You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Alex01 Silver Sport Build Thread

- Thread starter Alex01

- Start date

....

After lots of trips to the press and some creative methods to try and get closer to the goal I arrived here.

....

Did you use heat?

*Note to self. Don't post things that are really difficult halfway through a project that you can easily screw up and need to scrap.

That said...... I wanted to share because I'm happy with the progress even if it means jinxing myself.

I spent 3 hours or so in the garage tonight for the first time in forever on the tj. I probably should be checking bolts and that kind of thing preping for moab but some aluminum bar has been staring at me since early summer when I ordered it after reading @starkey480 build. The front armor and slider he made really inspired this. Goal is to make some rub rails since savvy doesn't any more.

Now I know the easy way out would be to just armor the flat panel but I bought enough to attempt a bend and worse case chop it off if I failed.

This was my starting point. A long piece of 1" by 1.25" 6160 (going off memory for the measurements)

View attachment 416207

I marked where the bend started plus 2" or so past the front so I had some room for error. I then marked 4 spots 1" from the bend, later on I added another mark 1 inch further down.

After lots of trips to the press and some creative methods to try and get closer to the goal I arrived here.

View attachment 416208

View attachment 416209

While there's still a gap and some waves from sanding going on I'm extremely happy with what came out bend wise.

Next, I took off the corner armor and clamped the piece in order to drill out the holes using the back of the corner as a guide. I used the top of the corner armor as a guide since I need room for the gr rear fenders.

View attachment 416210

I drilled out all the holes and used the counter sink bit I have so the bolts will sit flush.

View attachment 416211

Next will come trimming off the edges and rounding the sides (pretty it up). Before that I need to do the other side, which I'm a bit nervous for because I feel like I already pulled off one miracle, and don't want to spend more time on this side before knowing the other side will work and I'm not chopping off the rounded area.

My thought was this is the harder side since it's longer but who knows.

So far a fun project and feels great to be working on the jeep again even if it ends up failing.

That’s totally awesome. I nearly bought some 1”x1.75” when I picked up the backers earlier this week. I’m glad I didn’t. I would have bought them too short.

Did you use heat?

No heat. Just the 20ton HF press.

I might try to copy you

It's worth a shot. I did about 6 pumps per press visit. Equal for all marks. It wasn't until around the corner I realized I needed the 5th mark.

I'm just hoping I can pull it off again. If I learn anything new as far as making the bend goes I'll update.

It's worth a shot. I did about 6 pumps per press visit. Equal for all marks. It wasn't until around the corner I realized I needed the 5th mark.

I'm just hoping I can pull it off again. If I learn anything new as far as making the bend goes I'll update.

How about some pics of the process?

How about some pics of the process?

I'm going to do the next piece either Sunday or Monday night so I can grab some then.

