Mid-way through my kitchen remodel. I see why people hire others for this type of work….

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What other projects are you working on?

- Thread starter Farmergreg

- Start date

View attachment 508692

View attachment 508693

Mid-way through my kitchen remodel. I see why people hire others for this type of work….

I'm doing a laundry room remodel right now. I know what you mean, but your kitchen will turn out so much better since you are doing it and you actually care. I can never get contract work done right. Seems they area always cutting freaking corners and doing crappy job and then it's a ton of money and I regret it, so I quit paying people to do it.

I'm doing a laundry room remodel right now. I know what you mean, but your kitchen will turn out so much better since you are doing it and you actually care. I can never get contract work done right. Seems they area always cutting freaking corners and doing crappy job and then it's a ton of money and I regret it, so I quit paying people to do it.

I do get that. My brother is a contractor/finish carpenter and said he’d do it for a very very reasonable price…. Why I didn’t, not sure.

I do get that. My brother is a contractor/finish carpenter and said he’d do it for a very very reasonable price…. Why I didn’t, not sure.

Now you're talking! Yeah, I'd probably have given that project to him! Maybe he'll finish it.

p.s. it looks good, way better, looks like good work from far away! I hope mine is as good from far.

TNHEADDUCK

TJ Enthusiast

Got a new to me tractor and bush hog, changed all the fluids,belts,hoses and lubed all the pivots and zerks on the tractor (its in really good condition).Welded up several cracks,replaced the 3 point lift pins, rebushed the tail wheel pivot and hub, put a fresh coat of paint on it as well and sharpened the blades on the bush hog. The bush hog may be for sale, I am going to look at a practically new 6' flail mower tomorrow that only has about 15 hrs. on it that I can get for around half price. I enjoy working on farm equipment and tractors.

Now you're talking! Yeah, I'd probably have given that project to him! Maybe he'll finish it.

p.s. it looks good, way better, looks like good work from far away! I hope mine is as good from far.

It actually looks good from pretty close too

I’m sure yours will turn out!

Every time Mrs.Cheesy brings up a kitchen remodel, I open and close a cabinet door, then tell her there's nothing wrong with it so why spend the money. Hasn't worked yet.  When she said that it's dated and needs to be replaced. I replied by saying she was dated, too. Using her logic, I should be able to replace her with a newer, younger one. That didn't work, either.

When she said that it's dated and needs to be replaced. I replied by saying she was dated, too. Using her logic, I should be able to replace her with a newer, younger one. That didn't work, either.

That said, I made chips today.

The tool was worn and the speed was too slow, so the finish isn't great. I eyeballed the steps. We'll get there.

That said, I made chips today.

The tool was worn and the speed was too slow, so the finish isn't great. I eyeballed the steps. We'll get there.

Every time Mrs.Cheesy brings up a kitchen remodel, I open and close a cabinet door, then tell her there's nothing wrong with it so why spend the money. Hasn't worked yet.When she said that it's dated and needs to be replaced. I replied by saying she was dated, too. Using her logic, I should be able to replace her with a newer, younger one. That didn't work, either.

That said, I made chips today.

View attachment 508720

The tool was worn and the speed was too slow, so the finish isn't great. I eyeballed the steps. We'll get there.

I would try that one but she’s 24 and I can’t get too much newer of a model….

The kitchen did function well before.

My sister is having a 3rd baby and decided that means she needed to upgrade her 2002 Nissan Xterra. She's the original owner of all 168k miles, the vehicle has never left Colorado, and she has always done a pretty decent job keeping up with the service items.

For $500 I couldn't not buy it.

Overall the body is in good shape beyond the normal things for this age (warn clear bra, faded plastics, etc) and the frame is clean.

One neglected item is the ignition system. It runs rough and feels like it stumbles a bit. Looking at these spark plugs and the rotor, no wonder!

Swapping those alone wasn't a magic pill, though it was improved. I popped the hood with it running and noticed at least one cylinder was arcing. New wires and it's running like a top, graduating this to my daily driver.

I think that blue adds 20hp.

With those issues solved there's one more CEL to deal with, the torque converter lockup solenoid. It's not really that important, so other things can happen now.

First, it was dangerous at night with lights even worse than the TJs. LED upgrade time.

The shocks were totally shot, so those needed a change. For this application I just went with some bilsteins.

While underneath I noticed the sway links were gapped, and they're were no more available threads to fix that. So, new links and bushings were necessary.

I'm 99% sure this suspension was nearly all stock (sans the KYBs I removed). The back looked low and under any amount of acceleration the rear end just dropped. This is on leafs for the rear, and while these are 180 of each other I'm sure you can spot the issue of most a missing leaf.

This solved a weird wobble issue over bumps some guys just told me were due to leaf springs I'm not used to ... No - one side had way more movement than the other!

Just before this I leveled the front tortion bars before I noticed this issue to compensate. This is now a bit Jack rabbited and needs the front end to have the same love applied (new tortion bars are in the garage).

When the suspension is riding correctly and shocks can do their job, things are so much better. If I didn't know better I'd say springs really improve the quality. But this just lets the shock do its job. These working together are great

That's a catch up of the last month, from here there's a few things to do: figure out a power steering leak, install the 1.5" shackles in the rear, new front tortion bars, and getting into the trans TCC solenoid. After that, it'll be pretty capable for a cheap family friendly vehicle.

For $500 I couldn't not buy it.

Overall the body is in good shape beyond the normal things for this age (warn clear bra, faded plastics, etc) and the frame is clean.

One neglected item is the ignition system. It runs rough and feels like it stumbles a bit. Looking at these spark plugs and the rotor, no wonder!

Swapping those alone wasn't a magic pill, though it was improved. I popped the hood with it running and noticed at least one cylinder was arcing. New wires and it's running like a top, graduating this to my daily driver.

I think that blue adds 20hp.

With those issues solved there's one more CEL to deal with, the torque converter lockup solenoid. It's not really that important, so other things can happen now.

First, it was dangerous at night with lights even worse than the TJs. LED upgrade time.

The shocks were totally shot, so those needed a change. For this application I just went with some bilsteins.

While underneath I noticed the sway links were gapped, and they're were no more available threads to fix that. So, new links and bushings were necessary.

I'm 99% sure this suspension was nearly all stock (sans the KYBs I removed). The back looked low and under any amount of acceleration the rear end just dropped. This is on leafs for the rear, and while these are 180 of each other I'm sure you can spot the issue of most a missing leaf.

This solved a weird wobble issue over bumps some guys just told me were due to leaf springs I'm not used to ... No - one side had way more movement than the other!

Just before this I leveled the front tortion bars before I noticed this issue to compensate. This is now a bit Jack rabbited and needs the front end to have the same love applied (new tortion bars are in the garage).

When the suspension is riding correctly and shocks can do their job, things are so much better. If I didn't know better I'd say springs really improve the quality. But this just lets the shock do its job. These working together are great

That's a catch up of the last month, from here there's a few things to do: figure out a power steering leak, install the 1.5" shackles in the rear, new front tortion bars, and getting into the trans TCC solenoid. After that, it'll be pretty capable for a cheap family friendly vehicle.

Last edited:

My sister is having a 3rd baby and decided that means she needed to upgrade her 2002 Nissan Xterra. She's the original owner of all 168k miles, the vehicle has never left Colorado, and she has always done a pretty decent job keeping up with the service items.

For $500 I couldn't not buy it.

Overall the body is in good shape beyond the normal things for this age (warn clear bra, faded plastics, etc) and the frame is clean.

View attachment 508734

One neglected item is the ignition system. It runs rough and feels like it stumbles a bit. Looking at these spark plugs and the rotor, no wonder!

View attachment 508735

Swapping those alone wasn't a magic pill, though it was improved. I popped the hood with it running and noticed at least one cylinder was arcing. New wires and it's running like a top, graduating this to my daily driver.

View attachment 508737

I think that blue adds 20hp.

With those issues solved there's one more CEL to deal with, the torque converter lockup solenoid. It's not really that important, so other things can happen now.

First, it was dangerous at night with lights even worse than the TJs. LED upgrade time.

View attachment 508740

The shocks were totally shot, so those needed a change. For this application I just went with some bilsteins.

View attachment 508741

View attachment 508742

While underneath I noticed the sway links were gapped, and they're were no more available threads to fix that. So, new links and bushings were necessary.

View attachment 508743

I'm 99% sure this suspension was nearly all stock (sans the KYBs I removed). The back looked low and under any amount of acceleration the rear end just dropped. This is on leafs for the rear, and while these are 180 of each other I'm sure you can spot the issue of most a missing leaf.

View attachment 508744

This solved a weird wobble issue over bumps some guys just told me were due to leaf springs I'm not used to ... No - one side had way more movement than the other!

Just before this I leveled the front tortion bars before I noticed this issue to compensate. This is now a bit Jack rabbited and needs the front end to have the same love applied (new tortion bars are in the garage).

When the suspension is riding correctly and shocks can do their job, things are so much better. If I didn't know better I'd say springs really improve the quality. But this just lets the shock do its job. These working together are great

That's a catch up of the last month, from here there's a few things to do: figure out a power steering leak, install the 1.5" shackles in the rear, new front tortion bars, and getting into the trans TCC solenoid. After that, it'll be pretty capable for a cheap family friendly vehicle.

Wow! Absolutely right you couldn’t pass that up. Looks like you made a lot of ground on the issues.

I’m liking my earlier 2000’s Japanese SUV for a cheap capable driver too.

I’m liking my earlier 2000’s Japanese SUV for a cheap capable driver too.

It's a bit sad how my 06 LJ with 80k on it has had far more issues than this thing ever has with double the miles.

My sister is having a 3rd baby and decided that means she needed to upgrade her 2002 Nissan Xterra. She's the original owner of all 168k miles, the vehicle has never left Colorado, and she has always done a pretty decent job keeping up with the service items.

For $500 I couldn't not buy it.

Overall the body is in good shape beyond the normal things for this age (warn clear bra, faded plastics, etc) and the frame is clean.

View attachment 508734

One neglected item is the ignition system. It runs rough and feels like it stumbles a bit. Looking at these spark plugs and the rotor, no wonder!

View attachment 508735

Swapping those alone wasn't a magic pill, though it was improved. I popped the hood with it running and noticed at least one cylinder was arcing. New wires and it's running like a top, graduating this to my daily driver.

View attachment 508737

I think that blue adds 20hp.

With those issues solved there's one more CEL to deal with, the torque converter lockup solenoid. It's not really that important, so other things can happen now.

First, it was dangerous at night with lights even worse than the TJs. LED upgrade time.

View attachment 508740

The shocks were totally shot, so those needed a change. For this application I just went with some bilsteins.

View attachment 508741

View attachment 508742

While underneath I noticed the sway links were gapped, and they're were no more available threads to fix that. So, new links and bushings were necessary.

View attachment 508743

I'm 99% sure this suspension was nearly all stock (sans the KYBs I removed). The back looked low and under any amount of acceleration the rear end just dropped. This is on leafs for the rear, and while these are 180 of each other I'm sure you can spot the issue of most a missing leaf.

View attachment 508744

This solved a weird wobble issue over bumps some guys just told me were due to leaf springs I'm not used to ... No - one side had way more movement than the other!

Just before this I leveled the front tortion bars before I noticed this issue to compensate. This is now a bit Jack rabbited and needs the front end to have the same love applied (new tortion bars are in the garage).

When the suspension is riding correctly and shocks can do their job, things are so much better. If I didn't know better I'd say springs really improve the quality. But this just lets the shock do its job. These working together are great

That's a catch up of the last month, from here there's a few things to do: figure out a power steering leak, install the 1.5" shackles in the rear, new front tortion bars, and getting into the trans TCC solenoid. After that, it'll be pretty capable for a cheap family friendly vehicle.

I always liked these is it a 3.5?

I always liked these is it a 3.5?

3.3L V6, sadly no super charger though.

Aw dang that stinks

I'm not sure they're worth 2.3x the vehicle for my impatience

https://www.turbochargerpros.com/buynow/2002/nissan/Xterra/Supercharger/40-10013_R?crid=21495

It's a bit sad how my 06 LJ with 80k on it has had far more issues than this thing ever has with double the miles.

My 4Runner has 230k miles. The only mechanical issue I have is a radiator that is leaking. I did replace most of the front suspension and brakes though.

My LJ has been pretty good reliability wise - I don't know in 5 years that I have replaced anything that wasn't preventative.

I'm not sure they're worth 2.3x the vehicle for my impatiencebut they are out there .

https://www.turbochargerpros.com/buynow/2002/nissan/Xterra/Supercharger/40-10013_R?crid=21495

Only one way to find out.

I'm not sure they're worth 2.3x the vehicle for my impatiencebut they are out there .

https://www.turbochargerpros.com/buynow/2002/nissan/Xterra/Supercharger/40-10013_R?crid=21495

Sheesh lol. If I remember right from when I was shopping for them the supercharger adds like 15hp or something miserable doesn't it?

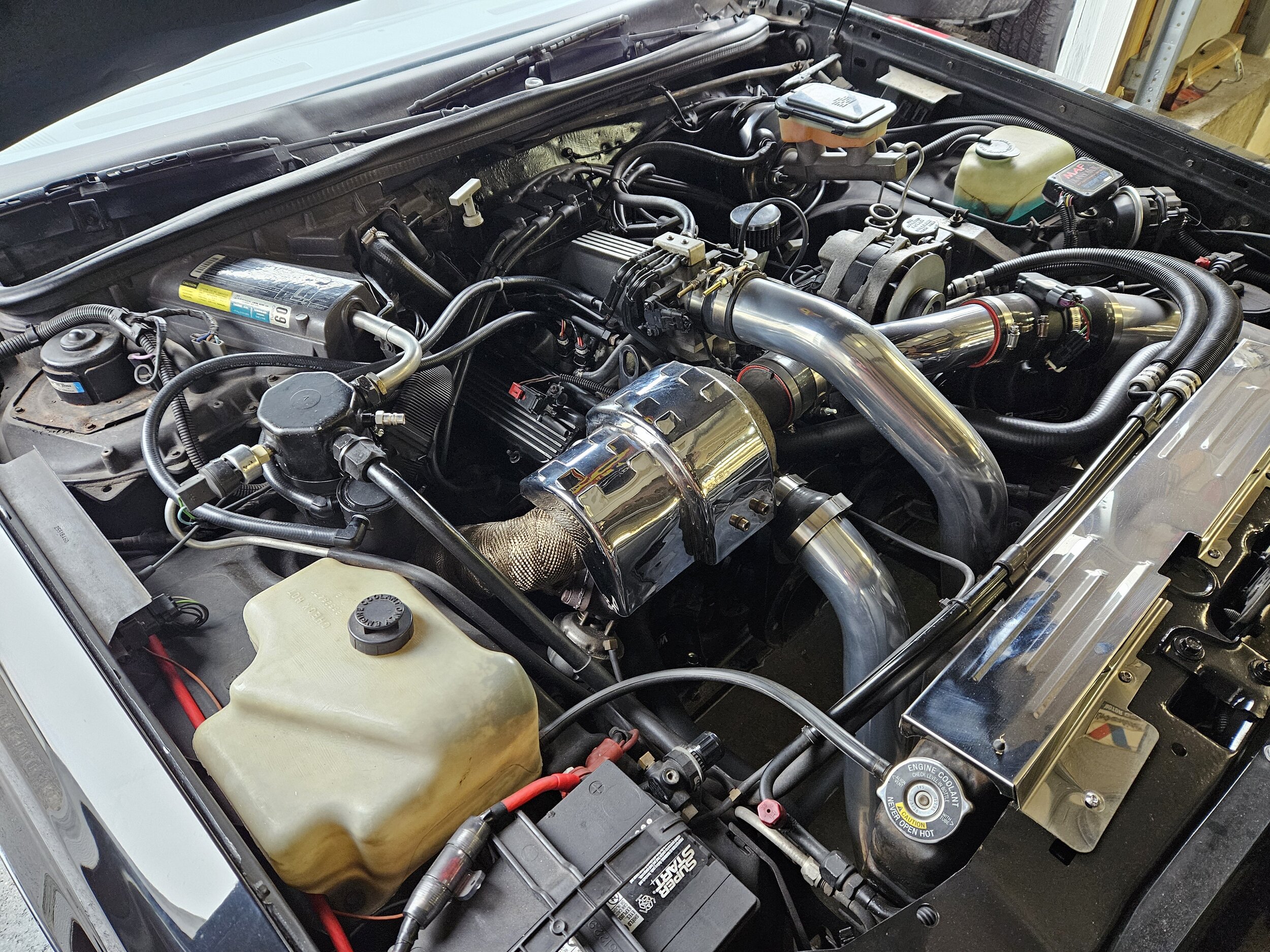

Working on the GN. Just doing basic maintenance for the upcoming season

I had a toolbox give out on me, so I thought I'd replace it, quick like...Here is the old set-up.

The box is actually my first "real" toolbox. My wife got it for me a long time ago in a galaxy far, far away. It was a cheapy, but she didn't know better. I used it as long as I could, and built my welding cart around it. The slides finally gave out a bit ago (like two or three years). I fixed it once, but it was happening again. I started keeping my eyes open for another box. Its kind of a unique size, so I really never found anything.

A couple months ago I found this Facebook group called the "stacked cart gang" The basic premise is to build a 10 drawer tool cart out of two 5 drawer mechanics carts from harbor freight. I had one mechanics cart here at the house (got it on a trade for something) that really wasn't being utilized, and the idea started to form. I took some measurements (Measure twice?) and I started watching my email for HF flyers since I knew I could get another cart for less than 200 bucks. Couple weeks ago, they had their parking lot sale and sure enough, the 5 drawer was on sale for something like 100 dollars off (190 total, IIRC). So I grabbed one.

After getting tired of moving the box around, last weekend I started working on the "stacked" cart to replace my old, broken toolbox. The plan was to stack the two drawer sections and slide them in where the red box goes. In the end, that is exactly what happened, but my two hour project turned into about 25 hours! I measured something incorrectly...My opening was 28 1/4 tall, and the two drawer sections stacked up was about 30 inches.

Honestly, about 8-10 hours of time (in a couple hour increments after work) were spent just noodling ideas on how I was going to make this work. I'd play with layouts, take measurements, move things around, etc. It took me a good amount of time to come up with a GOOD plan for making this work. More than once, I thought I should just build the damn cart and sell it as stock. I could probably sell it assembled and make money. BUT, I would still have a shitty tool box in my welding cart.

Over the last couple days, I figured out what needed to happen and I got busy. The positive for this is I got to decide how I wanted my drawers laid out, instead of just taking the two boxes and putting one on top of another. So, I have two deep drawers on the bottom, two shallow drawers, then it goes to 6 half width drawers, with the two deep ones side by side on the bottom again, and the 4 shallow ones on top. This was an "in progress" picture

My first plan was to use the 4 shallow half drawers on the left side and the two Deep half drawers on the right. I didn't have quite enough vertical space to get the layout correct and still have enough of a gap between the drawers.

Here is the test fit of the cabinet into its space. I had to rebend the upper flange so the whole cabinet would fit my space. That was truely the point of no return. I had to cut the corners, remove the locking rail, etc to get the new flange bent. Up to that point, I just had been drilling rivets.

After much dinking around with drawer slides, I finally got them aligned in the right spots to make all the drawers open and close smothly. This is the final layout, but needing a couple more adjustments (top drawers slid down about 1/8" on the inside tracks, and the second drawer from the bottom needed to move down about 1/16" on one side...that one was factory holes!)

After getting the drawers correct, I got some touchup paint (Rustoleum 2x Deep Gloss Blue and 2x Clear) and hit the face frame and any areas where I burned the paint with spot welds and / or grinding, and slid the thing home. The paint isn't a perfect match, but its DAMN close. Good enough for me.

The last thing to do now is get the little locking tabs to engage the edges. I'll need to get one more RH side lock, then make some square holes. But the main part of the project is finished and I'll probably get to the locks, maybe, someday. I'm really happy with how it turned out and its going to make storing my welding and other fab tools SO much better. It was a way longer road to get here than I expected though.

The box is actually my first "real" toolbox. My wife got it for me a long time ago in a galaxy far, far away. It was a cheapy, but she didn't know better. I used it as long as I could, and built my welding cart around it. The slides finally gave out a bit ago (like two or three years). I fixed it once, but it was happening again. I started keeping my eyes open for another box. Its kind of a unique size, so I really never found anything.

A couple months ago I found this Facebook group called the "stacked cart gang" The basic premise is to build a 10 drawer tool cart out of two 5 drawer mechanics carts from harbor freight. I had one mechanics cart here at the house (got it on a trade for something) that really wasn't being utilized, and the idea started to form. I took some measurements (Measure twice?) and I started watching my email for HF flyers since I knew I could get another cart for less than 200 bucks. Couple weeks ago, they had their parking lot sale and sure enough, the 5 drawer was on sale for something like 100 dollars off (190 total, IIRC). So I grabbed one.

After getting tired of moving the box around, last weekend I started working on the "stacked" cart to replace my old, broken toolbox. The plan was to stack the two drawer sections and slide them in where the red box goes. In the end, that is exactly what happened, but my two hour project turned into about 25 hours! I measured something incorrectly...My opening was 28 1/4 tall, and the two drawer sections stacked up was about 30 inches.

Honestly, about 8-10 hours of time (in a couple hour increments after work) were spent just noodling ideas on how I was going to make this work. I'd play with layouts, take measurements, move things around, etc. It took me a good amount of time to come up with a GOOD plan for making this work. More than once, I thought I should just build the damn cart and sell it as stock. I could probably sell it assembled and make money. BUT, I would still have a shitty tool box in my welding cart.

Over the last couple days, I figured out what needed to happen and I got busy. The positive for this is I got to decide how I wanted my drawers laid out, instead of just taking the two boxes and putting one on top of another. So, I have two deep drawers on the bottom, two shallow drawers, then it goes to 6 half width drawers, with the two deep ones side by side on the bottom again, and the 4 shallow ones on top. This was an "in progress" picture

My first plan was to use the 4 shallow half drawers on the left side and the two Deep half drawers on the right. I didn't have quite enough vertical space to get the layout correct and still have enough of a gap between the drawers.

Here is the test fit of the cabinet into its space. I had to rebend the upper flange so the whole cabinet would fit my space. That was truely the point of no return. I had to cut the corners, remove the locking rail, etc to get the new flange bent. Up to that point, I just had been drilling rivets.

After much dinking around with drawer slides, I finally got them aligned in the right spots to make all the drawers open and close smothly. This is the final layout, but needing a couple more adjustments (top drawers slid down about 1/8" on the inside tracks, and the second drawer from the bottom needed to move down about 1/16" on one side...that one was factory holes!)

After getting the drawers correct, I got some touchup paint (Rustoleum 2x Deep Gloss Blue and 2x Clear) and hit the face frame and any areas where I burned the paint with spot welds and / or grinding, and slid the thing home. The paint isn't a perfect match, but its DAMN close. Good enough for me.

The last thing to do now is get the little locking tabs to engage the edges. I'll need to get one more RH side lock, then make some square holes. But the main part of the project is finished and I'll probably get to the locks, maybe, someday. I'm really happy with how it turned out and its going to make storing my welding and other fab tools SO much better. It was a way longer road to get here than I expected though.