If you have a second set of hands it would be smarter to just have someone wiggle the tire while you stick your hands on the C and Knuckle by the balljoint. If the BJ has play you will feel it knocking. If its the hub, you can look at the rotor and the knuckle. There should be no movement between the rotor and the knuckle.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Measure Once, Cut Twice: A Story of Excitement and Impatience

- Thread starter taylormade73

- Start date

Tried again with a someone else. You can feel the play when moving the wheel at 12 and 6 but cannot see anything. I also cannot feel anything on the BJ when moving the wheel. I'm stumped. Something is causing the play, but I cannot see where it is coming from.If you have a second set of hands it would be smarter to just have someone wiggle the tire while you stick your hands on the C and Knuckle by the balljoint. If the BJ has play you will feel it knocking. If its the hub, you can look at the rotor and the knuckle. There should be no movement between the rotor and the knuckle.

Not that the gaps between knuckle and C indicate anything, I still measured them with a caliper. Under weight driver side was .25in and passenger .29in. Jacked up not under weight passenger side gap increased to .33in. Other than seeing that vertical movement when jacking it up, I cannot see the lateral movement when wiggling the wheel.

Before under vehicle weight

After jacked up

Btw, I found a post where Blaine lists the DW Inspection Basics I'm going to walk through.

Before under vehicle weight

After jacked up

Btw, I found a post where Blaine lists the DW Inspection Basics I'm going to walk through.

I wouldn't think the knuckle would move with or without weight. Your lower might be shot or loose. Were the tapers clean when you installed? No paint? Nut is torqued "gutentite" (or 80 ft-lbs, IIRC)? I mean, we're only talking 0.005" of an inch (not much) but the fact that its moving at all concerns me. Compared to the axle, Ball joints are cheap. I'd probably pick up a set and try to return those.Not that the gaps between knuckle and C indicate anything, I still measured them with a caliper. Under weight driver side was .25in and passenger .29in. Jacked up not under weight passenger side gap increased to .33in. Other than seeing that vertical movement when jacking it up, I cannot see the lateral movement when wiggling the wheel.

Before under vehicle weight

View attachment 177420

After jacked up

View attachment 177421

Btw, I found a post where Blaine lists the DW Inspection Basics I'm going to walk through.

