You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TJ's TJ

- Thread starter TJ's-TJ

- Start date

New stainless steel hat section to replace rotten section:

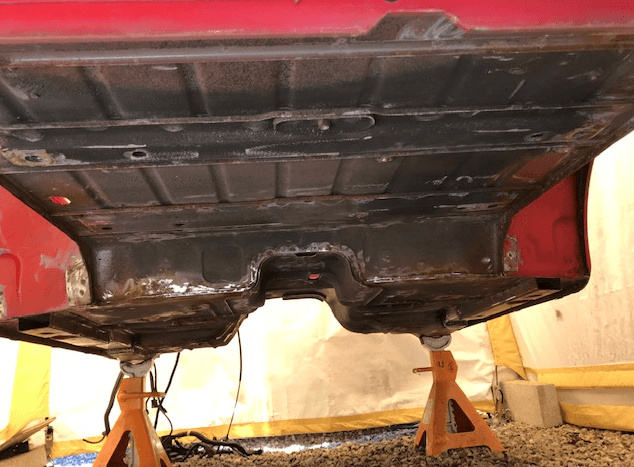

Bottom and firewall were then scuffed and coated with grey POR-15 (same paint, different lighting):

Bottom and firewall were then scuffed and coated with grey POR-15 (same paint, different lighting):

We got the front driveshaft disassembled to check the splines prior to buying rebuild parts. There is not a lot of information on the web about how to check the slip joints on our drive shafts. So I sent an e-mail to Tom Woods with some questions, I have never dealt with him before, but have heard only good things. Not surprisingly he got right back to me with some advice. To check splines, disassemble the joint, clean it, then reassemble and check for play, more than .008" of play may cause vibrations. Ours is tight with only a few thousandths of play. So maybe a candidate to rebuild.

View attachment 59280

View attachment 59281

Is that an old South Bend lathe in the pic.?

Yes, good eye. Its a heavy 10. Old tools tend to follow me home.Is that an old South Bend lathe in the pic.?

Yes, good eye. Its a heavy 10. Old tools tend to follow me home.

Thought so. Great multi purpose lathe.

Thanks, may seem like a waste of time to some, but remember 1/2 the point of this project is to teach a 14 year old...

That is an excellent project to involve/teach a 14 year old.

r3d

New Member

Yes, good eye. Its a heavy 10. Old tools tend to follow me home.

Cut my teeth on South Bend lathes in high school taking machine shop in junior & senior years. Many years ago.

We are prepping the body for POR-15 and ultimately Raptor liner top coat. I know that not everyone on here loves raptor liner, but it is an order of magnitude easier and cheaper than a real paint job. And a perfect paint job just doesn't make that much sense on a jeep (to us anyways).

We drilled out all the fender flare holes and installed 5mm riv-nuts. If you are not familiar with them, here is how you install them:

Drill out the hole:

Then we coat the hole with POR-15:

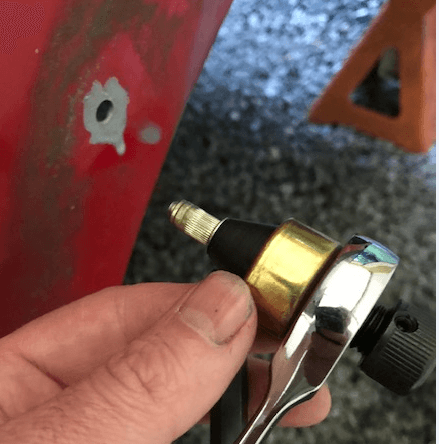

Here is the installation tool, we install the riv-nuts while the POR is still wet:

The tool is threaded and draws the rivet nut up tight to the sheet metal:

I am not a huge fan of sheet metal screws into painted sheet metal, so we installed riv-nuts around the fuel filler as well:

We drilled out all the fender flare holes and installed 5mm riv-nuts. If you are not familiar with them, here is how you install them:

Drill out the hole:

Then we coat the hole with POR-15:

Here is the installation tool, we install the riv-nuts while the POR is still wet:

The tool is threaded and draws the rivet nut up tight to the sheet metal:

I am not a huge fan of sheet metal screws into painted sheet metal, so we installed riv-nuts around the fuel filler as well:

I found these round LED tail lights made by Grote (55202). They make lighting for tractor trailers. Integrated stop, tail, turn, and back-up with a stainless steel flange. We will paint the flange black.

They need around a 4.375" hole to go into, but we drilled it at 4.125" and then enlarged (only had that size saw). Drilled for the riv-nuts first, assuming it would be difficult to drill the edge of the hole after.

They need around a 4.375" hole to go into, but we drilled it at 4.125" and then enlarged (only had that size saw). Drilled for the riv-nuts first, assuming it would be difficult to drill the edge of the hole after.

We filled in the license plate holes (going with a tailgate mounted plate) and the running board holes:

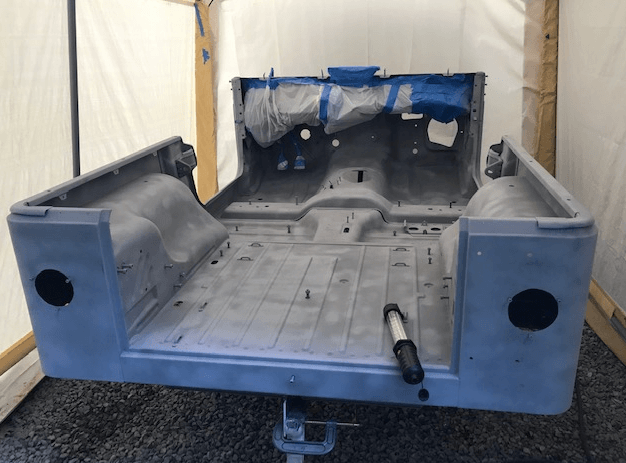

Scuff the entire body in/out and apply some filler:

Then brushed on the grey POR-15 into every crevice:

Scuff the entire body in/out and apply some filler:

Then brushed on the grey POR-15 into every crevice:

Last edited:

Scuffed and hit with light coat of grey primer:

We bought the adjustable gun that UPOL sells:

You adjust it by cranking the tip in and out. Hard to see on our test piece, but the top below is the finest texture (2 turns out) and the bottom is the roughest (8 turns out). We went with the finest texture. Pressure at the gun was 50 psi with the trigger pulled.

The body took 6 bottles to do 2 full coats inside, out side, and under. The trick to consistent sheen is to do a light mist coat at about 24" at the very end over everything:

Back on the frame (on wood blocks until we sort the body mounts):

Also got the bumpers, rock sliders, and flares sprayed in black:

We bought the adjustable gun that UPOL sells:

You adjust it by cranking the tip in and out. Hard to see on our test piece, but the top below is the finest texture (2 turns out) and the bottom is the roughest (8 turns out). We went with the finest texture. Pressure at the gun was 50 psi with the trigger pulled.

The body took 6 bottles to do 2 full coats inside, out side, and under. The trick to consistent sheen is to do a light mist coat at about 24" at the very end over everything:

Back on the frame (on wood blocks until we sort the body mounts):

Also got the bumpers, rock sliders, and flares sprayed in black:

Here is a close up of the rear bumper, Raptor liner came out very consistent:

3D printed new Jeep Logos for the side of the body since the standard vinyl decal will never stick to the new textured finish these will be painted and will go on with double sided foam tape:

Last edited:

Wow. Every time I look through this thread, it impresses me. You and your son have done a wonderful job restoring that TJ. You and he should be very proud!

The other fender and the grill, this took almost (1) bottle to fully coat both with a second coat on the outside surfaces:

And we took a chance on the ebay Aluminum hood louvers for $98 shipped. Came in 2 days and is really nice. The Aluminum measures 0.082" if anyone is wondering, so a decent thickness that should hold up:

And we took a chance on the ebay Aluminum hood louvers for $98 shipped. Came in 2 days and is really nice. The Aluminum measures 0.082" if anyone is wondering, so a decent thickness that should hold up:

Here is the template that comes with the hood louvers. We decided to only cut out the front 6 louvers on each side to try and limit the water that gets onto the engine during rain.

The louver piece was then positioned with 2 drill bits into the bumper holes and (4) of the securing holes were drilled, screws and nuts put in and then the rest were drilled to guarantee alignment of all of the holes.

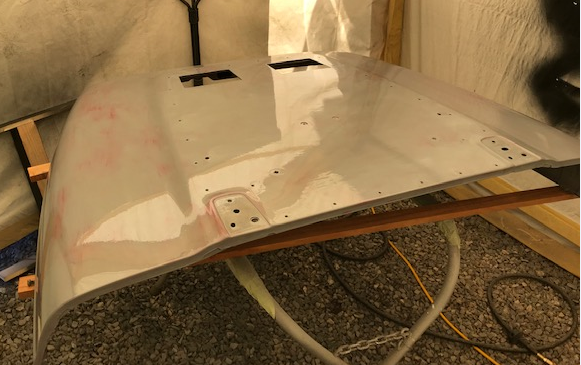

Hood in POR-15:

Hood scuffed with a light coat of primer prior to Raptor liner:

The louver piece was then positioned with 2 drill bits into the bumper holes and (4) of the securing holes were drilled, screws and nuts put in and then the rest were drilled to guarantee alignment of all of the holes.

Hood in POR-15:

Hood scuffed with a light coat of primer prior to Raptor liner:

Last edited: