OK. I'm hoping this will be a good general guide for troubleshooting A/C / Heater blower failure issues so I'm making it pretty thorough. Note that if you're fan runs at only high speed or just some of the higher speeds, it's almost certain to be the blower motor resistor block and you should start there...if that does not fix it, it's the blower speed switch or some connector/wiring issue between the switch and the resistor block.

I'm still going to be adding a bit of background and general knowledge stuff to this but I think it's complete for what it covers. If anyone finds an error, please let me know. Once it's nailed down, I'll be putting it in it's own "how to troubleshoot blower motor problems" thread.

Before continuing, familiarize yourself with the terms and symbols used in the wiring diagrams as well as some basics of diagnosis and testing by reading pages 8W – 01 – 1 through 8W – 01 – 10. in the 2000-2001 Factory Service Manual available for download

here.

Drawings of each connector with pinouts can be found on pages 8W – 80 – 4 through 8W – 80 – 42 and drawings of the physical locations of each connector and ground connection is in the next section (8W – 90).

One thing I should add is that almost no one uses analog (swinging needle) meters anymore because digital meters are so cheap and are far easier to use. Two things you should know to use a digital meter; how to check for voltage and how to check for continuity:

1 -

Checking for voltage. Refer to the fig. 4 on page 8W - 01 - 9 of the FSM. Your meter should be connected the same way but, for a digital meter, it will read the voltage as an actual number like "12.8" for 12.8 volts and, if you get the leads reversed, it will work fine, it will just show negative voltage like "-12.8". If your meter has selectable ranges like this HF model

then select the 20 volt DC setting (two clicks counter-clockwise from the position shown) and connect the black lead to the COM connector and the red lead to the VΩmA connector.

If you have an auto-ranging meter like this simple Amazon model

then select the DC Volts (one click clockwise from the OFF position shown).

1 -

Checking for continuity. Refer to the fig. 5 on page 8W - 01 - 9 of the FSM. Your meter should be connected the same way but, for a digital meter, it will read the resistance as an actual number like "0.3" for 0.3 Ohms and, if you get the leads reversed, it makes

no difference. For a meter with selectable ranges, set it to the lowest resistance (Ω) range which is usually 200 Ohms. For auto-ranging meters, just select the resistance (Ω) function.

If a meter reads infinite resistance (no connection), it will show a specific display but that display varies from meter to meter...some will display "OL" (over limit), some will show a 1 with no decimal, etc. To find out what your meter displays with infinite resistance, just put it into any resistance (Ω) scale/mode with the leads not connected to anything...it will show its open-circuit/infinite resistance display.

Note: never test for continuity on a powered circuit. Always turn it off or disconnect it first.

First, unplug your blower motor, put the ignition in the ON position, the blower speed to high/max, and the A/C heater mode control to anything

except OFF. Put your voltmeter between the two contacts in the blower motor connector. If you get 12 volts (probably more like 12.8 [or higher if engine is running]), then you probably have a bad motor. Either the blower motor is bad or there is at least one bad connection in the wiring that is failing under load. You can “bench test” the blower motor by taking it out and connecting its contacts directly to a battery or high-current (40 Amp) 12V power source…if it runs, you have a bad connection somewhere in either the 12V or Ground side circuits. To determine which one, you will almost certainly have to start probing for voltage at certain points with everything connected, which means cutting wires or probing into the backs of connectors and that's a whole other checklist that I will have to consider...if there is any demand.

The step-by-step below is in two parts; one to troubleshoot the 12V side of the motor connection and the other to troubleshoot the ground side.

I am using the wiring diagram for a 2000 TJ which is on page 8W-42-2 (heater only) or 8W-42-4 (A/C + heater) of the

2000-2001 Factory Service Manual available for download on this site

here. Other years should be very similar though you may want to compare your year's manual to the 2000-2001 manual to verify wire colors and connector numbers.

As you go through these steps, be aware that any wire or connector that is burned, melted, bent, broken, or corroded is likely a problem.

