You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TJ's TJ

- Thread starter TJ's-TJ

- Start date

Total cost $435 including new O2 sensors:

View attachment 72596

You had me at making the muffler. Impressive workmanship on this project.

Thanks, may seem like a waste of time to some, but remember 1/2 the point of this project is to teach a 14 year old...

Fully understand. My 20yo and I work quite a bit together. He's got a great work ethic.Thanks, may seem like a waste of time to some, but remember 1/2 the point of this project is to teach a 14 year old...

He's building a K30 off road truck. In fabrication he's years ahead of where I was at his age. (It doesn't hurt that I have way more tools around that weren't available to me in my youth.)

BTW: Its going to be too nice to put on the salt....going to have to get a HOOPTY car for the winter!

Truely a Build Thread. Nice job

I agree, too clean underneath for Northeastern winters!

BTW: Its going to be too nice to put on the salt....going to have to get a HOOPTY car for the winter!

I agree, too clean underneath for Northeastern winters!

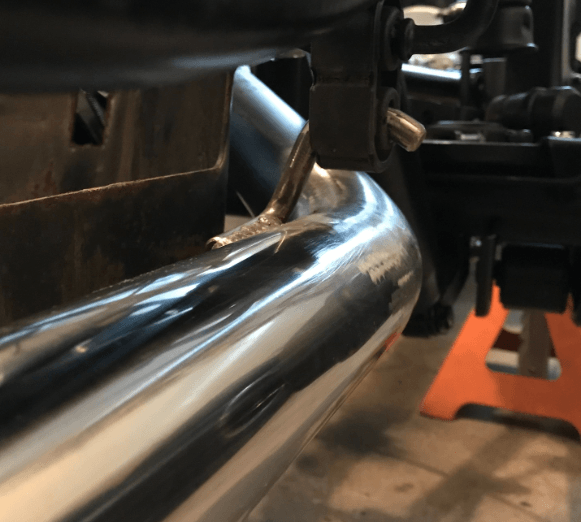

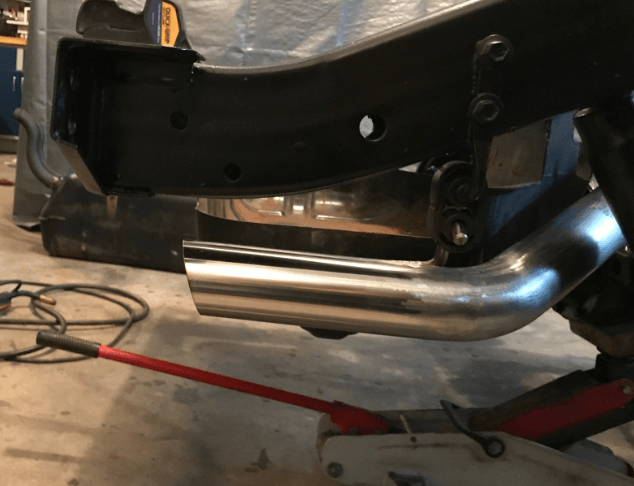

We got the rear hanger done (7/16" stainless rod) and decided to put an angled cut on the tail pipe that is basically flush with the gas tank skid.

Last edited:

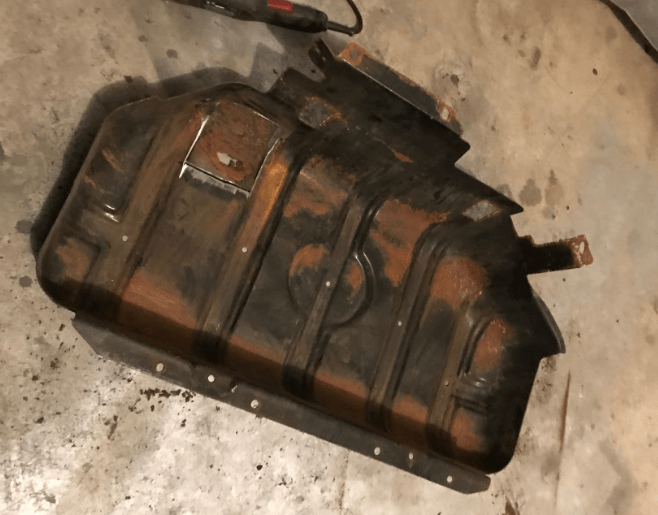

Gas tank skid had one bad area where crap must have been trapped:

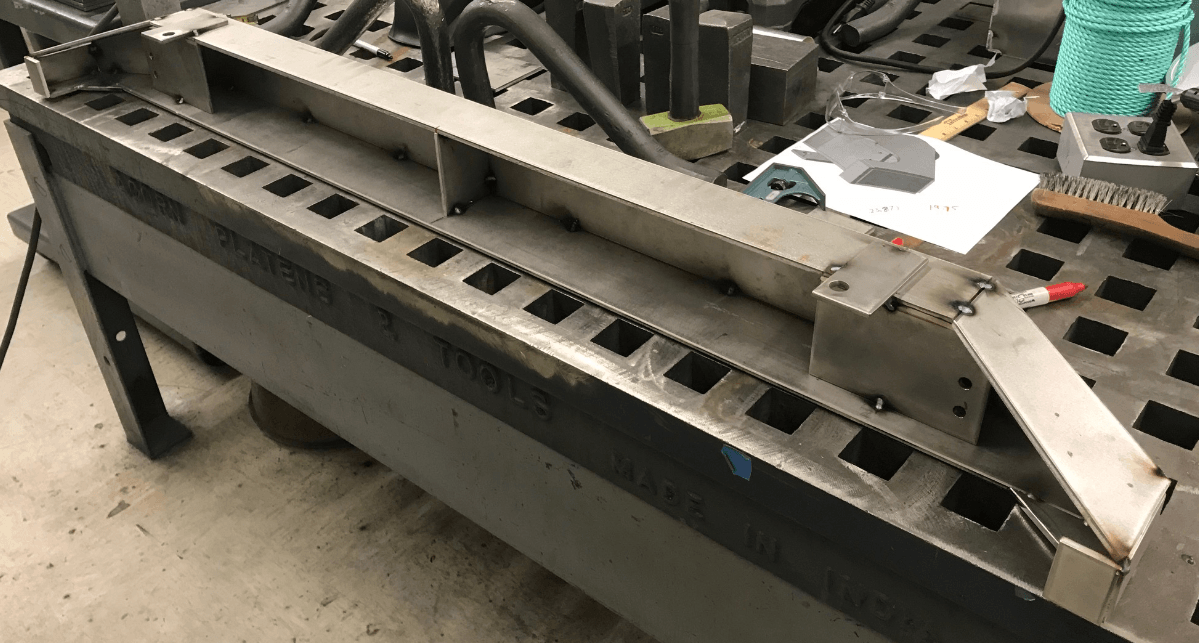

Patch panel cut and bent on the homemade break:

Fresh coat of POR-15:

Patch panel cut and bent on the homemade break:

Fresh coat of POR-15:

And the tire and wheel fairy came:

285/75R16 (~33”x11.7”) Nitto Trail Grapplers on Vision Manx 16x8" wheels with 4.5" BS. I know they are Load Range E, but we wanted 4.5" backspacing in an 11.5" tire and this seemed to be the only way to get there. By my math and research, these should just clear the front control arms and should only stick out around 3/4" past the rubicon flares... We haven't put them on yet, will report back once we do.

285/75R16 (~33”x11.7”) Nitto Trail Grapplers on Vision Manx 16x8" wheels with 4.5" BS. I know they are Load Range E, but we wanted 4.5" backspacing in an 11.5" tire and this seemed to be the only way to get there. By my math and research, these should just clear the front control arms and should only stick out around 3/4" past the rubicon flares... We haven't put them on yet, will report back once we do.

itszachmiller

New Member

I've really enjoyed this thread. Absolutely awesome workmanship. I'm sure your son must be so appreciative for this! He's learning such an awesome set of skill at a young age!

Caster Check:

Pinion shows 83 degrees:

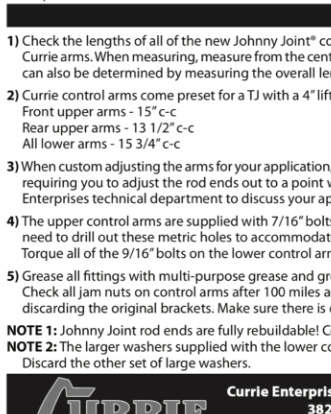

With the arms set to the Currie recommended control arm lengths for a 4" lift:

According to this table, the 83 degree pinion angle on a Dana 35 low pinion should translate to ~5 degrees of caster:

This seems to be reasonable middle ground. More pinion angle would put the front driveshaft into better alignment, but would decrease caster angle. I guess we will just have to see how it drives...

Pinion shows 83 degrees:

With the arms set to the Currie recommended control arm lengths for a 4" lift:

According to this table, the 83 degree pinion angle on a Dana 35 low pinion should translate to ~5 degrees of caster:

This seems to be reasonable middle ground. More pinion angle would put the front driveshaft into better alignment, but would decrease caster angle. I guess we will just have to see how it drives...

I've really enjoyed this thread. Absolutely awesome workmanship. I'm sure your son must be so appreciative for this! He's learning such an awesome set of skill at a young age!

Thanks. Yes, he is very proud of his project. Maybe that is the best lesson that will come out of it. The "Built, not Bought" mentality.

Caster Check:

Pinion shows 83 degrees:

View attachment 74724

With the arms set to the Currie recommended control arm lengths for a 4" lift:

View attachment 74725

According to this table, the 83 degree pinion angle on a Dana 35 low pinion should translate to ~5 degrees of caster:

View attachment 74726

This seems to be reasonable middle ground. More pinion angle would put the front driveshaft into better alignment, but would decrease caster angle. I guess we will just have to see how it drives...

Pinion angle trumps Caster. Get the pinion angle correct, then dial caster in until it vibs...then back it back off until the vibs go away.

Pinion angle trumps Caster. Get the pinion angle correct, then dial caster in until it vibs...then back it back off until the vibs go away.

Good to know. We will find the limits once it is driving. thanks

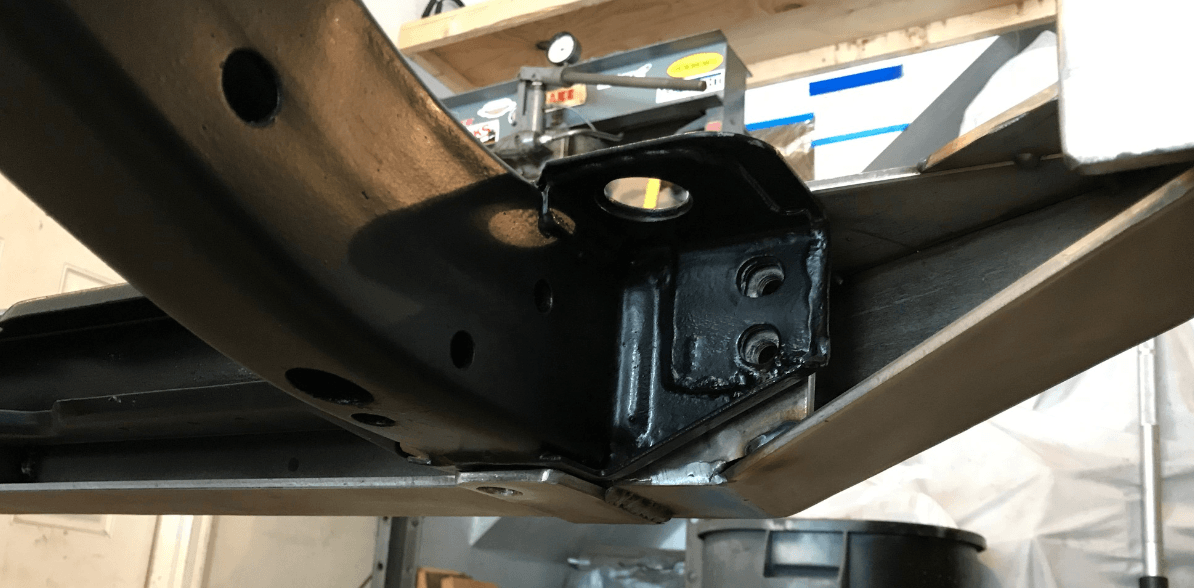

I went poking around the shop and found a bunch of 4" wide x 1/4" Stainless Steel strips about 6' long. Guys in the shop said it had been there for years and it was ok to use some. Perfect for a rear bumper. We have been looking for a while and can't find something in a reasonable price range. Lots of nice ones for $500+, but we can't justify spending that much on a bumper. So off we go to build one that matches our $200 EAG Front bumper:

Wow that's a lot of weld:

And a lot of grinding:

Fits perfect:

Very heavy and strong.

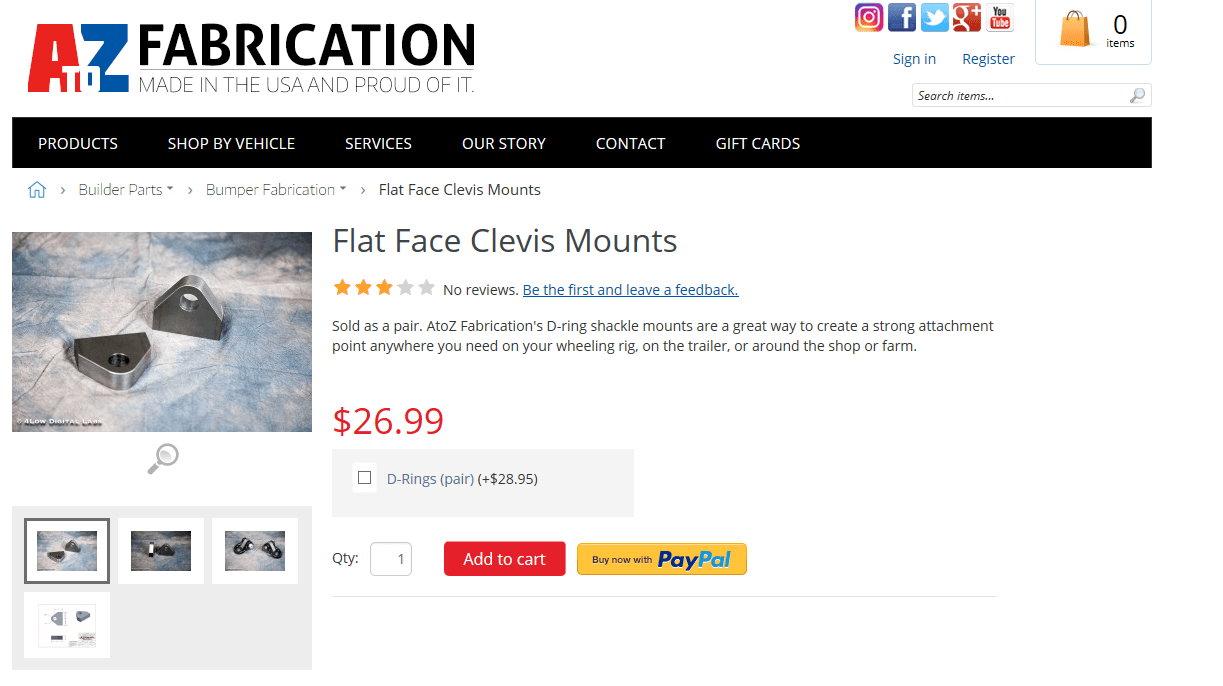

We ordered a set of these to add to it next:

So with shipping we will have all of $37 into this bumper...

Wow that's a lot of weld:

And a lot of grinding:

Fits perfect:

Very heavy and strong.

We ordered a set of these to add to it next:

So with shipping we will have all of $37 into this bumper...

If you have ever tried to drill stainless steel, then you know that it can be hit or miss, very often endind up in an overheated drill bit that will harden the local area, making it impossible to continue with drilling as an option. We are adding provisions for a bolt on hitch receiver. A quick template was made for the plasma cutter. It made quick work of adding 3/4" clearance holes in the bottom.

5/8" stainless Steel nuts on the inside:

and a $22 step bumper receiver hitch (very well built I will add), makes for a easily removable hitch for the occasional tow. His request was to be able to tow our very light 3 rail dirt bike trailer:

Also, the clevises came from AtoZ fabrication, very nice pieces, well worth the $27. They were a bit tall, so we machined off about 5/8" of material prior to welding them on:

5/8" stainless Steel nuts on the inside:

and a $22 step bumper receiver hitch (very well built I will add), makes for a easily removable hitch for the occasional tow. His request was to be able to tow our very light 3 rail dirt bike trailer:

Also, the clevises came from AtoZ fabrication, very nice pieces, well worth the $27. They were a bit tall, so we machined off about 5/8" of material prior to welding them on:

We need work ethic like crazy. It’s almost vanished. It’s so important for fathers to invest in their sons and daughters to instill in them this work ethic and know how mentality! KudosAwesome thread. Your boy is going to have a great work ethic compared to most.

We don't plan on putting lights all over our jeep, so we cut the light tabs cut off the front bumper:

Then got both the front and rear 100% coated in POR-15:

They will get top-coated with black raptor liner this spring with the flares and the hard top

Then got both the front and rear 100% coated in POR-15:

They will get top-coated with black raptor liner this spring with the flares and the hard top