You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

High travel, high clearance & high octane, a streetable adventure LJ story

- Thread starter toximus

- Start date

Sorry for kinda derailing your build tox - wasn’t my intention.

It's all on topic here on my build thread.

I made a little bracket for the horn:

View attachment 125164

I also removed portions of my factory wiring harness that aren't being used. After, I tested the horn and it makes a pathetic VOOOT sound on the aluminum fender. That might need to change.

That's an interesting observation. During my bicycle building days, aluminum bells never sounded as good as brass bells. But I wouldn't have thought the aluminum fenders would change the tone and resonance of a car horn.

That's an interesting observation. During my bicycle building days, aluminum bells never sounded as good as brass bells. But I wouldn't have thought the aluminum fenders would change the tone and resonance of a car horn.

Maybe the horn is making the fender resonate since I'm firing the horn down into the thin fender? I don't want to change the angle or water can get trapped inside.

The Savvy bumper is installed, winch mounted, and steering skid on.

I replaced my steel cable with light weight synthetic from Tactical Recovery Equipment with a SafetyThimble on the end and their fairlead. Not all fairleads and winch ends are created equal and the owner, @Garza, has done an incredible job making a good safe product down to the little details. I could go on about these details but it deserves a thread of it's own. I'll be going over what recovery gear I'm packing in a later post so keep an eye out for that.

I cleaned up and enlarged the winch lugs to fit over my 5/8" military terminal bolts:

I replaced my steel cable with light weight synthetic from Tactical Recovery Equipment with a SafetyThimble on the end and their fairlead. Not all fairleads and winch ends are created equal and the owner, @Garza, has done an incredible job making a good safe product down to the little details. I could go on about these details but it deserves a thread of it's own. I'll be going over what recovery gear I'm packing in a later post so keep an eye out for that.

I cleaned up and enlarged the winch lugs to fit over my 5/8" military terminal bolts:

In a push Sunday night to get my build rolling before snowfall I stayed up until 3am tidying loose ends so I could pull the fenders off for painting the steel brackets. Somehow my 3am welds turned out great looking despite me forgetting some details about the night the next morning like where I placed nuts and bolts...

Unfortunately winter officially came and as I walked to bed that night I was standing in 2" of snow. I had planned on getting exhaust work done on the coming Friday the 15th but that date didn't seem as relevant anymore since the roads are already covered in salt.

I've been trying to sell a Genright 05-06 gas tank, but decided to use it as my new fuel cell instead.

For solely the purpose of a test drive and getting the Jeep onto a trailer for exhaust work I placed the fuel cell in the back. It's held down by ratchet straps. There's nothing proper or final about what I'm doing here and I don't want pictures of it floating around the internet. Instead, here are some mockup pics of how the fuel cell and spare tire sit.

Once I get the Jeep back from getting the exhaust work I'll be securing it properly and cover all of the plumbing at once to avoid confusion (although my fuel line plumbing is done properly).

I was able to fit the 37" spare tire in flat by deflating it. Since I have OBA I can fill it back up before use.

I've been trying to sell a Genright 05-06 gas tank, but decided to use it as my new fuel cell instead.

For solely the purpose of a test drive and getting the Jeep onto a trailer for exhaust work I placed the fuel cell in the back. It's held down by ratchet straps. There's nothing proper or final about what I'm doing here and I don't want pictures of it floating around the internet. Instead, here are some mockup pics of how the fuel cell and spare tire sit.

Once I get the Jeep back from getting the exhaust work I'll be securing it properly and cover all of the plumbing at once to avoid confusion (although my fuel line plumbing is done properly).

I was able to fit the 37" spare tire in flat by deflating it. Since I have OBA I can fill it back up before use.

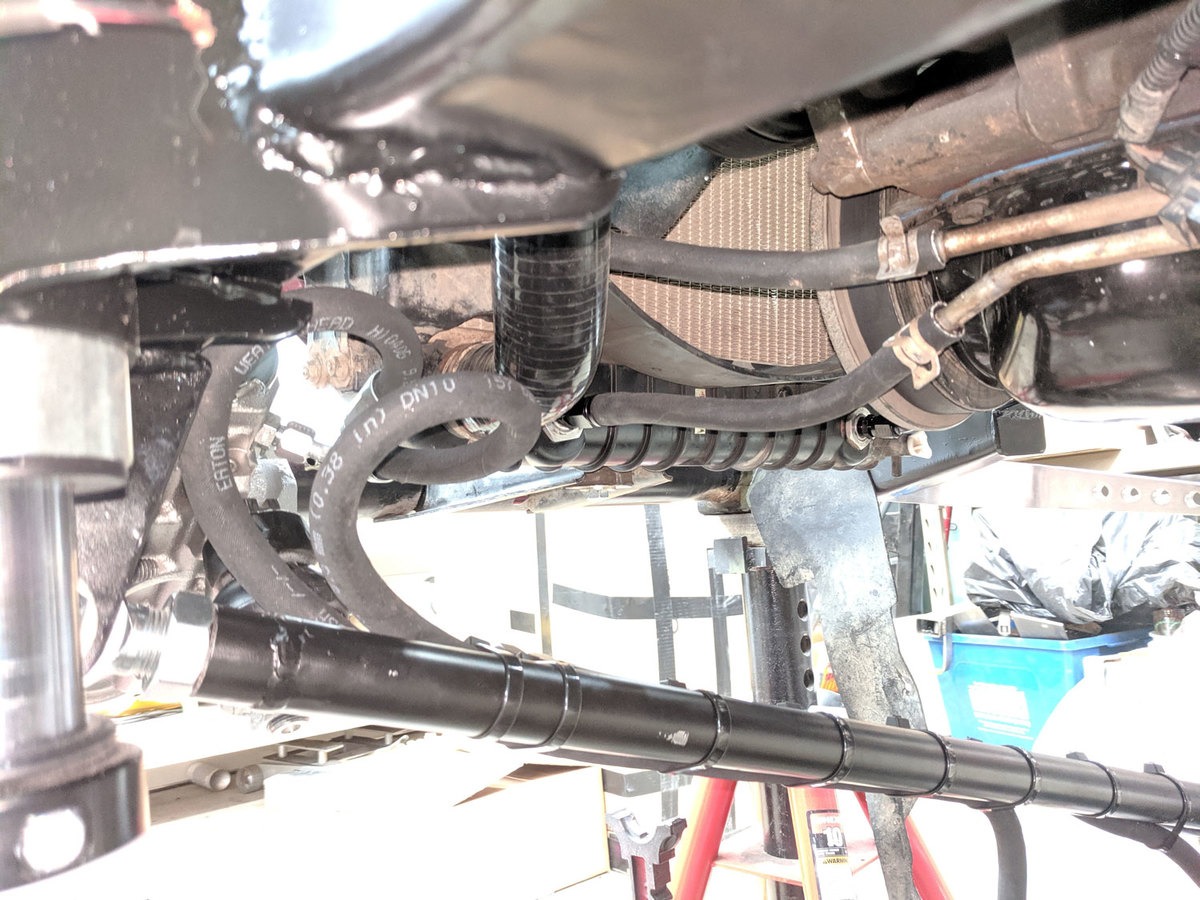

I had previously tried putting filters on my transmission and transfercase breathers, to simplify things I replaced them with 3/8" barbed unions.

I tightened down the adapters in the steering res before reinstalling on back on the fender.

I plumbed the hydroassist hoses down the track bar. There's no right or wrong way to route them as long as they don't get pinched or make contact with things they shouldn't. I cycled the axle several times to verify and am holding the lines in place with large 150lb zip ties.

I plumbed the hydroassist hoses down the track bar. There's no right or wrong way to route them as long as they don't get pinched or make contact with things they shouldn't. I cycled the axle several times to verify and am holding the lines in place with large 150lb zip ties.

