You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

which joint to choose

- Thread starter Eddie Greenlee

- Start date

PStov98TJ

TJ Enthusiast

I will do some measuring on my jeep a little later today and see what my upper mount width is and get back with ya.Just did a quick check, the upper CA mounts use 2" joints. Lower's use 2.625". So unless you can weld...you're gonna need 2" wide joints.

Chris, not taking up for RC, but the have a johnny joint in their adjustable control arms , now from other opinions I agree that Currie is the originator for the johnny joint but take a look at the RC johnny joint repair kit .

Just some stuff I know that may help with this. Daystar was one of the first to knock off the JJ. Their first marketing language for it included the following (para) phrase- We've made the urethane races smaller so you don't need a press to get the snap rings seated unlike some other brands.

What they overlooked is one of the features of the JJ that has made it so durable and successful is just how tight they are and how much preload is on the races when the snap ring gets seated fully into the groove after using a shop press to mash the crap out of them.

There is far more to joint design that the average user can tell simply by looking at them.

I've got another one for you. I know of a race car that was running the RK joints. After testing, the joints were toast. The owner of the company was present and his comment was, Yeah, we just replace the joints after every race.

To put that in perspective, I know of race cars in KOH that have never changed their JJ's after several races because they don't need to.

PStov98TJ

TJ Enthusiast

To put that in perspective, I know of race cars in KOH that have never changed their JJ's after several races because they don't need to.

That's impressive to say the least.

Granted I don't wheel in the rocks like some of you guys down in Johnson Valley (we don't really have those sorts of rocks up here in the PNW), but I can tell you that I do wheel it, and my JJs are going on close to 2 years now I believe, without any issues whatsoever.

They're both excellent on-road and off-road.

They're both excellent on-road and off-road.

ok i just measured the brackets for the upper front and rear control arms on my 97 tj sport.

and they are ((((( 2" ))))) . how bout that. so upon further scientific studying the 2 1/2" joint just wont go in. ha. anyway ill continue my quest for a better joint or ill deal with the RC till i can pocket better quality joints.

and they are ((((( 2" ))))) . how bout that. so upon further scientific studying the 2 1/2" joint just wont go in. ha. anyway ill continue my quest for a better joint or ill deal with the RC till i can pocket better quality joints.

Last edited:

thanks for your input Mr BlaineJust some stuff I know that may help with this. Daystar was one of the first to knock off the JJ. Their first marketing language for it included the following (para) phrase- We've made the urethane races smaller so you don't need a press to get the snap rings seated unlike some other brands.

What they overlooked is one of the features of the JJ that has made it so durable and successful is just how tight they are and how much preload is on the races when the snap ring gets seated fully into the groove after using a shop press to mash the crap out of them.

There is far more to joint design that the average user can tell simply by looking at them.

I've got another one for you. I know of a race car that was running the RK joints. After testing, the joints were toast. The owner of the company was present and his comment was, Yeah, we just replace the joints after every race.

To put that in perspective, I know of race cars in KOH that have never changed their JJ's after several races because they don't need to.

Ahoragi

TJ Addict

- Joined

- Mar 25, 2016

- Messages

- 1,272

I have personal experience rebuilding RC joints that were on my XJ's long arms and will never use one of them again. I swapped em out for Currie JJ's.

Six years later and they are still tight with zero play.

The problem with the RC joints was that the races were not designed properly to allow a clamping force against the ball. No matter how tight you adjusted the joint they ball just moved around freely without any tension on it. I tightened one replacement until the tool broke and the ball still rotated in there without any tension. It clunked after one day.

Six years later and they are still tight with zero play.

The problem with the RC joints was that the races were not designed properly to allow a clamping force against the ball. No matter how tight you adjusted the joint they ball just moved around freely without any tension on it. I tightened one replacement until the tool broke and the ball still rotated in there without any tension. It clunked after one day.

thats sad .

ok i called northridge and not only is the the currie jj diameter 2 1/2" which would probably work but the width is actually 2.625" wide. the dang thing is growing. ha.

ok i called northridge and not only is the the currie jj diameter 2 1/2" which would probably work but the width is actually 2.625" wide. the dang thing is growing. ha.

PStov98TJ

TJ Enthusiast

If you buy a set of upper rear arms, they will be the correct size. The problem you're having is they don't make a 2" wide JJ with a 1.25" shank. I suppose because the upper arms don't need to be quite as beefy as the lowers do, so the tube doesn't need to be as big, and therefore the shank on the joint doesn't need to be as big.

We just went through the same thing with some clunking RE hard plastic races. The gap between the two halves was non existent so when you tightened down the adjuster ring, the halves butted into each other and didn't take up the slop around the ball. We sanded down the two halves and finally got them to tighten that way but it was painful.I have personal experience rebuilding RC joints that were on my XJ's long arms and will never use one of them again. I swapped em out for Currie JJ's.

Six years later and they are still tight with zero play.

The problem with the RC joints was that the races were not designed properly to allow a clamping force against the ball. No matter how tight you adjusted the joint they ball just moved around freely without any tension on it. I tightened one replacement until the tool broke and the ball still rotated in there without any tension. It clunked after one day.

Even with a single upper doing all the work on a front 3 link, we only use joints with 1" shanks.If you buy a set of upper rear arms, they will be the correct size. The problem you're having is they don't make a 2" wide JJ with a 1.25" shank. I suppose because the upper arms don't need to be quite as beefy as the lowers do, so the tube doesn't need to be as big, and therefore the shank on the joint doesn't need to be as big.

that makes since to me for some reason. Im all about making something work right thats wrong.We just went through the same thing with some clunking RE hard plastic races. The gap between the two halves was non existent so when you tightened down the adjuster ring, the halves butted into each other and didn't take up the slop around the ball. We sanded down the two halves and finally got them to tighten that way but it was painful.

im at a stand still. My new shocks will be in monday ( thats a good thing) as will the used upper fronts CAs . I guess ill stop for today and rethink things monday. Might be doing a little sanding monday too. ha.

We just went through the same thing with some clunking RE hard plastic races. The gap between the two halves was non existent so when you tightened down the adjuster ring, the halves butted into each other and didn't take up the slop around the ball. We sanded down the two halves and finally got them to tighten that way but it was painful.

Last edited:

So you did replace the RC X-FLex JJ out for Currie JJs?????I have personal experience rebuilding RC joints that were on my XJ's long arms and will never use one of them again. I swapped em out for Currie JJ's.

Six years later and they are still tight with zero play.

The problem with the RC joints was that the races were not designed properly to allow a clamping force against the ball. No matter how tight you adjusted the joint they ball just moved around freely without any tension on it. I tightened one replacement until the tool broke and the ball still rotated in there without any tension. It clunked after one day.

im at a stand still. My new shocks will be in monday ( thats a good thing) as will the used upper fronts CAs . I guess ill stop for today and rethink things monday. Might be doing a little sanding monday too. ha.

Put the shocks in first, focus on the joints after you take it for a ride with the new shocks. That would be my suggestion.

And remember the saying... Buy once, cry once.

just got my shocks , so my son and I are about to put them on. Thought there might be some instructions with them but hopefully things are pretty straight forward. RS55255 and RS55256 are the shock part numbers.

wonder what the torque specs are on the bar pin bolts and the shock nut?

wonder what the torque specs are on the bar pin bolts and the shock nut?

You don't need instructions to install shocks, trust me. It's a walk in the park, not even kidding. I could probably replace all 4 shocks on my TJ in about 15 minutes per shock (most of that time being taking off the wheels and jacking up the vehicle).

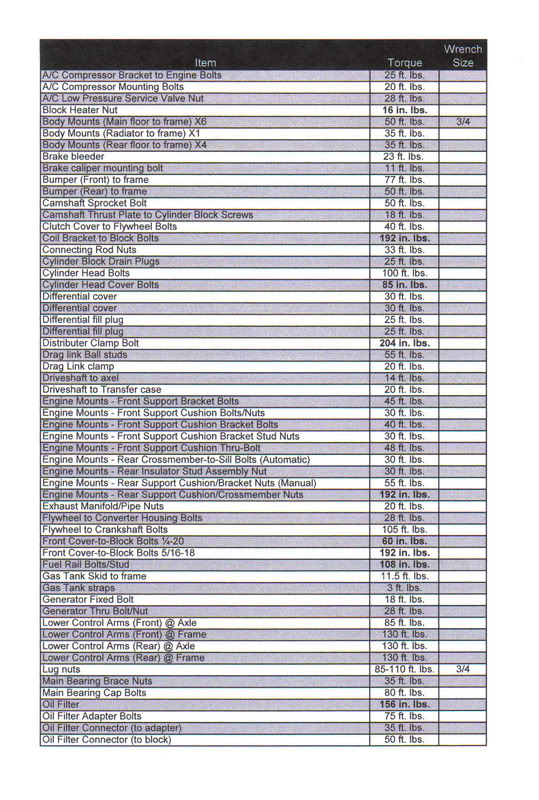

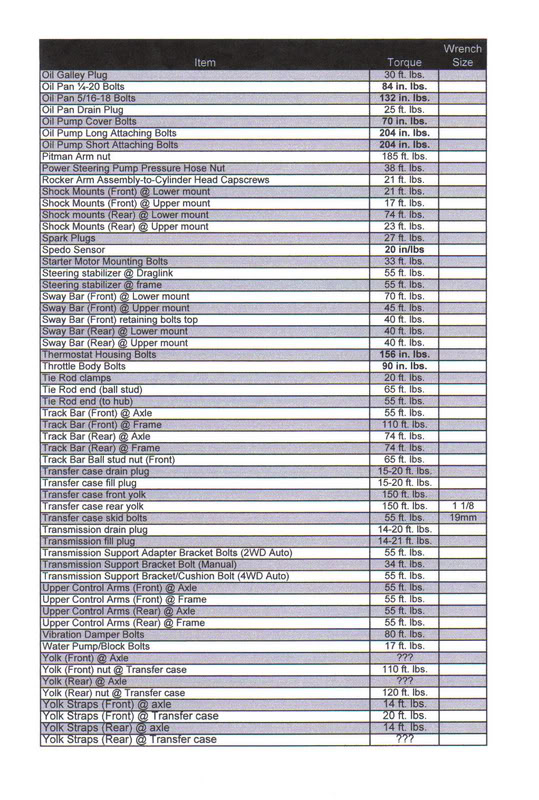

Here's a torque spec sheet for you:

Here's a torque spec sheet for you: