I posted it on OfferUp last night and I guess it violates their policy so they took the listing down. I listed it for $200…Nice write-up!

I got ~$300 for a stock TJ cat a few weeks ago. $20 for the Chinese aftermarket unit that failed while under warranty.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The LS Swap Begins

- Thread starter beaufrusetta

- Start date

Interesting…I will call around. Thank you!Local scrap yard gave me that price. You might want to call around. The price might be enough to deal with the private party hassle.

That's a really good cost for the swap. A lot of work but still. I am not sure if the ECM does. Is the VIN still on the motor anywhere? Maybe you could look it up on carfax lol$5k is what I’m tracking as spent + to spend in Excel.

The guy I bought it from said it was “low mileage”, and judging by the look of all the accessories and the internals, it definitely doesn’t look like it has more than 100k.

You know, I haven’t checked, but I wonder if the ECM stores mileage? I’ve built a bench harness and can spin up and read the ECM…

I have the VIN that I pulled from the ECM…that’s a good idea, never thought of that.That's a really good cost for the swap. A lot of work but still. I am not sure if the ECM does. Is the VIN still on the motor anywhere? Maybe you could look it up on carfax lol

Not sure if it's worth paying the 35$ or whatever for it but might be a good option if you're reallyyy curious, with low miles and scrapped the title must've changed hands right before the motor was pulled I'd thinkI have the VIN that I pulled from the ECM…that’s a good idea, never thought of that.

Ok - so I've been in cleaning mode for the past several days, and trying to organize all the posts I have to sell all the things that are leftover from this swap. Please check the parts for sale thread and let me know if you need anything.

Today I dug in to the Jeep wiring harness to get everything labeled, and to document the connections here. I'd also like to get a sanity check on it before I start cutting - not that I can't put a wire back in, but I'd rather cut once and be done.

strikethrough. Let me know if I've got this wrong:

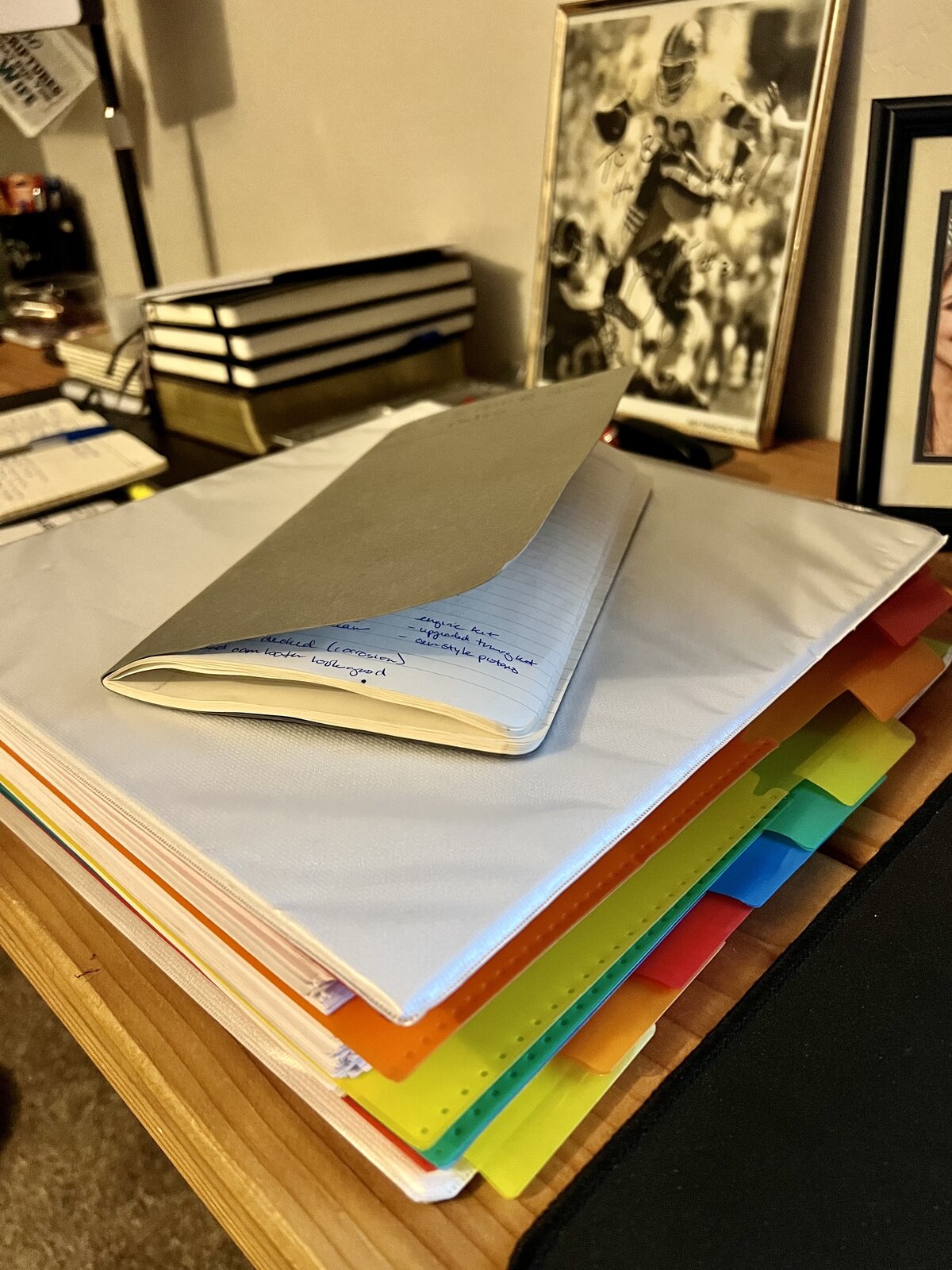

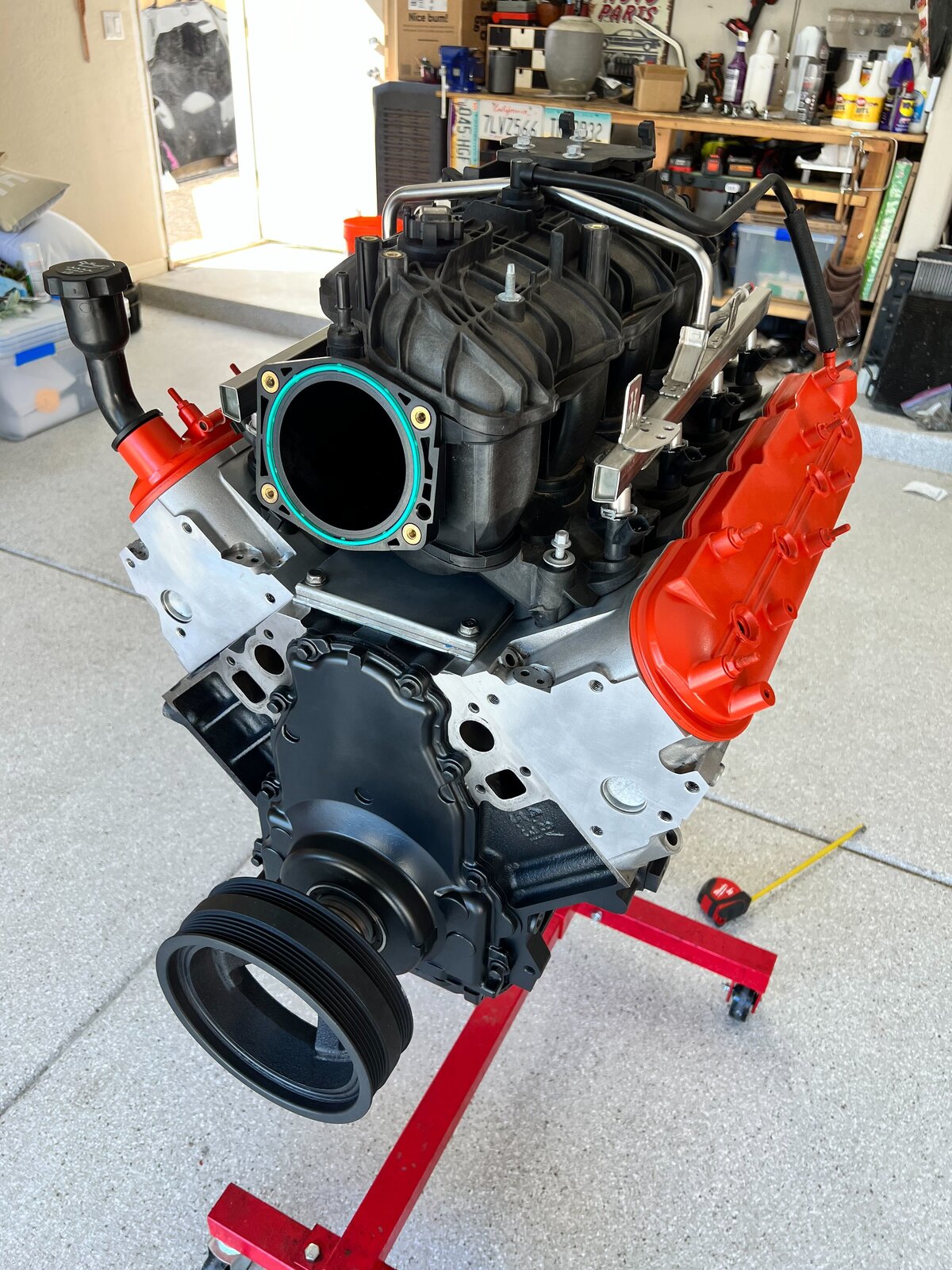

Altogether, that is just about half of the wires gone. I'm going to give this sanity check some time to simmer here on the forum, and then I'm going to go Edward Scissor Hands on it. And since a post is no good without pictures...here are 2...one of the engine made to look like I've made more progress with the heads than I really have (they sure clean up nice tho!), and the other is of my swap binder (research and service manual print outs) with my notebook of random thoughts, findings, and calculations.

Today I dug in to the Jeep wiring harness to get everything labeled, and to document the connections here. I'd also like to get a sanity check on it before I start cutting - not that I can't put a wire back in, but I'd rather cut once and be done.

2004 Jeep Wrangler Rubicon 4.0 Wiring Harness Clean-Up for LS Swap

Here are the connections that I've got on the main wiring harness for the engine. I've marked the connections I'm going to remove with aMAP Sensor- AC High Pressure Sensor

- Keeping this connection and sensor for when I figure out how I'm going to do the AC setup.

Intake Air Temperature Sensor4 Oxygen SensorsThrottle Position SensorIdle Air ControlFuel Injectors 1-6- Engine Coolant Temperature Sensor

- Keeping this because I'll run it in the other head with an adapter since I'll be keeping the stock gauges.

- AC Compressor Clutch Switch

- Keeping this connection for when I figure out how I'm going to do the AC setup.

- AC Low Pressure Sensor

- Keeping this connection and sensor for when I figure out how I'm going to do the AC setup.

Ignition Coil- Crankshaft Position Sensor

- Keeping this because...I'm pretty confident I'll need to feed data through it to get my tach to work.

- Oil Pressure Sensor

- Keeping this because...stock gauges.

- Starter

- Keeping this for obvious reasons...stock ignition through stock ECM...through stock starter connection connected to GM starter. Also, this is the one connector that gave me the most grief, and I broke it completely off - it's just the wire connector. Whoops.

- Keeping this for obvious reasons...stock ignition through stock ECM...through stock starter connection connected to GM starter. Also, this is the one connector that gave me the most grief, and I broke it completely off - it's just the wire connector. Whoops.