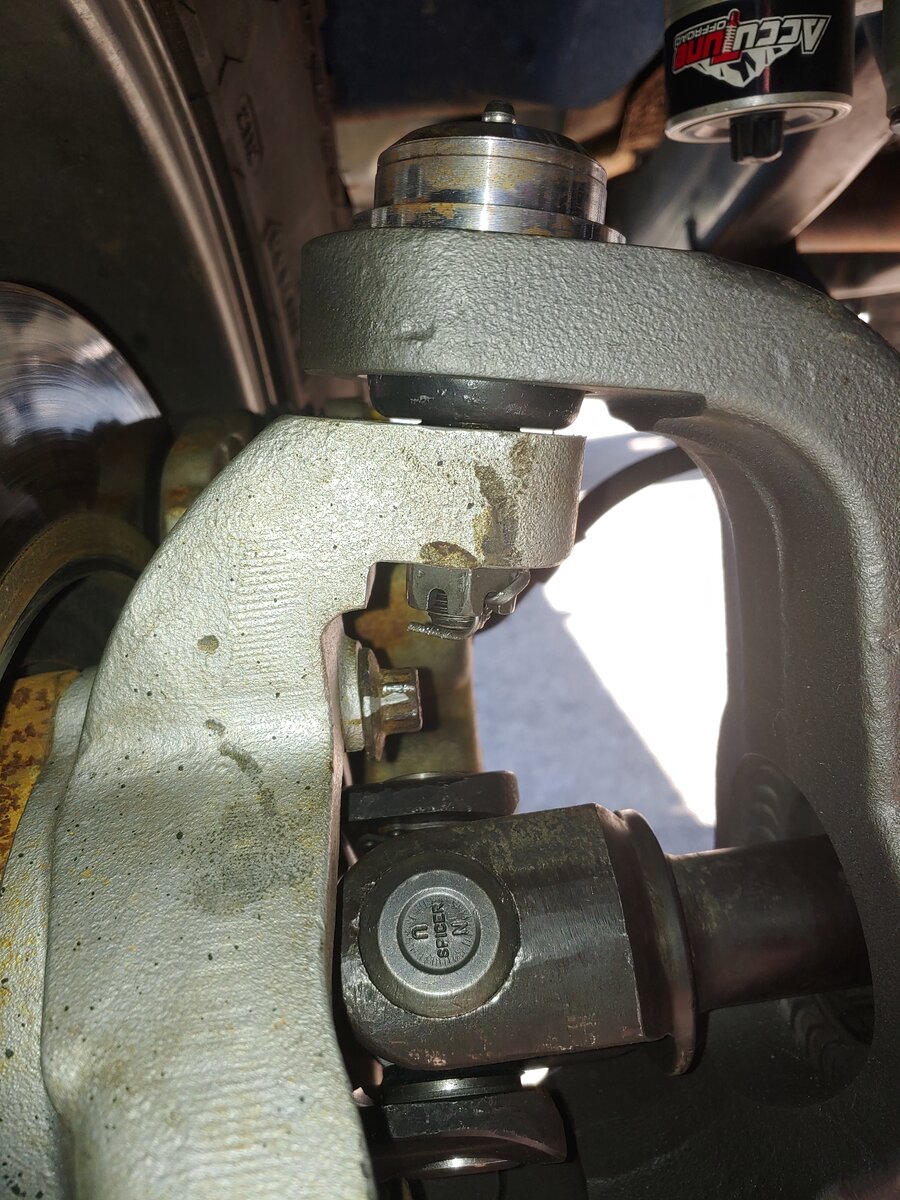

I replaced all 4 ball joints, several months ago with new spicer joints. My uppers have the same gap with no DW.

The ball joints are new and came pre-installed on the new axle. Tapers were clean as they are new BJs. They painted the axle then installed the BJs. Lower was torqued to 80 on install and I pulled cotter pin and rechecked torque 2 days ago and its still at 80. Sent the pics and description of issues to Jeremy as Disciple where I ordered the axle. We'll see what Carbon says.I wouldn't think the knuckle would move with or without weight. Your lower might be shot or loose. Were the tapers clean when you installed? No paint? Nut is torqued "gutentite" (or 80 ft-lbs, IIRC)? I mean, we're only talking 0.005" of an inch (not much) but the fact that its moving at all concerns me. Compared to the axle, Ball joints are cheap. I'd probably pick up a set and try to return those.

Same gap both sides? Mine is different from passenger to driver. And the gap widens when weight is lifted during jacking up.I replaced all 4 ball joints, several months ago with new spicer joints. My uppers have the same gap with no DW.

I was referring to the tapers in the knuckle. Did the new axle come with new knuckles? The upper ball joint moves up and down to let the lower ball joint locate the knuckle vertically. The lower ball joint is not supposed to move up and down. If its moving up and down, I'd guess that the ball joint is no good, or there is something in the taper that is not allowing good metal to metal contact.The ball joints are new and came pre-installed on the new axle. Tapers were clean as they are new BJs. They painted the axle then installed the BJs. Lower was torqued to 80 on install and I pulled cotter pin and rechecked torque 2 days ago and its still at 80. Sent the pics and description of issues to Jeremy as Disciple where I ordered the axle. We'll see what Carbon says.

Just because a part is new, doesn't always mean its good. I ran into that on a set of Mevotech TTX ball joints. I put a brand new set in, the uppers developed play in about 100 miles. Replaced them, and noticed that the next new set I got also had play in them. At that point I returned the C-suckers and got some Napa Chassis parts (long story why I didn't go with Spicer). Those have been good now for over 1000 miles.

