A few years ago at the SEMA Show I talked with a compressor company about different ideas for mounting a compressor in a Jeep and they supplied me with a compressor and tank to prototype with.

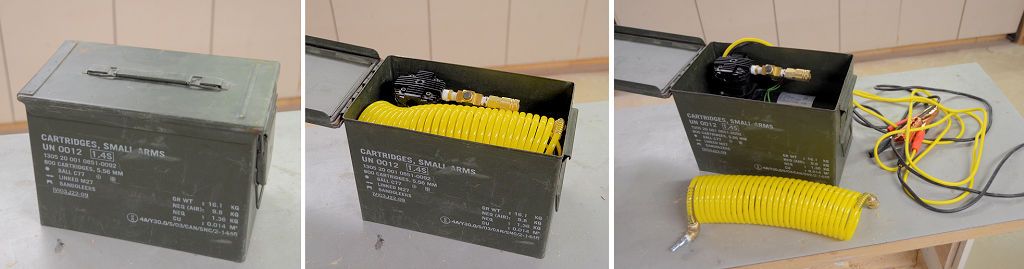

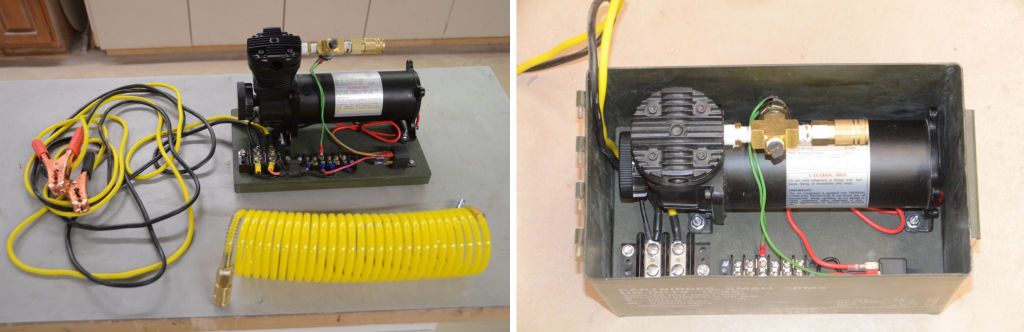

Since I have 3 Jeeps and may want to use the compressor with any of them, I decided not to do a fixed on board air mount so for a first prototype I mounted the compressor on a base that fits inside a Fat50 ammo can. There's enough room in the can for the jumper cables to connect the compressor to the Jeep's battery and a 25' coiled air line.

I've used it a couple of times and it worked well.

