Hey everyone,

I'm looking to piece together a hand throttle, and think I have it all worked out except for the attachment point at the throttle body. I have a manual so no cruise control, so I'll be routing it around where the cruise control cable normally sits and where it attaches at the throttle body. I'm thinking I can either try to sourse a OEM plastic connector, or simply make a loop in the hand throttle cable and try to find a way to keep it on the little knob on the throttle body. Anyone have any experience with either method?

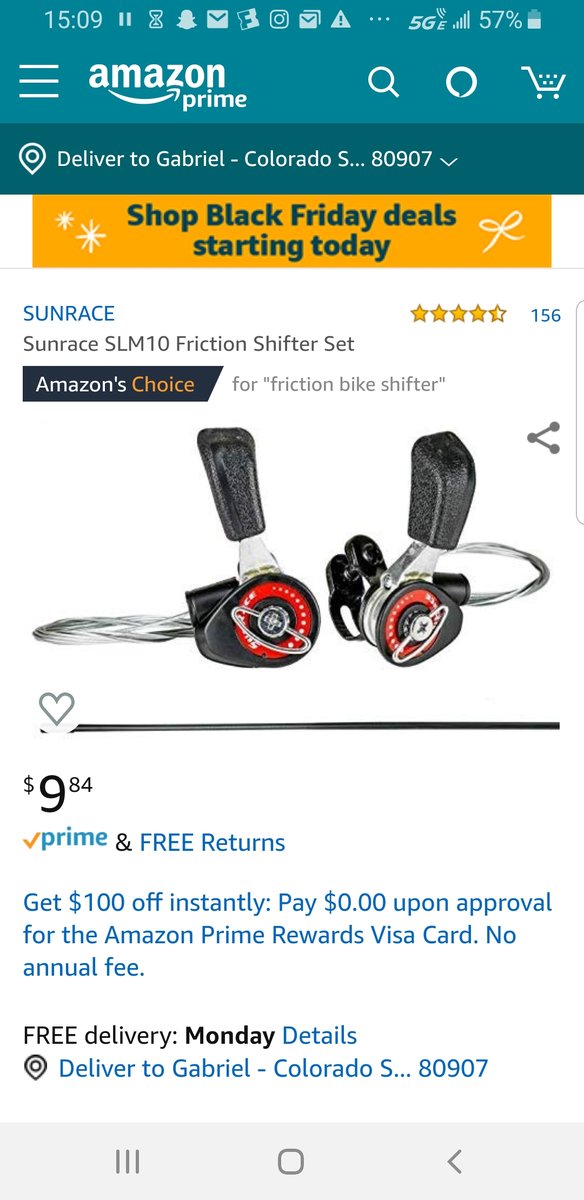

Also, I'm going with a friction shifter. I read that it's good to keep some slack just incase I accidently engage it. Anyone know how many clicks they have to move the hand throttle until it starts to raise rpm? Obviously I know that there's no right number, just wondering what worked for you.

Thank you!

I'm looking to piece together a hand throttle, and think I have it all worked out except for the attachment point at the throttle body. I have a manual so no cruise control, so I'll be routing it around where the cruise control cable normally sits and where it attaches at the throttle body. I'm thinking I can either try to sourse a OEM plastic connector, or simply make a loop in the hand throttle cable and try to find a way to keep it on the little knob on the throttle body. Anyone have any experience with either method?

Also, I'm going with a friction shifter. I read that it's good to keep some slack just incase I accidently engage it. Anyone know how many clicks they have to move the hand throttle until it starts to raise rpm? Obviously I know that there's no right number, just wondering what worked for you.

Thank you!