How do you keep the garage so tidy with things like grinding, painting and wood work happening? I don’t do half the stuff you seem to and my garage looks like a foundry…

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nashville TJ's Build - Continued

- Thread starter NashvilleTJ

- Start date

How do you keep the garage so tidy with things like grinding, painting and wood work happening? I don’t do half the stuff you seem to and my garage looks like a foundry…

No magic, I just make sure I clean up after every project. Just like the jeep, if you don’t stay after it the dirt starts to become permanent. I vacuum a lot during a project, and use dust collection for woodworking. At the end of a project, I open up the doors and use compressed air to blow the dust off the shelves, machinery, and out the door.

Thanks to a legit tip from our Purple TJ Friend ( @PurpleTJAZ ), this morning I saved some weight and storage space in the rig.

Our purple TJ friend should be up for TJ owner of the year.

Our purple TJ friend should be up for TJ owner of the year.

He saved me .625 oz a month!

I ordered another filter from aFe Power to try out. The last one I ordered was way too big - this one looks closer to being able to work. We'll see.

I ordered another filter from aFe Power to try out. The last one I ordered was way too big - this one looks closer to being able to work. We'll see.

View attachment 497777

You're the MAN... I'm watching.

You're the MAN... I'm watching.

I hope it fits. It appears to be very good quality, and much more surface area than the oiled Spectre. I'll just need to see if there is enough space left over with this thing in the filter assembly to actually allow air to pass through...

I ordered another filter from aFe Power to try out. The last one I ordered was way too big - this one looks closer to being able to work. We'll see.

View attachment 497777

Oops. You know what? I posted the wrong picture. This is the filter I just received:

The pic I posted above was the first filter I received - which was way to big.

Oops. You know what? I posted the wrong picture. This is the filter I just received:

View attachment 497780

The pic I posted above was the first filter I received - which was way to big.

Yep that one is looking a lot better.

This morning I test fit the new aFe Power air filter in the rig. Here it is next to the original Spectre Oiled cone filter, and the enclosure.

The aFe is just a bit taller, but most of that is in the flange. which is a half inch taller.

This is how the filter mounts inside of the enclosure. And no, I've haven't cleaned the thing since Moab...

To create a bit more clearance at the top of the enclosure, I trimmed 500 thou off of the flange (and yeah, I mic'd it... ):

):

I missed getting a pic of the original fit, but here it is after the trim: It looks like plenty of clearance - especially given the additional inverted cone in the end.

And all back together.

So I'm pretty stoked. At long last I've found a high-quality dry cotton filter to replace the high-maintenance oiled cone filter element.

@Wildman was also looking for a dry filter, as he runs the same Spectre enclosure.

Rick - here is the part number and link:

aFe Power Part # 21-91020

https://afepower.com/afe-power-21-91020-magnum-flow-pro-dry-s-air-filter

The aFe is just a bit taller, but most of that is in the flange. which is a half inch taller.

This is how the filter mounts inside of the enclosure. And no, I've haven't cleaned the thing since Moab...

To create a bit more clearance at the top of the enclosure, I trimmed 500 thou off of the flange (and yeah, I mic'd it...

I missed getting a pic of the original fit, but here it is after the trim: It looks like plenty of clearance - especially given the additional inverted cone in the end.

And all back together.

So I'm pretty stoked. At long last I've found a high-quality dry cotton filter to replace the high-maintenance oiled cone filter element.

@Wildman was also looking for a dry filter, as he runs the same Spectre enclosure.

Rick - here is the part number and link:

aFe Power Part # 21-91020

https://afepower.com/afe-power-21-91020-magnum-flow-pro-dry-s-air-filter

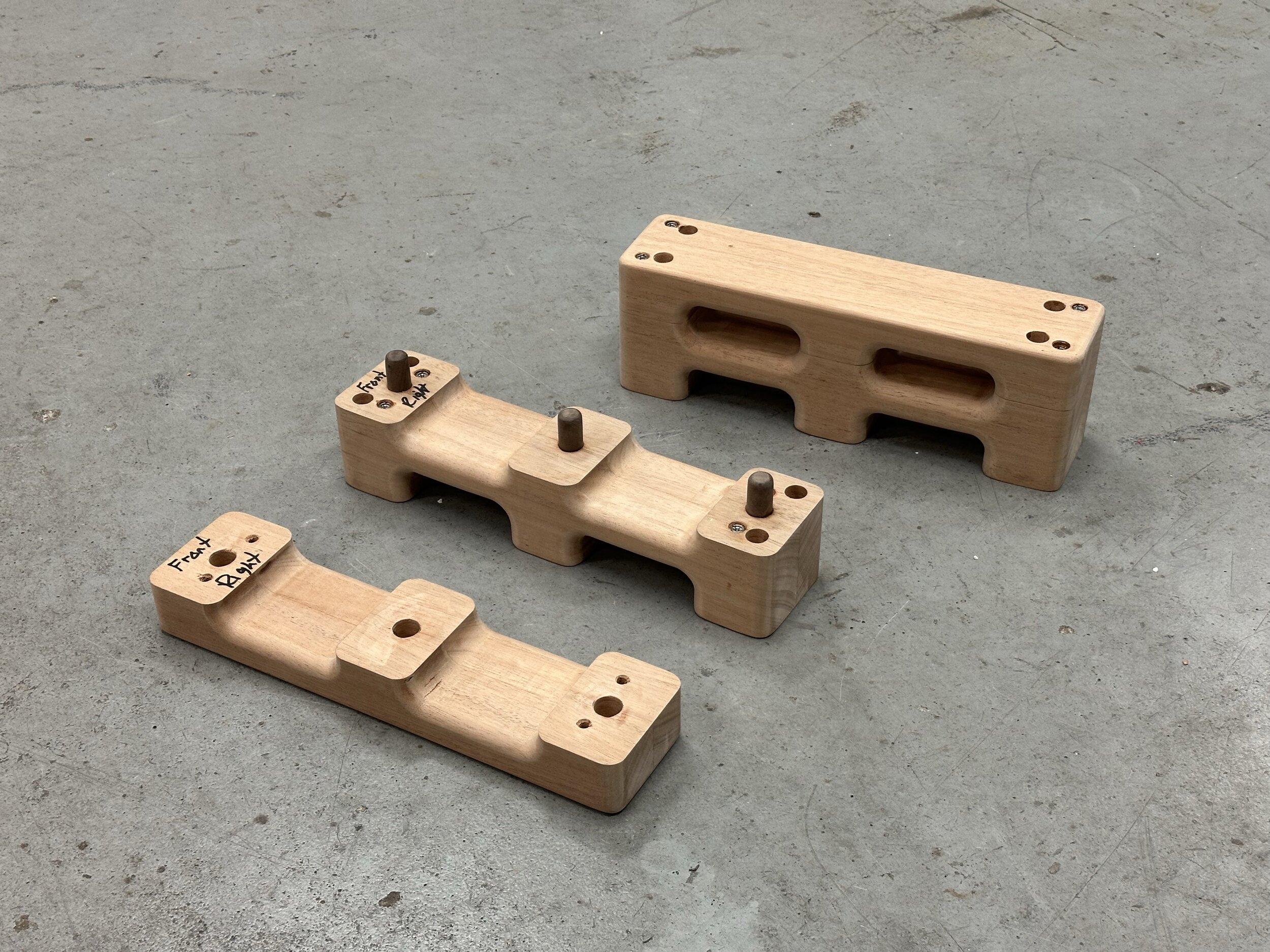

I posted this drawing earlier for a set of seat risers I built for the boat of a good friend up on the Eastern Shore of Maryland.

For anyone curious, here is how they turned out. The wood is Mahagony.

For anyone curious, here is how they turned out. The wood is Mahagony.

Last edited:

This morning I test fit the new aFe Power air filter in the rig. Here it is next to the original Spectre Oiled cone filter, and the enclosure.

View attachment 499232

The aFe is just a bit taller, but most of that is in the flange. which is a half inch taller.

This is how the filter mounts inside of the enclosure. And no, I've haven't cleaned the thing since Moab...

View attachment 499235

To create a bit more clearance at the top of the enclosure, I trimmed 500 thou off of the flange (and yeah, I mic'd it...):

View attachment 499240

I missed getting a pic of the original fit, but here it is after the trim: It looks like plenty of clearance - especially given the additional inverted cone in the end.

View attachment 499241

And all back together.

View attachment 499244

So I'm pretty stoked. At long last I've found a high-quality dry cotton filter to replace the high-maintenance oiled cone filter element.

@Wildman was also looking for a dry filter, as he runs the same Spectre enclosure.

Rick - here is the part number and link:

aFe Power Part # 21-91020

https://afepower.com/afe-power-21-91020-magnum-flow-pro-dry-s-air-filter

I've had the same afe dryflow on my tacoma for 15 years.spent plenty of time on dirt roads. The inside of the intake tube isn't dusty and dirty if thats an indication of effectiveness. But i never wash it.just knock it out since a dirty filter actually filters better.

I forgot to mention this earlier but your filter enclosure doesn't look like anything special. If it came down to it for flow would it be possible to weld up a larger diameter can for the afe?

I've had the same afe dryflow on my tacoma for 15 years.spent plenty of time on dirt roads. The inside of the intake tube isn't dusty and dirty if thats an indication of effectiveness. But i never wash it.just knock it out since a dirty filter actually filters better.

I forgot to mention this earlier but your filter enclosure doesn't look like anything special. If it came down to it for flow would it be possible to weld up a larger diameter can for the afe?

Thanks for the positive feedback, Ricky. Good to hear.

It would certainly be possible to build a larger enclosure, but a larger diameter tube would not fit there under the hood. A longer one would be tight as well.

But, I’ve never had a problem with flow. My main reason for the switch was to get away from the oiled element.

That being said - that oiled Spectre filter works very well. As often as I have run hard in very dusty places, the inside of my intake has always been spotless - as it was this time.

This morning I test fit the new aFe Power air filter in the rig. Here it is next to the original Spectre Oiled cone filter, and the enclosure.

View attachment 499232

The aFe is just a bit taller, but most of that is in the flange. which is a half inch taller.

This is how the filter mounts inside of the enclosure. And no, I've haven't cleaned the thing since Moab...

View attachment 499235

To create a bit more clearance at the top of the enclosure, I trimmed 500 thou off of the flange (and yeah, I mic'd it...):

View attachment 499240

I missed getting a pic of the original fit, but here it is after the trim: It looks like plenty of clearance - especially given the additional inverted cone in the end.

View attachment 499241

And all back together.

View attachment 499244

So I'm pretty stoked. At long last I've found a high-quality dry cotton filter to replace the high-maintenance oiled cone filter element.

@Wildman was also looking for a dry filter, as he runs the same Spectre enclosure.

Rick - here is the part number and link:

aFe Power Part # 21-91020

https://afepower.com/afe-power-21-91020-magnum-flow-pro-dry-s-air-filter

Great Jeff, thanks for doing the leg work on this. I'll get one ordered for mine.

Hello I have a question about your laser alignment method. I can't send PM's for some reason.

https://wranglertjforum.com/threads/nashville-tjs-build-continued.42035/post-798889

I get the chalking a center line down the jeep and then finding the center of the axles and lining everything up. What I don't understand is the 90 degree chalk lines perpendicular to the center line in front of the axles. You mention to "get the axles strait". Does this mean you are adjusting the lower control arms to get the axle fore/aft even on both sides using the perpendicular line? Is this the thrust angle?

Im still learning but I thought you set your lower control arms to center with bumpstops at full bump and that was that.

Also do you do the entire alignment process at ride height? Can it be done with all 4 tires on the ground?

edit: after studying the post some more it seems like you keep load on the front axle with jackstands and match the axle height of the rear axle - is this is the ideal way to do your alignment method?

Thanks!

@NashvilleTJ

https://wranglertjforum.com/threads/nashville-tjs-build-continued.42035/post-798889

I get the chalking a center line down the jeep and then finding the center of the axles and lining everything up. What I don't understand is the 90 degree chalk lines perpendicular to the center line in front of the axles. You mention to "get the axles strait". Does this mean you are adjusting the lower control arms to get the axle fore/aft even on both sides using the perpendicular line? Is this the thrust angle?

Im still learning but I thought you set your lower control arms to center with bumpstops at full bump and that was that.

Also do you do the entire alignment process at ride height? Can it be done with all 4 tires on the ground?

edit: after studying the post some more it seems like you keep load on the front axle with jackstands and match the axle height of the rear axle - is this is the ideal way to do your alignment method?

Thanks!

@NashvilleTJ

Last edited:

I can't send PM's for some reason.

https://wranglertjforum.com/threads/why-cant-i-send-private-messages.23254/

Hello I have a question about your laser alignment method. I can't send PM's for some reason.

https://wranglertjforum.com/threads/nashville-tjs-build-continued.42035/post-798889

I get the chalking a center line down the jeep and then finding the center of the axles and lining everything up. What I don't understand is the 90 degree chalk lines perpendicular to the center line in front of the axles. You mention to "get the axles strait". Does this mean you are adjusting the lower control arms to get the axle fore/aft even on both sides using the perpendicular line? Is this the thrust angle?

The main reason I do this type of alignment is to get the axle assemblies perpendicular to the centerline of the vehicle. I align the axles with this line. To do this you must adjust all of the control arms - upper and lower.

Im still learning but I thought you set your lower control arms to center with bumpstops at full bump and that was that.

Also do you do the entire alignment process at ride height? Can it be done with all 4 tires on the ground?

edit: after studying the post some more it seems like you keep load on the front axle with jackstands and match the axle height of the rear axle - is this is the ideal way to do your alignment method?

Thanks!

@NashvilleTJ

Correct - this alignment needs to be done at ride height, with the vehicle weight on the axles.

Thanks! Your method seems to be the best one i've seen.

Do you prioritize getting the axles perpendicular to the center-line of the vehicle over having both corners bumpstops dead on centered? I suppose the bumps can be off a bit if it means my thrust angle is ideal.

Do you prioritize getting the axles perpendicular to the center-line of the vehicle over having both corners bumpstops dead on centered? I suppose the bumps can be off a bit if it means my thrust angle is ideal.

I posted this drawing earlier for a set of seat risers I built for the boat of a good friend up on the Eastern Shore of Maryland.

View attachment 499251

For anyone curious, here is how they turned out. The wood is Mahagony.

View attachment 499249

View attachment 499250

Those are sooo beautiful.

Thanks! Your method seems to be the best one i've seen.

Do you prioritize getting the axles perpendicular to the center-line of the vehicle over having both corners bumpstops dead on centered? I suppose the bumps can be off a bit if it means my thrust angle is ideal.

I get the axles where they need to be - and then I position the bump stops…

(Don’t forget, all my stuff is custom)