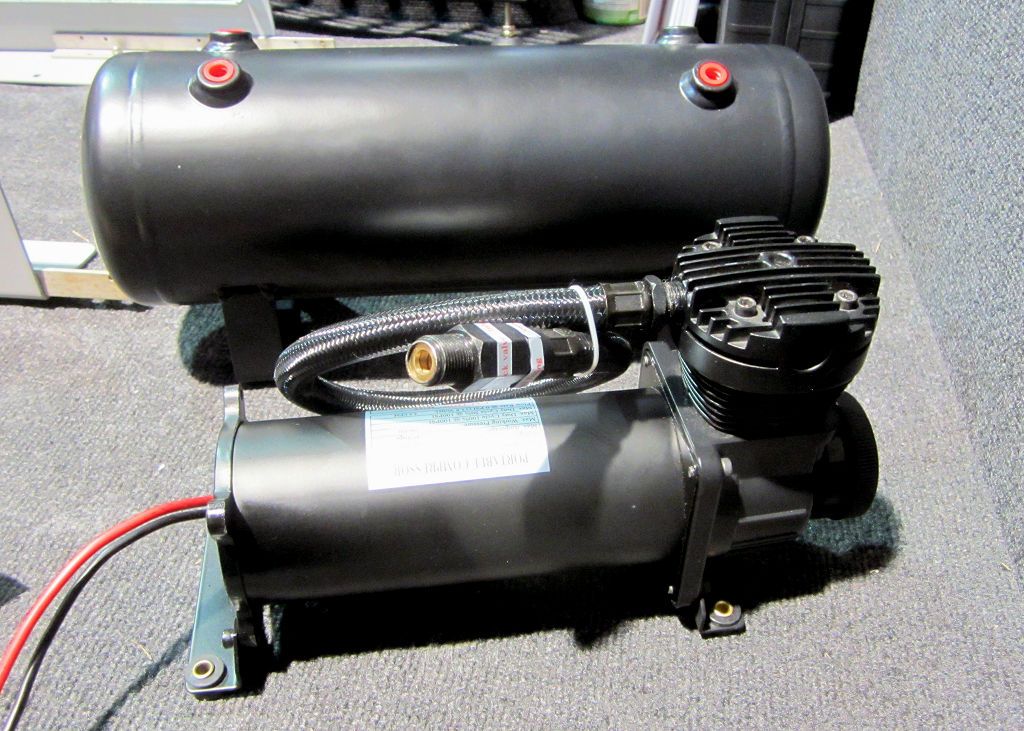

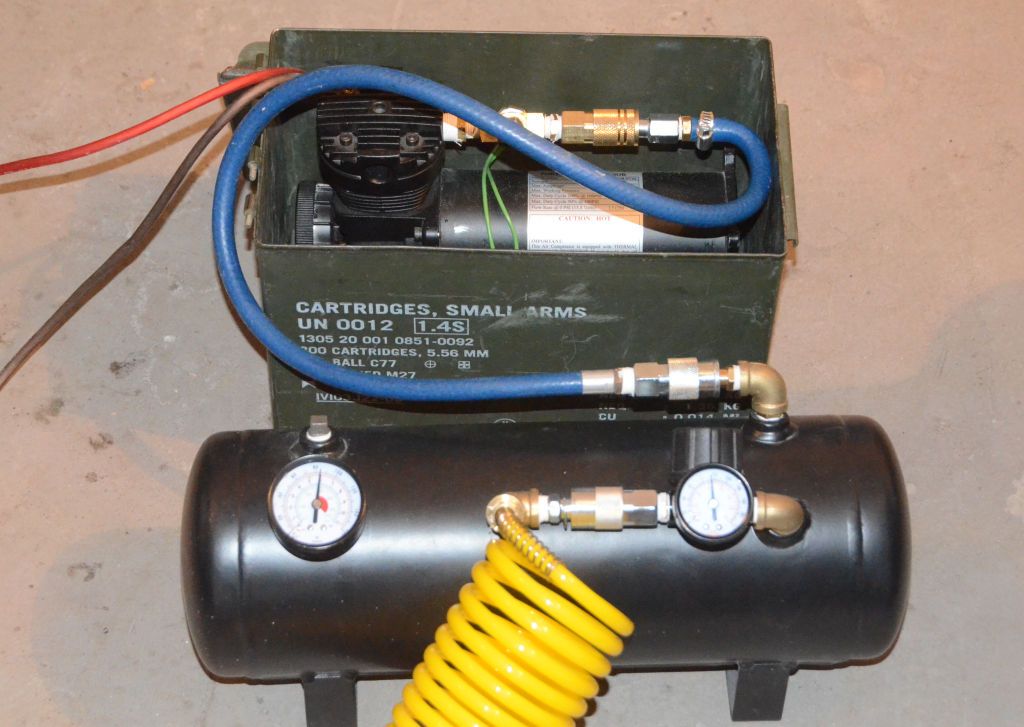

I also tested the compressor with the 2-gallon tank the compressor company gave me. I configured the tank with a pressure regulator with output pressure gauge and the larger gauge shows the pressure in the tank.

It takes less than a minute for the compressor to get the tank up to full pressure (100 psi). Airing up a tire is a bit quicker with the tank, but since my 32" tires have a volume of about 12 gallons, the tank doesn't go too far before the compressor has to kick in. Based on my tests with the tank it may not be worth using the tank if the main use of the compressor is airing up tires, especially since storage space is at a premium in most Jeeps.

One thing I don't like about the ammo can solution is that the hard ammo can is a little more difficult to store in some places in the Jeep than a more flexible soft fabric bag might be, so I designed a bag. There are compressor bags on the market, but as far as I know, they're all just bags for storing/carrying the compressor - they're not designed so the compressor can stay in the bag when it's being used.

I did some research on compressor sizes (ViAir, etc.) and sized my bag design so it'll fit all of the portable/on board air compressors of this type that I found. I included two outside pockets and two inside pockets into the bag design to hold common acessories and supplies, like tire plugs and tools. I sewed a prototype bag from olive drab military canvas:

It has a plywood bottom for mounting the compressor and opens diagonally to provide full air flow for compressor cooling. There are outside zipper pockets on both sides of the bag, plus pockets on the inside for things like tire repair supplies (tire plug tools, etc.). There's plenty of room inside for a coiled air line and long power cords to connect it to the battery.

It's wired with a pressure shut off switch and the hoses are set up so it's plug and play to use it with an air tank.

There's wiring to support the pressure shut-off function; that's on the plywood base and is protected with a swing-up cover:

There are two pockets on the outside and two on the inside as well as elastic to hold a pressure gauge and inflator. In this photo the contents of one of the inside pockets are laid out and the elastic for the tools is also visible.

Since I have 3 Jeeps and may want to use the compressor with any of them, I decided not to do a fixed on board air mount so for a first prototype I mounted the compressor on a base that fits inside a Fat50 ammo can. There's enough room in the can for the jumper cables to connect the compressor to the Jeep's battery and a 25' coiled air line.

I've used it a couple of times and it worked well.

I also tested the compressor with the 2-gallon tank the compressor company gave me. I configured the tank with a pressure regulator with output pressure gauge and the larger gauge shows the pressure in the tank.

It takes less than a minute for the compressor to get the tank up to full pressure (100 psi). Airing up a tire is a bit quicker with the tank, but since my 32" tires have a volume of about 12 gallons, the tank doesn't go too far before the compressor has to kick in. Based on my tests with the tank it may not be worth using the tank if the main use of the compressor is airing up tires, especially since storage space is at a premium in most Jeeps.

One thing I don't like about the ammo can solution is that the hard ammo can is a little more difficult to store in some places in the Jeep than a more flexible soft fabric bag might be, so I designed a bag. There are compressor bags on the market, but as far as I know, they're all just bags for storing/carrying the compressor - they're not designed so the compressor can stay in the bag when it's being used.

I did some research on compressor sizes (ViAir, etc.) and sized my bag design so it'll fit all of the portable/on board air compressors of this type that I found. I included two outside pockets and two inside pockets into the bag design to hold common acessories and supplies, like tire plugs and tools. I sewed a prototype bag from olive drab military canvas:

It has a plywood bottom for mounting the compressor and opens diagonally to provide full air flow for compressor cooling. There are outside zipper pockets on both sides of the bag, plus pockets on the inside for things like tire repair supplies (tire plug tools, etc.). There's plenty of room inside for a coiled air line and long power cords to connect it to the battery.

It's wired with a pressure shut off switch and the hoses are set up so it's plug and play to use it with an air tank.

There's wiring to support the pressure shut-off function; that's on the plywood base and is protected with a swing-up cover:

There are two pockets on the outside and two on the inside as well as elastic to hold a pressure gauge and inflator. In this photo the contents of one of the inside pockets are laid out and the elastic for the tools is also visible.