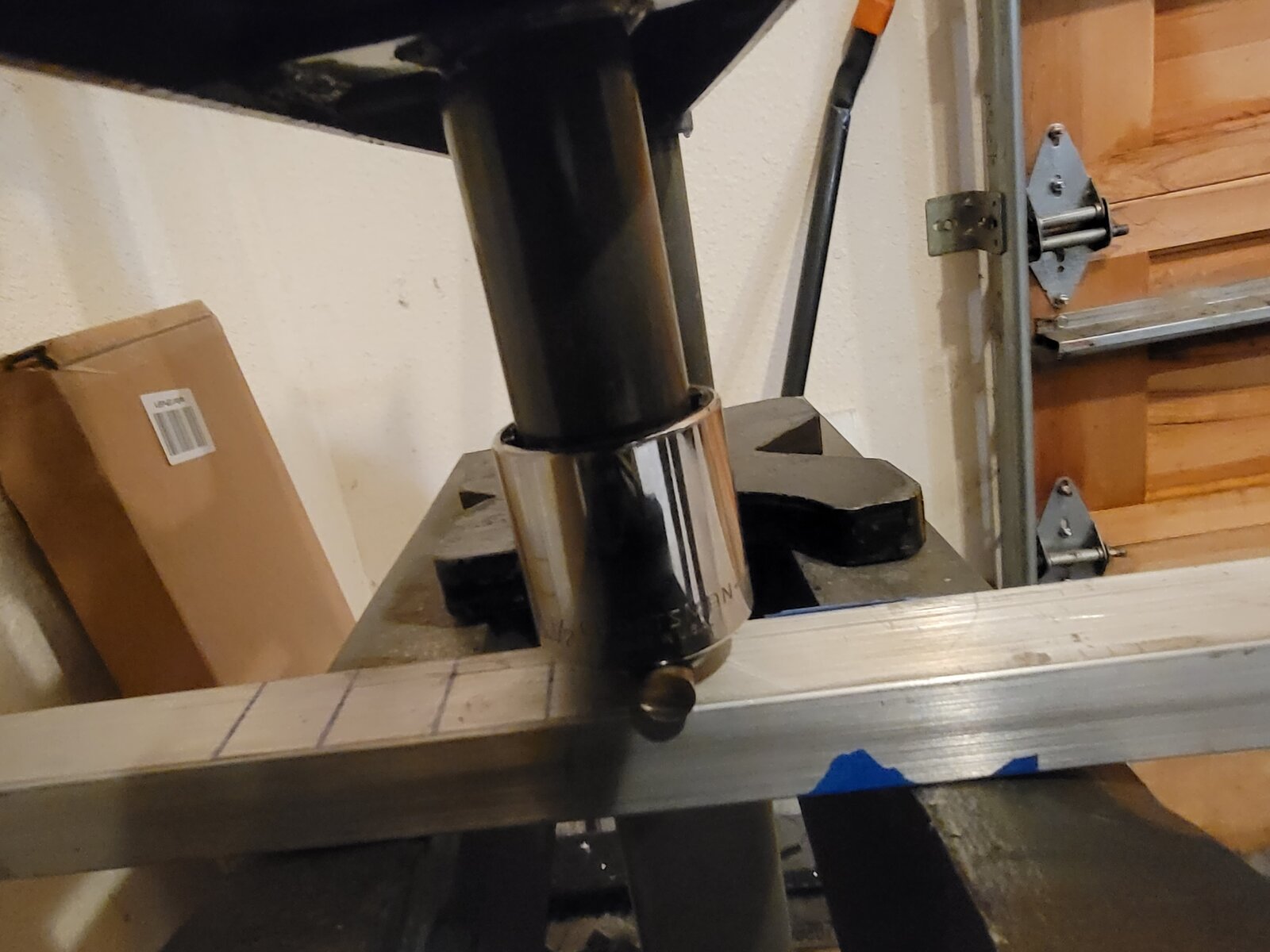

But as far as the press set up goes I had a spare 1.5" socket that I tack welded a bolt to, i believe it was a spare body mount or control arm bolt, and cut off the edges so only the smooth part remained.

Markings for attempt 2. I added the fifth bend location this time. As I said the first line is 1" past were the bend on the corner armor starts and each additional line is another inch away from the last.

The nasty looking press tool. My smaller tacks broke durning midway through the first piece and I only have a 120v power source to play with right now so it's not hot enough to really bond the two together.

I laid the piece on the H channel, or whatever the base is called on the press, and cranked 6 times after I felt pressure, on each on each mark.

I did damage my Presses H channel a bit on the edges though when I attempted to take a bit of bend out when I overshot it a bit.

That was the scariest part because I know aluminum doesn't like bending back on a bend. Luckily it was small and didn't cause an issue.

Last edited:

Hey, your suspension will probably fall off, but your corners will be protected, lol!

*Note to self. Don't post things that are really difficult halfway through a project that you can easily screw up and need to scrap.

That said...... I wanted to share because I'm happy with the progress even if it means jinxing myself.

I spent 3 hours or so in the garage tonight for the first time in forever on the tj. I probably should be checking bolts and that kind of thing preping for moab but some aluminum bar has been staring at me since early summer when I ordered it after reading @starkey480 build. The front armor and slider he made really inspired this. Goal is to make some rub rails since savvy doesn't any more.

Now I know the easy way out would be to just armor the flat panel but I bought enough to attempt a bend and worse case chop it off if I failed.

This was my starting point. A long piece of 1" by 1.25" 6160 (going off memory for the measurements)

View attachment 416207

I marked where the bend started plus 2" or so past the front so I had some room for error. I then marked 4 spots 1" from the bend, later on I added another mark 1 inch further down.

After lots of trips to the press and some creative methods to try and get closer to the goal I arrived here.

View attachment 416208

View attachment 416209

While there's still a gap and some waves from sanding going on I'm extremely happy with what came out bend wise.

Next, I took off the corner armor and clamped the piece in order to drill out the holes using the back of the corner as a guide. I used the top of the corner armor as a guide since I need room for the gr rear fenders.

View attachment 416210

I drilled out all the holes and used the counter sink bit I have so the bolts will sit flush.

View attachment 416211

Next will come trimming off the edges and rounding the sides (pretty it up). Before that I need to do the other side, which I'm a bit nervous for because I feel like I already pulled off one miracle, and don't want to spend more time on this side before knowing the other side will work and I'm not chopping off the rounded area.

My thought was this is the harder side since it's longer but who knows.

So far a fun project and feels great to be working on the jeep again even if it ends up failing.

Absolutely awesome work. I've been looking at options to replace Savvy's rails for the LJ. Any pics of the bending process would be helpful!

Hey, your suspension will probably fall off, but your corners will be protected, lol!

At least it will look good when it's sitting on the side of the trail. I'll make sure to face the driver's side to the trail in case the other side doesn't come out as well.

Absolutely awesome work. I've been looking at options to replace Savvy's rails for the LJ. Any pics of the bending process would be helpful!

Will do. I'm sure if enough people attempt it a better method will be found but this seemed to work. A large jig would likely result in a better bend but the practicality of making one for a one-off project doesn't make sense imo.

I ran out to the garage to do a single pass on the other side, ended up doing two, just to give you guys a visual.

This was with 10 pulls on the press.

Like I said easier I bent the base of the press yesterday, on the egdges, when trying to unbend the other side. (Dont recommend.

Second pass 10 more pulls for each line.

That's all I got time for now but hopefully, it gives everyone who is interested enough of an understanding to decide if they'd be interested or not.

The total time to that point was about 10 min.

To he continued Sunday or Monday.

This was with 10 pulls on the press.

Like I said easier I bent the base of the press yesterday, on the egdges, when trying to unbend the other side. (Dont recommend.

Second pass 10 more pulls for each line.

That's all I got time for now but hopefully, it gives everyone who is interested enough of an understanding to decide if they'd be interested or not.

The total time to that point was about 10 min.

To he continued Sunday or Monday.

I ran out to the garage to do a single pass on the other side, ended up doing two, just to give you guys a visual.

This was with 10 pulls on the press.

Like I said easier I bent the base of the press yesterday, on the egdges, when trying to unbend the other side. (Dont recommend.

View attachment 416312

View attachment 416313

View attachment 416314

View attachment 416315

Second pass 10 more pulls for each line.

View attachment 416319

That's all I got time for now but hopefully, it gives everyone who is interested enough of an understanding to decide if they'd be interested or not.

The total time to that point was about 10 min.

To he continued Sunday or Monday.

Thanks, looks like I might be buying some more aluminum damn it...

Thanks, looks like I might be buying some more aluminum damn it...

That was my goal. I figured you don't have enough on your plate.

Thanks, looks like I might be buying some more aluminum damn it...

Hey squirrel chaser, get it mobile first. June is coming quickly.

Here's what I got from midwest steel supplyThanks.....

6061 Aluminum Flat Bar (61AFB1112)

Dimensions: 1 x 1-1/2

Quantity: 2

Width: 1

Length: 60

Price: $44.64

Item Total: $89.28

I didn't realize I've been sitting on this since November 2021 though. @Midnight LJR would be amazed by my procrastination.

Here's what I got from midwest steel supply

6061 Aluminum Flat Bar (61AFB1112)

Dimensions: 1 x 1-1/2

Quantity: 2

Width: 1

Length: 60

Price: $44.64

Item Total: $89.28

I didn't realize I've been sitting on this since November 2021 though. @Midnight LJR would be amazed by my procrastination.

That's convenient. If I do this I could go pick it up.

At least it will look good when it's sitting on the side of the trail. I'll make sure to face the driver's side to the trail in case the other side doesn't come out as well.

Will do. I'm sure if enough people attempt it a better method will be found but this seemed to work. A large jig would likely result in a better bend but the practicality of making one for a one-off project doesn't make sense imo.

The one other attempt at this that I am aware of used a large die to form the bend and the result was cracking. The compromise here is that the bend isn't as clean as might be desired or required. But for a one off home project, the multiple bends with the little steps might become more acceptable when there is no longer another option.