Gotcha. The knuckles did not come with the axle. I bought them and unit bearings from BMB when I bought my 16" BBK. The knucks and unit bearings went on with new spicer BJs last Fall when I out the BBK on. They have maybe 5k miles on them. I took them off the old Dana 44 and installed them on this RJ44. I had no slop ot issues prior to removing them. I did not check the taper in the knuck though.

I will check/measure for movement in the lower BJ when I get home.

I will check/measure for movement in the lower BJ when I get home.

Yeah. Gapped on both sides. I recently installed all new suspension and after the first weekend of wheeling, I washed everything off and checked all my nuts/bolts etc. I decided to put a little grease in the ball joints as I hadn’t done previously since installing them. Even with a pump of grease there’s still a gap between the boot and the knuckle.Same gap both sides? Mine is different from passenger to driver. And the gap widens when weight is lifted during jacking up.

Ball joints are seated completely and no rotational or lateral play with weight off the whee and tire.

It's not the tires. They balanced out to 0 on all 4 and it still does it. Only 1 was out of balance and it was on the rear. They did a steering test and said all joints and ends are tight, including steering box. They checked and verified that all bolts are torqued to spec.

One of the senior guys there was pretty cool. He told me to bring it back tomorrow morning and we'll put it on the rack and he wants his mechanic to look at it as well. No charge; he's just curious as well.

We'll see! TBC

One of the senior guys there was pretty cool. He told me to bring it back tomorrow morning and we'll put it on the rack and he wants his mechanic to look at it as well. No charge; he's just curious as well.

We'll see! TBC

It doesn't make sense because you had these tires and wheels b4 the axle swap, but I've had a set of wheels and tires that I had balanced over 10 times and every time "they balanced out to 0" but I continually had DW. Got a new set of wheels and tires and no more DW. I had no worn components and no components were changed. As soon as I got different wheels and tires on the jeep, DW was gone.

Wheels and tires can static balance to 0 and still be very dynamically unbalanced to cause DW. Not saying this is your problem but its possible. Do you have any buddies that you could try their front wheels/tires from their rig?

Wheels and tires can static balance to 0 and still be very dynamically unbalanced to cause DW. Not saying this is your problem but its possible. Do you have any buddies that you could try their front wheels/tires from their rig?

None close. I do have the 31's on my stock TJR.It doesn't make sense because you had these tires and wheels b4 the axle swap, but I've had a set of wheels and tires that I had balanced over 10 times and every time "they balanced out to 0" but I continually had DW. Got a new set of wheels and tires and no more DW. I had no worn components and no components were changed. As soon as I got different wheels and tires on the jeep, DW was gone.

Wheels and tires can static balance to 0 and still be very dynamically unbalanced to cause DW. Not saying this is your problem but its possible. Do you have any buddies that you could try their front wheels/tires from their rig?

Putting it on the rack this morning yielded no new info. Everything tight: rod ends, bolts, etc. Set the alignment with the machine while on the rack just because. At this point, I'm just going to take it back apart and "redo" the axle swap. This time going very slowly and focusing on installing and torquing everything properly. I'm also going to check the tapers on the knucks while im at it. Laters for now...I've got a shit ton of work to do. Wish me luck.

CostcoPizza

Member

Bummer about the setback, but you're on the way forward with increasing your knowledge through sweat equity.

Rather than typing twice, I'll place the link to the DW thread for my update.

https://wranglertjforum.com/threads/death-wobble-question.38040/post-631626

https://wranglertjforum.com/threads/death-wobble-question.38040/post-631626

Put the half doors on today. Still need to get them painted. It looks like the Batmobile.

I also put the Rubi rockers back on till I get the Savvys ready to install.

I also put the Rubi rockers back on till I get the Savvys ready to install.

Getting some good numbers from my build results. Ride height net 4.5" springs front/4"springs rear.

Shock travel bias

Rear 9.6" travel roughly 50/50

Front 10.6" travel roughly 45/55 up/down

Frame height 21.375"

Gas tank skid 18.75"

Shock travel bias

Rear 9.6" travel roughly 50/50

Front 10.6" travel roughly 45/55 up/down

Frame height 21.375"

Gas tank skid 18.75"

Last edited: