have seen where people run a bead of silicone along the top to keep water and dirt out, but I'm wondering if there is something else worth doing. Thanks.

Some come with rubber liners that go between the body and sliders. Off the top of my head, I don't remember the brands.

You may have luck using a material like this. https://www.amazon.com/gp/product/B00L8NSXNY/?tag=wranglerorg-20

I've used that to make some smaller gasket like material in the past. There are different sizes and thickness available on Amazon.

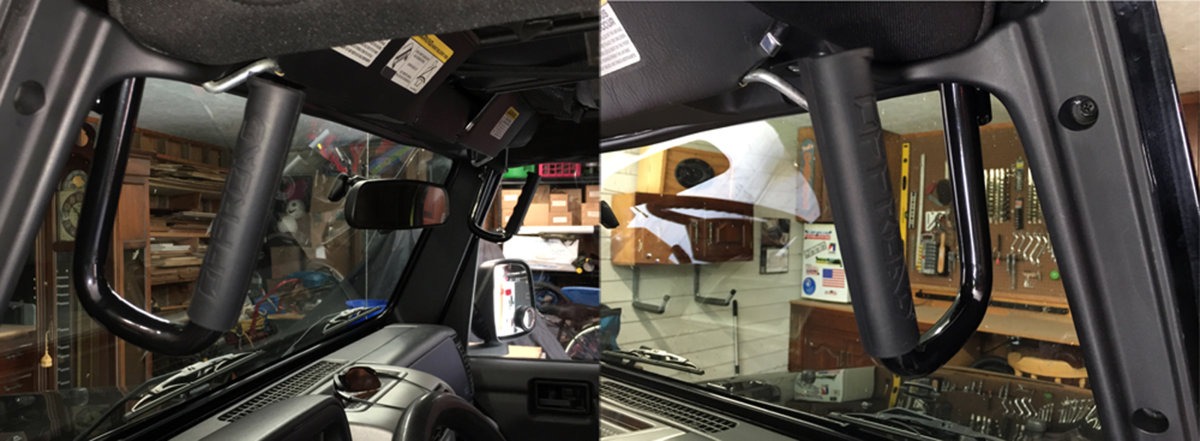

Someone said it was grab handle week (@Kiwi TJ). I've been wanting grab handles for a while, found these on Amazon for 27 bucks. Not the prettiest welds, but plenty solid, inexpensive, and practical.

GeorgeSully

TJ Enthusiast

Someone said it was grab handle week (@Kiwi TJ). I've been wanting grab handles for a while, found these on Amazon for 27 bucks. Not the prettiest welds, but plenty solid, inexpensive, and practical.

View attachment 104602View attachment 104603

Those are the same ones I got just a different name on the handle. They’ve stood up to some abuse.

Sent from my iPhone using Tapatalk

derekmac

TJ Addict

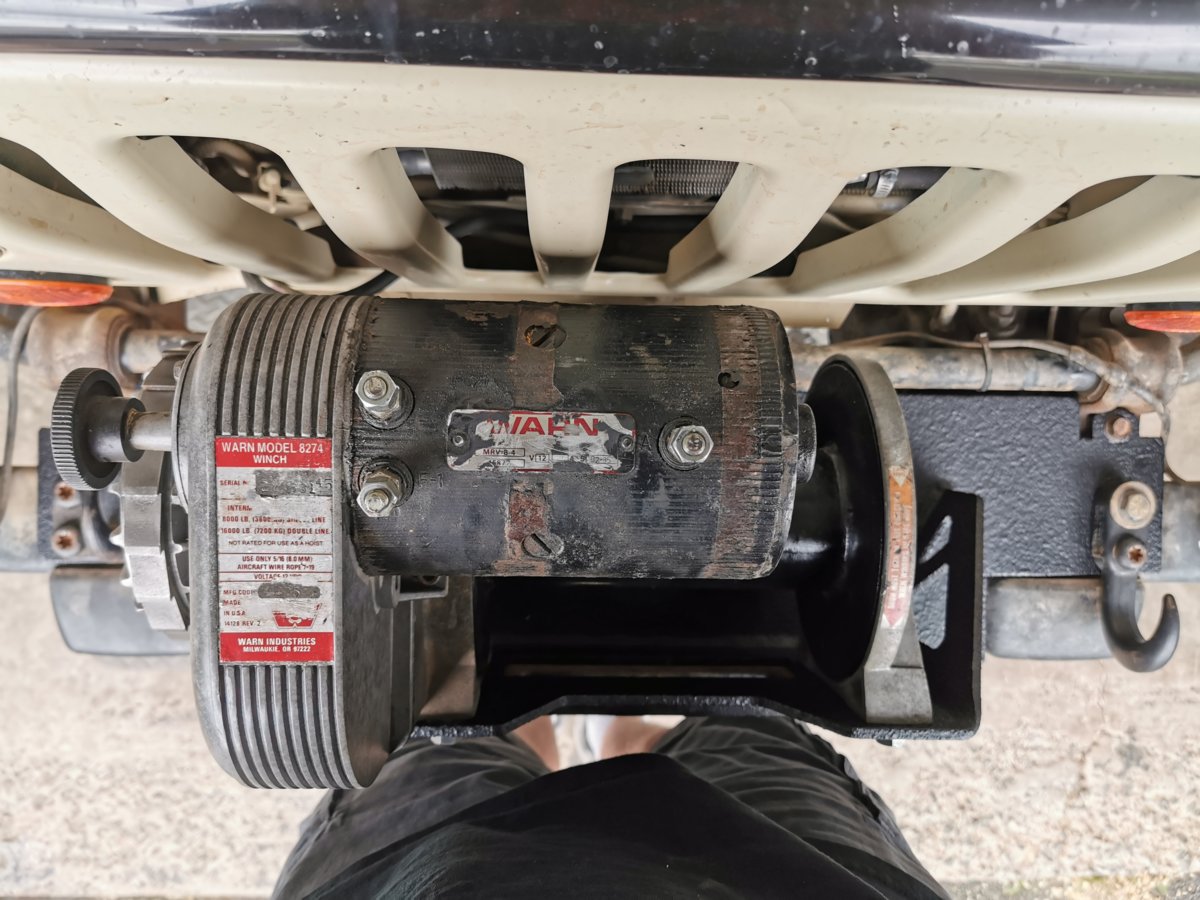

Mounted my 8274. Now to just do the wiring for it, but I need to wait for the wire crimper to get here so I can crimp the 1/0 wire I'm using.

The stock bumper looks good the way you cut it.Mounted my 8274. Now to just do the wiring for it, but I need to wait for the wire crimper to get here so I can crimp the 1/0 wire I'm using.

View attachment 104636View attachment 104637View attachment 104638View attachment 104639