12V side: The Jeep's battery must be connected in order to do these tests.

1. Unplug the blower motor connector and, with the ignition in the ON position, check for 12V at the blower motor connector contact A (dark green wire). If present, skip to step 1 of the

Ground side checklist, otherwise continue to step 2. Leave the connector off of the motor for now.

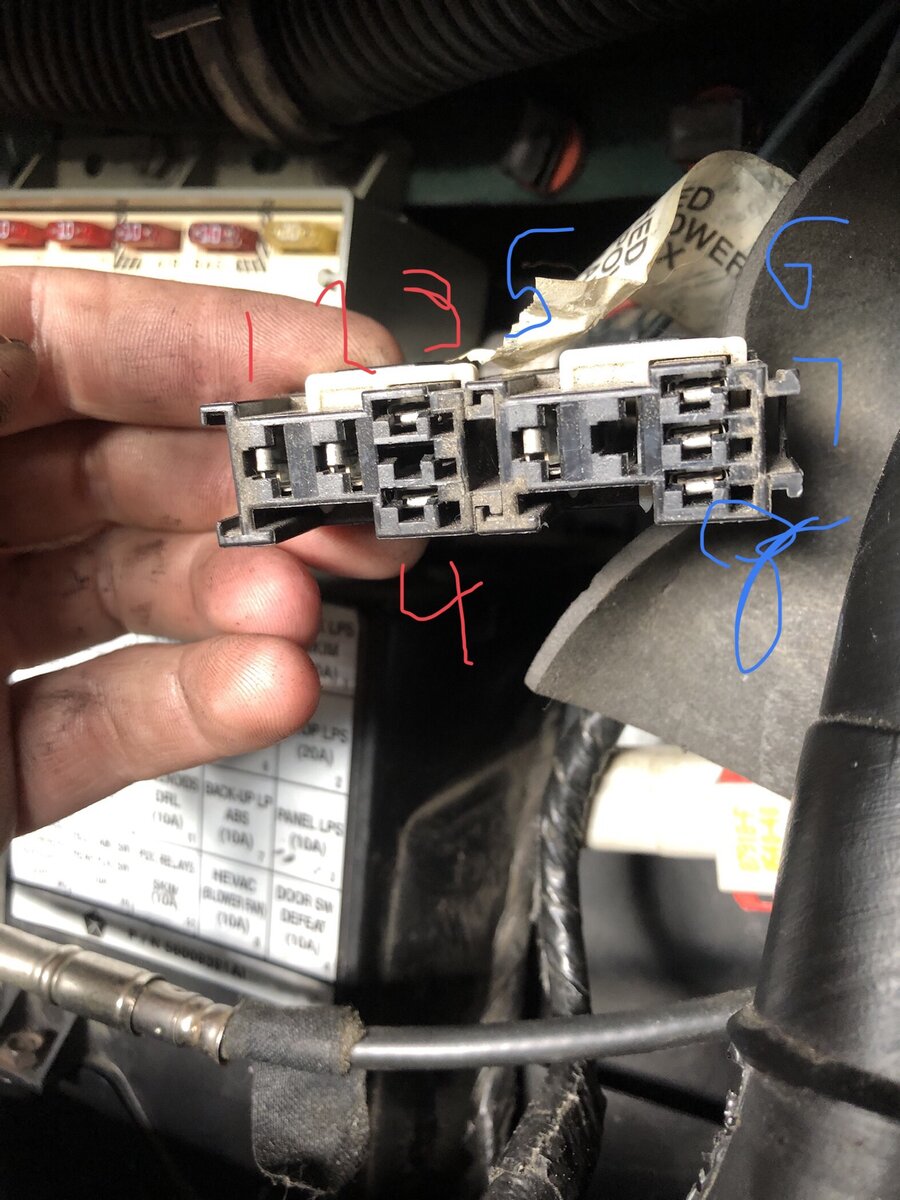

2. Unplug the blower motor relay and, with the ignition in the ON position, check for 12V at the #4 contact (red / light green wire) of the connector. If NOT present, skip to step 4 otherwise, continue to step 3.

3. Turn off the ignition. Use a piece of scrap wire or a paper clip to short contacts #1 (dark green wire) and #4 (red / light green wire) together. Let it hang carefully to insure it won’t touch anything. Connect your meter back to contact A (dark green wire) of the blower motor connector and ground and then turn the key to ON.

a. If you still do not get 12V, either the blower motor connector is bad or so corroded that you can’t get good contact with your jumper wire or the dark green wire going from it to the motor connector is bad (burned out, cut, corroded out).

b. If you DO now get 12V, either the blower motor relay connector is damaged or corroded in such a way that it is not properly working with the relay but will work with the piece of wire you inserted, or the relay itself is bad, or the relay is not being energized. Check for corrosion or physical damage on the connector’s contacts and on the relay’s contacts. If you get it to work by cleaning, remember that, due to the high currents involved, iffy connections here may overheat, causing a fire…it’s best to just replace any damaged or corroded parts (relay or relay connector).

To check for the relay being energized:

i. Place your meter on contact #5 (dark blue/white wire) of the relay connector to see if you get 12V. If you DO get 12 volts go to step 3.a.ii. If you do NOT, the relay is not being energized due to a 12V issue...

1. Trace down the dark blue/white wire to find connector C205, disconnect it and test for 12 volts at the far side of contact 9 (red / dark green wire). If it dose NOT have 12V, go to step 3.b.i.2. If it DOSE have 12V, the connector or the wire from it to the relay (dark brown / white) is bad.

2. Check fuse #8 in the fuse block (behind the glove box). This is a 10A fuse and you should be able to probe both sides of it because they run the contact of each side up through the fuse's plastic body so you can do just that. Note the little rectangular probe points on ether side of the "10" on this fuse:

If you don't get 12V on either side, there is a problem with your fuse block (no power to it, corroded, etc.)...pull the fuse and check for visible issues. If you can't see anything, now would be time to get someone familiar with automotive electrics involved as this problem would be pretty high current and could be a big fire hazard if not fixed properly.

If you get 12V on one side of the fuse but not the other, the fuse is bad. Replace it, test your blower and, if still not operating, start over at step 1.

If you get 12V on both sides, trace the red / dark green wire from the C205 connector you found in step 3.b.i.1 back to connector C202. Unplug C202 and check for 12V at the A1 contact, opposite the red / dark green wire that goes back to C205 (it may also be red / dark green, the manual does not specify...or it may be that C202 connects directly to the back of the fuse block). If you do NOT have 12V here, we again have a fuse block issue that will require an experienced hand to deal with it. If you DO have 12V here, C202 or the red / dark green wire(s) is/are bad.

ii. Check for continuity between the #2 contact (black wire) of the relay connector and ground. If you get continuity, the relay is being energized. If you do not get continuity, the black wire ther, connector C205 (contact 10), or the grounding point G200 is bad/corroded/broken/cut.

4. Trace the red / light green wire back from the relay connector to find connector C205. Unplug this connector and check for 12V at the far side of contact #8 (red / light blue). If it does NOT have 12V, go to step 5. If it DOES have 12V, then C205 or the red / light green wire is bad.

5. Reconnect C205. Trace the red / light blue wire back from C205 to connector C202. Disconnect C202 and check for 12V on the contact on the other side from the red / light blue wire (manual does not indicate a color). If it does NOT have 12V, go to step 6. If it Does have 12V, connector C202 or the red / light blue is bad.

6. The manual indicates that there is one more connector; C106 between this point and the power distribution center (fuse box under hood). Locate that connector and verify contact #12 (again, no color specified) on the distrib center side has 12V. If it does NOT, check the 40A fuse #1 in the distib center box, if it is good, you have an issue in your distribution center box and, again, you would need to get a qualified automotive electrician envolved. If it DOES have 12V, we're back to a distribution center issue and the need to get a qualified automotive electrician involved.

Ground side: You can do these tests with the battery negative terminal disconnected, if you wish.

1. With the ignition off, and the blower motor speed control set to high, and the heater mode control set to anything other than OFF, unplug the blower motor connector and, test for continuity between the B contact (not sure of the color of the wire but it's the one that is

not dark green) and a good ground (remember, the battery negative is not a good ground if you disconnected it

). Any clean non-painted surface of the body (avoid using the hood) to which you can make positive contact should be good. Sometimes you have to really push and scrape a little to get good contact. If you do NOT get continuity to ground, go to step 2. If you DO get continuity to ground, then the ground side is working. Assuming you already did the 12V side checks and you have 12V at the A contact of the blower motor connector, then, either the blower motor is bad or there is at least one bad connection that is failing under load. You can “bench test” the blower motor by taking it out and connecting its contacts directly to a battery or high-current (40 Amp) 12V power source…if it runs, you have a bad connection somewhere in either the 12V or Ground side circuits. To determine which one, you will almost certainly have to start probing for voltage at certain points with everything connected, which means cutting wires or probing into the backs of connectors.

2. To be here, you should have NOT had continuity on contact B of the blower motor connector to ground.

Remember, the blower speed control needs to be on the High setting and the heater mode control set to anything other than OFF. Leave the motor connector unplugged for now. Remove and unplug the Blower Motor Resistor Block from its connector. Check for continuity between contact #4 (black / tan wire) of that connector and ground. If you do NOT get continuity, go on to step 3. If you DO get continuity, then the black / tan wire going from that connector or the shunt S208 going to the blower motor connector is bad (burned/broken/cut/corroded out). Trace it down and repair/replace the wiring.

3. You can reconnect and re-mount the resistor block. Pull out the A/C heater control module from the dash (here’s a

vid but, unless you are replacing the entire module, DO NOT disconnect the vacuum lines as shown in the video because those tangs are pretty easy to break. If you want to pull the control all the way out, just yank the knob off and unscrew the vacuum control from the back of the module). Unplug the electrical connector C1 to the blower speed switch. Check for continuity from the contact

on the switch (not the connector) that goes to the brown / tan wire (contact A) to ground. If you do NOT have continuity, go on to step 4. If you DO have continuity, the connector is bad/corroded, or the brown / tan wire is burned/cut/broken/corroded through at the connector or between it and connector C205, or connector C205 is bad/melted/corroded (trace down the wires to find that connector and test it for continuity from the contact attached to the brown / tan wire to ground).

4. Check for continuity from contact E in the C1 connector (dark green wire) to ground. If you do NOT have continuity, go on to step 5. If you DO have continuity, the switch is bad…to verify, check for continuity between the contacts E (dark green wire) and contact A (brown/tan wire)

on the switch [remember, this all needs to be done with the speed switch in the high position, and the heater mode control set to anything other than OFF]…if no continuity, the switch is bad… if continuity, retest from the top of step 3.

5. Disconnect the C3 connector (dark green, light green, and black wires) and check for continuity from the contact B (goes to dark green wire)

on the switch/module to ground. If no continuity, go to step 6. If you do have continuity, either connector C3 is bad, the dark green wire is bad (it’s just a jumper between connectors C1 and C3) or connector C3 (specifically contact E) is bad.

6.

On the module, check for continuity between contact B (the one that goes to the dark green wire) and contact C (the one that goes to the black wire). If you have continuity, go to step 7. If no continuity, the mode switch is bad. You can retest it in any of the other positions (except off) to see if any of them give continuity and, if they do, see if the blower will work with it in that position. If it will then you know the switch is the only issue.

7. Check for continuity from the C (black wire) contact of the C3 connector to ground. If you do NOT have continuity, the C3 connector or the black wire is bad or the ground point G202 (at the other end of the black wire) is corroded/disconnected/broken. If you DO have continuity, we missed something along the way because that all there is. You can try unplugging and visually re-checking all of the connectors mentioned in all the steps to see if any are corroded/burned/melted/damaged.