Before replacing the fenders I hand sanded each one around the edges to make sure there are no burrs that could catch skin.

As I had been working on mounting components on the fenders I had been taking inventory of what fasteners I needed for each part and standardized the fasteners to a few sizes so not many tools would be needed to work on the Jeep in the future. I then ordered a bunch of nuts and bolts from McMaster-Carr to use for the final install.

I don't plan to remove the fenders for a while (could be a few years) so I applied loctite and antiseize where appropriate and took care during the assembly. Thankfully everything puzzled together exactly as I had planned!

From this:

To this in 2 days:

As I had been working on mounting components on the fenders I had been taking inventory of what fasteners I needed for each part and standardized the fasteners to a few sizes so not many tools would be needed to work on the Jeep in the future. I then ordered a bunch of nuts and bolts from McMaster-Carr to use for the final install.

I don't plan to remove the fenders for a while (could be a few years) so I applied loctite and antiseize where appropriate and took care during the assembly. Thankfully everything puzzled together exactly as I had planned!

From this:

To this in 2 days:

After a day of troubleshooting the fuel pump, I started the engine 2 days ago and it fired right up and is running smooth. I got all fluids topped off.

Yesterday I got the plates on...

...coilovers in and charged them up...

(unfortunately I was sent one 12" coil instead of the 14" coils I had ordered)

...Put the wheels on...

...And went for a test drive!

(Link with sound: 43MB )

Yesterday I got the plates on...

...coilovers in and charged them up...

(unfortunately I was sent one 12" coil instead of the 14" coils I had ordered)

...Put the wheels on...

...And went for a test drive!

(Link with sound: 43MB )

And?

And... I sold it to a guy... I'm sick of this build. Time for 33s and I'm actually going to take it offroad this time!

So what now?

That drive was a big moment that I had been working 2 and a half years for. Down to the week it's been 9 years since I've owned this Jeep and 2 years since I started seriously planning the details of this build. It's not done yet!

This test drive simply was a test to make sure I could get it onto a trailer to bring it to the exhaust shop. The coilovers aren't really setup, the fuel cell still needs to be completed, the wiring harnesses aren't tidied up, there's some small details that I'm waiting on parts for, a few underhood brackets that need to be made, etc, etc, etc. AND I HAVEN'T EVEN TALKED ABOUT HOW THE TEST DRIVE WENT! I'll be sure to keep the tech coming as I wrap up the build and after that I have a "redo list" of things that I'm not satisfied with that I'll be doing as more of weekend projects slowly over the coming year.

I need to regroup this weekend since the roads are currently worse than I want to be towing on and then I'll pound this build out. Stay tuned!

That drive was a big moment that I had been working 2 and a half years for. Down to the week it's been 9 years since I've owned this Jeep and 2 years since I started seriously planning the details of this build. It's not done yet!

This test drive simply was a test to make sure I could get it onto a trailer to bring it to the exhaust shop. The coilovers aren't really setup, the fuel cell still needs to be completed, the wiring harnesses aren't tidied up, there's some small details that I'm waiting on parts for, a few underhood brackets that need to be made, etc, etc, etc. AND I HAVEN'T EVEN TALKED ABOUT HOW THE TEST DRIVE WENT! I'll be sure to keep the tech coming as I wrap up the build and after that I have a "redo list" of things that I'm not satisfied with that I'll be doing as more of weekend projects slowly over the coming year.

I need to regroup this weekend since the roads are currently worse than I want to be towing on and then I'll pound this build out. Stay tuned!

It's really amazing to see that engine bay @toximus. Very glad to see the build getting closer to the finish line!

It's really amazing to see that engine bay @toximus. Very glad to see the build getting closer to the finish line!

Thanks for the encouragement!

Here's a bonus picture of the unfinished engine bay as it sits today for you:

I have really enjoyed reading this thread, thank you for making it.

Thank you for your comment!