Raceline beadlocks are a great looking wheel and mounting them is much easier than you'd think. The only tedious part is tightening all those bolts in stages. It's a good you're doing them yourself because nobody in my area will touch them. Some didn't even want to balance them.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

05 Flame Red TJ Build

- Thread starter JMT

- Start date

Raceline beadlocks are a great looking wheel and mounting them is much easier than you'd think. The only tedious part is tightening all those bolts in stages. It's a good you're doing them yourself because nobody in my area will touch them. Some didn't even want to balance them.

You don't tighten in stages, that is wrong, it doesn't work and should not be done and is a complete waste of time. The simple and basic rule of bead lock ring bolts is they will not come up to the correct torque until the ring makes contact with the mating surface on the rim. Run them down with an impact without blasting them, keep working that around until the ring makes contact. At that point, switch over to the torque wrench set at the final torque value and get after it. You are done when no bolts turn when you hit the torque value with the torque wrench.

You will notice that until they get close, when you tighten one, the two on either side of it are almost completely at zero or a very low torque value which is precisely why stages don't and can't work. Only when you get close to them all being near the same value does the torque stop dropping off so far.

Yep, I knew you had to get the ring and wheel to touch or you’d just keep turning each bolt 1/8th turn as you NeverYou don't tighten in stages, that is wrong, it doesn't work and should not be done and is a complete waste of time. The simple and basic rule of bead lock ring bolts is they will not come up to the correct torque until the ring makes contact with the mating surface on the rim. Run them down with an impact without blasting them, keep working that around until the ring makes contact. At that point, switch over to the torque wrench set at the final torque value and get after it. You are done when no bolts turn when you hit the torque value with the torque wrench.

You will notice that until they get close, when you tighten one, the two on either side of it are almost completely at zero or a very low torque value which is precisely why stages don't and can't work. Only when you get close to them all being near the same value does the torque stop dropping off so far.

Here is how I did mine, Jeremy:

View attachment 509630

View attachment 509631

View attachment 509632

View attachment 509634

Ok, nice! I was partially thrown by the steering pump cooler and barely saw the 1/8” x 1 1/4” flat bar. Looks like easiest to unbolt the shroud, radiator and air dam to slip out the V bar, then do the work and reinstall. Thanks. It’s warming up here and I want to get this cooler in before I do much wheelin’.

Those are the ends of the welds you are seeing.

Here is how I did mine, Jeremy:

View attachment 509630

View attachment 509631

View attachment 509632

View attachment 509634

Low on 1/4" bar stock, were we?

Sometimes holding something is more impressive than seeing it. This cooler is super nice. The quality is obvious. I kinda love it.

Who says Jeeps aren’t race cars?!

Who says Jeeps aren’t race cars?!

Last edited:

This is a nice piece too. I could get away without it with the manual, but with the auto pan right in harms way it was a non-negotiable. I rolled under the Jeep and held it in place just for fun. Noticed my Savvy TCase skid is dented/bent on the front edge toward the passenger side.

Can’t wait to install this. I need to get this done, it was 57* today and I wheeled and watched my temps. At 37 minutes it was already over 180* and climbing.

Can’t wait to install this. I need to get this done, it was 57* today and I wheeled and watched my temps. At 37 minutes it was already over 180* and climbing.

Sometimes holding something is more impressive than seeing it. I kinda love it.

Freud would have a few things to say about that

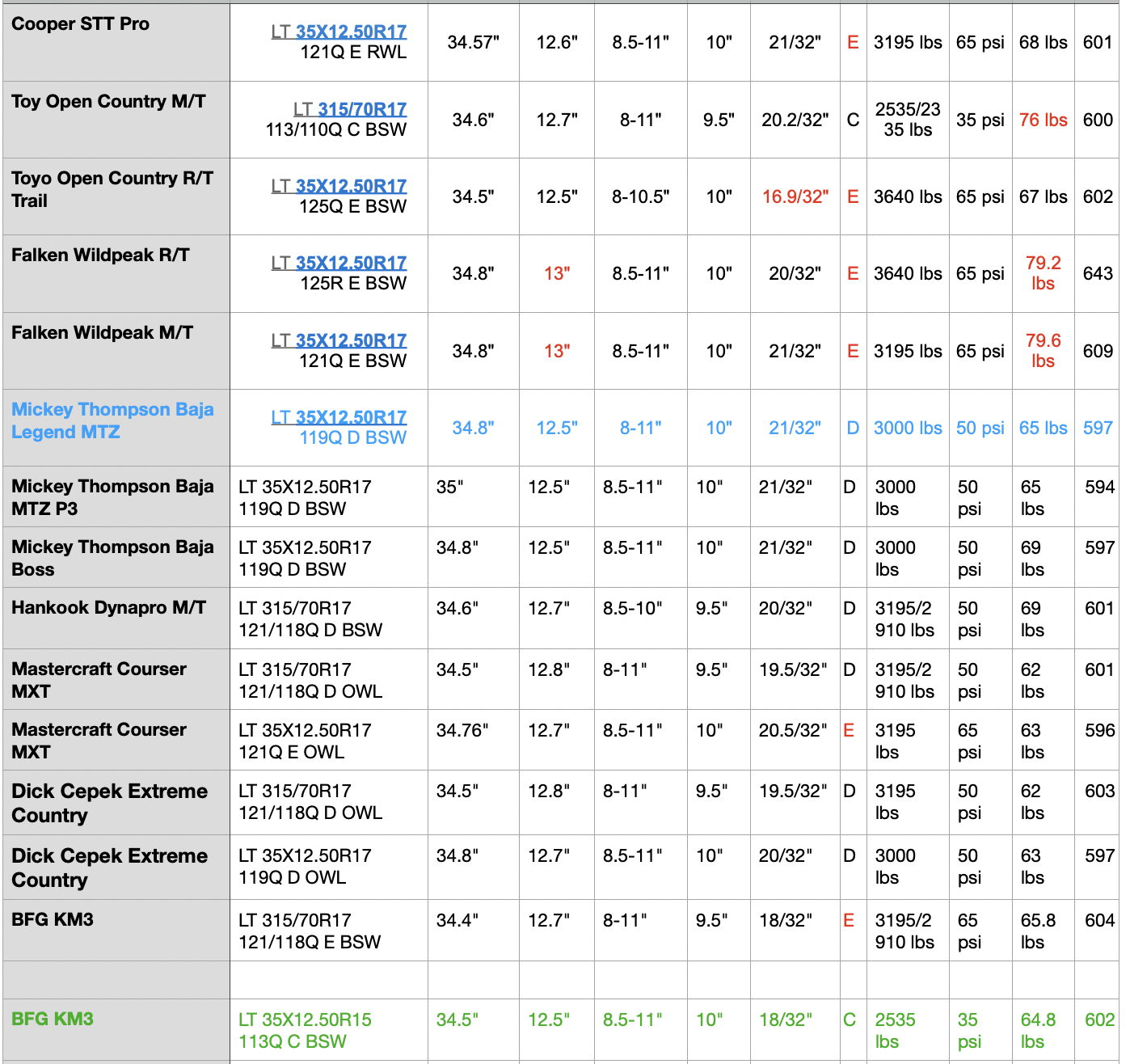

Here's a chart I put together when evaluating tires including most of the categories I was interested in for my purposes. The Tire Installer I use suggested I look at four tires (Toyo Open Country M/T and R/T Trail, Falken Wildpeak MT and R/T). Anything in red was a show stopper for me. Some of these tires may no longer be available. I settled on the Mickey Thompson Baja Legend MTZ in 3512.5R17 which is in blue. The tire in green is the tire I currently run.

Last edited:

Here's a chart I put together when evaluating tires including most of the categories I was interested in for my purposes. The Tire Installer I use suggested I look at four tires (Toyo Open Country M/T and R/T Trail, Falken Wildpeak MT and R/T). Anything in red was a show stopper for me. Some of these tires may no longer be available. I settled on the Mickey Thompson Baja Legend MTZ in 3512.5R17 which is in blue. The tire in green is the tire I currently run.

View attachment 510517

What's the far right column?

What's the far right column?

tire rotations/mile

Smaller number equates to larger rolling radius (i.e. larger tire for this class size relative to other tires in the class)

tire rotations/mile

Smaller number equates to larger rolling radius (i.e. larger tire for this class size relative to other tires in the class)

That's good, I knew it couldn't be price.

Sorry I couldn't resist

Here's a chart I put together when evaluating tires including most of the categories I was interested in for my purposes. The Tire Installer I use suggested I look at four tires (Toyo Open Country M/T and R/T Trail, Falken Wildpeak MT and R/T). Anything in red was a show stopper for me. Some of these tires may no longer be available. I settled on the Mickey Thompson Baja Legend MTZ in 3512.5R17 which is in blue. The tire in green is the tire I currently run.

View attachment 510534

I’m out here being indecisive about tires and now you drop a spreadsheet.

All good. Good eye. That happened in 2017 on my very first wheelin’ trip. I dubbed it “extra clearance”. It was so far up I figured nothing would ever hit it, and I was right. It never contacted anything for the 6 years it was there. With the swap I got a new pan because I didn’t know if my leak was RMS or oil pan, and now that that’s solved the transmission pan is closer to the TCase and more vulnerable, so I’m at that point and don’t want to hit it!

Last edited:

I mounted the beadlocks today using @mrblaine method.

To get the tire on the wheel set the wheel on the ground face up and put some lube on the edge of the bead on the side of the tire that you want on the backside. Set tire on top of the wheel and wrangle it on.

Next you’ll need a couple of flat blade screwdrivers to make sure the lip of the bead edge is outside the edge of the wheel face. Pry in one screwdriver and push out so the rubber pops over the edge, then move clockwise and do the same with the other screwdriver, and keep going till it’s all the same all around. Usually only needs about 1/3-1/2 of the circumference done to be centered.

Now it’s time for the ring. I mounted one wheel without a spacer, but the ring was coning more than I was comfortable with, so I got some 1/8” spacers.

Get four bolts and put some blue threadlocker on the threads to prevent corrosion where the bolts meet the threads on the wheel. Keep everything clean. No dirt or laziness here.

Put the four bolts in according to the points of the compass (+), hand start each one and make sure they will go in easily. Use your impact and usually a 1/2” 5/16-18 bolt and give it a go just enough to get it scrunched down a bit. You won’t reach the torque spec till the ring (with or without spacer) is touching the wheel.

Once I got those four on I moved one bolt to the right and did those four, then one more to the right and those four (hand start each one). Then I scrunched those down about the same as the first four. Then I just put all the others in and did the same.

Then I looked and you could see which ones were loose now (the first bolts you put in most likely). Snugged then down and any others that needed it. Check spacing between Ring and wheel. Do what you need to get them really close.

Then pull out your torque wrench (I set mine to 200 in-lb, but follow whatever your Beadlock manufacturer states), and start working around. You’ll go around till they are all equally torqued to spec.

I like to lay a flat board or piece of aluminum across the diameter of the ring to check for coning. You want them as flat as possible.

I timed the second wheel from start to finish and it was 40min.

Set on the ground and air up with your compressor. They usually catch the bead at 7-8lb. Keep going up to 23-24lb for 35’s. The limit on my Raceline’s is 24lb.

At this point you’ll be done and probably need to go get them balanced.

To get the tire on the wheel set the wheel on the ground face up and put some lube on the edge of the bead on the side of the tire that you want on the backside. Set tire on top of the wheel and wrangle it on.

Next you’ll need a couple of flat blade screwdrivers to make sure the lip of the bead edge is outside the edge of the wheel face. Pry in one screwdriver and push out so the rubber pops over the edge, then move clockwise and do the same with the other screwdriver, and keep going till it’s all the same all around. Usually only needs about 1/3-1/2 of the circumference done to be centered.

Now it’s time for the ring. I mounted one wheel without a spacer, but the ring was coning more than I was comfortable with, so I got some 1/8” spacers.

Get four bolts and put some blue threadlocker on the threads to prevent corrosion where the bolts meet the threads on the wheel. Keep everything clean. No dirt or laziness here.

Put the four bolts in according to the points of the compass (+), hand start each one and make sure they will go in easily. Use your impact and usually a 1/2” 5/16-18 bolt and give it a go just enough to get it scrunched down a bit. You won’t reach the torque spec till the ring (with or without spacer) is touching the wheel.

Once I got those four on I moved one bolt to the right and did those four, then one more to the right and those four (hand start each one). Then I scrunched those down about the same as the first four. Then I just put all the others in and did the same.

Then I looked and you could see which ones were loose now (the first bolts you put in most likely). Snugged then down and any others that needed it. Check spacing between Ring and wheel. Do what you need to get them really close.

Then pull out your torque wrench (I set mine to 200 in-lb, but follow whatever your Beadlock manufacturer states), and start working around. You’ll go around till they are all equally torqued to spec.

I like to lay a flat board or piece of aluminum across the diameter of the ring to check for coning. You want them as flat as possible.

I timed the second wheel from start to finish and it was 40min.

Set on the ground and air up with your compressor. They usually catch the bead at 7-8lb. Keep going up to 23-24lb for 35’s. The limit on my Raceline’s is 24lb.

At this point you’ll be done and probably need to go get them balanced.