Ignition Coil Capacitor- Camshaft Position Sensor

- Keeping this...and I'm not sure why, but it feels like I should.

- Alternator

- Wondering about this one...does the Jeep ECM feed the voltage gauge from the alternator or from a reading off the battery?

- Backup Lamp

- Keeping this for obvious reasons.

- Transfer Case Switch

- Keeping my NP241D, so this makes sense.

- Vehicle Speed Sensor

- This should feed back in to the Jeep ECM as well as in to the Dakota Digital converter then on to the GM ECM so it knows that I'm moving.

- Front Locker Pump Switch

- Keeping because OEM lockers are where it's at.

- Front Locker Indicator Switch

- Keeping because OEM lockers are where it's at.

- Rear Locker Pump Switch

- Keeping because OEM lockers are where it's at.

- Rear Locker Indicator Switch

- Keeping because OEM lockers are where it's at.

- Fuel Pump

- Utilizing the fuel pressure regulator bypass setup from Novak, and for the stock fuel level gauge.

- C1 (ECM)

- C2 (ECM)

- C104 (On the firewall, above the rear of the valve cover)

- C103 (On the firewall, above the rear of the valve cover)

Altogether, that is just about half of the wires gone. I'm going to give this sanity check some time to simmer here on the forum, and then I'm going to go Edward Scissor Hands on it. And since a post is no good without pictures...here are 2...one of the engine made to look like I've made more progress with the heads than I really have (they sure clean up nice tho!), and the other is of my swap binder (research and service manual print outs) with my notebook of random thoughts, findings, and calculations.

So I tried on some paint today at lunch time. Set everything in place (not fully installed) so I could get a visual. I like the paint scheme...gonna move forward.

More updates.

I've got the motor nearly 100% assembled, however, I do need to swap out the alternator I've got with a 4-pin version. I ended up with a 2006 Tahoe 4x4 version (2-pin) that has voltage regulated via the ECM, however, I decided to go with my 1999 Silverado wiring harness and ECM, and that feature did not exist for that harness/ECM. I realize that I could probably just throw a 2-pin pigtail on the harness and go with it, but I won't be getting all the juice out of the alternator...soooo...I'll just go with swapping it out.

Also, I discovered that some time in the early/mid 2000s GM moved away from vacuum-based brake boosters to this lovely thing called "hydroboost". From what I've read, this is a hydraulic system that supports both the power steering and braking, and has a cooler mated to the system somewhere along the way. Instead of having 1 return port on the pump reservoir, it has 2. Now...given that these are low-pressure return ports...I'm thinking I can simply insert a T-fitting into main return from the steering box and have it dump to the second port as well - I mean, it's all going to the same place...right?

I'm still going back and forth and doing research on the steam/coolant crossover lines. I don't see why they are entirely necessary if you evacuate all the air out of the system. I see the point if you do have air that is trapped in the heads, but if you use something like that bucket thing that connects to the radiator fill port...and turn your engine on with radiator fluid in the bucket...shouldn't it create a completely sealed system and you don't need the crossover and "steam port" on the radiator?

I've decided (and accepted) that I'm going to complete the A/C install after I get the motor in & running. I realize I'm running up against the blistering heat of AZ summer...so, that will be a great motivator to get it done quickly. Installing A/C was also one of the reasons why I decided to utilize the 1999 Silverado harness/ECM due to some research I did that explained it was easier to implement AC with that version ECM than the other that I had.

Still...waiting...on...parts...from Novak. Transmission adapter, fuel pressure regulator bypass, return line bung, hydraulic clutch retro kit, and brake booster insert. I've got almost everything else ordered and/or delivered, so that's good.

Budget creep has set in ever so slightly, but it's not that far over, so that's actually surprising - I expected budget creep.

Next up - finish routing the wiring harnesses (the mating of the two takes place at the firewall), shorten wires, install fuse box, determine ECM mounting placement, cut/solder upgraded fuel injector pigtails, replace evap plug back to the TJ harness (literally just realized I snipped that off yesterday damn it), continue with clean/prep/paint engine bay, and I think I'll swing the motor over and set it down to test fit on the mounts and look for clearance issues.

Lunch time office space. Not bad at all.

My son about lost his mind when he came home and walked through the garage and saw me thinning out the GM harness. LOL

It's cleaning up quite nicely...

I've got the motor nearly 100% assembled, however, I do need to swap out the alternator I've got with a 4-pin version. I ended up with a 2006 Tahoe 4x4 version (2-pin) that has voltage regulated via the ECM, however, I decided to go with my 1999 Silverado wiring harness and ECM, and that feature did not exist for that harness/ECM. I realize that I could probably just throw a 2-pin pigtail on the harness and go with it, but I won't be getting all the juice out of the alternator...soooo...I'll just go with swapping it out.

Also, I discovered that some time in the early/mid 2000s GM moved away from vacuum-based brake boosters to this lovely thing called "hydroboost". From what I've read, this is a hydraulic system that supports both the power steering and braking, and has a cooler mated to the system somewhere along the way. Instead of having 1 return port on the pump reservoir, it has 2. Now...given that these are low-pressure return ports...I'm thinking I can simply insert a T-fitting into main return from the steering box and have it dump to the second port as well - I mean, it's all going to the same place...right?

I'm still going back and forth and doing research on the steam/coolant crossover lines. I don't see why they are entirely necessary if you evacuate all the air out of the system. I see the point if you do have air that is trapped in the heads, but if you use something like that bucket thing that connects to the radiator fill port...and turn your engine on with radiator fluid in the bucket...shouldn't it create a completely sealed system and you don't need the crossover and "steam port" on the radiator?

I've decided (and accepted) that I'm going to complete the A/C install after I get the motor in & running. I realize I'm running up against the blistering heat of AZ summer...so, that will be a great motivator to get it done quickly. Installing A/C was also one of the reasons why I decided to utilize the 1999 Silverado harness/ECM due to some research I did that explained it was easier to implement AC with that version ECM than the other that I had.

Still...waiting...on...parts...from Novak. Transmission adapter, fuel pressure regulator bypass, return line bung, hydraulic clutch retro kit, and brake booster insert. I've got almost everything else ordered and/or delivered, so that's good.

Budget creep has set in ever so slightly, but it's not that far over, so that's actually surprising - I expected budget creep.

Next up - finish routing the wiring harnesses (the mating of the two takes place at the firewall), shorten wires, install fuse box, determine ECM mounting placement, cut/solder upgraded fuel injector pigtails, replace evap plug back to the TJ harness (literally just realized I snipped that off yesterday damn it), continue with clean/prep/paint engine bay, and I think I'll swing the motor over and set it down to test fit on the mounts and look for clearance issues.

Lunch time office space. Not bad at all.

My son about lost his mind when he came home and walked through the garage and saw me thinning out the GM harness. LOL

It's cleaning up quite nicely...

DETOUR

TJ Enthusiast

Drool drool beaufrusettaMore updates.

I've got the motor nearly 100% assembled, however, I do need to swap out the alternator I've got with a 4-pin version. I ended up with a 2006 Tahoe 4x4 version (2-pin) that has voltage regulated via the ECM, however, I decided to go with my 1999 Silverado wiring harness and ECM, and that feature did not exist for that harness/ECM. I realize that I could probably just throw a 2-pin pigtail on the harness and go with it, but I won't be getting all the juice out of the alternator...soooo...I'll just go with swapping it out.

View attachment 319616

View attachment 319619

Also, I discovered that some time in the early/mid 2000s GM moved away from vacuum-based brake boosters to this lovely thing called "hydroboost". From what I've read, this is a hydraulic system that supports both the power steering and braking, and has a cooler mated to the system somewhere along the way. Instead of having 1 return port on the pump reservoir, it has 2. Now...given that these are low-pressure return ports...I'm thinking I can simply insert a T-fitting into main return from the steering box and have it dump to the second port as well - I mean, it's all going to the same place...right?

I'm still going back and forth and doing research on the steam/coolant crossover lines. I don't see why they are entirely necessary if you evacuate all the air out of the system. I see the point if you do have air that is trapped in the heads, but if you use something like that bucket thing that connects to the radiator fill port...and turn your engine on with radiator fluid in the bucket...shouldn't it create a completely sealed system and you don't need the crossover and "steam port" on the radiator?

I've decided (and accepted) that I'm going to complete the A/C install after I get the motor in & running. I realize I'm running up against the blistering heat of AZ summer...so, that will be a great motivator to get it done quickly. Installing A/C was also one of the reasons why I decided to utilize the 1999 Silverado harness/ECM due to some research I did that explained it was easier to implement AC with that version ECM than the other that I had.

Still...waiting...on...parts...from Novak. Transmission adapter, fuel pressure regulator bypass, return line bung, hydraulic clutch retro kit, and brake booster insert. I've got almost everything else ordered and/or delivered, so that's good.

Budget creep has set in ever so slightly, but it's not that far over, so that's actually surprising - I expected budget creep.

Next up - finish routing the wiring harnesses (the mating of the two takes place at the firewall), shorten wires, install fuse box, determine ECM mounting placement, cut/solder upgraded fuel injector pigtails, replace evap plug back to the TJ harness (literally just realized I snipped that off yesterday damn it), continue with clean/prep/paint engine bay, and I think I'll swing the motor over and set it down to test fit on the mounts and look for clearance issues.

Lunch time office space. Not bad at all.

View attachment 319615

My son about lost his mind when he came home and walked through the garage and saw me thinning out the GM harness. LOL

View attachment 319620

It's cleaning up quite nicely...

View attachment 319618

View attachment 319617

• I envy you , not so much for the LS swap,( I’m a coal rolling individual lol) , but more so on how well you’re progressing , keep it up with your interesting write up !

Ps: I have to admit that a V8 rumble at idle or accelerating wide open, is

DETOUR

~•lllllll•~

I tend to talk to myself quite a bit …sooo, the interesting write up you mention is just an extension of how I’m literally talking to myself…mostly.Drool drool beaufrusetta

• I envy you , not so much for the LS swap,( I’m a coal rolling individual lol) , but more so on how well you’re progressing , keep it up with your interesting write up !

Ps: I have to admit that a V8 rumble at idle or accelerating wide open, isto our custom vehicle tuned ears

%

DETOUR

~•lllllll•~

Ok, I don’t have any pics to share, but after being idle for a few weeks waiting on parts, I’ve finally made some significant progress and will post pics later.

I’ve got a few buddies coming by this evening to help get me over the finish line and crank it up tonight. I’m beyond excited to hear it start up for the first time.

I’m not entirely confident that I’ll be able to drive it because I’m pretty sure the driveshafts are going to be off. Looks like my setup has moved me forward an inch or more. Won’t know definitively until I get the transfer case on and measure.

I do have a question. The shifter from the shift tower is hitting the firewall side of the tunnel cut out. I can shift in to 2/4/R and can stay in neutral. Can move it up for 1/3/5. What are my options? Do I just cut the tunnel shield? That’s easy enough. Or is there a different stick that’s offset that would work. Mine is literally straight up from the tower, but I’ve seen other NV3550 shift towers that the stick base is straight then goes to a 45 degree bend or something like that. I’m up for suggestions before I just cut it and move on.

I’ve got a few buddies coming by this evening to help get me over the finish line and crank it up tonight. I’m beyond excited to hear it start up for the first time.

I’m not entirely confident that I’ll be able to drive it because I’m pretty sure the driveshafts are going to be off. Looks like my setup has moved me forward an inch or more. Won’t know definitively until I get the transfer case on and measure.

I do have a question. The shifter from the shift tower is hitting the firewall side of the tunnel cut out. I can shift in to 2/4/R and can stay in neutral. Can move it up for 1/3/5. What are my options? Do I just cut the tunnel shield? That’s easy enough. Or is there a different stick that’s offset that would work. Mine is literally straight up from the tower, but I’ve seen other NV3550 shift towers that the stick base is straight then goes to a 45 degree bend or something like that. I’m up for suggestions before I just cut it and move on.

Ok, I don’t have any pics to share, but after being idle for a few weeks waiting on parts, I’ve finally made some significant progress and will post pics later.

I’ve got a few buddies coming by this evening to help get me over the finish line and crank it up tonight. I’m beyond excited to hear it start up for the first time.

I’m not entirely confident that I’ll be able to drive it because I’m pretty sure the driveshafts are going to be off. Looks like my setup has moved me forward an inch or more. Won’t know definitively until I get the transfer case on and measure.

I do have a question. The shifter from the shift tower is hitting the firewall side of the tunnel cut out. I can shift in to 2/4/R and can stay in neutral. Can move it up for 1/3/5. What are my options? Do I just cut the tunnel shield? That’s easy enough. Or is there a different stick that’s offset that would work. Mine is literally straight up from the tower, but I’ve seen other NV3550 shift towers that the stick base is straight then goes to a 45 degree bend or something like that. I’m up for suggestions before I just cut it and move on.

Something like this is what people do with a magnum swap.

This is the easier way.

Also, I discovered that some time in the early/mid 2000s GM moved away from vacuum-based brake boosters to this lovely thing called "hydroboost". From what I've read, this is a hydraulic system that supports both the power steering and braking, and has a cooler mated to the system somewhere along the way. Instead of having 1 return port on the pump reservoir, it has 2. Now...given that these are low-pressure return ports...I'm thinking I can simply insert a T-fitting into main return from the steering box and have it dump to the second port as well - I mean, it's all going to the same place...right?

Here is Vanco's website on the hydroboost. And here is how they do the plumbing.

http://www.vancopbs.com/default.asp

2.5 months later...I fired it up briefly last night with my son. Was only on for a couple of seconds before my ghetto rigged 12v wire to trip the relay popped out and killed power to the injectors/pcm/etc. I don't know if it has been the lack of sleep this week trying to get it passed the finish line or what, but for the life of me, I can't find a 12v key on power wire to tap in to for the GM fuse block relay. I've never been a wiring guy...so I thought I was clever that I found a wire in the transmission harness that's blocked off and I used that. Well...I learned last night that I can't trip a 12v relay with a 5v source. LOL

Does ANYONE know where I can find this magical 12v key-on power unicorn wire? I'm sure it's right underneath my nose...I think I've had a total of maybe 10-12 hours of sleep this week...so my brain isn't functioning too well at this point.

Oh...and I need new driveshafts made. Anyone have a recommendation? I've never had that done before and don't know of any reputable places. I'm in Gilbert, AZ...

Does ANYONE know where I can find this magical 12v key-on power unicorn wire? I'm sure it's right underneath my nose...I think I've had a total of maybe 10-12 hours of sleep this week...so my brain isn't functioning too well at this point.

Oh...and I need new driveshafts made. Anyone have a recommendation? I've never had that done before and don't know of any reputable places. I'm in Gilbert, AZ...

Best place IMO for driveshafts is Tom Woods. @Shawn at Tom Wood's is here on the forum. Call them up and give them your measurements and desired Yokes and you'll have them in 2-3 days.

And she lives. Lots of updates to do, but wanted to at least post this.

sounds gnarlyAnd she lives. Lots of updates to do, but wanted to at least post this.

Then mission accomplished!sounds gnarly

This might be the quickest I've ever seen an engine swap done, let alone an LS swap. Well done.