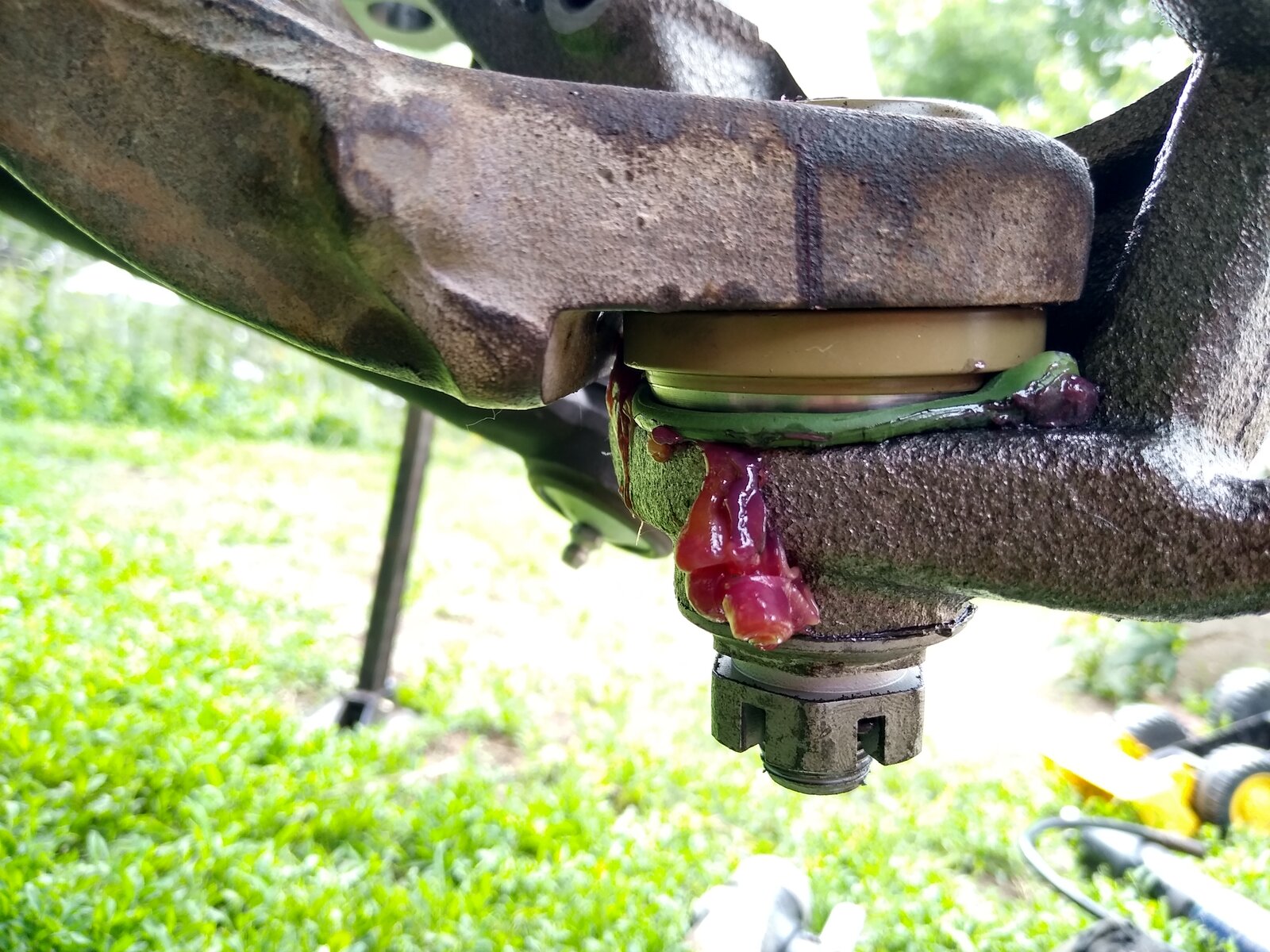

Having major issues with a new set of knuckles and ball joints. Driver's side went together fine. Passenger side is completely ..... Used Dorman knuckles and TTX ball joints (wanted good quality). First install crushed the lower joint boot when torqued basically destroying it. Not knowing what the problem was, I got both another Dorman knuckle, and another TTX ball joint. When I swapped to the second set of new parts, I had the same issue. See pics. Any ideas? I need my jeep functional, right now I am at a loss.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

02 TJ ball joint and knuckle issue

- Thread starter Derweibhai

- Start date

Tried the factory knuckle out of exasperation. It fits just fine. So Dorman has a bad run of passengers side Jeep knuckles out there. Now to deal with returning both. Warranty service these days SUCKS!!!

@mrblaine you ever run into this? I wasn't aware dorman made knuckles for a tj?

Op I think you are wise to use the oem knuckles what made you buy the dorman ones?

I'm aware of those type issues. We used a lot of the Crown crap for a bit and fully half of them had to have the hole for the unit bearing sanded open so they would fit. He needs to go back to a good set of OEM knuckles since Dorman is likely using the same shit head foundries that Crown does.

I'm aware of those type issues. We used a lot of the Crown crap for a bit and fully half of them had to have the hole for the unit bearing sanded open so they would fit. He needs to go back to a good set of OEM knuckles since Dorman is likely using the same shit head foundries that Crown does.

I am replacing all of the bushings and joints to eliminate a death wobble issue. Figured while I was in there, I may as well swap knuckles along with ball joints, as mine have wollered out tie rod holes from some dip shit leaving them loose (which is where my wobble came from. Lesson learned on going aftermarket with them, but many OEM parts are gone for even the TJ now.

A set of stock Dana 30 knuckles are not hard to come by. Check Facebook or your local u Pull it yard.

Why not cone out the wallered holes, fill with weld and drill new holes?

-Mac

A few reasons. First, they are tapered, you would need two tapered reamers, 1.5" per foot and a 2" per foot. Then they would have to be super special carbide and even then you may not get it done with one set. The weld will pull carbon out of the iron which somehow manages to make the weld about as hard as carbide or impossible to drill for the average person and even if you do drill it, next to impossible to taper after drilling. BTDT, threw away a brand new set of OEM WJ knuckles.

I am replacing all of the bushings and joints to eliminate a death wobble issue. Figured while I was in there, I may as well swap knuckles along with ball joints, as mine have wollered out tie rod holes from some dip shit leaving them loose (which is where my wobble came from. Lesson learned on going aftermarket with them, but many OEM parts are gone for even the TJ now.

A set of good used knuckles will cost you shipping. I'll even tidy up any divots they have where the brake pads ride.

bout to trash a Dana 30 maybe i should take the knuckles and keep those if new stuff is crap.

New aftermarket is iffy at best. They don't control the patterns very well and get a lot of pattern shift when they cast so they wind up fairly messed up because they don't fixture the same part to part.

Some of the Crown parts we tried to use were just terrible. They don't understand the end result they were trying to accomplish so they didn't know how to QC them with an eye on the final result.

This is one of the issues we ran into that was very common. The alignment axis of the lower ball joint hole is supposed to be on center with the axis of the upper. That is a correct taper reamer shoved in the lower hole to show where it points. Rusty is OEM, other is Crown.

In the last pic, note that the reamer shows the hole slightly offset to the right side. That brings the lower support rib into contact with the side of the lower part of the OEM inner C and limits full rotation of the knuckle on the inner C.

That is very disheartening

down right sad. no interest in working in the trades anymore, can't get enough followers. we gotta choke on the garbage they send us from outsourced manufacturers.

T

TRE3TOP

Guest

bout to trash a Dana 30 maybe i should take the knuckles and keep those if new stuff is crap.

Pull the knuckles and shafts, ditch the rest.

T

TRE3TOP

Guest

Having major issues with a new set of knuckles and ball joints. Driver's side went together fine. Passenger side is completely ..... Used Dorman knuckles and TTX ball joints (wanted good quality). First install crushed the lower joint boot when torqued basically destroying it. Not knowing what the problem was, I got both another Dorman knuckle, and another TTX ball joint. When I swapped to the second set of new parts, I had the same issue. See pics. Any ideas? I need my jeep functional, right now I am at a loss.

View attachment 336407

View attachment 336408

View attachment 336409

View attachment 336410

View attachment 336411

Never heard of TTX ball joints… why not go with spicer?

Pull the knuckles and shafts, ditch the rest.

already got 1 side off/out.

T

TRE3TOP

Guest

already got 1 side off/out.

I actually could use a housing at some point as I’ve got some slightly bent pass side C’s but I’m not going to Ohio to get it. I can find one around here. It’s not bad enough to cause concern yet though.

That is very disheartening

It is and it doesn't stop there. This is a pic taken from their ads. They have zero shame.

One of our competitors is using that knuckle to build their brake kits on.

This is it in real life.

In the below pic, the arrows show the direction one half of the mold pattern shifted. That likely means they are using the other side as the datum to locate the part in the fixture. One side shifts or rotates which throws the other side off. It is cause by worn patterns, crappy foundry practices, or lazy workers. The machinist should reject those parts since they skew the strength first and then the overall appearance of the part. When we have ours done they sometimes shift a tiny bit and that bugs me even though I know casting is fairly imprecise.

This is what we shoot for. We don't always get it this good but we never stop trying to.

You'd think someone would be able to run a CNC version on a 3 or 4 axis mill...but I suppose there are enough used and close enough crappy ones to flood the market and discourage quality.

-Mac

-Mac