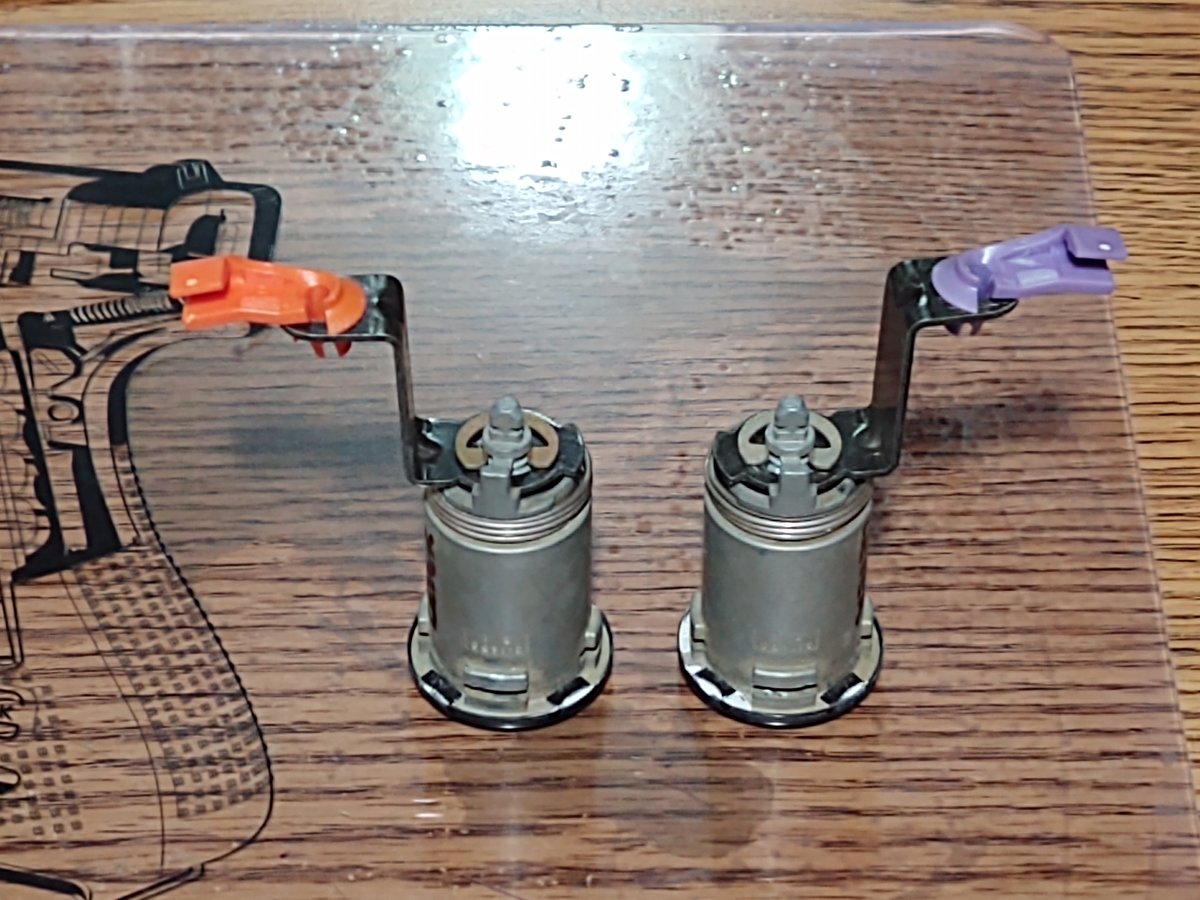

While my half doors are apart it gave me a chance to rekey the lock sets to match the other locks so I only need 1 key.

I sort of did what is covered in some other threads on the forum, but instead of buying new parts I went cheap and reused the parts I had. I was just careful and removed the cover so I could reuse it. I then went one by one and reused the wafers untill they matched up with my key.

Much better than using 2 different keys..

I also started cleaning and prepping my half doors inner panels for the color change to Khaki from gray. Started with Dawn and a Scotch Brite pad, will move to something a little stronger in a day or two..

Not really anything to see with this so I didn't take any pictures.

I sort of did what is covered in some other threads on the forum, but instead of buying new parts I went cheap and reused the parts I had. I was just careful and removed the cover so I could reuse it. I then went one by one and reused the wafers untill they matched up with my key.

Much better than using 2 different keys..

I also started cleaning and prepping my half doors inner panels for the color change to Khaki from gray. Started with Dawn and a Scotch Brite pad, will move to something a little stronger in a day or two..

Not really anything to see with this so I didn't take any pictures.