Swapping in the 8.25 rear axle for two reasons....one because its much stronger than the dana 35 it is replacing....thicker axle shafts...much beefier axle......and the second reason is the Liberty instrument cluster that we're using gets its speed signal from ABS system...necessitating the need for the axle swap...abs sensor is located at the top of the differential on the 8.25 axle...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VM 2.8 turbo diesel frame-up TJ build

- Thread starter Mike Alfano

- Start date

Swapping in the 8.25 rear axle for two reasons....one because its much stronger than the dana 35 it is replacing....thicker axle shafts...much beefier axle......and the second reason is the Liberty instrument cluster that we're using gets its speed signal from ABS system...necessitating the need for the axle swap...abs sensor is located at the top of the differential on the 8.25 axle...

Gotcha, that makes perfect sense! First time I've seen anyone do such a swap, so I wasn't sure.

Hoping to have tub painted and ready for installation by easter.

It is an untapped option for people wanting to do a axle swap. I didn't know until about a month ago that they had been putting the 8.25 in the kJ. They were used in XJ's also so there are a lot of them around.Gotcha, that makes perfect sense! First time I've seen anyone do such a swap, so I wasn't sure.

I am really liking this and wish I had gone to a high school that had an auto shop like this. It is a dying class from what I have read and seen. My local high school doesn't offer a shop class, not that my daughter would want to take it any how but it is a shame.

It is an untapped option for people wanting to do a axle swap. I didn't know until about a month ago that they had been putting the 8.25 in the kJ. They were used in XJ's also so there are a lot of them around.

I am really liking this and wish I had gone to a high school that had an auto shop like this. It is a dying class from what I have read and seen. My local high school doesn't offer a shop class, not that my daughter would want to take it any how but it is a shame.

I graduated in 2002, and we had an amazing shop class similar to this in my high school. It was an elective, but one I opted to take for all 4 years. We had all sorts of crazy projects going on in those classes, and it was a lot of fun. I'm not sure how many schools do stuff like this anymore, but I have a feeling it's a dying thing.

jtf440

TJ Enthusiast

I'm currently a senior and my sophomore year was the last year metal shop was offered, luckily I took it. Then the summer after my junior year I took a welding class through the ag teacher. He also teaches a small engines class, which has a team that's won state multiple times in the past years. I can see that its dying, but it's not gone yet.

The other cool part about the rear axle swap is the upgrade to rear disc brakes!It is an untapped option for people wanting to do a axle swap. I didn't know until about a month ago that they had been putting the 8.25 in the kJ. They were used in XJ's also so there are a lot of them around.

I am really liking this and wish I had gone to a high school that had an auto shop like this. It is a dying class from what I have read and seen. My local high school doesn't offer a shop class, not that my daughter would want to take it any how but it is a shame.

Temporarily installed the Chrysler 8.25" rear axle so that we can weld the track bar bracket onto the axle. Tomorrow we weld the bracket, then off to the body shop it goes for sandblast, epoxy and paint. We also modified the Liberty's in-tank fuel pump so that is would fit into the TJ fuel tank.

Do you have a pic of return setup? I was kinda curious on this with my install as the Cummins manual mentioned being so many inches away from the suction tube.

It's looking great. I can't wait to hear about this when you're finished. It stinks this wasn't an OEM option for the Wrangler in the US.

It's looking great. I can't wait to hear about this when you're finished. It stinks this wasn't an OEM option for the Wrangler in the US.

Do you have a pic of return setup? I was kinda curious on this with my install as the Cummins manual mentioned being so many inches away from the suction tube.

It's looking great. I can't wait to hear about this when you're finished. It stinks this wasn't an OEM option for the Wrangler in the US.

I'm sorry...II didn't take photos of the pump before we installed it into the tank...but from memory I can tell you that the suction and return were within 3 to 3 1/2" from each other. I can't agree with you more that this drivetrain should have been available in the TJ.......especially since they were already producing diesel wranglers and exporting them overseas!! Keep checking in on the build.....I'm quickly realizing how wrong I was about a June completion date....oh well....anyway thanks for checking it out!

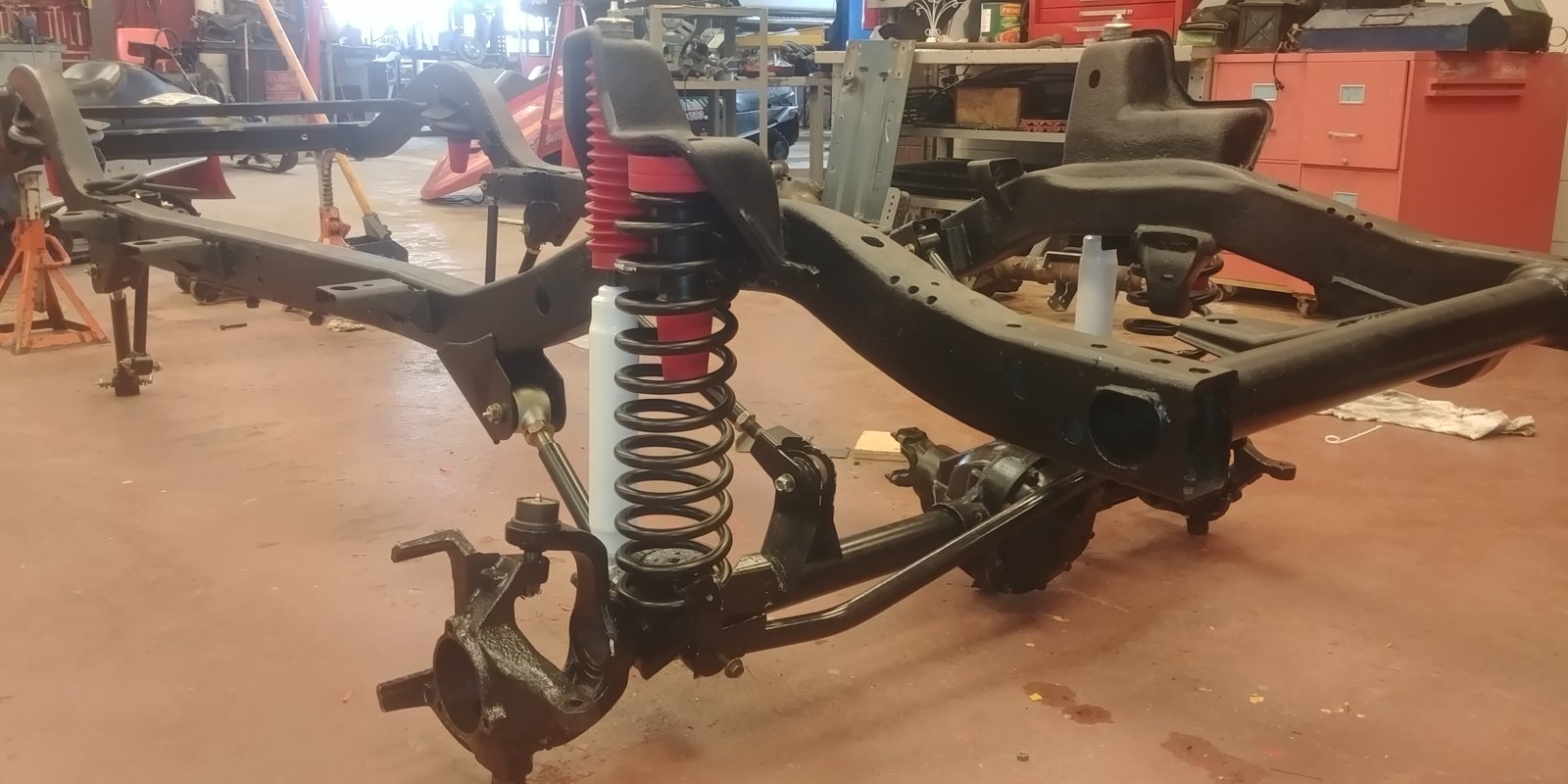

Front axle installed today....progress is slow but students are doing great work! We ran into a problem with the Liberty front wheel bearings...while they fit on the tj knuckles...they are too deep and need 5/16" spacers so that they sit further out on the axle...machine shop students are fabricating spacers and they should be ready tomorrow! Will post pics when they are done.

I love it! Putting those kids to work.

Of course I'm sure they enjoy it. This is far better than sitting in math class. I remember doing stuff like this in shop class when I was in high school, and I would have happily done it all day long.

Of course I'm sure they enjoy it. This is far better than sitting in math class. I remember doing stuff like this in shop class when I was in high school, and I would have happily done it all day long.

Like i said...our progress is painfully slow but students are fully invested in this project and are having a great time working on it.I love it! Putting those kids to work.

Of course I'm sure they enjoy it. This is far better than sitting in math class. I remember doing stuff like this in shop class when I was in high school, and I would have happily done it all day long.

Like i said...our progress is painfully slow but students are fully invested in this project and are having a great time working on it.

No doubt about that. Being able to do something like that in high school is a real treat. It's rare that most high schools even have a shop class anymore unfortunately. My high school had a shop class, manufacturing class, forge, foundry, etc. Of course I also went to a polytechnic high school, so others aren't as fortunate.

Very cool stuff to say the least!

Axle finally painted....just need to bore the hole for a wheel speed sensor....then its ready for assembly and planting.

Front axle installed today....progress is slow but students are doing great work! We ran into a problem with the Liberty front wheel bearings...while they fit on the tj knuckles...they are too deep and need 5/16" spacers so that they sit further out on the axle...machine shop students are fabricating spacers and they should be ready tomorrow! Will post pics when they are done.

View attachment 87476

View attachment 87477

Why do you need to use the KJ front wheel bearings? Is for the ABS or some thing else?

Liberty front wheel bearings are necessary because we need a functioning ABS system otherwise the speedometer won't work...we're using the Liberty instrument cluster and it gets speed signal from the abs system.Why do you need to use the KJ front wheel bearings? Is for the ABS or some thing else?

Liberty front wheel bearings are necessary because we need a functioning ABS system otherwise the speedometer won't work...we're using the Liberty instrument cluster and it gets speed signal from the abs system.

Why was the KJ instrument cluster needed? I look forward to seeing how you graft it into the dash on the TJ. I've never looked at a diesel KJ so have no idea what the wiring/computer looks like. I'm interested in all this not because I'm looking to do the same swap but because I like this kind of thing.

Thanks for all you are doing and sharing on here plus what you are teaching these kids. It might be lost on some of them now but in years to come I'll bet it won't be.