I remember. There is also a chance that I'll be moving a little closer that direction in the coming months.Moab trip plans in the works next year. Just saying.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Daily Driver, Go Where I Want To Build

- Thread starter jjvw

- Start date

June 2015

Unlimited04 driving though Leavenworth Creek.

Freeskier follows behind. (JF,WF guys)

Camping on Saxon Mountain a week later

Unlimited04 driving though Leavenworth Creek.

Freeskier follows behind. (JF,WF guys)

Camping on Saxon Mountain a week later

August 2015

A daily driver mod.

I have never cared much about car audio, though I was beginning to want both better sound out of the Jeep along with a better way to listen to music and podcasts through my phone. I haven't bought or listened to a CD in over 10 years, so I don't need that. Nor do I want a big touch screen that I need to stare at to operate. I settled on a Kenwood KMRM312BT Marine Digital Media Receiver.

But that isn't the interesting part. I had just receiived my first phone with Qi wireless charging. The Kenwood head unit is a single DIN that needs an adaptor to fit inside the factory 1.5 DIN opening. Several of the adaptor plates have a small slot for maps or cds. I figured I could make that slot into a wireless charging port.

This is how I did it.

https://wranglertjforum.com/threads/qi-wireless-phone-charging-in-your-tj.9529/#post-147668

Wireless charging is great to have!

A daily driver mod.

I have never cared much about car audio, though I was beginning to want both better sound out of the Jeep along with a better way to listen to music and podcasts through my phone. I haven't bought or listened to a CD in over 10 years, so I don't need that. Nor do I want a big touch screen that I need to stare at to operate. I settled on a Kenwood KMRM312BT Marine Digital Media Receiver.

But that isn't the interesting part. I had just receiived my first phone with Qi wireless charging. The Kenwood head unit is a single DIN that needs an adaptor to fit inside the factory 1.5 DIN opening. Several of the adaptor plates have a small slot for maps or cds. I figured I could make that slot into a wireless charging port.

This is how I did it.

https://wranglertjforum.com/threads/qi-wireless-phone-charging-in-your-tj.9529/#post-147668

Wireless charging is great to have!

Another daily driver mod that happened around this time was adding seat heaters. The switches can be seen above on the center dash.

http://www.amazon.com/dp/B008D2LIRG/?tag=wranglerorg-20

These are the second best thing I have installed after the Antirock.

http://www.amazon.com/dp/B008D2LIRG/?tag=wranglerorg-20

These are the second best thing I have installed after the Antirock.

As mentioned earlier, I never cared much about car audio. I never really intended to go beyond the new headunit. But now the factory speakers don't really sound that good. As with all things Jeeps and car audio, one thing leads to another.

I add a pair of Polk db521 5.25" speakers to the front dash using adaptor plates and foam baffles.

Polk db651 6'5" speakers go in the sound pods stuffed with fiber fill.

The new speakers do sound better, but there is distortion at higher volumes. I need an amp and maybe a better sub. One thing leads to another. I have a plan...

I add a pair of Polk db521 5.25" speakers to the front dash using adaptor plates and foam baffles.

Polk db651 6'5" speakers go in the sound pods stuffed with fiber fill.

The new speakers do sound better, but there is distortion at higher volumes. I need an amp and maybe a better sub. One thing leads to another. I have a plan...

During a trip out to Minnesota to visit my dad and family, I get the opportunity to begin fixing the latch on my Nate's 4x4 rear carrier.

This is the original latch with the J-bolts I put in a year earlier. Notice that the latch pulls away from the hinge and not into the stop. Only the tension of the latch against the hinge is what keeps the carrier from swinging.

This is the fix and the way Nate should have done it from the beginning.

Now the latch pulls the carrier against the stop. If we had removed the bumper, the work would have been cleaner, but I just wanted the thing to work correctly.

For the first time ever, my tire carrier is silent and is actually easier to open and close. There is no good reason Nate can't do it this way.

This is the original latch with the J-bolts I put in a year earlier. Notice that the latch pulls away from the hinge and not into the stop. Only the tension of the latch against the hinge is what keeps the carrier from swinging.

This is the fix and the way Nate should have done it from the beginning.

Now the latch pulls the carrier against the stop. If we had removed the bumper, the work would have been cleaner, but I just wanted the thing to work correctly.

For the first time ever, my tire carrier is silent and is actually easier to open and close. There is no good reason Nate can't do it this way.

November 2015

The track bar is feeling a little sloppy and creaky at 102k miles.

I have 2" of spring lift. Keeping in mind that the bushing is old and probably deflected a little, here is how much the stock track bar is off. Roughly 1/8".

Here is a brand new Metalcloak front track bar.

Install is very easy. Both mounting holes need to be drilled out. Metalcloak sells one of the few track bars that won't hit the front diff cover without additional bump stop at full suspension bump.

tj front adjustable track bars for 0-3.5", does yours hit or fit?

It certainly feels better than a worn out factory bar. My front axle had been just slightly off center since the lift two years ago. I also have a couple washers on the steering stops to accommodate the 33's. Though I intentionally left a bit of rub in order to keep a little more turning radius. The passenger side always rubbed a little more than the driver's side. Now with the axle centered just that little bit, the minor rubbing is the same on either side. It is inconsequential, but knowing things are centered is a nice feeling.

The track bar is feeling a little sloppy and creaky at 102k miles.

I have 2" of spring lift. Keeping in mind that the bushing is old and probably deflected a little, here is how much the stock track bar is off. Roughly 1/8".

Here is a brand new Metalcloak front track bar.

Install is very easy. Both mounting holes need to be drilled out. Metalcloak sells one of the few track bars that won't hit the front diff cover without additional bump stop at full suspension bump.

tj front adjustable track bars for 0-3.5", does yours hit or fit?

It certainly feels better than a worn out factory bar. My front axle had been just slightly off center since the lift two years ago. I also have a couple washers on the steering stops to accommodate the 33's. Though I intentionally left a bit of rub in order to keep a little more turning radius. The passenger side always rubbed a little more than the driver's side. Now with the axle centered just that little bit, the minor rubbing is the same on either side. It is inconsequential, but knowing things are centered is a nice feeling.

Last edited:

December 2015

One last fix on my rear carrier.

The jerry can holders just don't work. You need to carry a small t-handle use the clamping bolts. The hold down clamps don't clamp securely.

The angle iron cradles for the cans only fit a jerry can.

I found an old pair of Blitz jerry can holders on eBay for next to nothing. To install them, I cut off the angle iron and made 2 pairs of steel straps to attach the Blitz holders to the carrier.

The cans are held with simple nylon straps. I now have the option to carry anything that fits inside the holders which I could not do before.

Supposedly Nate is aware of these same complaints which go way before my time. But he just doesn't care.

https://tinyurl.com/yajsmztp

It's a shame, because I do think the overall design it good. It just has several major flaws that to correct, would not add costs and could even reduce labor to build.

A better mount for the can that would have a more universal fit wold be these...

MORryde Tall Jerry Can Tray

I found them after I bought the Blitz holders. Jscherb uses them on his projects. Someday I may make the switch if I find reason enough to do.

One last fix on my rear carrier.

The jerry can holders just don't work. You need to carry a small t-handle use the clamping bolts. The hold down clamps don't clamp securely.

The angle iron cradles for the cans only fit a jerry can.

I found an old pair of Blitz jerry can holders on eBay for next to nothing. To install them, I cut off the angle iron and made 2 pairs of steel straps to attach the Blitz holders to the carrier.

The cans are held with simple nylon straps. I now have the option to carry anything that fits inside the holders which I could not do before.

Supposedly Nate is aware of these same complaints which go way before my time. But he just doesn't care.

https://tinyurl.com/yajsmztp

It's a shame, because I do think the overall design it good. It just has several major flaws that to correct, would not add costs and could even reduce labor to build.

A better mount for the can that would have a more universal fit wold be these...

MORryde Tall Jerry Can Tray

I found them after I bought the Blitz holders. Jscherb uses them on his projects. Someday I may make the switch if I find reason enough to do.

After installing the can holders, I saw that I had made a really nice spot for these small LED light bars to use as back up lights.

I have them pointed towards the street. The additional brighter light is surprisingly helpful when parallel parking at night. It is a good daily driver mod.

I see that during this time I also installed a Warrior Products wrap around license plate holder.

I have them pointed towards the street. The additional brighter light is surprisingly helpful when parallel parking at night. It is a good daily driver mod.

I see that during this time I also installed a Warrior Products wrap around license plate holder.

On the front I also put in these cheap Chinese light bars. The 20" fits very well inside the hoop. The two smaller 7" floods are wired to the factory fog switch and point out to the side of the road providing more than 180* of light. I aimed everything to light the ground. The end caps have all been removed and sealed with silicone. I also noticed that you can loosen the LED chips and center them in the reflectors, FWIW.

You def. have enough lights to see where your going ! I’m curious, when you went on the trip with your dad, or anyone for that matter, do you do off-roading in the dark? I can see why you want to be lit up if so.

I recall several nights setting up camp. More lighting would have been useful.You def. have enough lights to see where your going ! I’m curious, when you went on the trip with your dad, or anyone for that matter, do you do off-roading in the dark? I can see why you want to be lit up if so.

There are thousands of miles of lonely roads out here with large herds of elk, deer, cattle and the occasional surprise horse. There is no comparison to what saw in growing up MN and WI. When I am by myself on the highway traveling at night, I will use the "off road only" lights to see what is far down the pavement. Obviously, if another car appears in the distance, the light bars immediately go off.

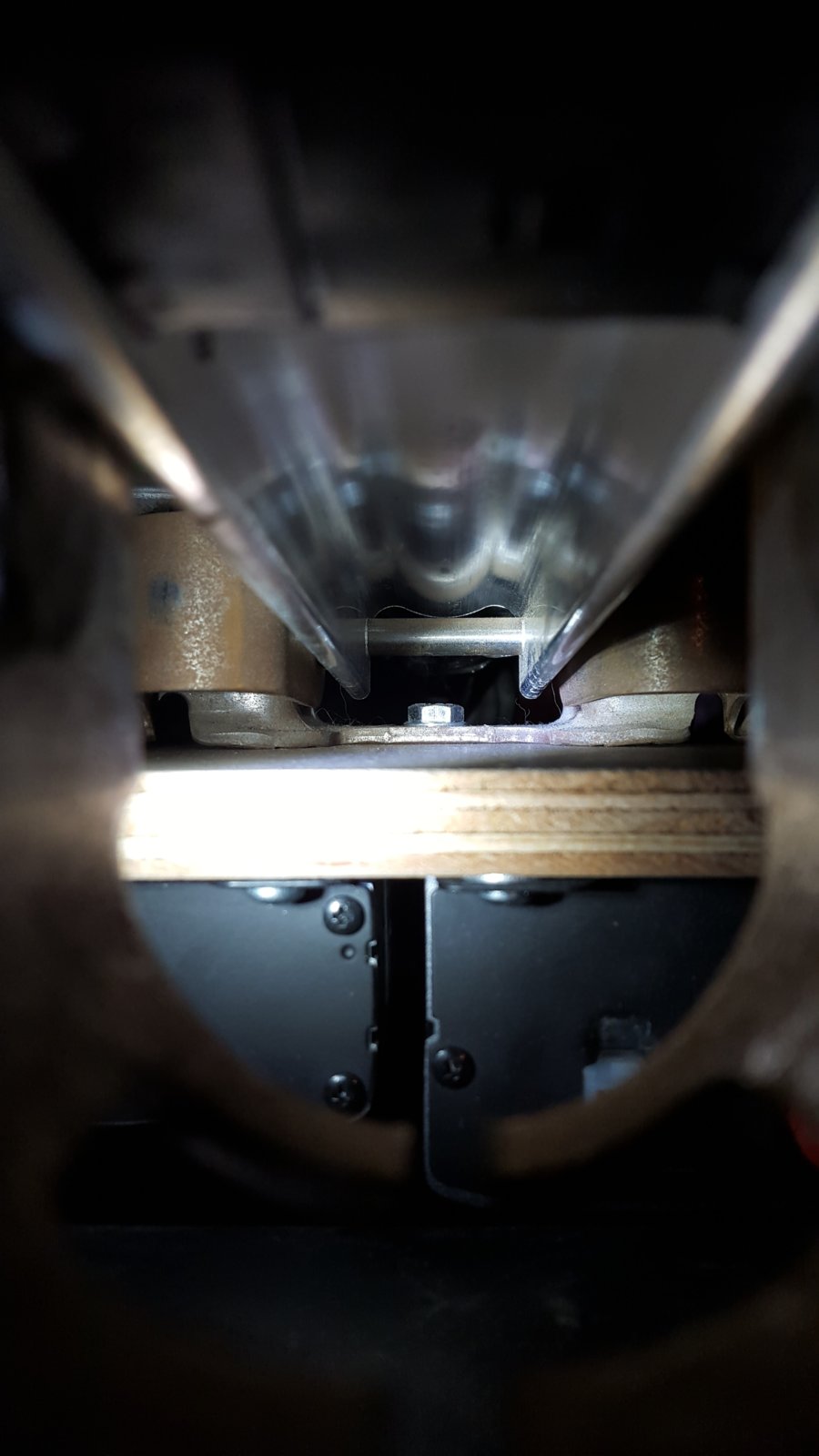

To continue with added storage in the Jeep, I have liked some of the ammo can center consoles people have done. To continue with the audio improvements, I needed a place to hide a slightly larger sub that wouldn't impact what little space there is in a Wrangler.

This is how I made a ammo can center console with a sub enclosure. This will trouble a few audiophiles.

30mm Ammo Can Center Console with 8" Sub Enclosure

Plywood and masonite enclosure for a Polk dbdb840 8-Inch Subwoofer.

It goes in here.

And makes noise out of here.

The console fits here.

Lift struts and a light for the lid.

Fully installed.

The sub doesn't rattle and to my ears sounds perfectly fine.

The height of the ammo can is the perfect height for shifting. And the larger lid is far more comfortable arm rest than the factory console. Even with the sub, there is about 3-4 times more room inside the can.

I don't care for my cup holder. I'll make it better soon.

This is how I made a ammo can center console with a sub enclosure. This will trouble a few audiophiles.

30mm Ammo Can Center Console with 8" Sub Enclosure

Plywood and masonite enclosure for a Polk dbdb840 8-Inch Subwoofer.

It goes in here.

And makes noise out of here.

The console fits here.

Lift struts and a light for the lid.

Fully installed.

The sub doesn't rattle and to my ears sounds perfectly fine.

The height of the ammo can is the perfect height for shifting. And the larger lid is far more comfortable arm rest than the factory console. Even with the sub, there is about 3-4 times more room inside the can.

I don't care for my cup holder. I'll make it better soon.

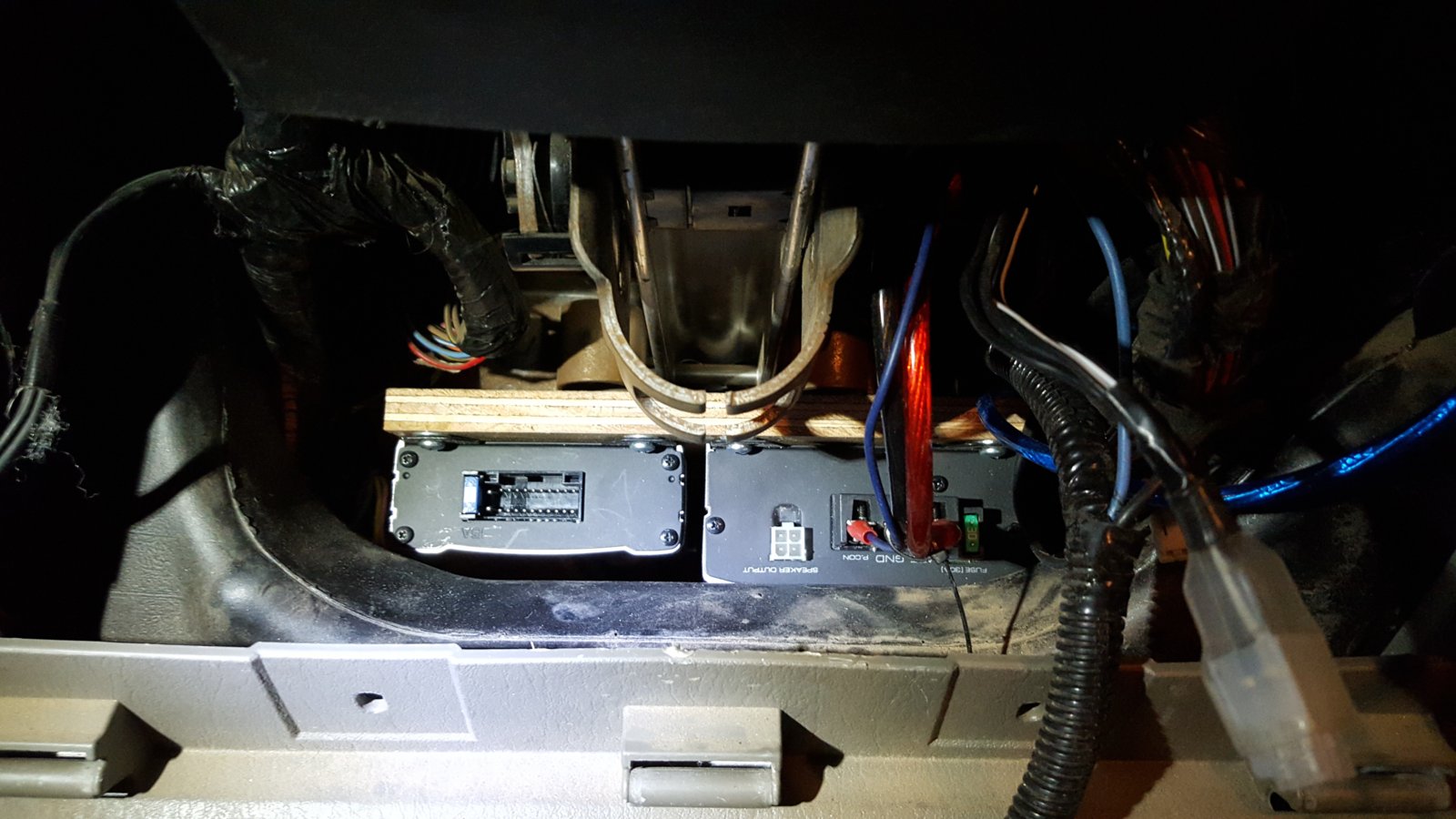

These are the amps.

Kenwood KAC-M1804 Compact 4-channel Amplifier

Kenwood KAC-M3001 Compact Mono Digital Amplifier

They both fit under the the steering column.

One bolt.

The amps are completely hidden.

Now the stereo sounds good.

Kenwood KAC-M1804 Compact 4-channel Amplifier

Kenwood KAC-M3001 Compact Mono Digital Amplifier

They both fit under the the steering column.

One bolt.

The amps are completely hidden.

Now the stereo sounds good.

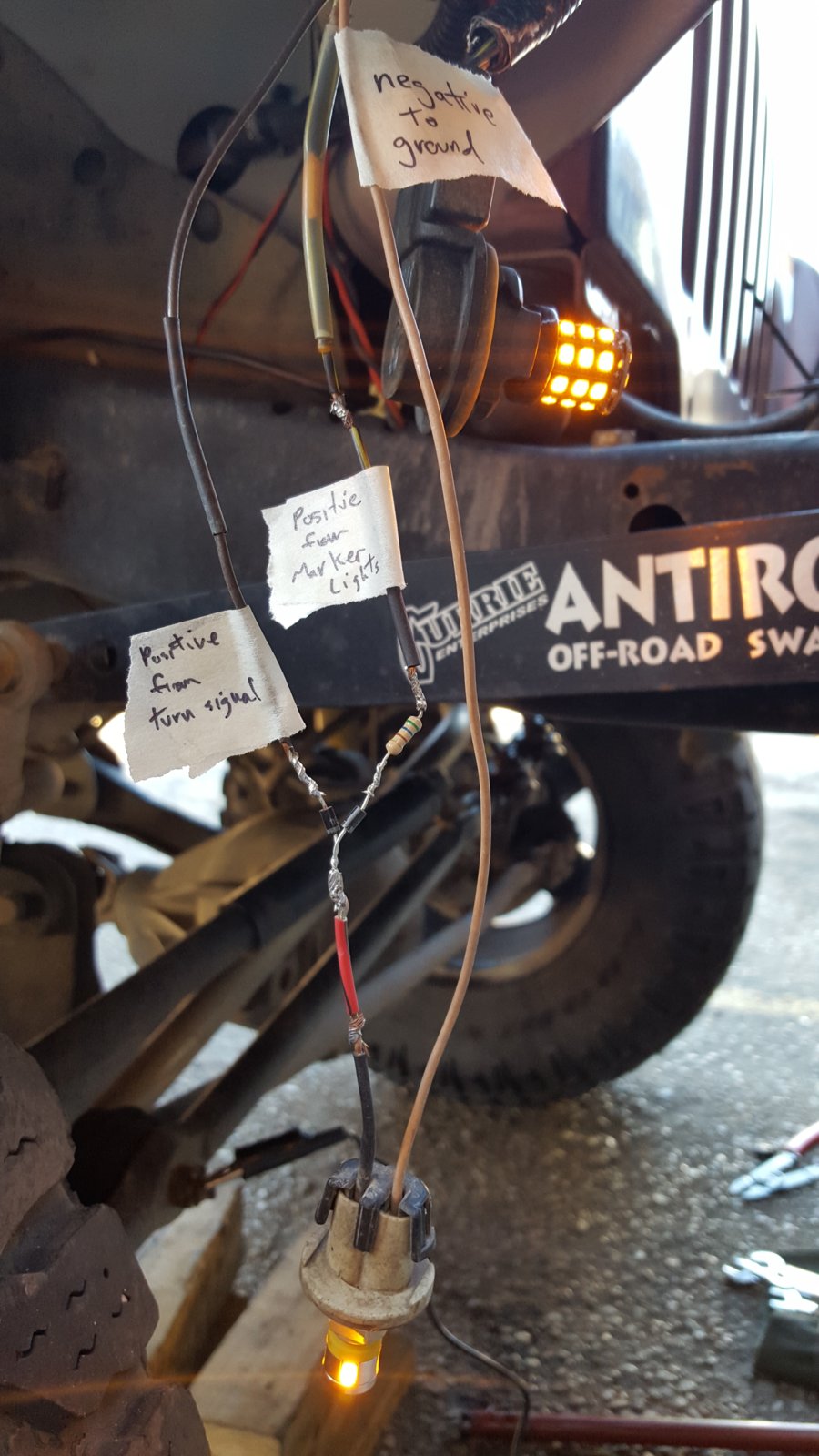

A current project that I am still in the middle of solving is converting the front turn signals and side markers to LED. This one of those projects that I did not need to do, but I was curious to try it and learn more about electrical because the modification requires resistors and diodes to change the floating ground that the factory lights utilize.

The Whole Story About Installing LEDs as Side Marker Lights

My problem is that with LEDs all around, I get a flicker on the opposite side that I am signaling. There appears to be a voltage leak somewhere. The problem is "fixed" if I install an incandescent bulb in one of the front turn signals.

The Whole Story About Installing LEDs as Side Marker Lights

My problem is that with LEDs all around, I get a flicker on the opposite side that I am signaling. There appears to be a voltage leak somewhere. The problem is "fixed" if I install an incandescent bulb in one of the front turn signals.

Someone on the forums mentioned that the dead pedal from an 80'-90's Mustang fits very well in a TJ and does not interfere with aftermarket floormats the way the MORE dead pedal does.

This is all true.

I have liked using a dead pedal on other vehicles. I like having one in my Jeep.

This is all true.

I have liked using a dead pedal on other vehicles. I like having one in my Jeep.

A few weeks ago at 104k miles, I replaced all four ball joints, the unit bearings, drag link and tie rod.

Spicer 706944X Socket Assembly

Timken HA597449 Axle Bearing and Hub Assembly

Crown Automotive HDSTRGCR1 Heavy Duty Steering Kit

I borrowed a balljoint press with the Dana30/44 adaptors. I also used a BJ separator, 36mm socket -and most importantly- a 4lb mallet. I would put solid pressure on a joint with either the press or separator and then give the ear a good hard hit with the mallet. Tie rod ends fell out effortlessly and the ball joints easily walked their way out of the inner C's. Same with the BJ install. Use a mallet with the press.

This was my first time replacing ball joints. The entire job took about 7 hours.

The steering and handling feels great!

Spicer 706944X Socket Assembly

Timken HA597449 Axle Bearing and Hub Assembly

Crown Automotive HDSTRGCR1 Heavy Duty Steering Kit

I borrowed a balljoint press with the Dana30/44 adaptors. I also used a BJ separator, 36mm socket -and most importantly- a 4lb mallet. I would put solid pressure on a joint with either the press or separator and then give the ear a good hard hit with the mallet. Tie rod ends fell out effortlessly and the ball joints easily walked their way out of the inner C's. Same with the BJ install. Use a mallet with the press.

This was my first time replacing ball joints. The entire job took about 7 hours.

The steering and handling feels great!

A daily driver mod.

During the ball joint replacement project, i heard mention of adding sprayers to the wiper arms of a TJ. GM cars and truck have this. The idea is to put wiper fluid directly onto the windshield as the blade wipes across the windshield. This helps with clearing the windshield on windy days and during heavy snow when the hood mounted sprayer might get covered. I have experience both problems often enough that the modification intrigued me. A quick trip to the junk yard and $7 later I have a big handful of GM sprayer nozzles, hoses and T's.

This became an education in the variety sprayer nozzles. The type I selected came off of a early-90's van. The middle piece below. It shoots water in three directions. Up, down and directly at the windshield. I blocked off the holes that sprayed down, because all they did was soak the hood.

Most of the nozzles have this little nub that needs to be cut away.

Find this retainer clip to help secure the hose to the wiper arm.

The nozzle is positioned so it is just below but not blocked by the wiper blade.

Remove the cowl and drill a hole.

This is easiest to do from the engine bay where there is a small dimple to the right of the bracket that hold the main wiring harness.

Image coming....

This tee fits through the new hole in the firewall.

Two water lines run from the tee to each wiper arm shaft.

Splice a tee into the factory water line.

Run a water line connecting the factory hose to the tee that passes into the cowl.

Replace the cowl cover and fit both water lines though the wiper arm holes. The 90* elbow serves as a quick release for all those time we remove our wipers and fold down the windshield.

Install the modded wiper arms and connect the new water lines.

You will now have a very clean windshield very quickly.

I added silicone to all the connections inside the cowl, just to make sure they stay sealed. I also kept the factory hood nozzle active. The pump has no trouble pushing all three sprayers.

A few days after, I drove 4 hours to Aspen during a heavy blizzard and the subsequent road spray combined with heavy winds. This was the perfect test. During similar conditions in the past, the wind could blow much of the spray away before hitting the windshield. The additional wiper fluid made quick work of the dirty salty mist that accumulates and quickly dries on the windshield.

During the ball joint replacement project, i heard mention of adding sprayers to the wiper arms of a TJ. GM cars and truck have this. The idea is to put wiper fluid directly onto the windshield as the blade wipes across the windshield. This helps with clearing the windshield on windy days and during heavy snow when the hood mounted sprayer might get covered. I have experience both problems often enough that the modification intrigued me. A quick trip to the junk yard and $7 later I have a big handful of GM sprayer nozzles, hoses and T's.

This became an education in the variety sprayer nozzles. The type I selected came off of a early-90's van. The middle piece below. It shoots water in three directions. Up, down and directly at the windshield. I blocked off the holes that sprayed down, because all they did was soak the hood.

Most of the nozzles have this little nub that needs to be cut away.

Find this retainer clip to help secure the hose to the wiper arm.

The nozzle is positioned so it is just below but not blocked by the wiper blade.

Remove the cowl and drill a hole.

This is easiest to do from the engine bay where there is a small dimple to the right of the bracket that hold the main wiring harness.

Image coming....

This tee fits through the new hole in the firewall.

Two water lines run from the tee to each wiper arm shaft.

Splice a tee into the factory water line.

Run a water line connecting the factory hose to the tee that passes into the cowl.

Replace the cowl cover and fit both water lines though the wiper arm holes. The 90* elbow serves as a quick release for all those time we remove our wipers and fold down the windshield.

Install the modded wiper arms and connect the new water lines.

You will now have a very clean windshield very quickly.

I added silicone to all the connections inside the cowl, just to make sure they stay sealed. I also kept the factory hood nozzle active. The pump has no trouble pushing all three sprayers.

A few days after, I drove 4 hours to Aspen during a heavy blizzard and the subsequent road spray combined with heavy winds. This was the perfect test. During similar conditions in the past, the wind could blow much of the spray away before hitting the windshield. The additional wiper fluid made quick work of the dirty salty mist that accumulates and quickly dries on the windshield.

July 2016

I am finally able to buy a Hobart 210 MIG welder. This opens up a whole new world of possibilities!

I am finally able to buy a Hobart 210 MIG welder. This opens up a whole new world of possibilities!