Jeepaholic

TJ Enthusiast

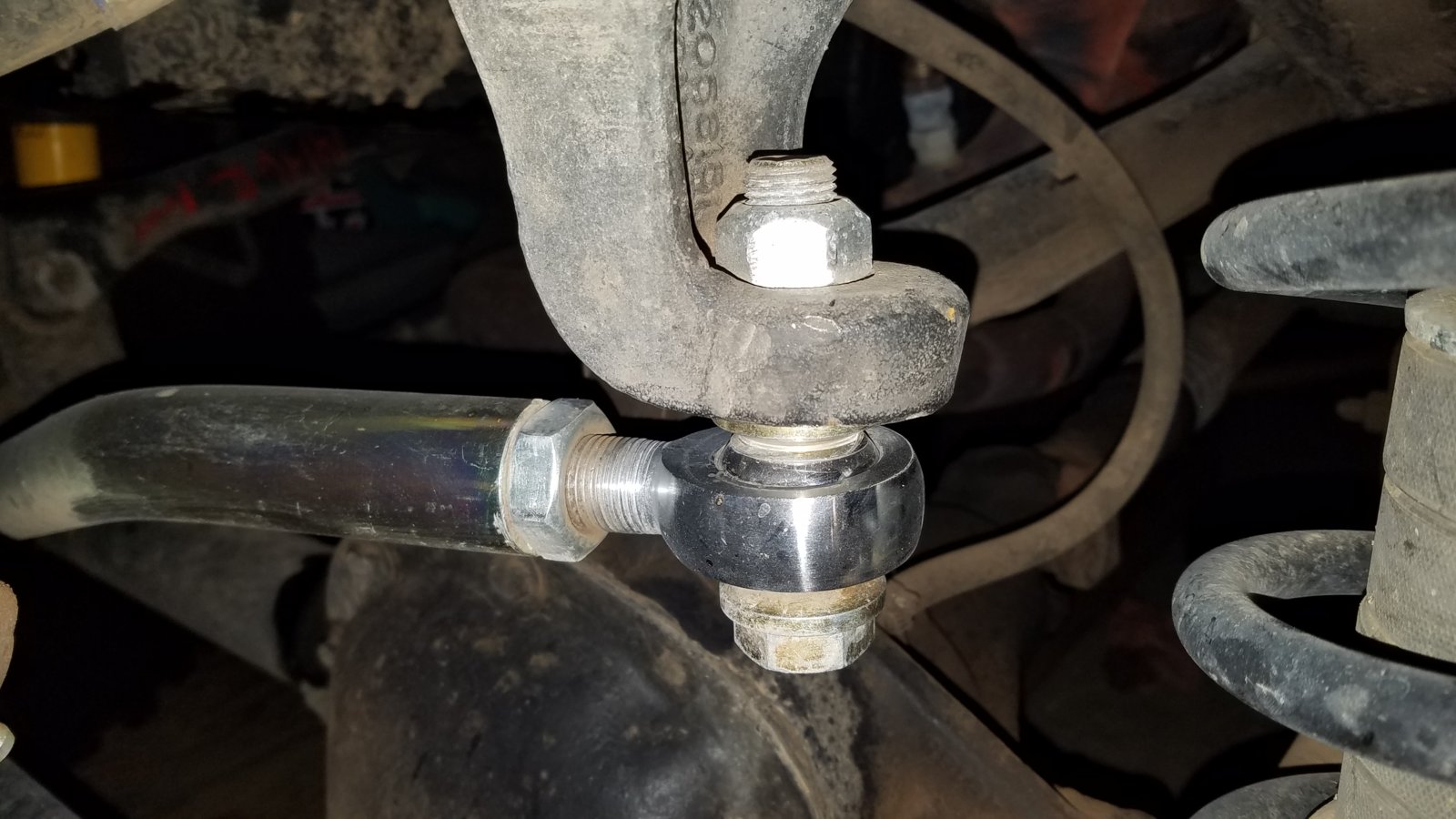

I've had no issues with my metal cloak bar either. Ihaven't seen very many complaints either, and also nobody with problems ever says why there was a problem. Badly balanced tires, bad bushings on control arms, etc can all be hard on any joint. I think the problem with the frame side mount is the way jeep has the mount oriented vertically, it limits the type of end that can be used. It needs to be able to pivot quite a bit, a horizontal mount like the jk uses can have the duroflex bushing, but the vertical mount would require a horizontal adapter, which brings up my question, how does the Currie bar mount frame side? You guys have me all worried about my m/c bar!