This is what they sent me with the axle assembly. I was probably right around 1.8 qts looking at what was left in the container. My pump wouldn't reach all the way down into the containers.I had a slight pinion seal leak on my front carbon44. I contacted them via email if they could send me a new seal. I let them know I filled the diff with 2 quarts. At this point they told me the spec was only 1.5 quarts. Since changing to 1.5 quarts the pinion seal hasn’t leaked.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Measure Once, Cut Twice: A Story of Excitement and Impatience

- Thread starter taylormade73

- Start date

Well, get the DW held at bay for my trip to Florida that begins today, whoohoo...now my AC only blows ambient air  . Just what I need to fail for Florida weather. Looks like doors and top off for the win.

. Just what I need to fail for Florida weather. Looks like doors and top off for the win.

Time to sell me that piece of junk. You have another to build up. I can probably muster up 6 or 7 thousand for it...

LOL

LOL

I've got so much time (physical and mental) into this thing, I've purchased a grave plot next to mine for it.Time to sell me that piece of junk. You have another to build up. I can probably muster up 6 or 7 thousand for it...

LOL

Damn don't I know this...I've got so much time (physical and mental) into this thing, I've purchased a grave plot next to mine for it.

Had a slight heat soak issue on injector 3 when we arrive here in Florida. Bought some heat shield from Autozone and wrapped it.

Well, home safely. Just shy of 2000 miles on the trip and not one DW incident or threat thereof. Work around successful for the trip. Actually, the rig handled that trip like a beast--75-80mph with no vibes and motor smooth. My wife now trusts it to take us anywhere. However, she complained about the seats and says the long trips must be spaced apart lol. Lastly, the Flowmaster is coming out and stock going back in. Thought I liked the sound until I had to listen to it for 12 hrs straight.

thought i saw you made a JJ tool, not finding info in this thread. am i mistaken?

if it was yours can you elaborate on the pieces and it's construction, plz.

if it was yours can you elaborate on the pieces and it's construction, plz.

Could try a thrush muffler instead of stock.Well, home safely. Just shy of 2000 miles on the trip and not one DW incident or threat thereof. Work around successful for the trip. Actually, the rig handled that trip like a beast--75-80mph with no vibes and motor smooth. My wife now trusts it to take us anywhere. However, she complained about the seats and says the long trips must be spaced apart lol. Lastly, the Flowmaster is coming out and stock going back in. Thought I liked the sound until I had to listen to it for 12 hrs straight.

I don't want any sound lol. Quiet as possible.Could try a thrush muffler instead of stock.

Yes I made one. I'm out and about right now. Will post pics and pieces tomorrow.thought i saw you made a JJ tool, not finding info in this thread. am i mistaken?

if it was yours can you elaborate on the pieces and it's construction, plz.

https://wranglertjforum.com/threads/death-wobble-question.38040/post-645816thought i saw you made a JJ tool, not finding info in this thread. am i mistaken?

if it was yours can you elaborate on the pieces and it's construction, plz.

I don’t think it’s much different than stock but people out in Moab asked what V8 I had.I don't want any sound lol. Quiet as possible.

The tool I made is for the small 2" JJ. You will need the following:thought i saw you made a JJ tool, not finding info in this thread. am i mistaken?

if it was yours can you elaborate on the pieces and it's construction, plz.

3/8" x 5" all-thread

3/8" nut with matching thread pitch to all-thread bolt

Anti-sieze between nut and 5/8" washer so nut spins freely

One 3/4" nut

One 7/8" socket (I used the actual JJ tool part here but the nut and socket should work as a substitute.)

One 7/16" hardened washer

Two 5/8" hardened washers

One 7/8" hardened washer

One 1.67" ID x 1.11" long barrel/sleeve (a 36 size socket with the teeth ground down will work as well)

***all washers should be hardened so the don't deform or bite into each other or other parts.

Construction is self-explanatory. See photos.

The tool will go on the joint like this so you can depress the washer to remove the preload and then snap ring.

Then you will need to reverse the tool and add the barrel like this to remove the joint.

Assembly is everything in reverse. Hope this helps.

NOTE: the large nut is to fit over the centering ball which sticks out past the barrel face.

Last edited:

@someguysjeep I didn't make a tool for the larger 2.5" JJ. But I measured the parts for the actual JJ tool I have and created a parts list for you. You will need the following:

1/2" x 6" all-thread

1/2" nut with matching thread pitch to all-thread bolt

Anti-sieze between nut and 5/8" washer so nut spins freely

One 7/8" nut

One socket with OD of 1.5" and 2" length

One 5/8" hardened washer

Two 3/4" hardened washers

One 1" hardened washer

One 2.16" ID x 1.75" long barrel/sleeve

Assembly and use will be similar to the smaller one.

1/2" x 6" all-thread

1/2" nut with matching thread pitch to all-thread bolt

Anti-sieze between nut and 5/8" washer so nut spins freely

One 7/8" nut

One socket with OD of 1.5" and 2" length

One 5/8" hardened washer

Two 3/4" hardened washers

One 1" hardened washer

One 2.16" ID x 1.75" long barrel/sleeve

Assembly and use will be similar to the smaller one.

Last edited:

Milwaukee Tool Fairy came this week. The collection is growing, albeit focused at this point with some guidance from Blaine. Despite it not being used much, I couldn't pass up on a deal to get the "Oh, so you want to be a little bitch bolt?" AKA "The Beast."

Well, somewhat regret taking the LJ to the Florida panhandle for a week recently. I keep it in the garage when not in use amd zero salt exposure so no rust issues. Ive had rock chips in my front bumper for a year and never any orange appeared. However, this is what one week did along the Gulf Coast. I even have some forming between my Savvy crossmember amd frame where the outer C took some of rhe paint off during install. Smh. Will be taking care of this soon.

A couple major assumptions here to start. First, I am posting this issue in my build thread as if enough people or the right people actually read it rather than it needing its own thread. Second, that those people are fed up with sports and won't be watching football bit will be waiting for me to post something in my thread on a Sunday.

If those 2 are true, then I shall get the help I need in identifying a leak, i.e., a rear pinion seal leak. Making sure my rig was road worthy to go to Michigan yesterday, I laid under to check things out before hitting the road. I saw a bunch of fluid all over the axle housing, tub above, and gas tank and skid and immediately thought brake fluid from the distribution block. Stuck my finger in it like the nosey head first person I am and not brake fluid (too thick). I checked my levels anyway--still full and brakes feel fine. Had wife stand on them a couple times while i inspected underneath for good measure. Still fine.

So, only other fluids in that location are diff and shock. Checked my diff breather to see if it spit it out. Maybe. Checked diff cover. Nope. All bolts tight and not coming from mating surface of pumpkin or any of the 3 plugs.

So I cleaned everything off good and took it for a test drive. No signs of fluid. We then went to Michigan. Checked on each stop we made and still no signs until last stop near Detroit. Fluid again. We left last night and came home.

I cleaned off everything good again this afternoon and have been taking it out on the highway for short tests while working on "other" adjustments. I am now seeing fluid spattered a bit in the same places and can see it around the pinion seal. I caught it before it saturated everything back there and hid its origin. Silver lining is all the gear oil will work as an excellent rust prohibitor.

