I didn't feel comfortable finalizing the steering without knowing for certain where the steering stops are at. The new gear comes in today, but I got a bit impatient over new years.

So I decided to build a roll cage! (I apologize to anyone who is here just to read about steering.)

I don't think our Jeeps need a cage for trail rides beyond stock even on more technical trails. That cage has been proven to do it's job. At the other end of the spectrum, a true roll cage with lots of triangulation, door bars, etc would be more of a danger and a annoyance for daily driving since there's more bars to hit your head on and climb over. And I'm not interested in getting groceries or going on a road trip in a helmet... So that brings us to the in between style of cage that I am building. My reasoning is that by adding in a little strength, if I lay the Jeep on it's side or against a tree/rock that the cage won't be as likely to be bent, also having a true A-pillar has some serious cool factor to the little 8 year old me who built a model RC monster truck will a full cage and the 80 year old old-school me that says "they don't make them like they use to".

I want to keep in balance the added weight of the cage and the intrusion of the cage. The rear is the least of my worries since I have no back seat. I would also like to be able to retain all tops that work with the factory cage.

The Synergy/Poly Performance cage kit fits my needs fairly well but has been discontinued. Fortunately in 2017 I found a Synergy front cage and frame tie-ins for sale and snatched them up. If anybody is looking to build a similar cage, the parts are really simple with single bends in each part with a couple of angled cuts at the floor. Somebody who's comfortable with a tube bender could bend something up for you. The Synergy cage parts are made primarily from 1.75" .120" wall DOM tubing. The shipping weight for the front half was 68lbs, I weighed the factory take off spreaders and they're 12lbs combined, so this cage addition is an addition of 56lbs to the Jeep (if I go on a diet I can make up for half of that.). The design of the cage isn't the most triangulated out there but I think it is a good balance of added strength and minimal intrusion. Even with the cage, the windshield still acts as the weak point in a rollover and will most likely need to be replaced before driving home, so let's hope I never roll my junk!

As I have been thinking more about the purpose of the cage I did decide to leave off the frame tie-ins. The reason here is that to protect against the type of roll that would benefit from tie-ins would also need a fully built cage. I see more negatives by adding them than I do positives.

I started by lowering the windshield, this opened up a can of worms that I had thought might be coming:

Yup, rust. I'm not entirely positive how water enters the windshield frame but it seems to be a thing. I will cut this area out and I bought on eBay a prebent piece of metal to replace as a bandaid fix that will hopefully last a few more years... In the meantime I will be keeping an eye out for a clean red windshield frame.

I think I could have done the repair with the glass in, but it was chipped anyway so I talked to a friend who used to work with glass about the best way to remove it and he stopped by to help.

Moving back to the cage, I used the dash cutting template from Synergy:

I used a rotary tool here instead of a knife so that I wouldn't start any cracks. I will later clean up the edge with a knife.

Looking down the dash on the driver's side I had a few things to massage out of the way. My favorite auto body tool here is the air hammer.

As I was fitting in the A to B pillar tube I realized that it wasn't fitting very well. I did a few measurements and the distance from the B pillar to the windshield is 1/2" different side to side. Since the doors and tops currently fit, function, and work in this position and even knowing it's skewed it still isn't noticeable visually, I will just account for it with the cage and make everything look right.

I can see how this install could either be a day install for somebody or a week long install. I got the week long install version. Ha!

So I decided to build a roll cage! (I apologize to anyone who is here just to read about steering.)

I don't think our Jeeps need a cage for trail rides beyond stock even on more technical trails. That cage has been proven to do it's job. At the other end of the spectrum, a true roll cage with lots of triangulation, door bars, etc would be more of a danger and a annoyance for daily driving since there's more bars to hit your head on and climb over. And I'm not interested in getting groceries or going on a road trip in a helmet... So that brings us to the in between style of cage that I am building. My reasoning is that by adding in a little strength, if I lay the Jeep on it's side or against a tree/rock that the cage won't be as likely to be bent, also having a true A-pillar has some serious cool factor to the little 8 year old me who built a model RC monster truck will a full cage and the 80 year old old-school me that says "they don't make them like they use to".

I want to keep in balance the added weight of the cage and the intrusion of the cage. The rear is the least of my worries since I have no back seat. I would also like to be able to retain all tops that work with the factory cage.

The Synergy/Poly Performance cage kit fits my needs fairly well but has been discontinued. Fortunately in 2017 I found a Synergy front cage and frame tie-ins for sale and snatched them up. If anybody is looking to build a similar cage, the parts are really simple with single bends in each part with a couple of angled cuts at the floor. Somebody who's comfortable with a tube bender could bend something up for you. The Synergy cage parts are made primarily from 1.75" .120" wall DOM tubing. The shipping weight for the front half was 68lbs, I weighed the factory take off spreaders and they're 12lbs combined, so this cage addition is an addition of 56lbs to the Jeep (if I go on a diet I can make up for half of that.). The design of the cage isn't the most triangulated out there but I think it is a good balance of added strength and minimal intrusion. Even with the cage, the windshield still acts as the weak point in a rollover and will most likely need to be replaced before driving home, so let's hope I never roll my junk!

As I have been thinking more about the purpose of the cage I did decide to leave off the frame tie-ins. The reason here is that to protect against the type of roll that would benefit from tie-ins would also need a fully built cage. I see more negatives by adding them than I do positives.

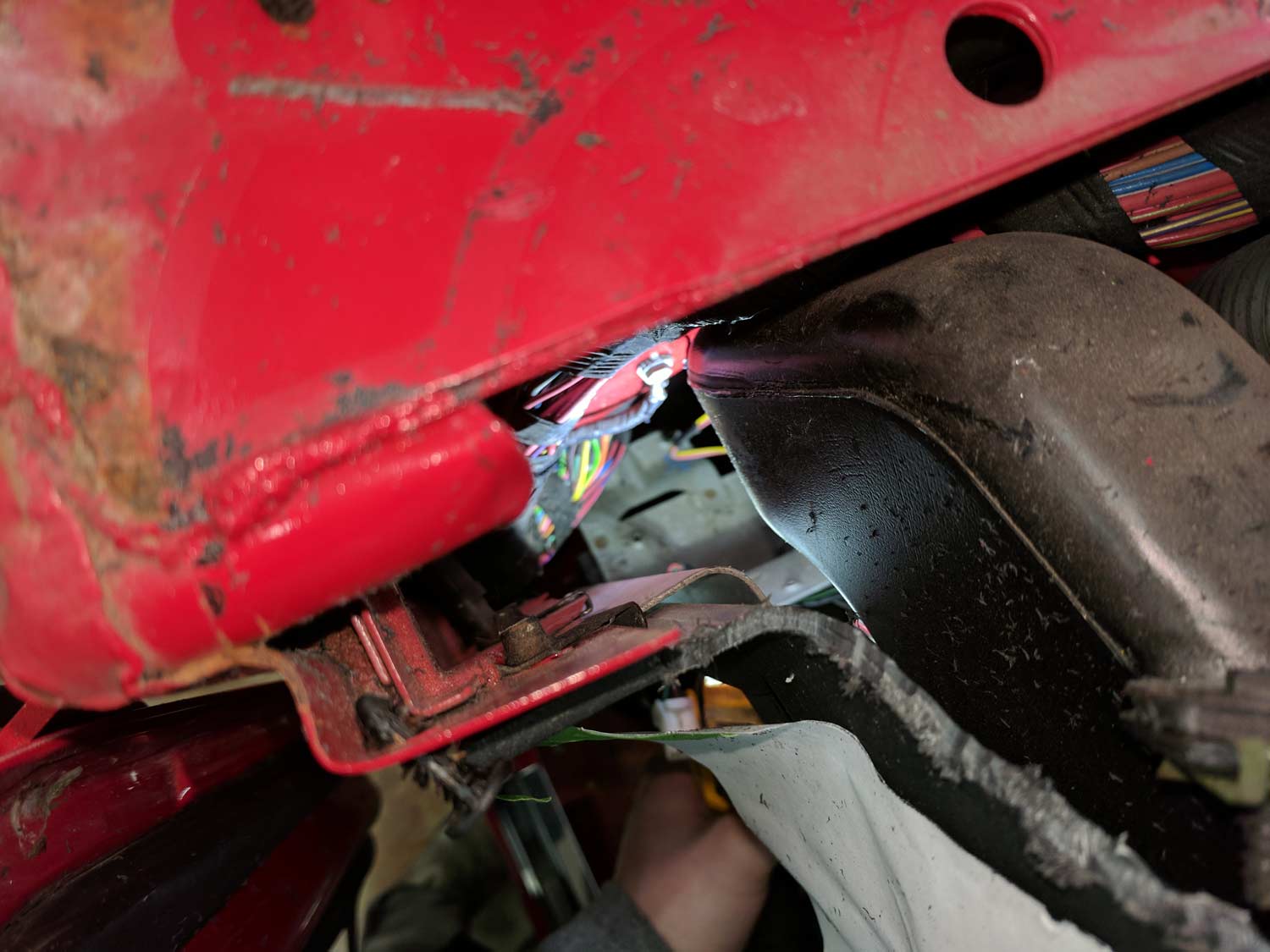

I started by lowering the windshield, this opened up a can of worms that I had thought might be coming:

Yup, rust. I'm not entirely positive how water enters the windshield frame but it seems to be a thing. I will cut this area out and I bought on eBay a prebent piece of metal to replace as a bandaid fix that will hopefully last a few more years... In the meantime I will be keeping an eye out for a clean red windshield frame.

I think I could have done the repair with the glass in, but it was chipped anyway so I talked to a friend who used to work with glass about the best way to remove it and he stopped by to help.

Moving back to the cage, I used the dash cutting template from Synergy:

I used a rotary tool here instead of a knife so that I wouldn't start any cracks. I will later clean up the edge with a knife.

Looking down the dash on the driver's side I had a few things to massage out of the way. My favorite auto body tool here is the air hammer.

As I was fitting in the A to B pillar tube I realized that it wasn't fitting very well. I did a few measurements and the distance from the B pillar to the windshield is 1/2" different side to side. Since the doors and tops currently fit, function, and work in this position and even knowing it's skewed it still isn't noticeable visually, I will just account for it with the cage and make everything look right.

I can see how this install could either be a day install for somebody or a week long install. I got the week long install version. Ha!