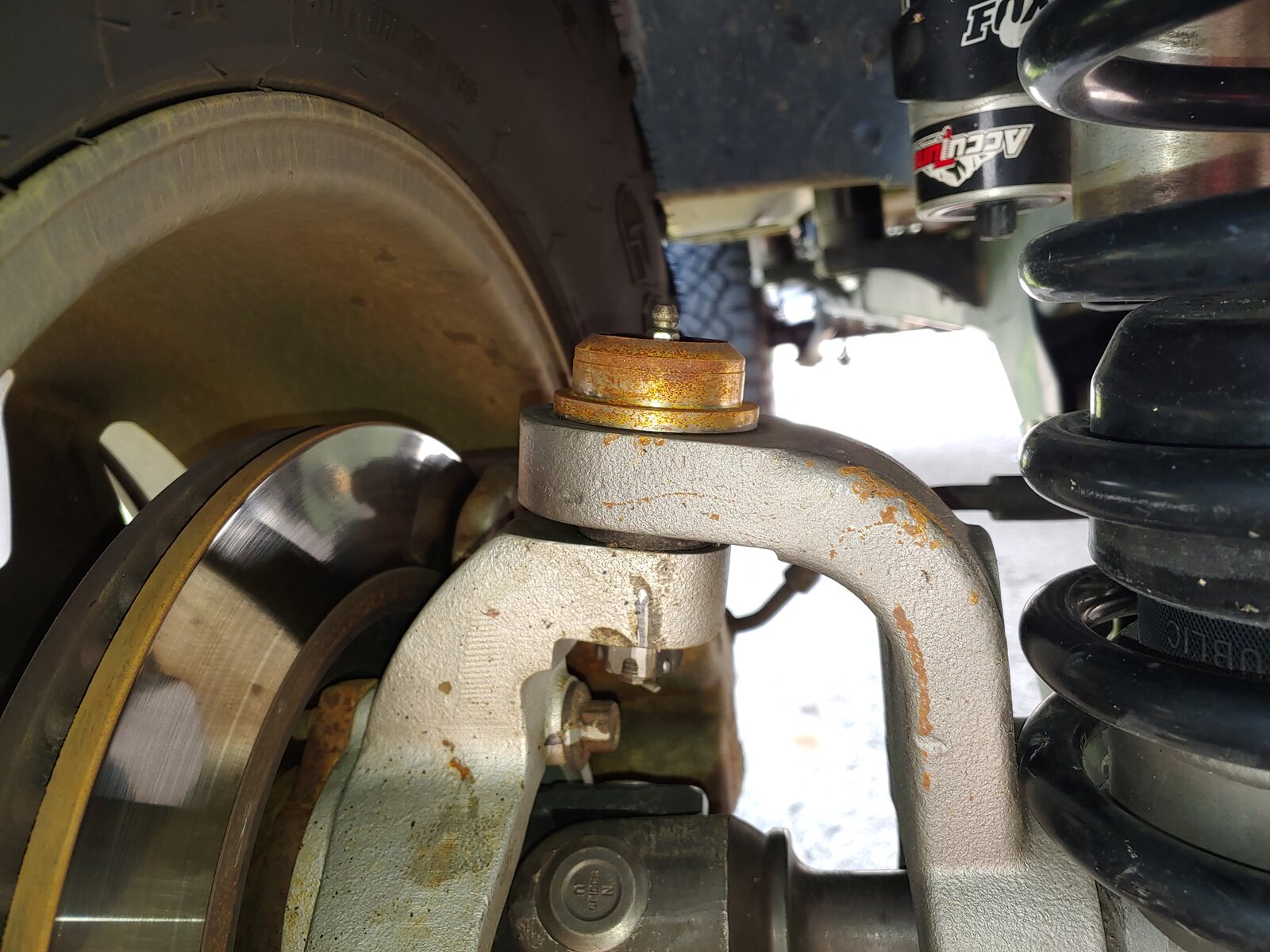

On a brighter note, no shimmy anymore when I hit "the bump." Going to unbind my UCAs and continue the quest for a solution to the DW and not a work around.

If those 2 are true, then I shall get the help I need in identifying a leak, i.e., a rear pinion seal leak. Making sure my rig was road worthy to go to Michigan yesterday, I laid under to check things out before hitting the road. I saw a bunch of fluid all over the axle housing, tub above, and gas tank and skid and immediately thought brake fluid from the distribution block. Stuck my finger in it like the nosey head first person I am and not brake fluid (too thick). I checked my levels anyway--still full and brakes feel fine. Had wife stand on them a couple times while i inspected underneath for good measure. Still fine.

So, only other fluids in that location are diff and shock. Checked my diff breather to see if it spit it out. Maybe. Checked diff cover. Nope. All bolts tight and not coming from mating surface of pumpkin or any of the 3 plugs.

So I cleaned everything off good and took it for a test drive. No signs of fluid. We then went to Michigan. Checked on each stop we made and still no signs until last stop near Detroit. Fluid again. We left last night and came home.

I cleaned off everything good again this afternoon and have been taking it out on the highway for short tests while working on "other" adjustments. I am now seeing fluid spattered a bit in the same places and can see it around the pinion seal. I caught it before it saturated everything back there and hid its origin. Silver lining is all the gear oil will work as an excellent rust prohibitor.

On a brighter note, no shimmy anymore when I hit "the bump." Going to unbind my UCAs and continue the quest for a solution to the DW and not a work around.

I would make sure the axle vent is not plugged or kinked and I would replace the pinion seal. Make sure you aren't overfilling the diff too..

the Elocker grommet can be a bitch to seal. I can't get either of mine completely perfect. But based on how much fluid is slinging everywhere, that's coming from the pinion seal.

the Elocker grommet can be a bitch to seal. I can't get either of mine completely perfect. But based on how much fluid is slinging everywhere, that's coming from the pinion seal.

Breather isn't clogged or crimped. I can def see the fluid leak around the pinion. So, I'll be changing that out. Can I just take the pinion nut off, remove and replace the seal, then reinstall and retorque the pinion nut? I've done all my own suspension, brake and engine work. However, have never done any diff work. It's an RJ60. I guess I'll be doing some research on RJ60 assemblies. Thanks for your help.I would make sure the axle vent is not plugged or kinked and I would replace the pinion seal. Make sure you aren't overfilling the diff too..

the Elocker grommet can be a bitch to seal. I can't get either of mine completely perfect. But based on how much fluid is slinging everywhere, that's coming from the pinion seal.